Group Project

Will find more time to do this more properly next week, although I did technically run some measurements while doing the individual project! See sneak peek below:

Output Devices

This week marked my first failure of the class! I think I overreached and it ended up biting me. But I'll share what I did.

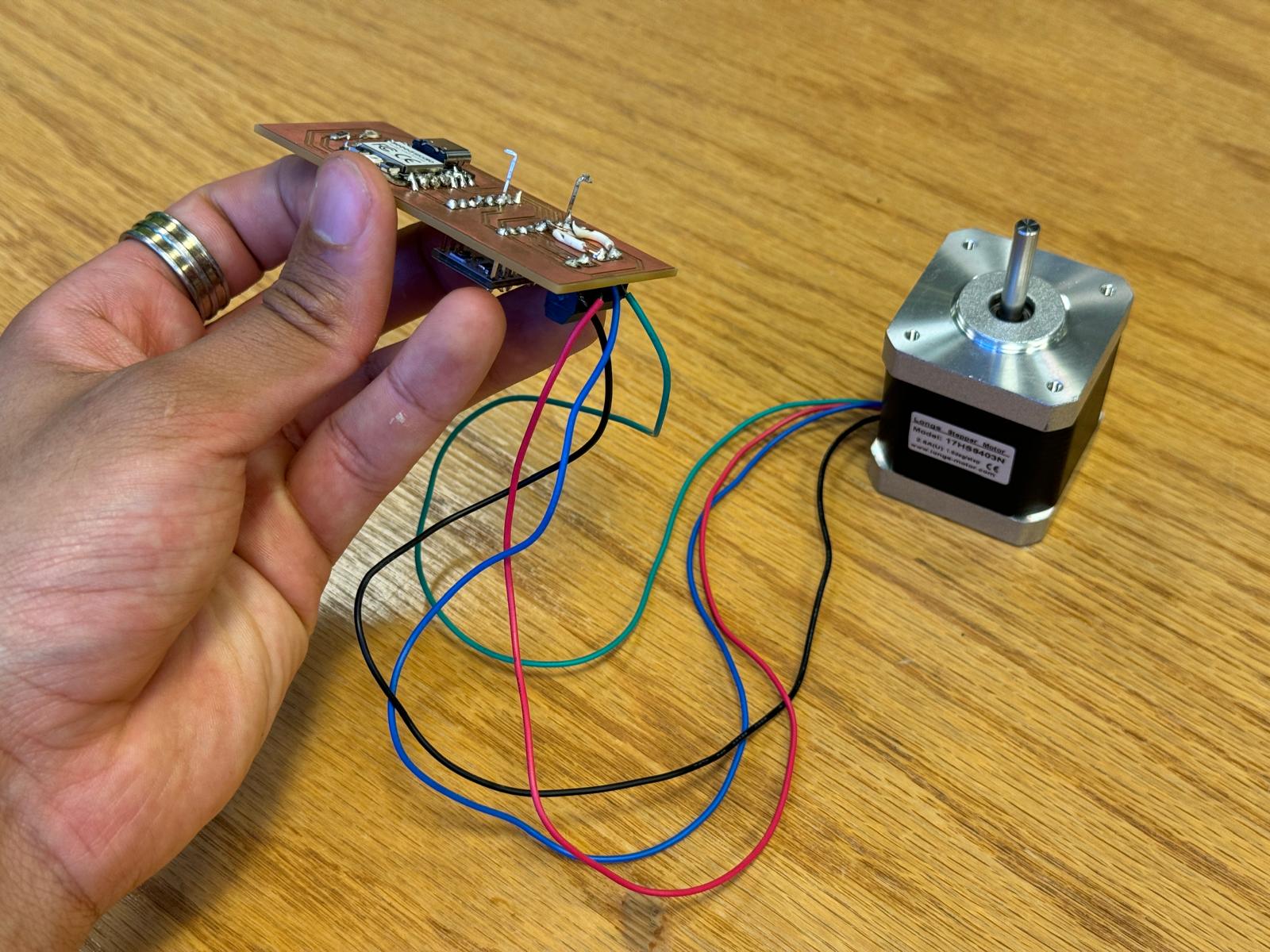

My mission for this week revolves around getting this stepper motor to spin. I can do that by hooking it up to the screw terminals on the board I milled last week. However, a slight hiccup came about there:

