Week 14

Wildcard Week

Part 1: Wild card

For this week, we were able to choose between many different options. I chose to do metal laser cutting (here), as I wanted to make some custom metal parts for decoration on my final project. Therefore my assignment for this week was: design a sheet metal part in Fusion360 and cut the part on a metal laser cutter (fablight).

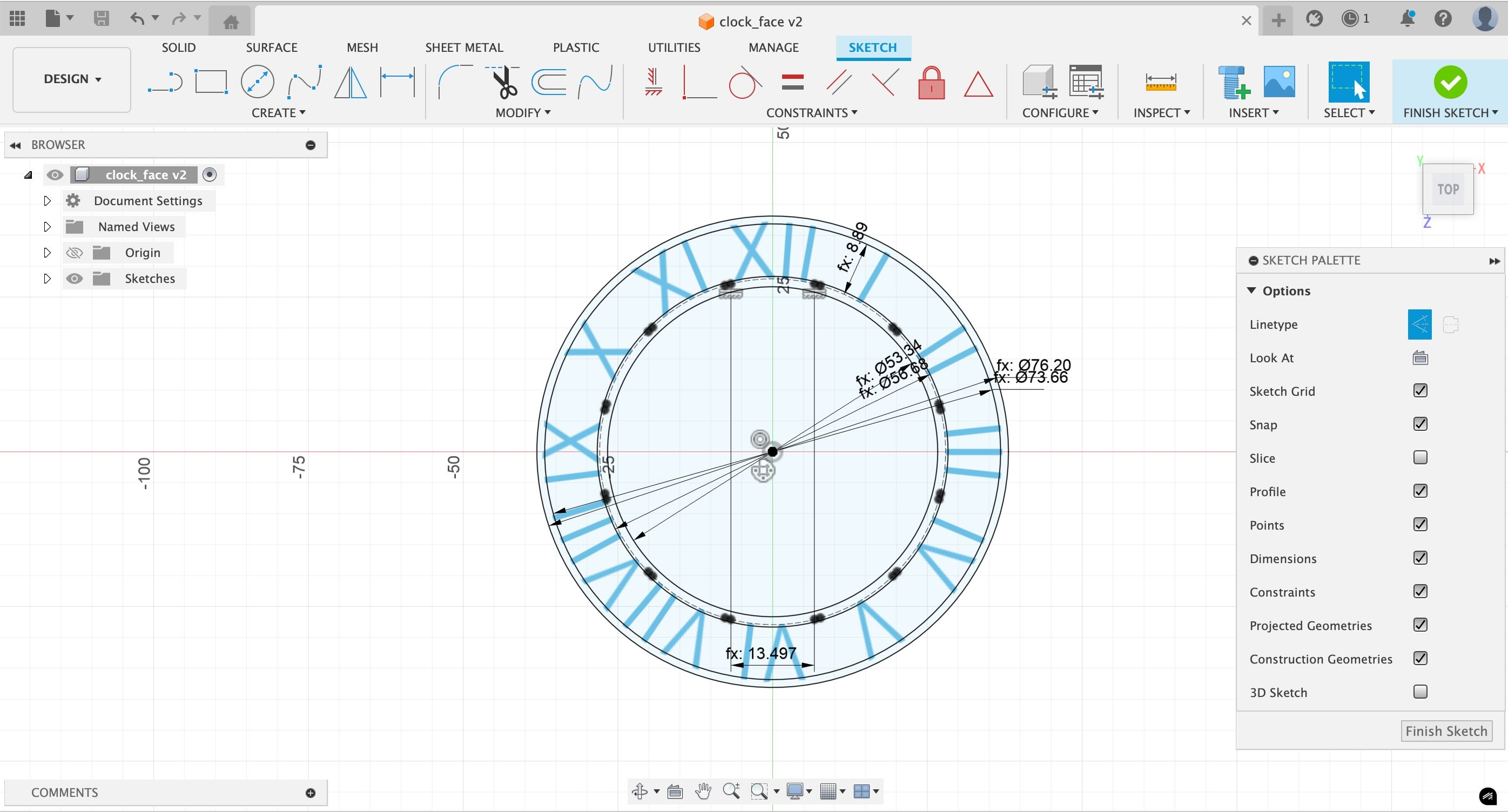

Part 2: Clock design

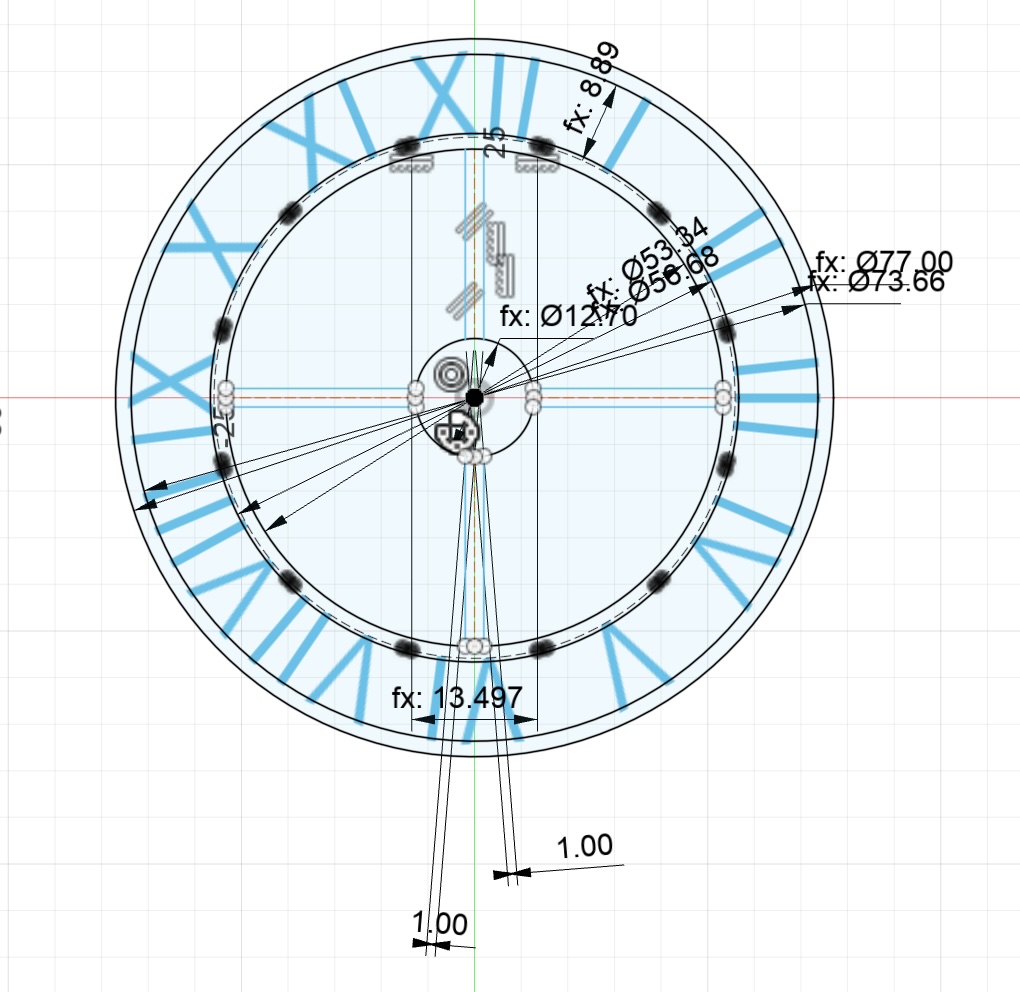

I wanted to make a small metal clock, so I started off with designing it in Fusion360, arranging roman numerals along a circular path:

And then adding in some additional pieces to hold in the clock hands:

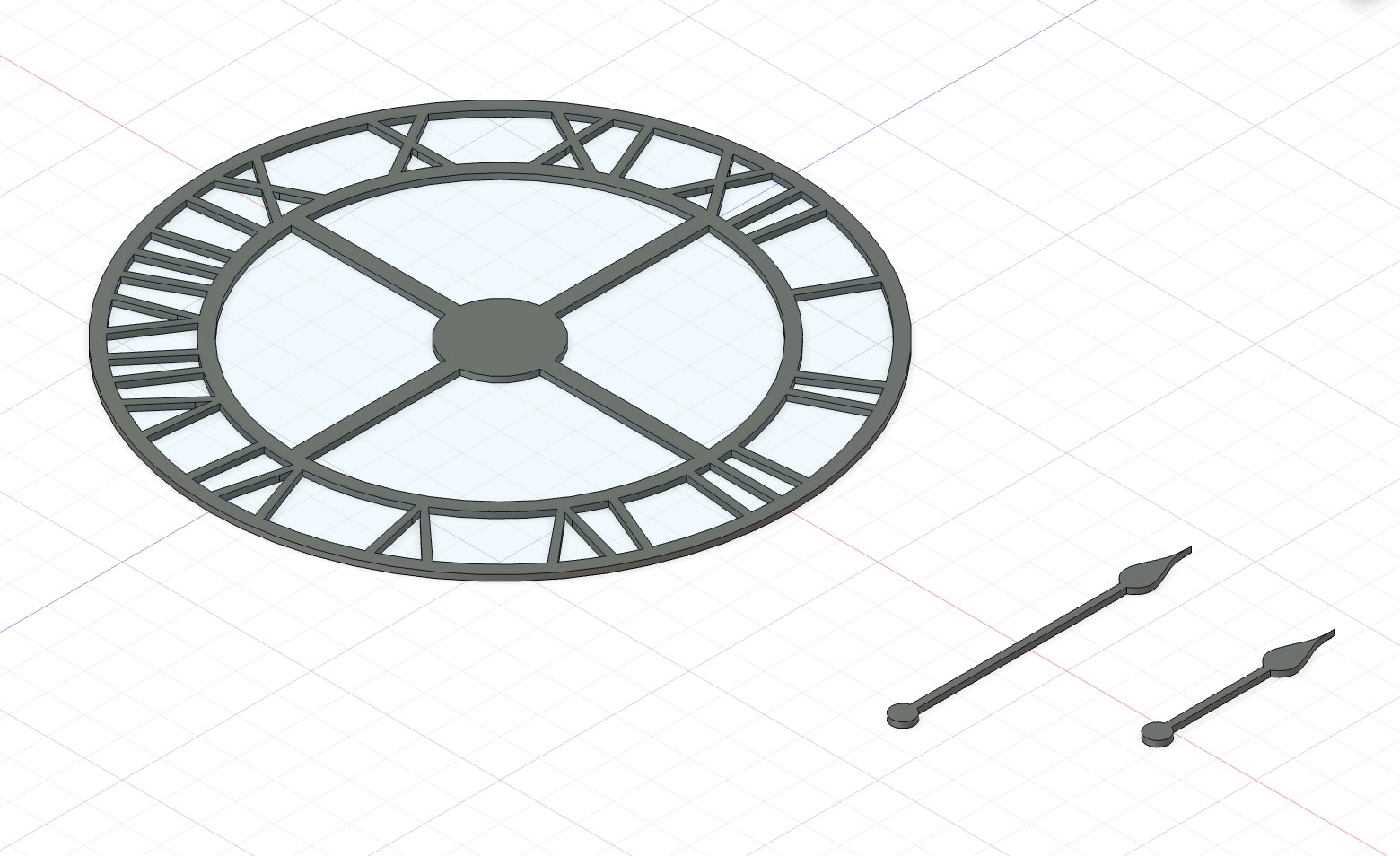

After extruding, I then had this clock shape:

