This week, my goal was to learn to cast in a new material to me - metal. In the architecture shop we have access to a tin-bismuth alloy, so I moved forward with that. I decided to design and cast a ring for myself. I modeled the ring in rhino to fit on two fingers and have a simple angular form. I then used that geometry to make the model of my mold.

I moved the geometry to MasterCAM and worked with Jen to set up my toolpaths. We created roughing and several finishing passes in different directions.

Then we exported the gcode and ran the file on the architecture shop Shopbot machine to mill my block of wax. The milling took about 40 minutes and required only switching endmills one time between the roughing (1/4") and finishing (1/8").

I then poured silicone to make my mold. Although you can see bubbles inside the silicone remain after lots of shaking, the actual finish of the mold came out perfectly clean.

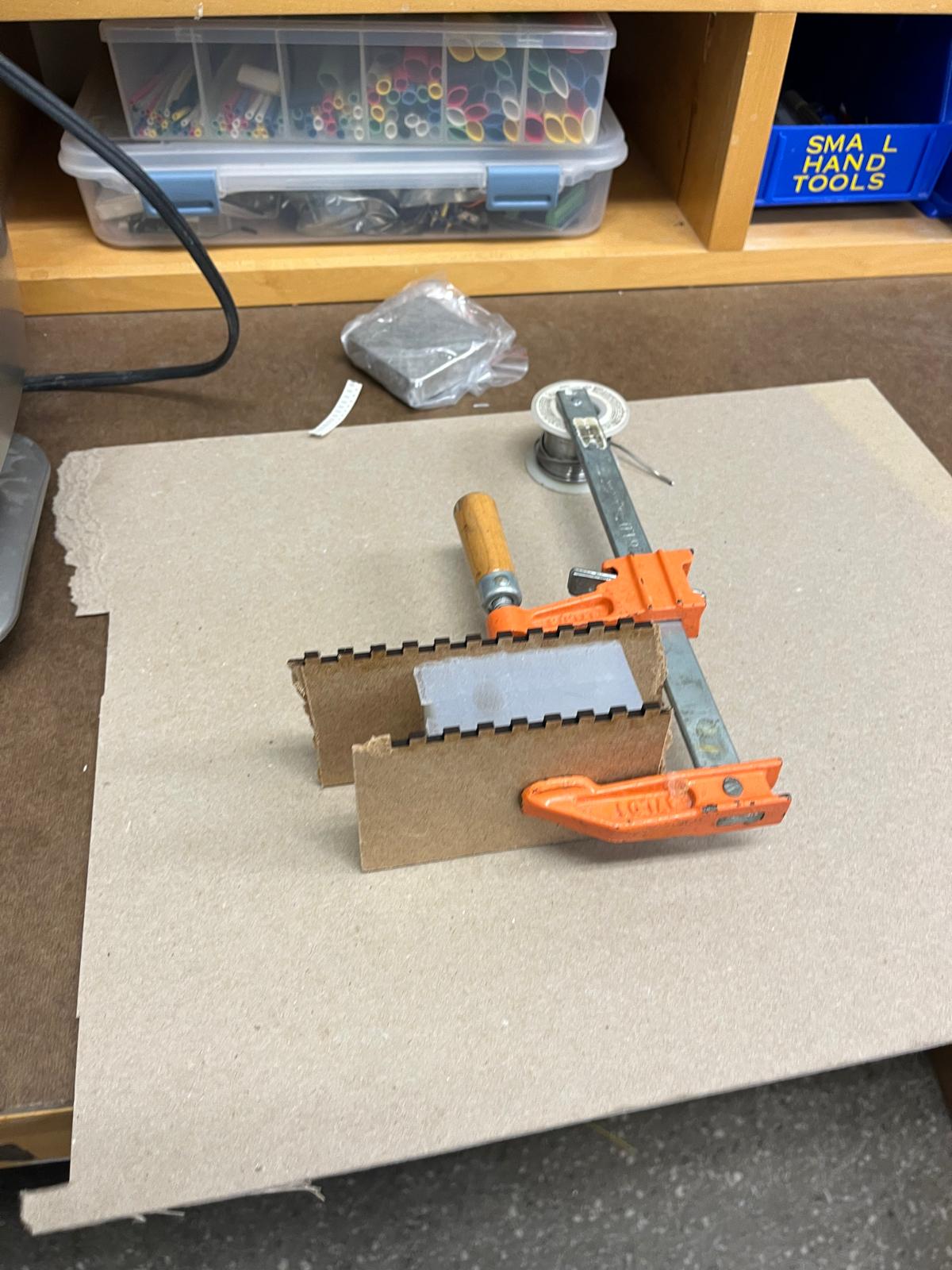

I heated tin-bismuth in a small toaster oven in the shop and carefully poured it into my mold, which was clamped together. The first attempt had an air pocket, so I knew I needed a second attempt. The second time around I had someone tapping the mold while I poured and it came out great! The tin-bismuth solidifies surprisingly quickly which is both a blessing and a curse.

To finish the part, I sawed off the funnel cone and sanded the part with finer and finer sandpaper until it looked perfectly brushed.