Week 6: Electronics Production

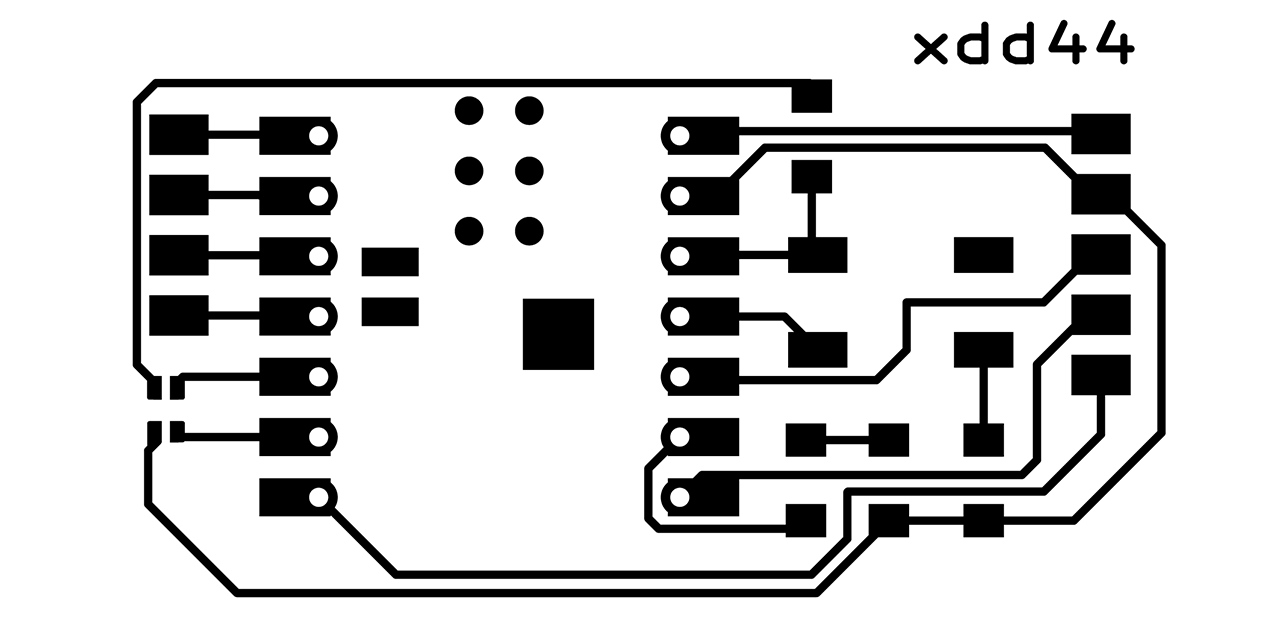

Continuing the PCB design from last week, I generated the milling pattern.

Milling Pattern

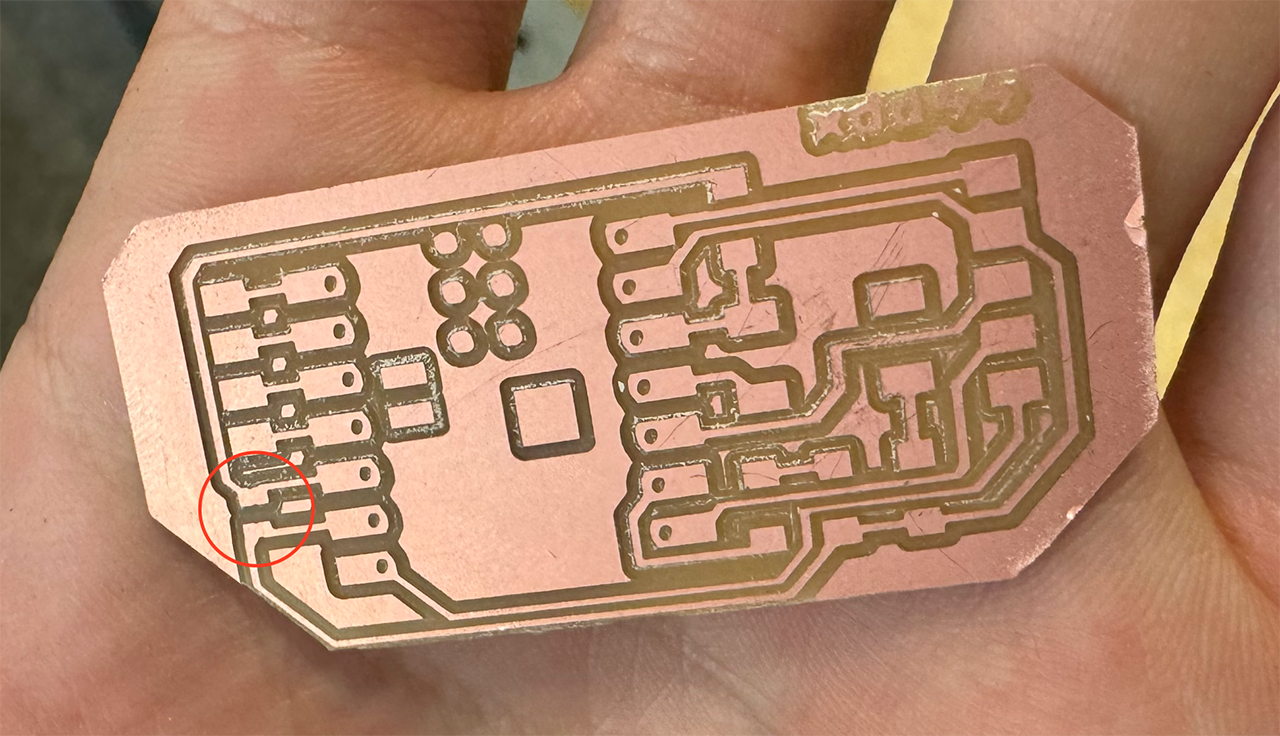

After milling, I immediately realized the scale, especially the gap between traces is smaller than I thought. The four pins for the sensor even merged together, so I skipped the sensor. The soldering still didn't went well. I could see solder shortering the traces.

Milled PCB

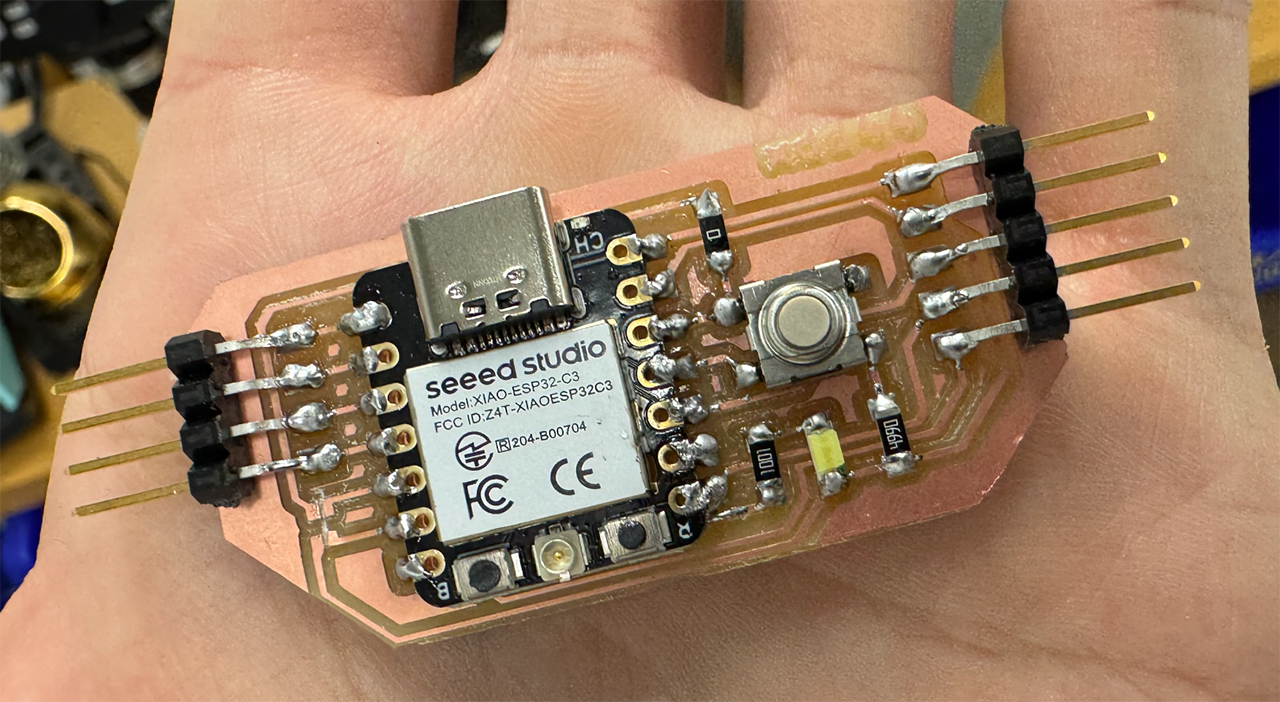

All parts soldered

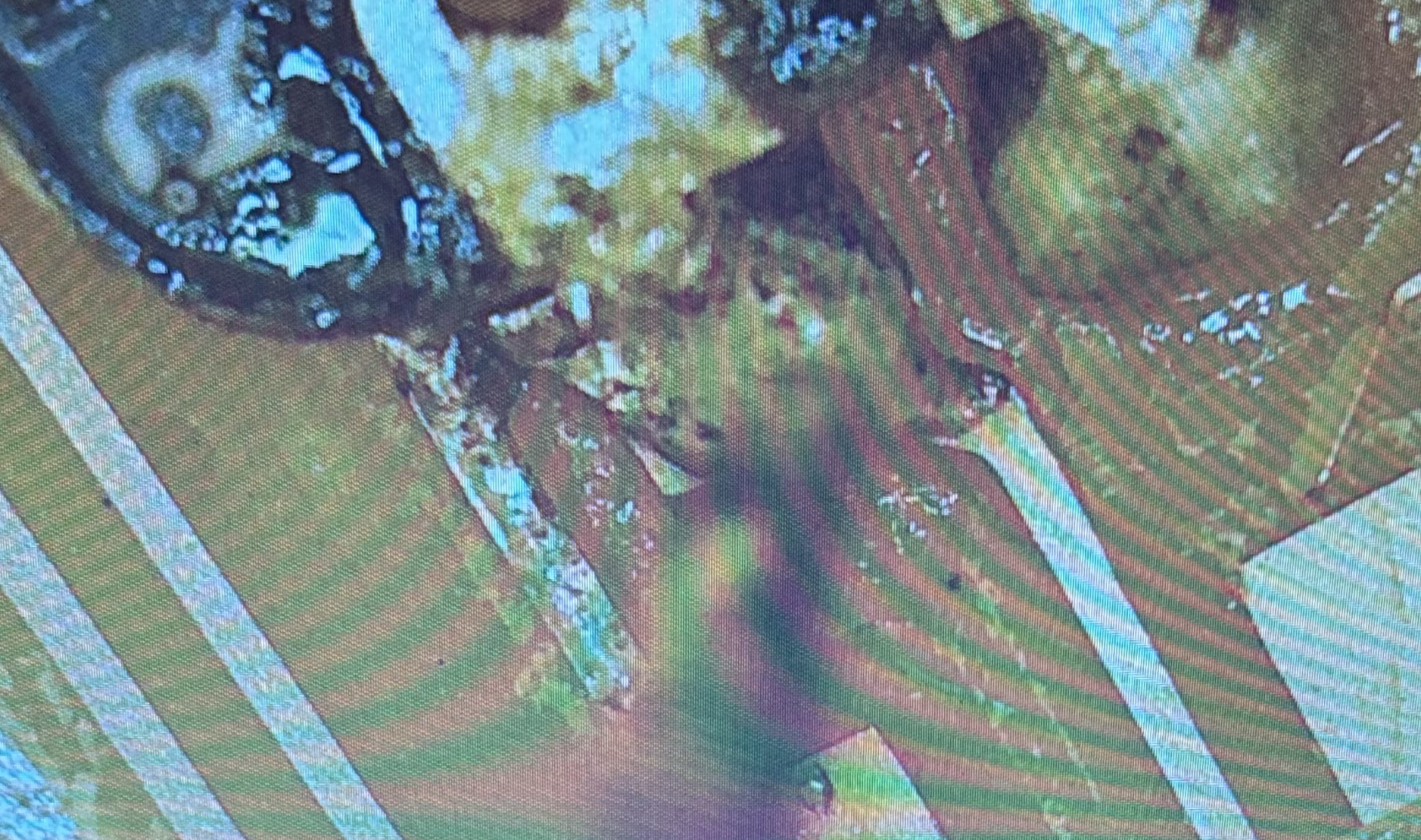

Solder at chip's button right corner pin attached to the trace below.

It's lucky that both LED and button works. But the traces to pinheaders must be shortened, since when I tried to stream data to my previous MAX 7291 LED matrix, the LED started to flash and didn't turn off.

The button turn on and off LED

The LED interfered when streaming data to pin headers