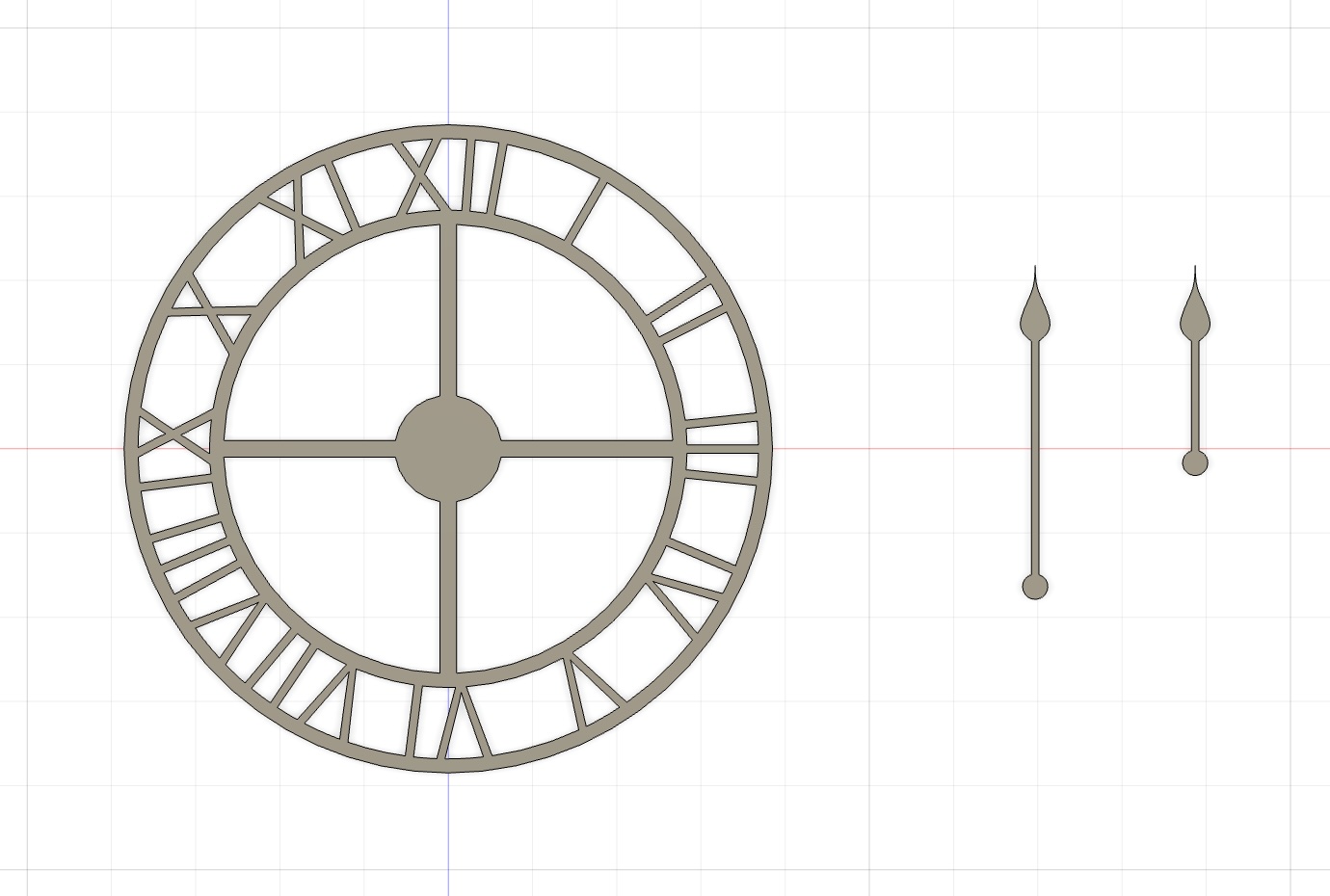

I created a new sketch on the surface of each of these pieces, which allowed me to export the sketches as DXF files for the laser cutter.

