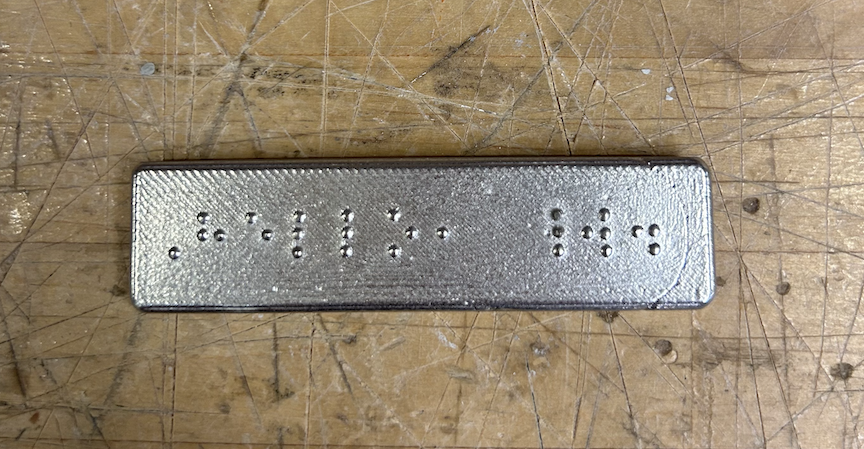

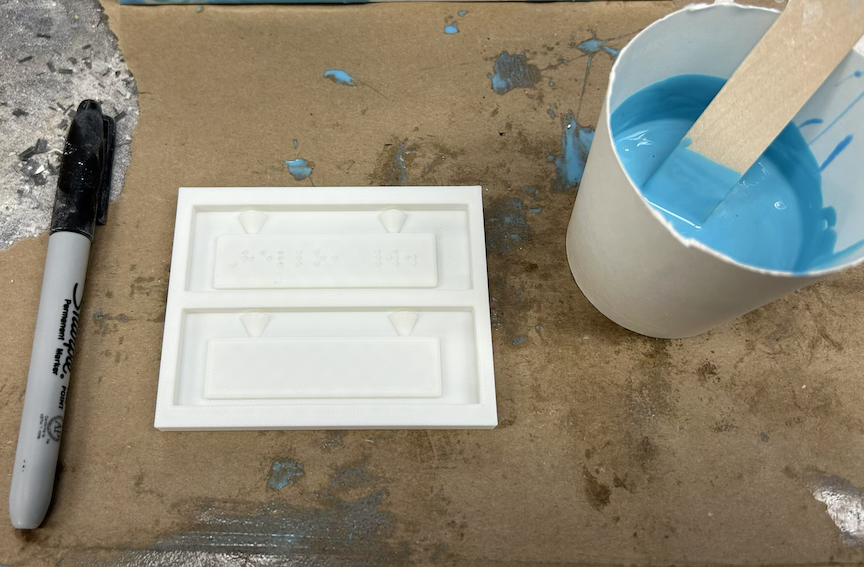

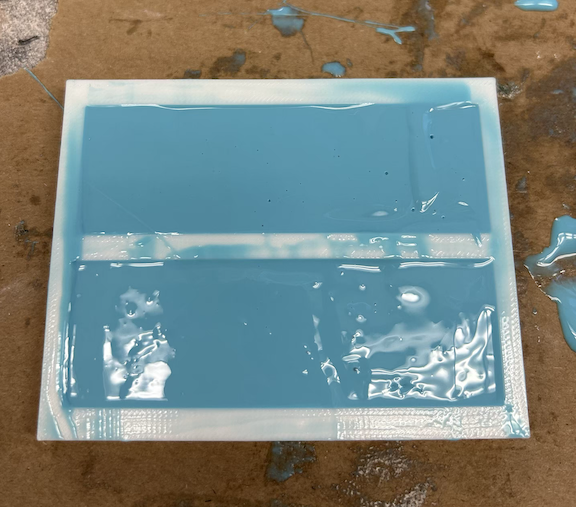

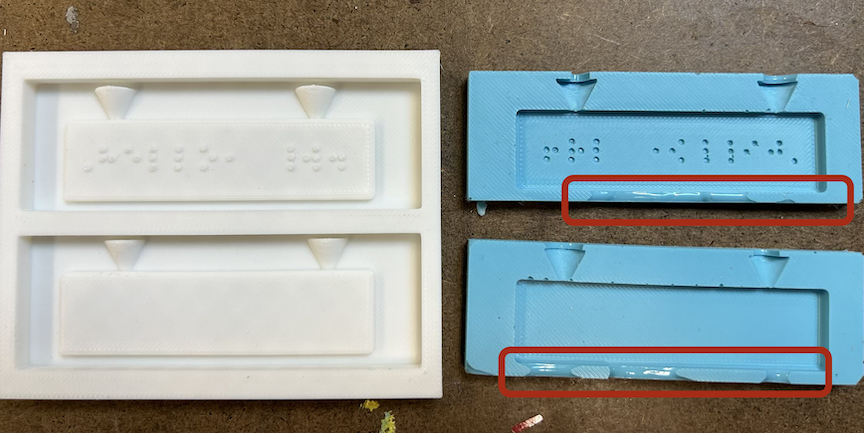

I wanted to take on the persistent challenge in the class to make something small. There were certainly challenges along the way (see my silicone mold below), it was cool to try different materials. Ultimately the tin-bismuth alloy was great for conforming to the precise geometry required by the braille mold. This 3cm ingot says, "Hello, world." Somewhat cliche, but relevant to my ongoing investigation of how the extent of language determines the bounds of reality.

This was an easy group assignment compared to past weeks, and most of the learning would have to come from using the material. Mixing properly, pouring at the right rate, etc.

Keys to successful use:

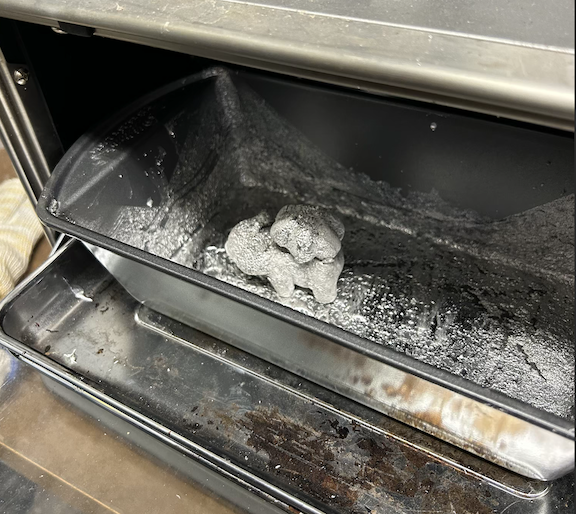

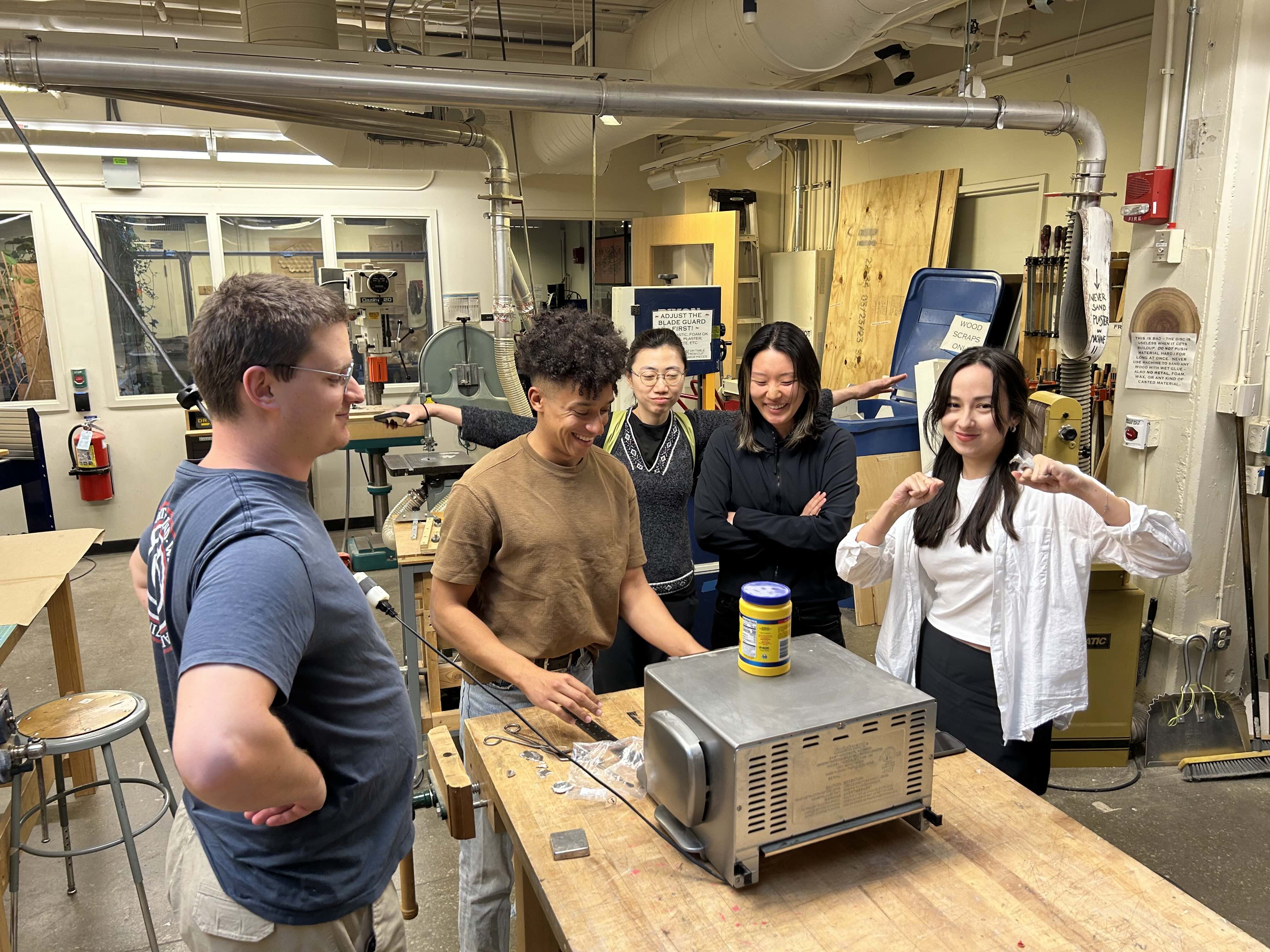

Jacob was kind enough to lead a group demo on how to handle the tin-bismuth alloy and easy-bake oven (we were surprised to learn that it was really a Cuisinart - this did make me want to make a model cast of a pizza). He did this in spite of having a midterm review the next day! The group definitely owes him, especially since so many of us used metal. He showed us how to handle the melting/pouring tray, the oven mitts, and did a demo pour so we would know how to handle the metal when pouring it ourselves.

This was a great week in terms of teamwork (note the apparent joy while gathered around the oven).

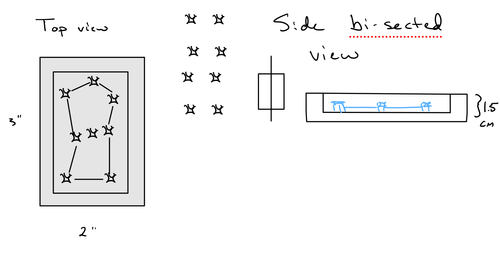

It was still a growing pain to use Rhino, but it was satisfying to make the entire design myself. I think I will try to use fusion in upcoming weeks... I had to really stretch to think about how to make the model, and opted to leave off the geometry I'd need to stabilize the mold (which I ended up not needing).

I want to include braille in my final project, so it was fun to experiment with the design this week. I was especially happy with the texture of the metal, which will work well incorporating the tactile experience of language into the World (working shorthand for the final project).

Highlights from this week that made it a success: