Electronics Production

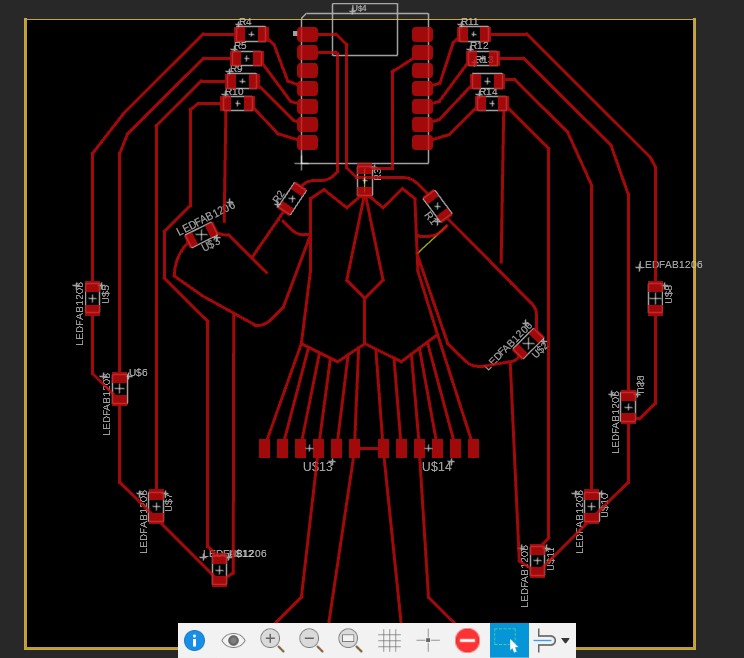

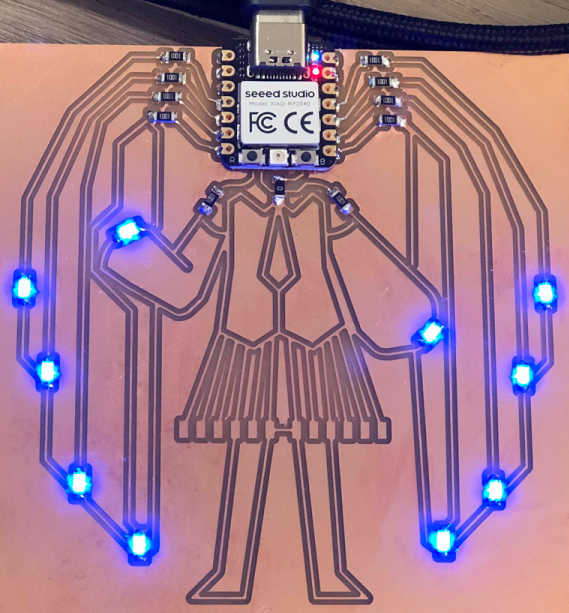

For this week, instead of the dev board I developed last week, I decided to make a Hatsune Miku shaped board.

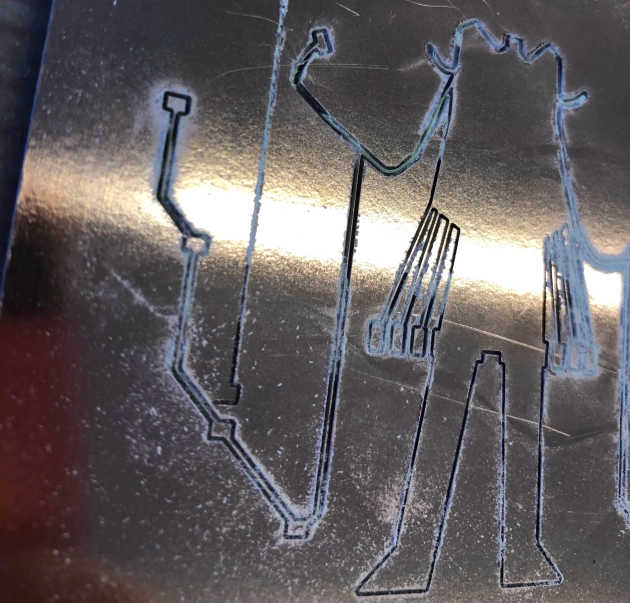

After checking that the board would be millable, I started to mill my board, only for the board to detach halfway through the milling process. After hitting the emergency stop button and resetting, I inspected the board.

The traces were very deep. What probably happened was that the bit was loose, and because how the mill bit is designed, it meant that it was being pulled into the board. So I reset and restarted the process (tightening the chuck more than before).

Next, it was time to solder the resistors and LEDs. It went surprisingly okay. I think I found a rhythm which made the process smoother.

To test out the board, I wrote a small program that made all the LEDS blink.

Resources

Code

//

// hello.button-blink.RP2040.1.ino

//

// Seeed XIAO RP2040 button, blink, echo hello-world, single core

//

// Neil Gershenfeld 12/28/23

//

// This work may be reproduced, modified, distributed,

// performed, and displayed for any purpose, but must

// acknowledge this project. Copyright is retained and

// must be preserved. The work is provided as is; no

// warranty is provided, and users accept all liability.

