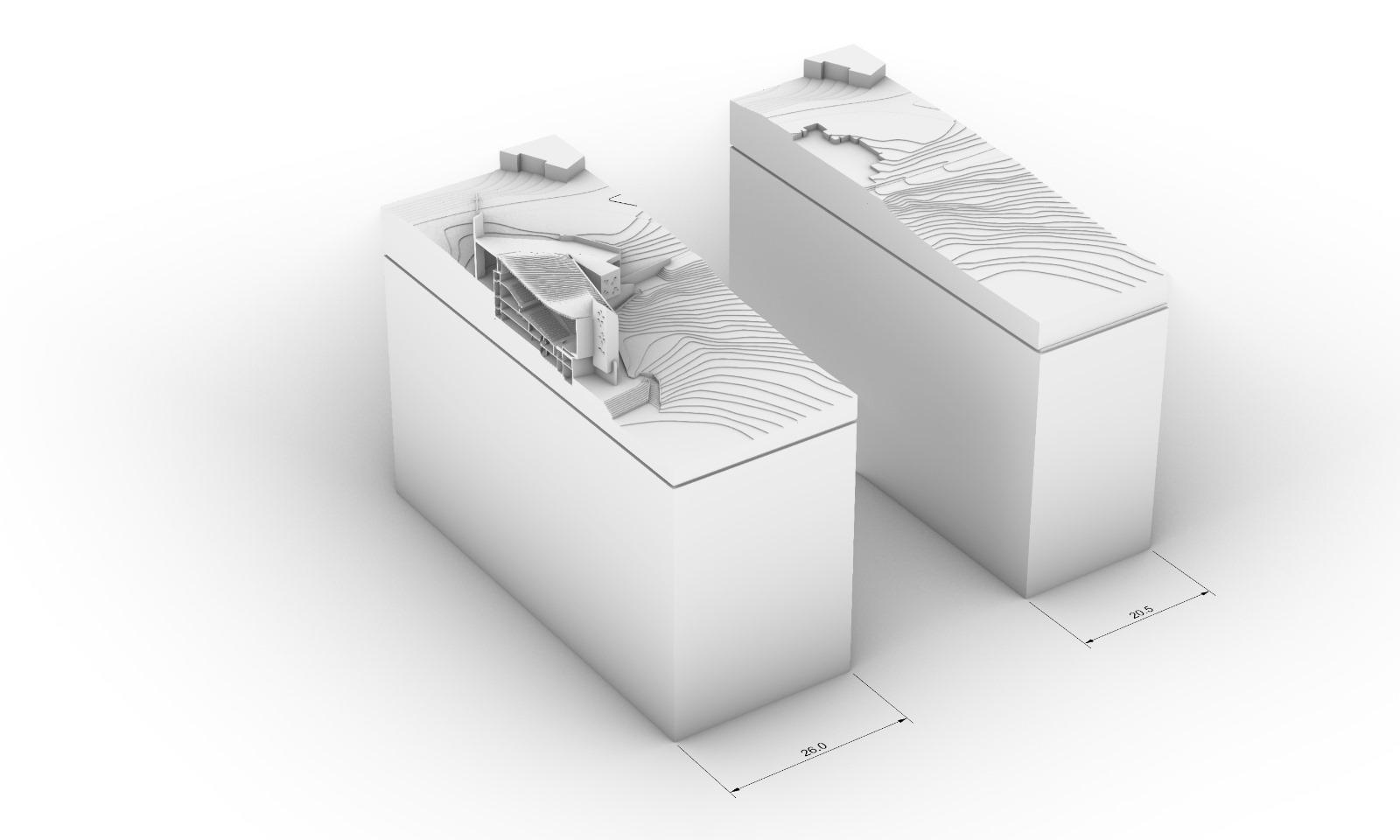

This week I ended up spending a lot of time in N51 setting up files in MasterCAM and running jobs on the Onsrud. This semester I am a TA for the architecture shops so it’s part of my job to run this machine and I have quite a bit of CNCing experience. Coincidentally this week also aligned with an exhibition model I’m making for another job, for which I need a very large site model. The site is at Tuskegee University in Alabama and the model will be a section model of the university’s chapel designed by Paul Rudolph.