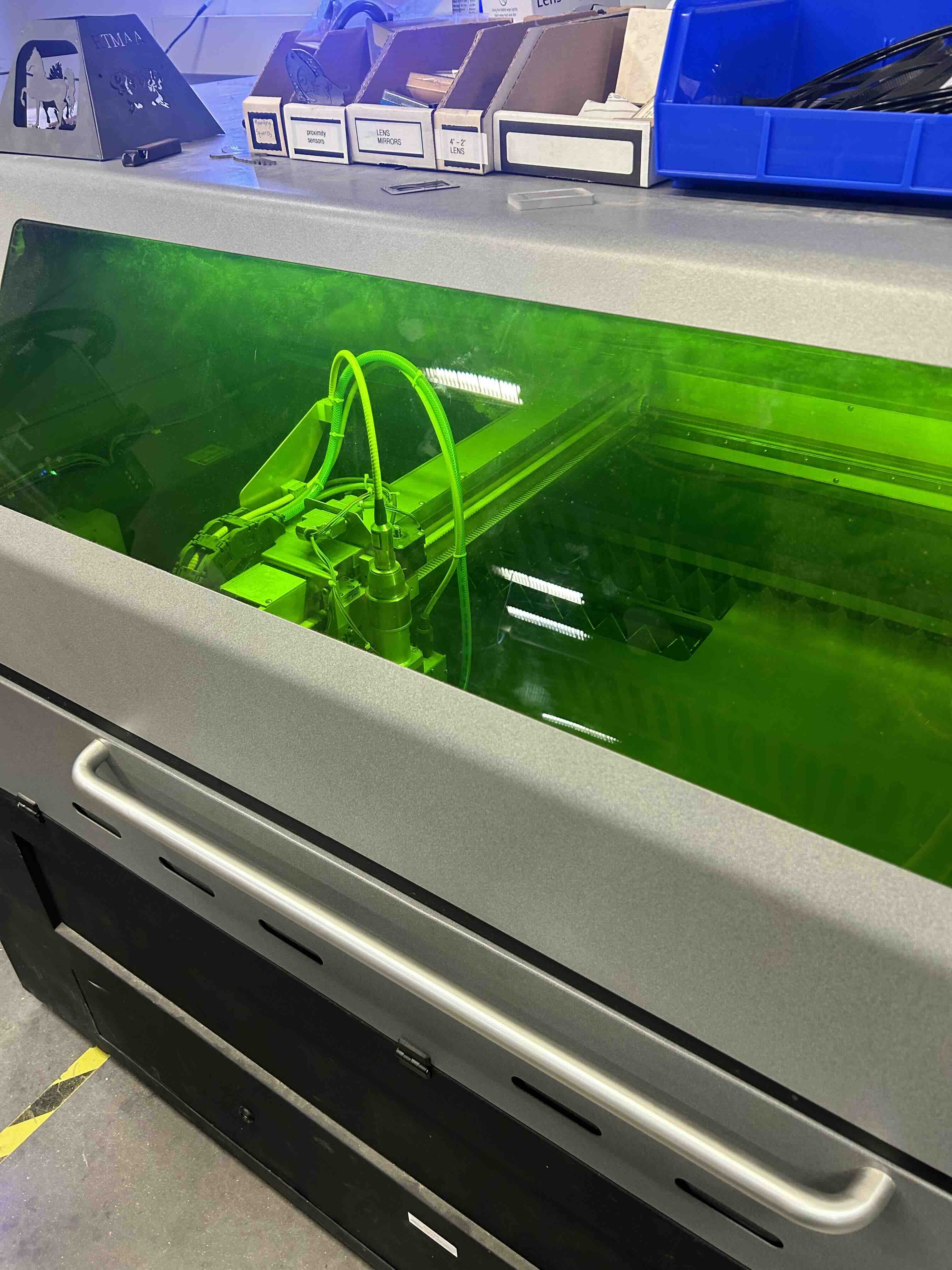

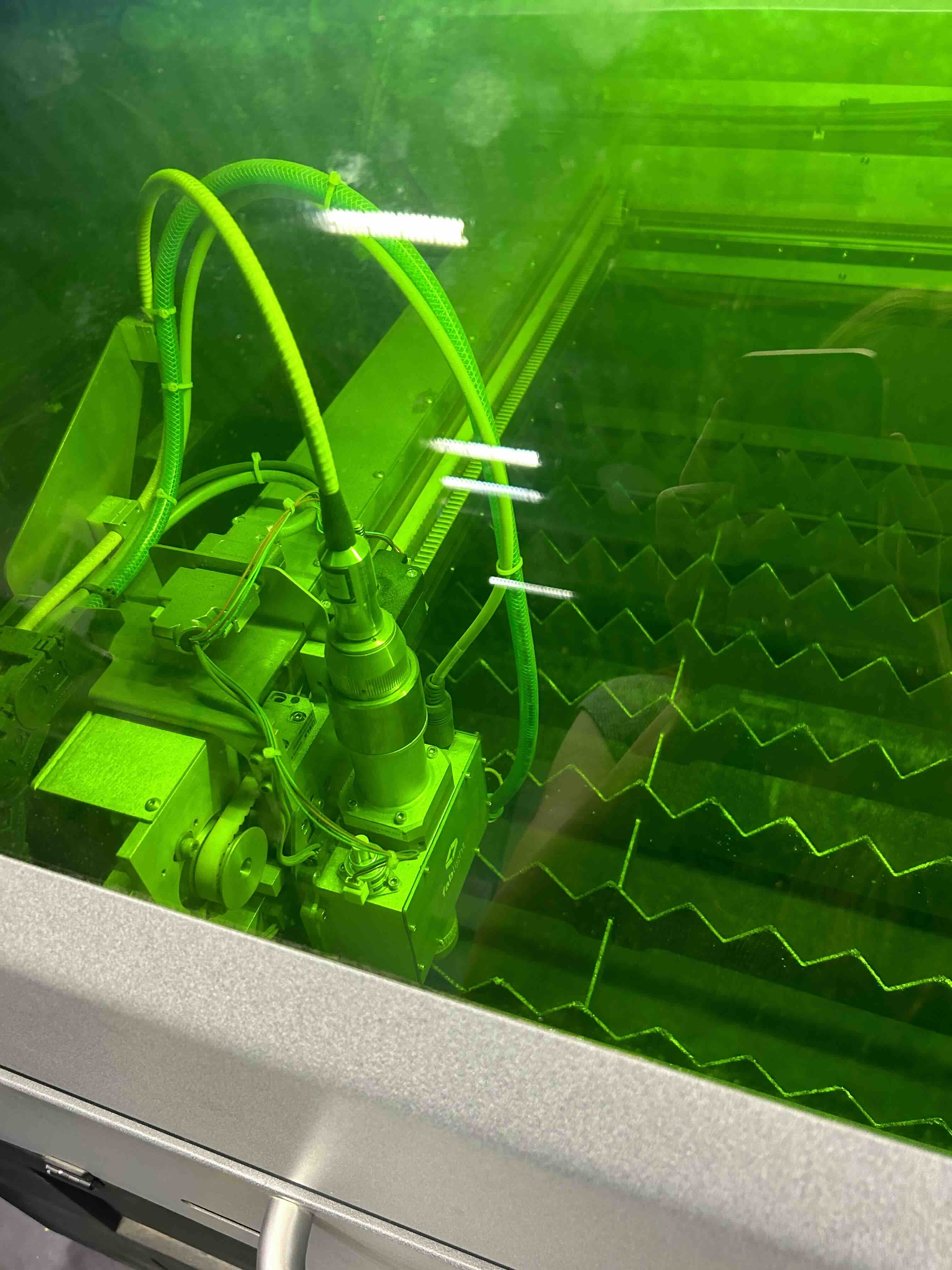

Part 3: Metal Laser Cutting

I used the fablight machine for laser cutting, uploading the necessary DXF files. I kept all of the basic import settings, just changing the kerf adjustment to 0mm because it's generally quite accurate, and selecting the steel option along with one of the preset thickness options (0.03"). I then started the cut! The first attempt seemed to throw some error, and it didn't end up finishing the cut. For some reason, it cut out the outline of the clock prior to the inner parts (causing it to fall through and not complete the inner parts), even though the order was set to do that last. The machine also didn't go on to cut the clock hands the first time, so it seems like there was some error generally. That left me with this piece:

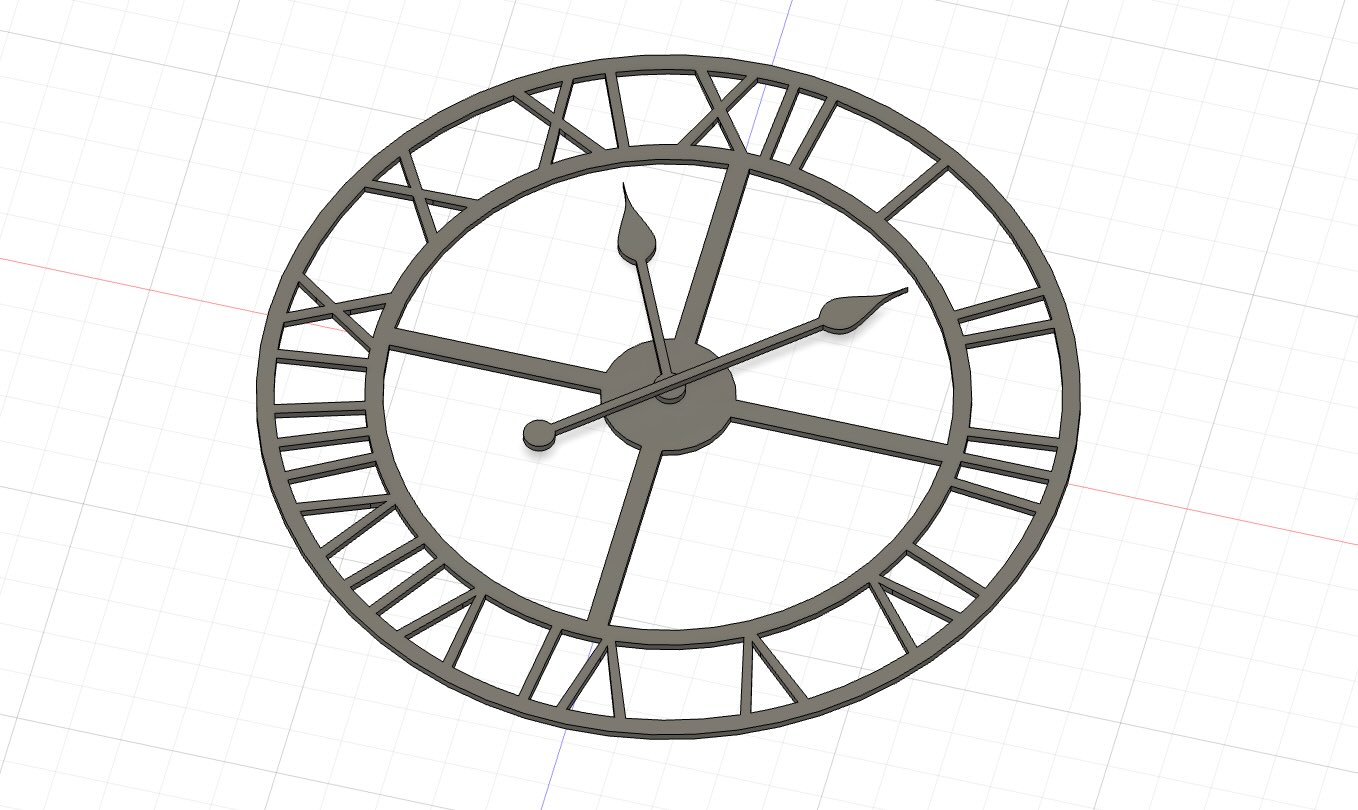

In case the problem was related to the file itself, I tried importing the DXF files fresh, with the clock outline in one file and the clock hands in another (such that I'd cut them as two separate jobs on the laser cutter). I also double checked the order of the cuts and made sure the thickness settings seemed right, as well as slightly upping the power on the machine (since it had the default set to 80 instead of 100). This time the cut finished successfully, leaving me with this outline!

