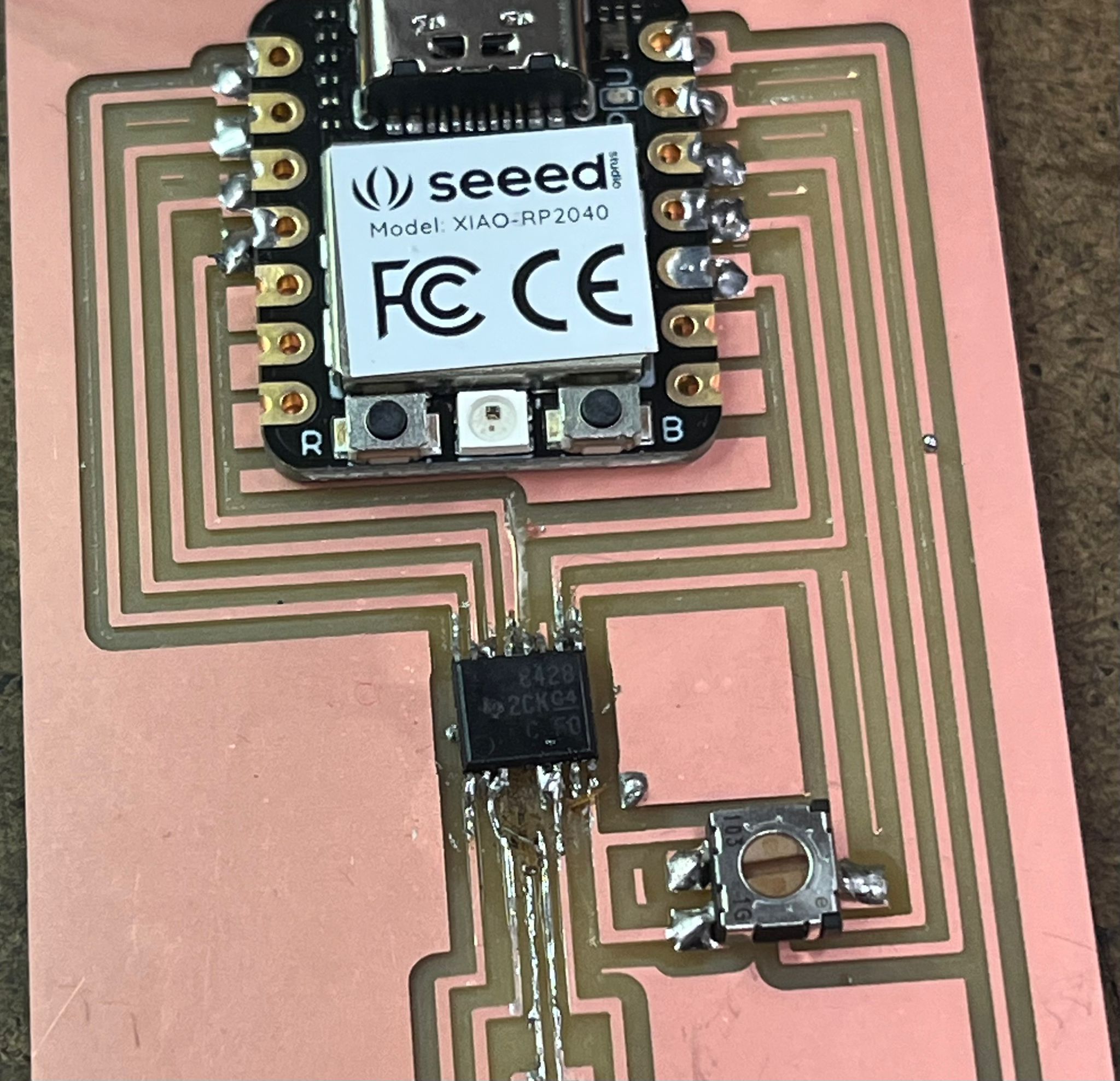

Week 9 didn't quite go my way. I set out with the goal of running a stepper motor with a Xiao RP2040. I went to Anthony for help with my electronis design. He guided me through the components I would need for this week and we went through their data sheets. I left feeling confident that I could design my PCB.