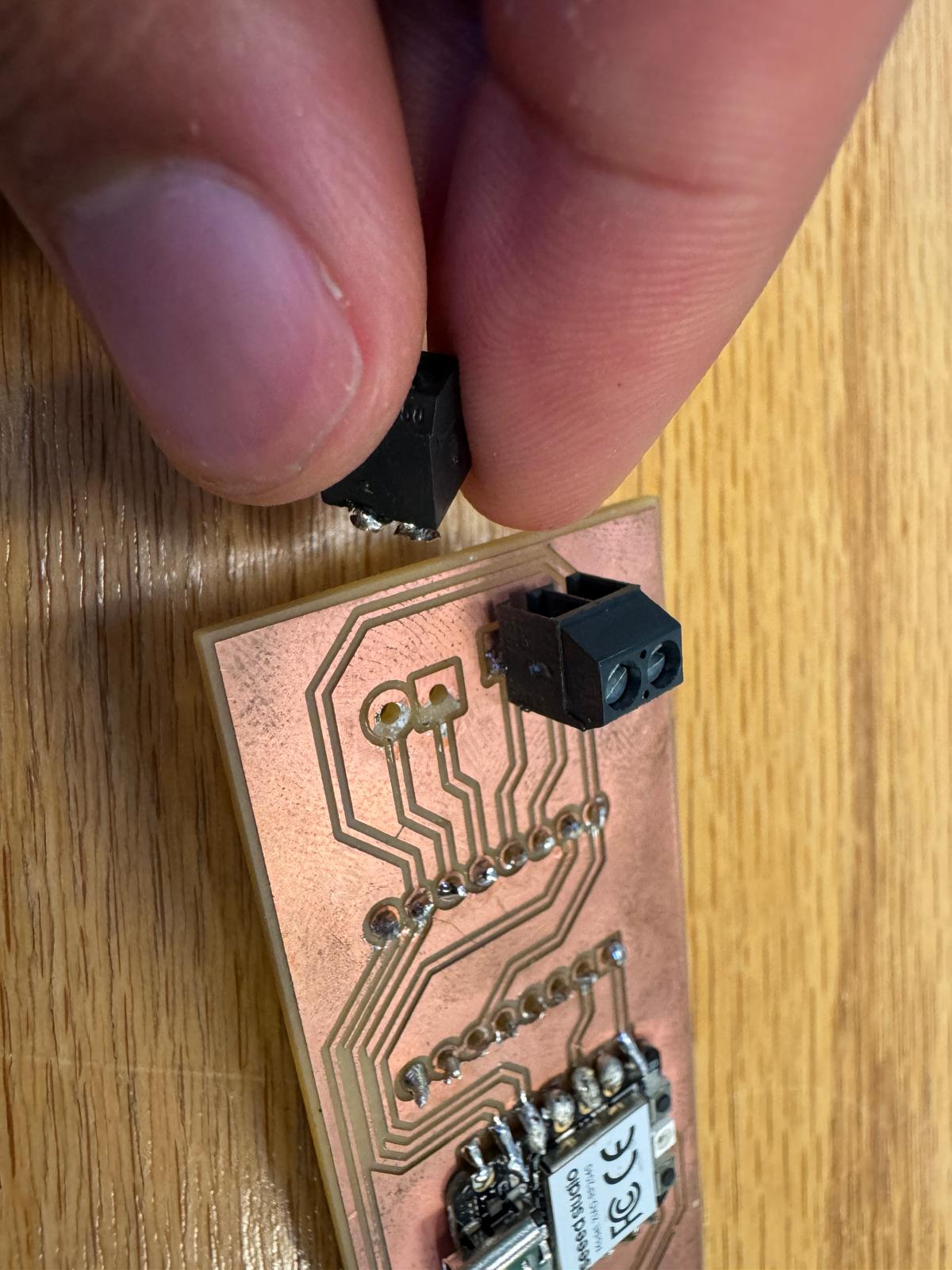

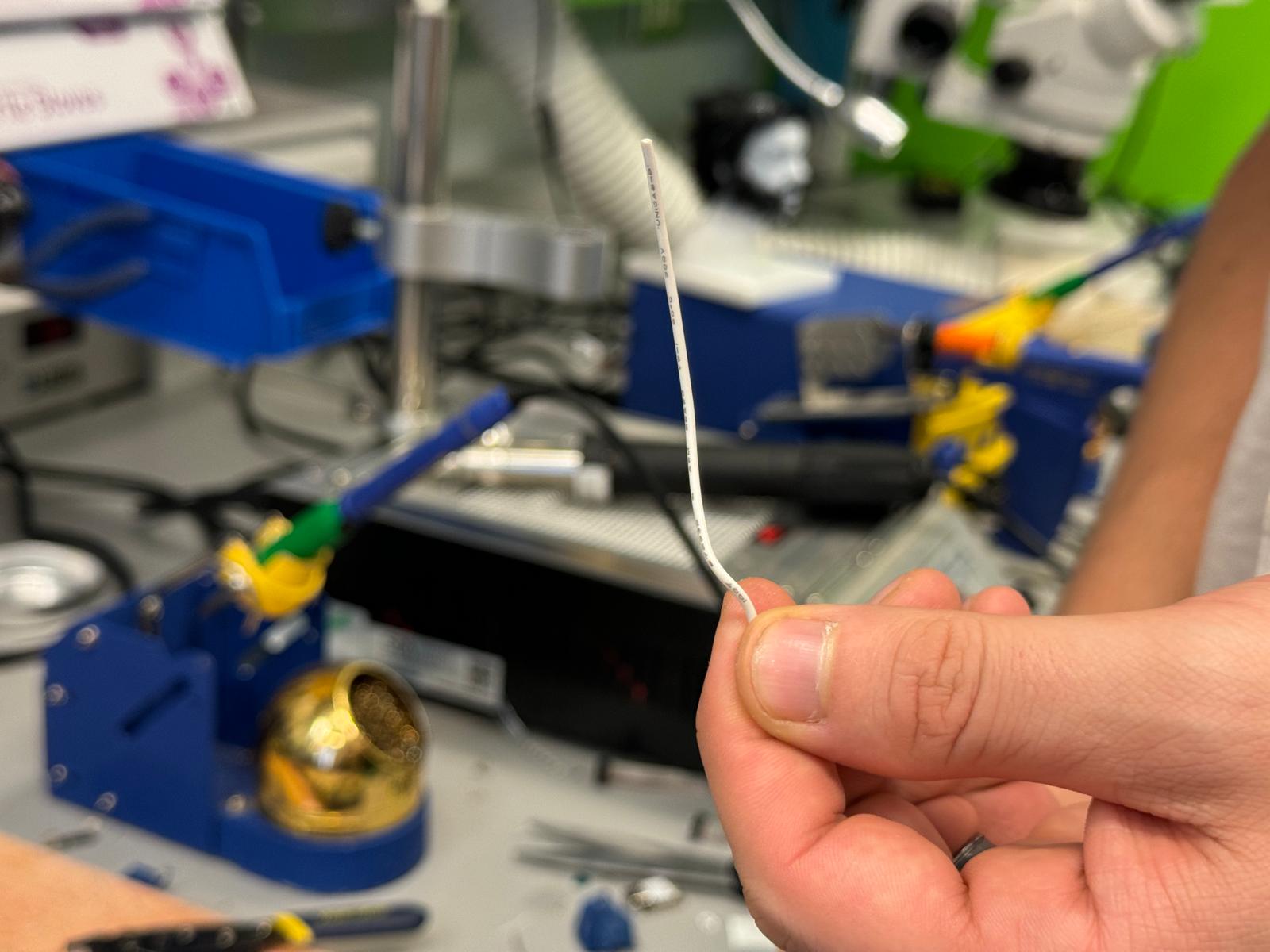

One of the screw terminals had been ripped off the board while it was just sitting in my backpack! And it took parts of the copper pads with it. This wouldn't be just a simple re-solder job. I had to reinforce the connection with wires (thanks to guidance from Anthony):