The rhino modelling for this project has taken several weeks, but this week I needed to sit down and finally make the tool paths in MasterCAM. The CAM setup includes a few paths - surface roughing, surface finishing, and contours (to clean up sharp lines).

The stock I was cutting was a made from basswood boards glued together to make a stock that is 26” x 66” with varying height.

I ran the Onsrud over the course of 2 days - roughing one day and finishing the next. The final model came out fairly clean - with some spots needing to be chiseled and cleaned by hand, as the complicated geometry means that the endmills couldn’t reach certain areas without crashing the machine.

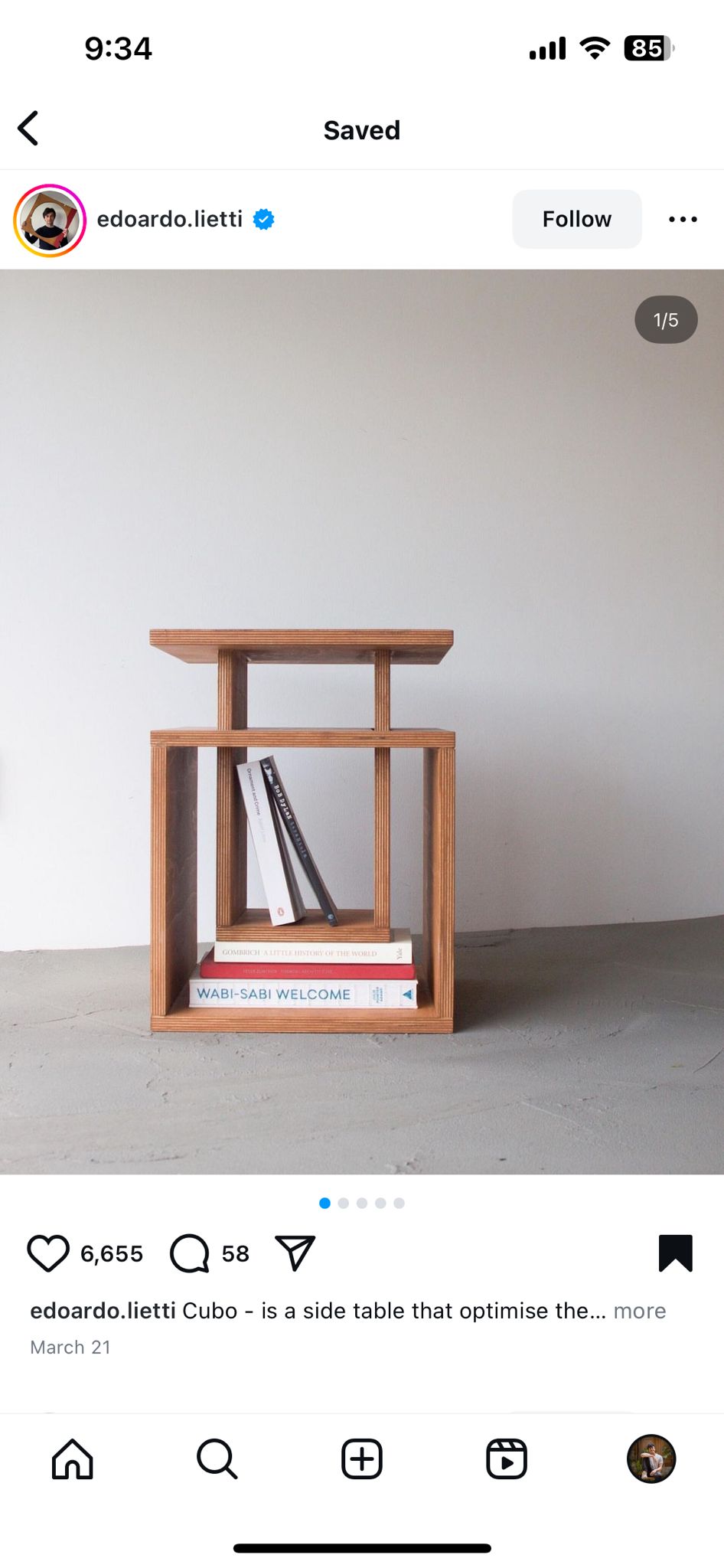

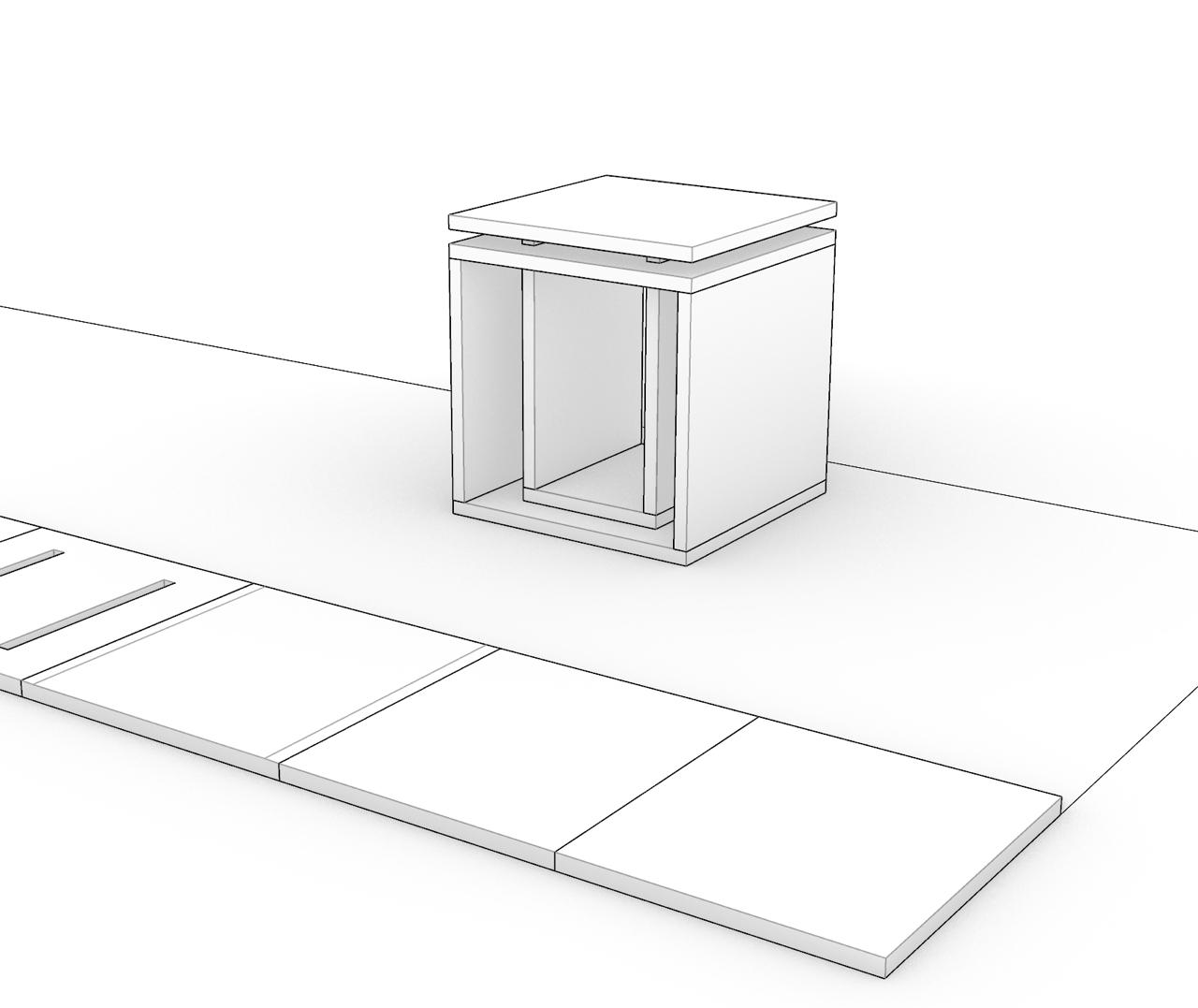

I had originally planned on making a side table on the mill out of sheet material specifically for this class before the Onsrud went down. The design was one that I’ve been looking at for a while, so I was excited to finally make one. I decided to model the parts I would need in rhino.

With the machine being down, I decided to make the table anyway with the table saw and jigsaw out of a plywood sheet.