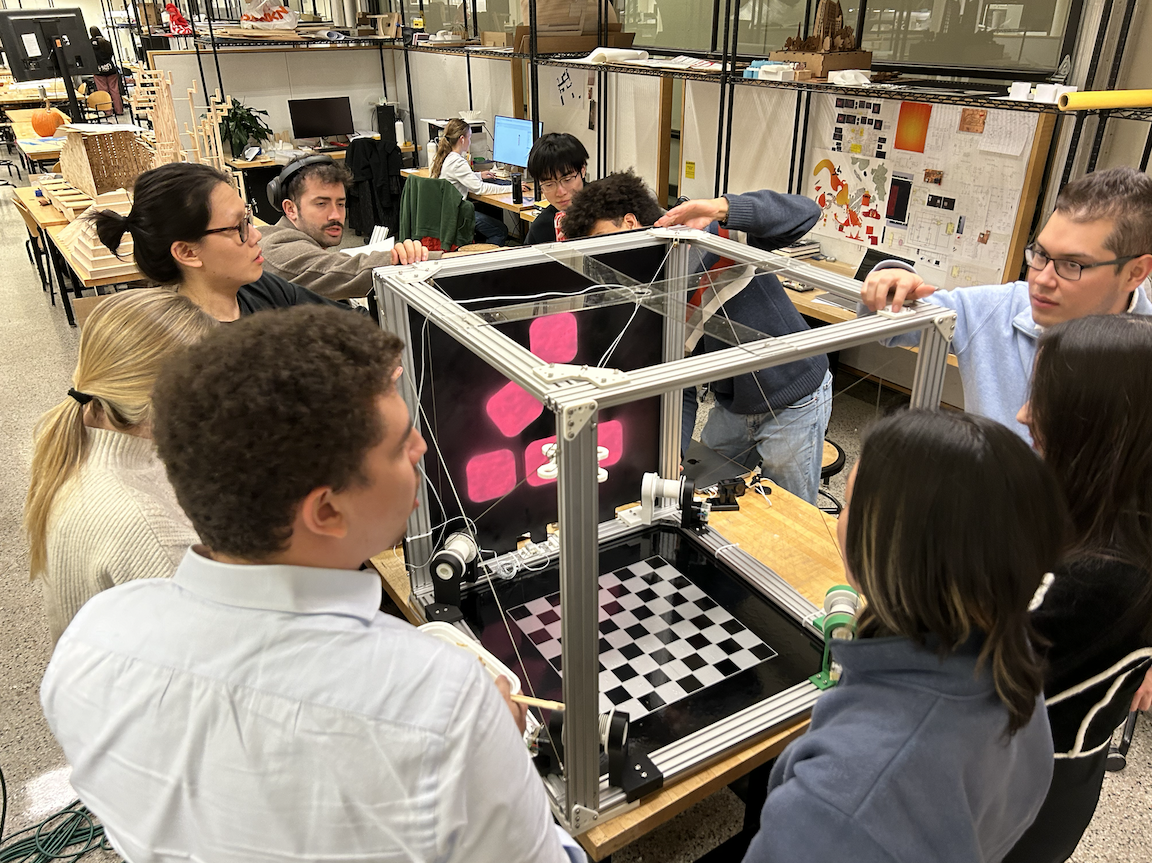

This week was so hard and so much fun. We did something as a team that I and we are proud of, and we worked really hard to bring it all together. I sorted myself into roles that could be helpful to the team. At the onset, this was helping to "frame" or organization for the week during brainstorming; during the project it was to help build and assemble the frame for the machine.

The Frame Team had to get started pretty early in the week since most other systems depended on having the frame built. We were also responsible for some of the finishing touches, such as the wire management, backing, and base of the structure.

Our team's list of tasks

While working on the project, we made slight adjustments based on the needs of the pulley team, including:

You'll see below one happy accident of the project was that the frame dimensions fit perfectly in my extended arms, making it easy(er) to transport from Building 3 to the Media Lab. I self-selected into some of the grunt work required, such as carrying the materials from N51 to Building 3, making our Blick run for materials, and, as mentioned above, carrying the machine.