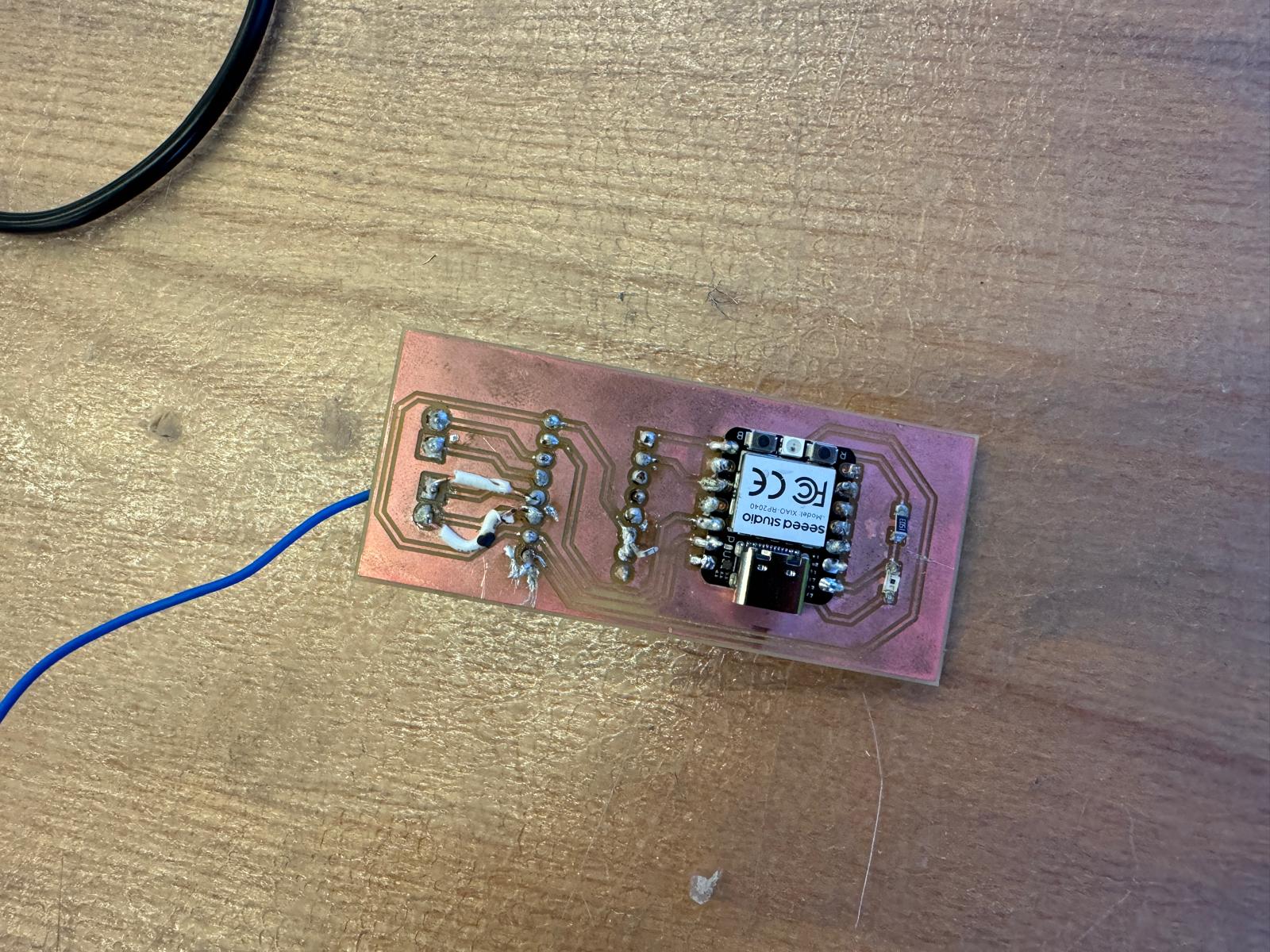

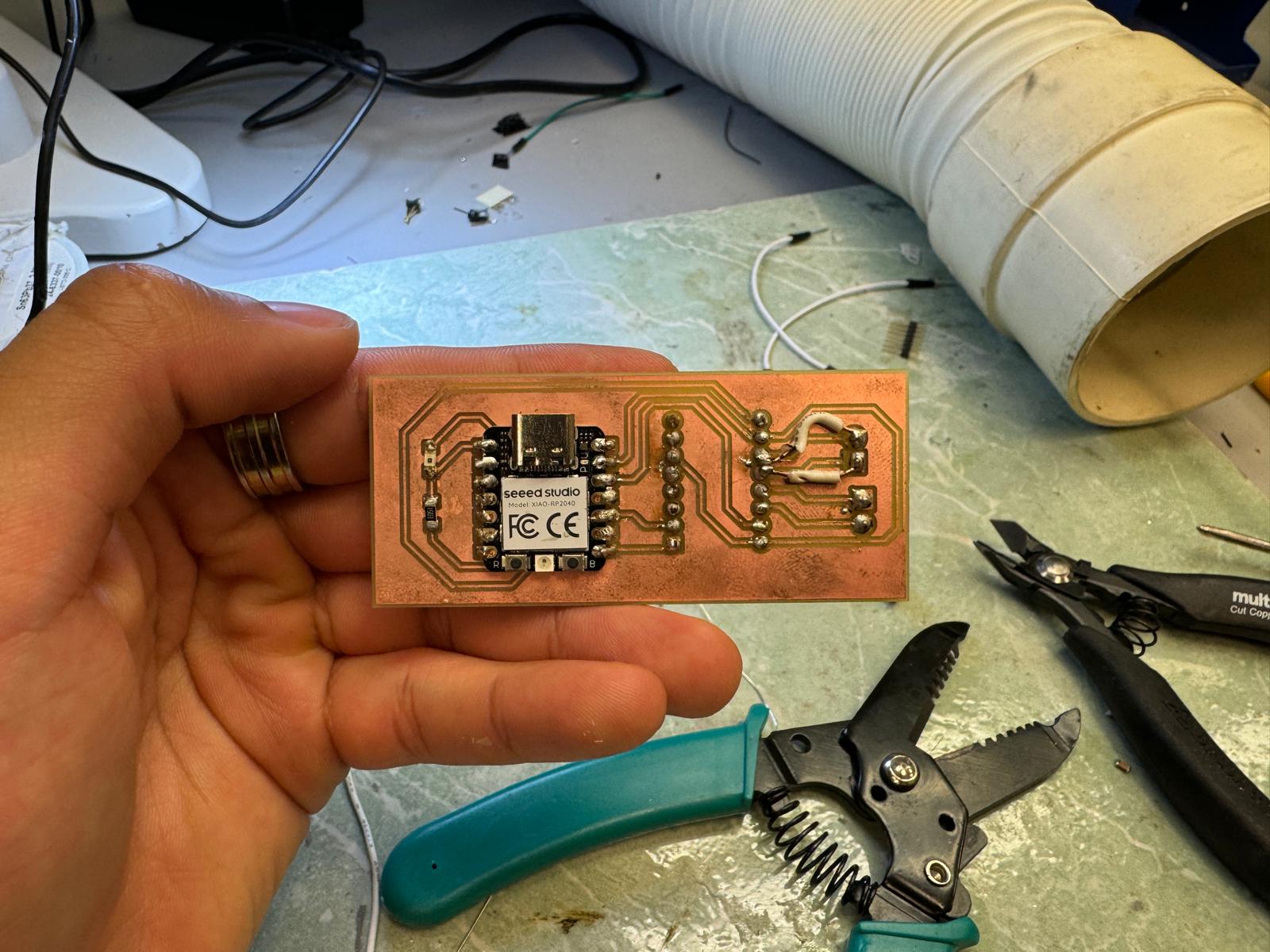

With my board repaired, it was time to hook up my stepper motor to my board and run some code to get it spinning...only that didn't work. See, the stepper motor needs more power than my little RP2040 can generate, so I had to hook my board up to a power supply, which meant I needed to solder prongs to my board to clamp to:

After that it was just cutting through the copper trace that was originally connecting the RP2040's power to the stepper motor driver carrier, and my board was good to go! This is quickly becoming a very ugly board, but it should theoretically still be functional.

First, hooking up to a power supply and running some simple code just to see if the motor will spin. And it did!:

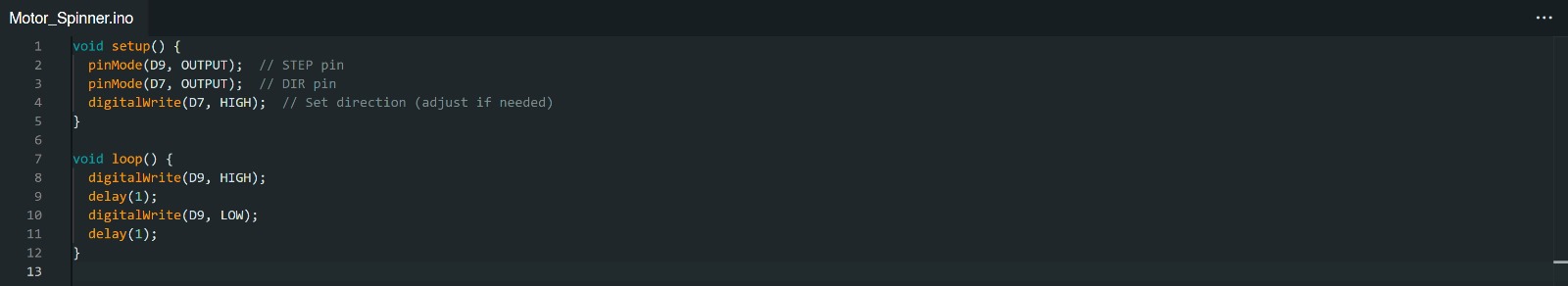

And now to spin it faster:

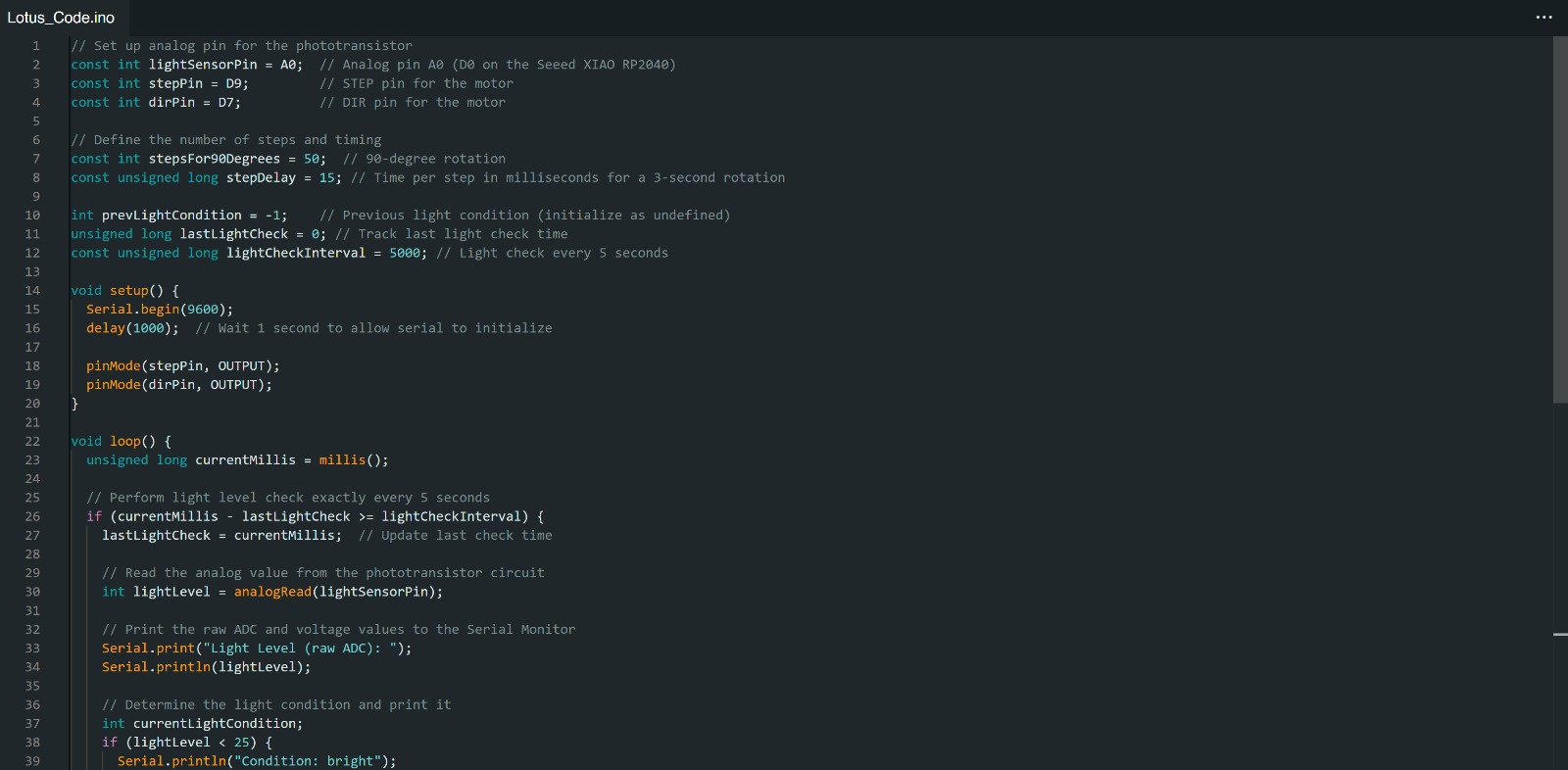

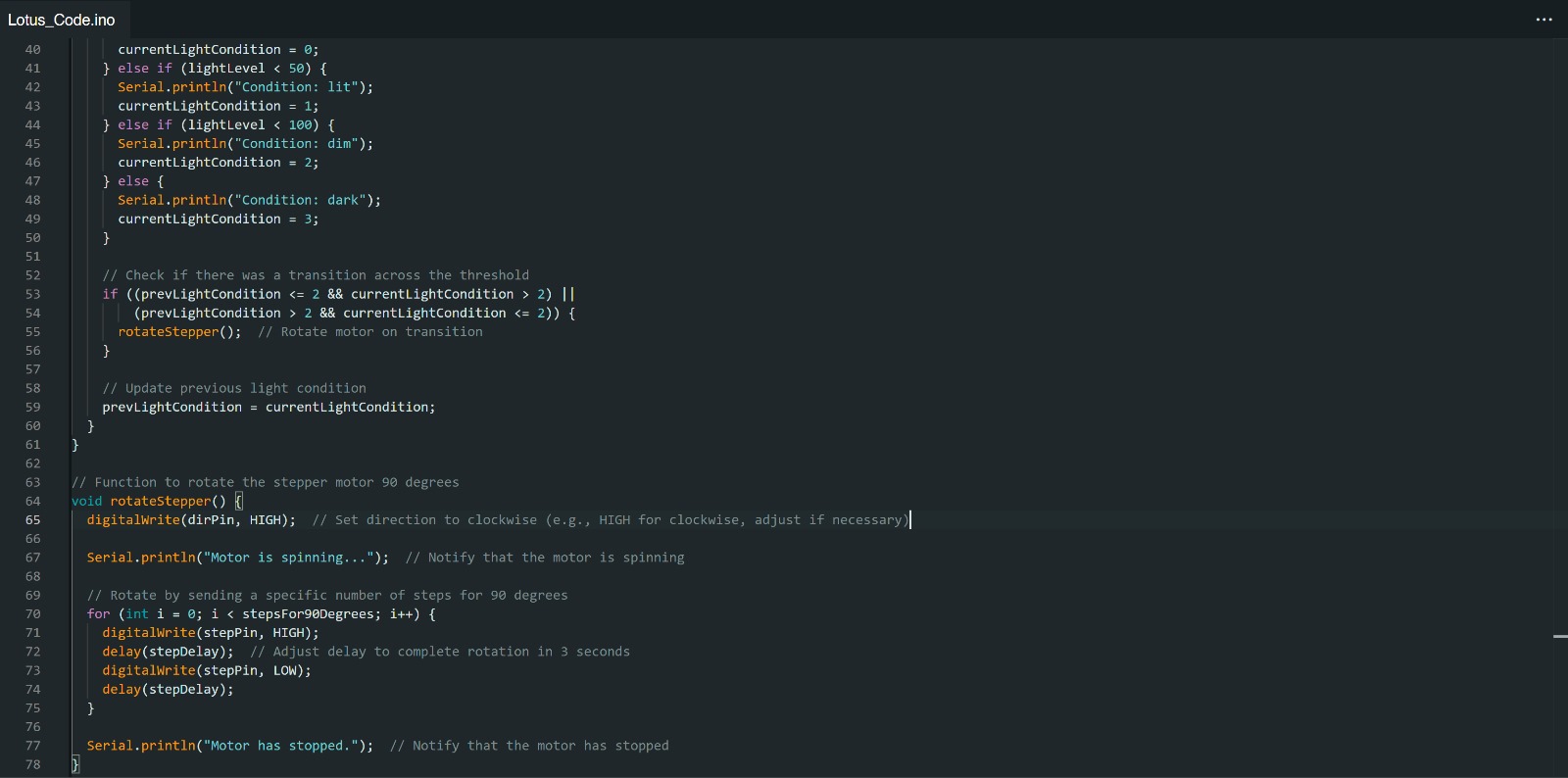

Cool, so the motor spins. Now, to link it to my input device! Ultimately, I want to take in the level of light, and, when the light level passes a certain threshold, tell my motor to spin. So here's the code I sent to my RP2040:

And here's the result:

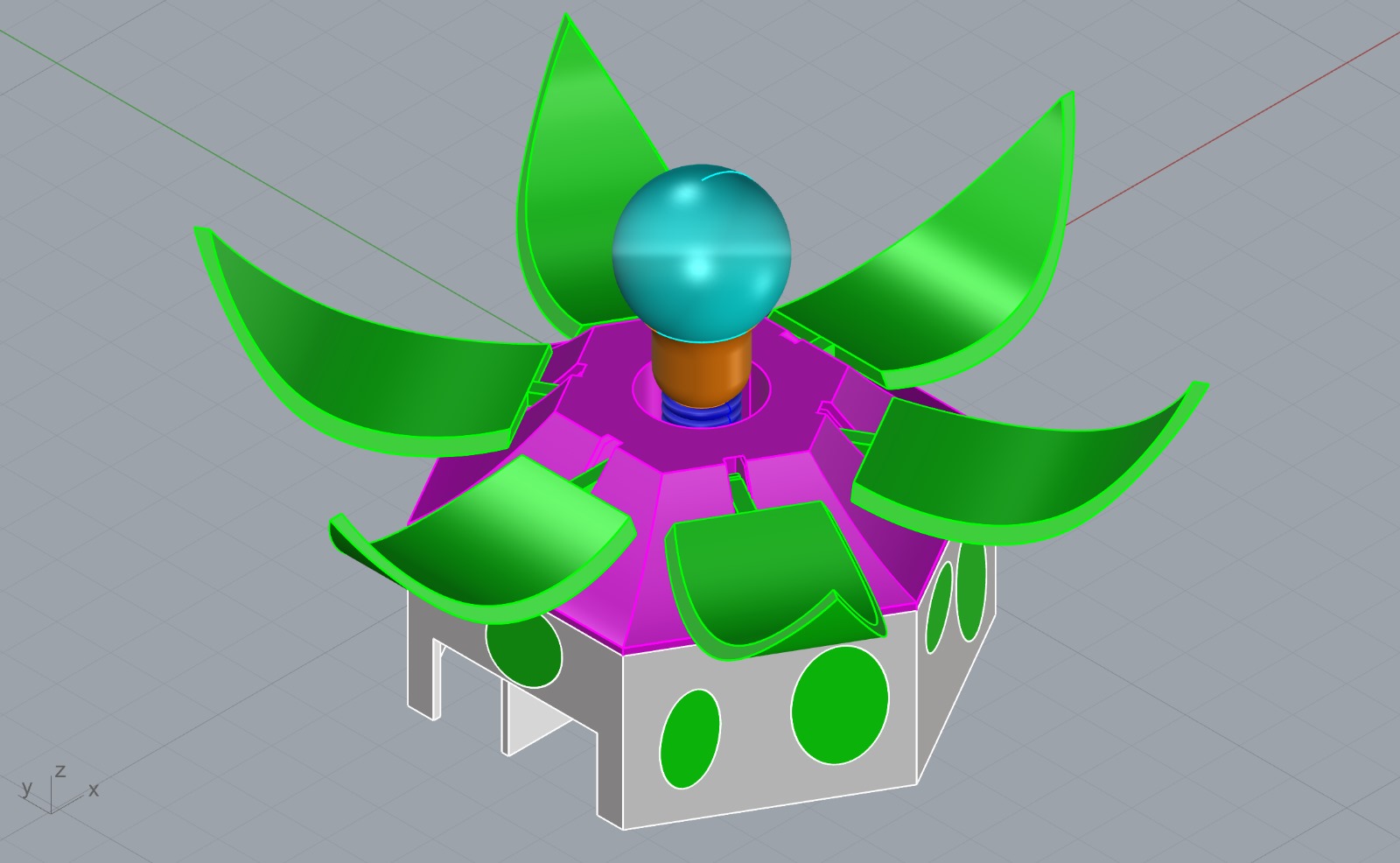

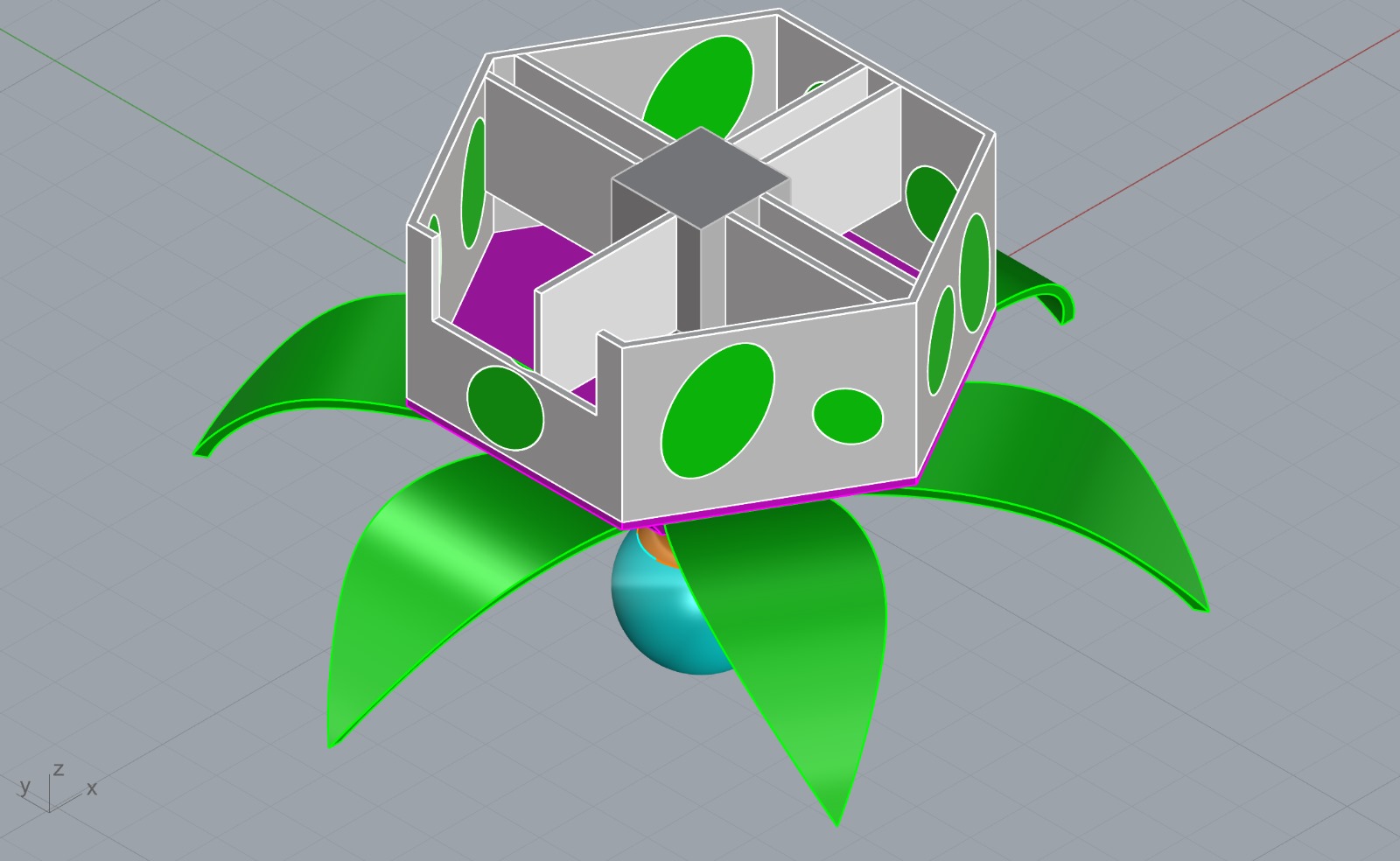

It worked! Now, for the real test: I wanted to hook the stepper motor up to the bottom of my lotus to get it to open up in response to the light! So, I designed and 3D printed a base for the lotus to set my motor into:

And I tried it and... it didn't work. I think the torque required to actually turn the gears in my lotus was too much for my simple stepper motor to handle. I heard it rattle a few times before it stopped responding altogether. Then one of my prongs came off, taking the pad with it. Then my driver carrier overheated. Then one of the motor wires came loose from a screw terminal. And at that point... I decided to call it quits.

There are so many things I can try in the future to get this thing to work down the line! For one, I can add bearings to the gears to reduce friction (right now it's just PLA scraping up on PLA). Eventually, I'll need to find a way to integrate solar power into the mix (so that my lamp can be portable and won't have to rely on a power supply to work). This was a good first try, though.

Widlarize and go again! I learned a lot this week. Looking forward to future improvements.