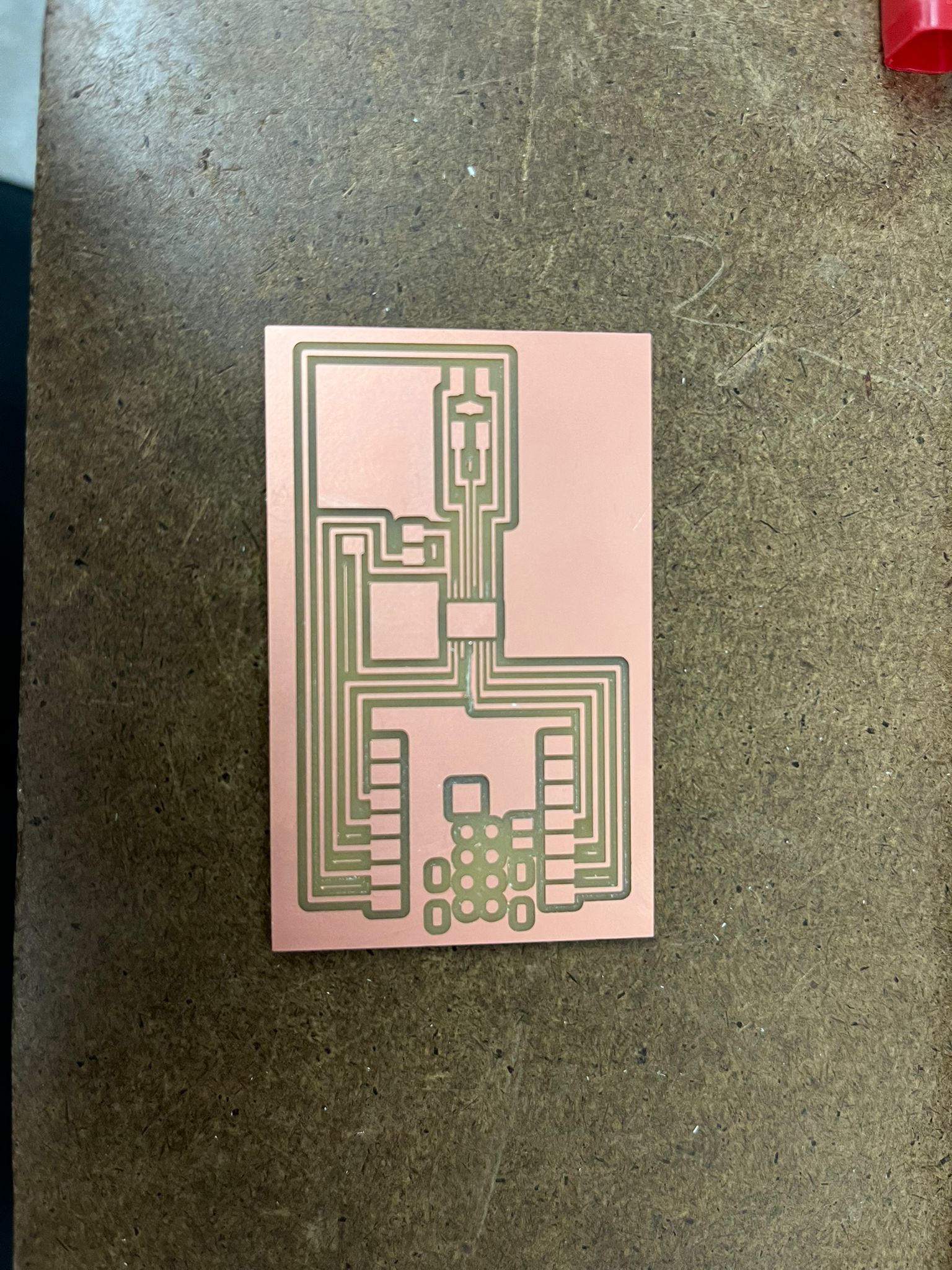

PCB design went okay and I got my board milled. The traces came out mostly fine except for a few small lines that either didn't get cut or were too small and got knocked off.

I tried to solder my components onto the board and ran into major issues with the motor driver. These traces and the legs of the component itself were just too small for my current skills and technique.

This is Jacob from the future with an update - after several weeks, I got a motor running.

After several failed attempts with the motor driver - failed soldering due to the small traces, and unidentifiable errors in debugging with Anthony, I decided I should switch to a breakout board with a motor driver instead to make things easier on myself. I was working with the A4988. I found a footprint for it on the internet and milled a new board and it worked first try!

I designed and printed a pully/winch attachment for the motor and tested it with a single cable and a tube that I intend on using in my final project chandelier and that worked great as well!

After several failed attempts with the motor driver - failed soldering due to the small traces, and unidentifiable errors in debugging with Anthony, I decided I should switch to a breakout board with a motor driver instead to make things easier on myself. I was working with the A4988. I found a footprint for it on the internet and milled a new board and it worked first try!