Large Format Machining

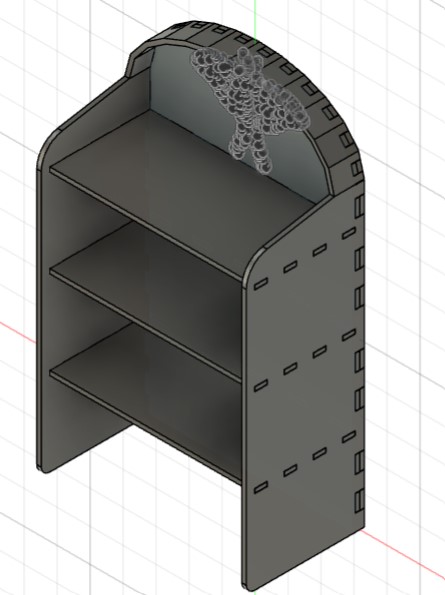

For this week, I decided to make a shelf, as I did not have one and could really use one. I was using 1/2" cardboard, so I made a CAD of my shelf. I measured the cardboard (around .54 inches), then intentionally set the thickness slightly less such that the joints would be able to fit (considering that cardboard can bend slightly), and then added a 0.01 mm cutting tolerance just in case.

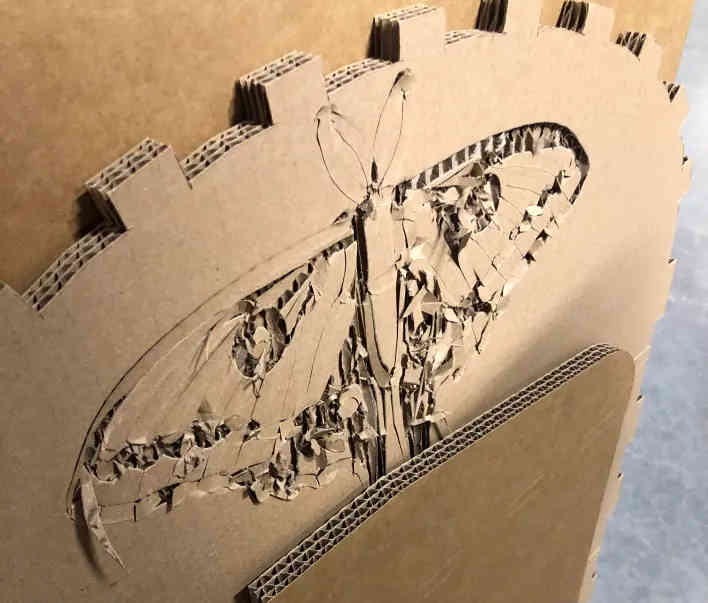

I ended up in the CBA shop using the Zund to cut the cardboard. Halfway through the first job, the bit/blade got pulled out of the chuck, but it was quickly put back in and restarted the job. I had also wanted to etch a moth into the cardboard, but it didn't really turn out great.

I think what happened was that since the angled blade was used, it ended up tearing and peeling off the top layer of the cardboard, so I ended up just flipping it around so it was hidden. The rest of the jobs were pretty straightforward, and the V-cuts worked as intended.

All my joints were snug (including the curved one), and the shelf is pretty stable! No glue needed.

Group(?) Project

The Zund uses vacuum to fix the material in place (enough to combat the curvature). The cutting tool is an oscillating blade (for V-cuts it is an angled blade), so there is no runout or need to dogbone. The feature size limit seems to be around 0.02 mm. The speeds can be changed, but for cardboard I used 300 mm/s for oscillating blade and 600 mm/s for V-cut.