//

// add RP2040 core

// https://github.com/earlephilhower/arduino-pico

//

void setup() {

pinMode(D0,OUTPUT);

pinMode(D1,OUTPUT);

pinMode(D3,OUTPUT);

pinMode(D4,OUTPUT);

pinMode(D5,OUTPUT);

pinMode(D6,OUTPUT);

pinMode(D7,OUTPUT);

pinMode(D8,OUTPUT);

pinMode(D9,OUTPUT);

pinMode(D10,OUTPUT);

Serial.begin();

Serial.setTimeout(10);

}

void loop() {

digitalWrite(D0,HIGH); //right hand

digitalWrite(D1,HIGH); // left hand

// digitalWrite(D3,HIGH); // left highest

digitalWrite(D4,HIGH);// left second highest

digitalWrite(D5,HIGH); // left second lowest

digitalWrite(D6,HIGH); //left lowest

digitalWrite(D7,HIGH); // right lowest

digitalWrite(D8,HIGH); // right second lowest

digitalWrite(D9,HIGH); // right second highest

digitalWrite(D10,HIGH); // right highest

delay(500);

digitalWrite(D0,LOW);

digitalWrite(D1,LOW);

digitalWrite(D3,LOW);

digitalWrite(D4,LOW);

digitalWrite(D5,LOW);

digitalWrite(D6,LOW);

digitalWrite(D7,LOW);

digitalWrite(D8,LOW);

digitalWrite(D9,LOW);

digitalWrite(D10,LOW);

delay(500);

}

Group Project

Going through the training for the PCB mill, the mill can be prompted to switch bits during a job. The bits were 1/64" and 1/32", but there were others like the engraving bit that can do smaller traces. The mill would do small details first before larger ones, and had a conservative mode where it would go slower.

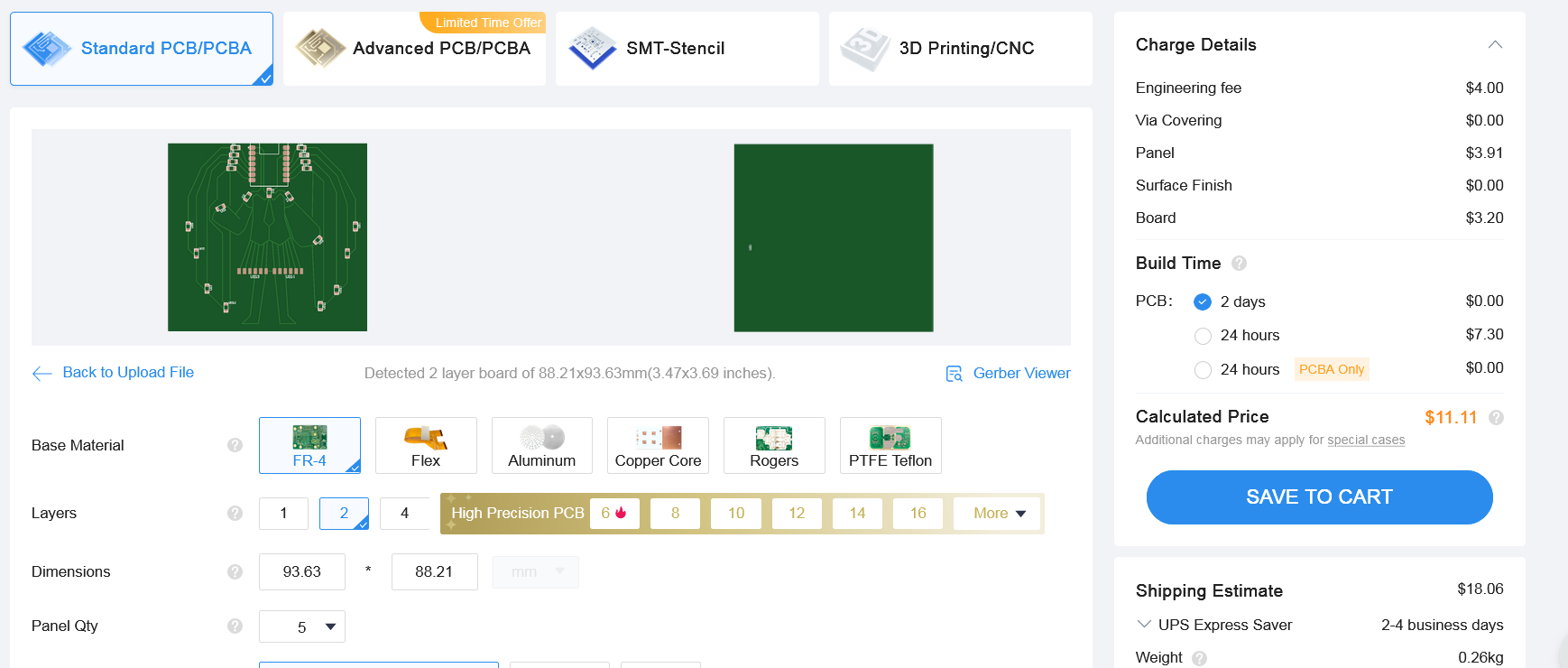

For submitting to a board house, I tried out JLCPCB.