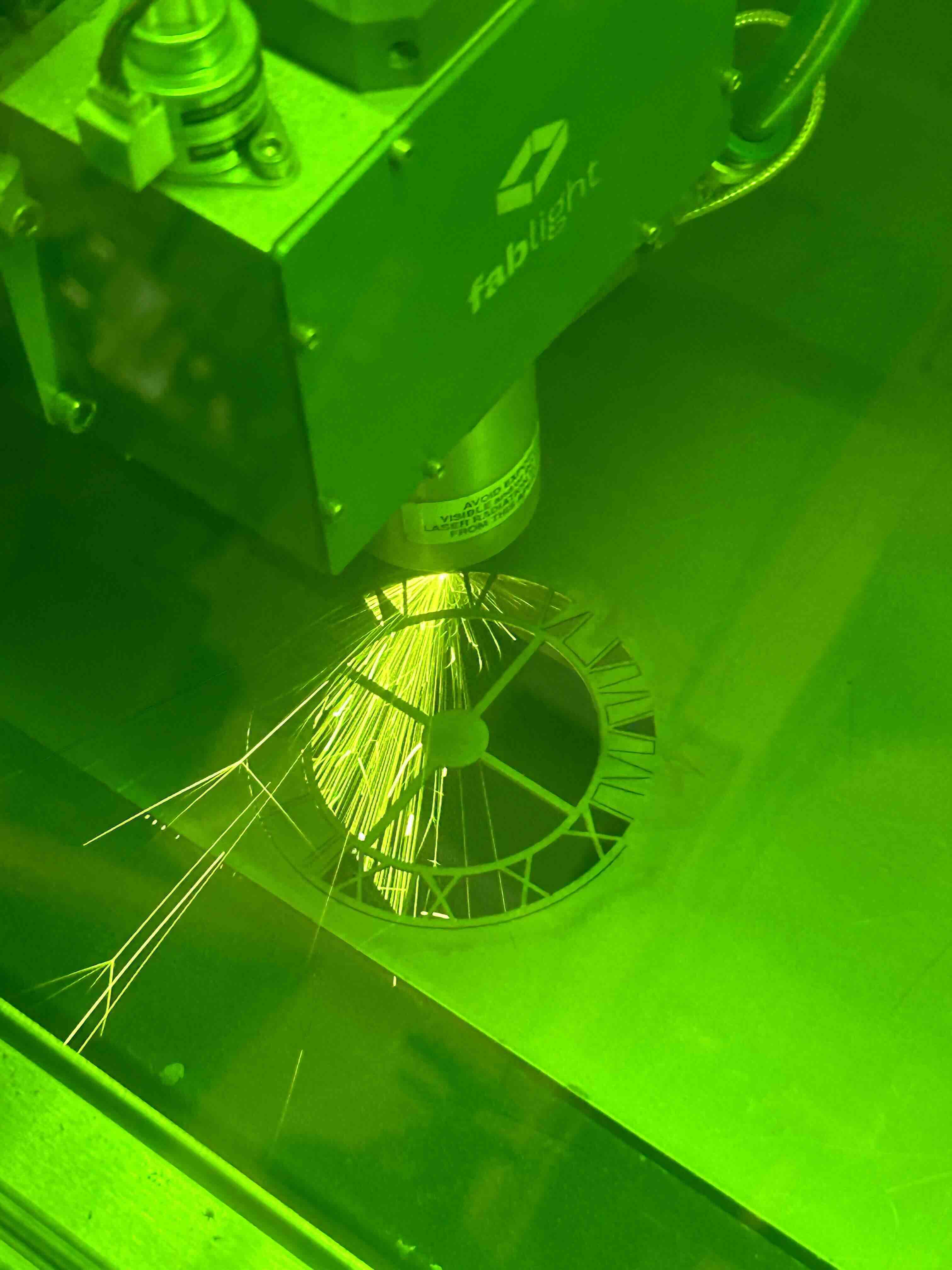

At first, I tried to cut out the clock hands in a different metal, trying copper so that I'd get a different color. Unfortunately, the only copper available was a pretty thick sheet, and my TA (shout out Miana) warned me that the machine does better with steel compared to copper as a general rule. Even after boosting up the thickness to max and increasing the power, the machine wasn't able to cut through the copper, and it threw a couple different errors while trying (primarily around failing to sense the material for some reason). After trying a bunch of parameters and not getting a clean cut through, I reverted back to the steel sheet metal to make the hands as well. These were pretty tiny pieces, so I ended up adding a tab to each of them, to keep the pieces from falling through and getting lost in the debris at the bottom of the machine. After cutting these out, I had the full clock!

Finally, here are some pictures of the laser cutter cutting out the pieces: