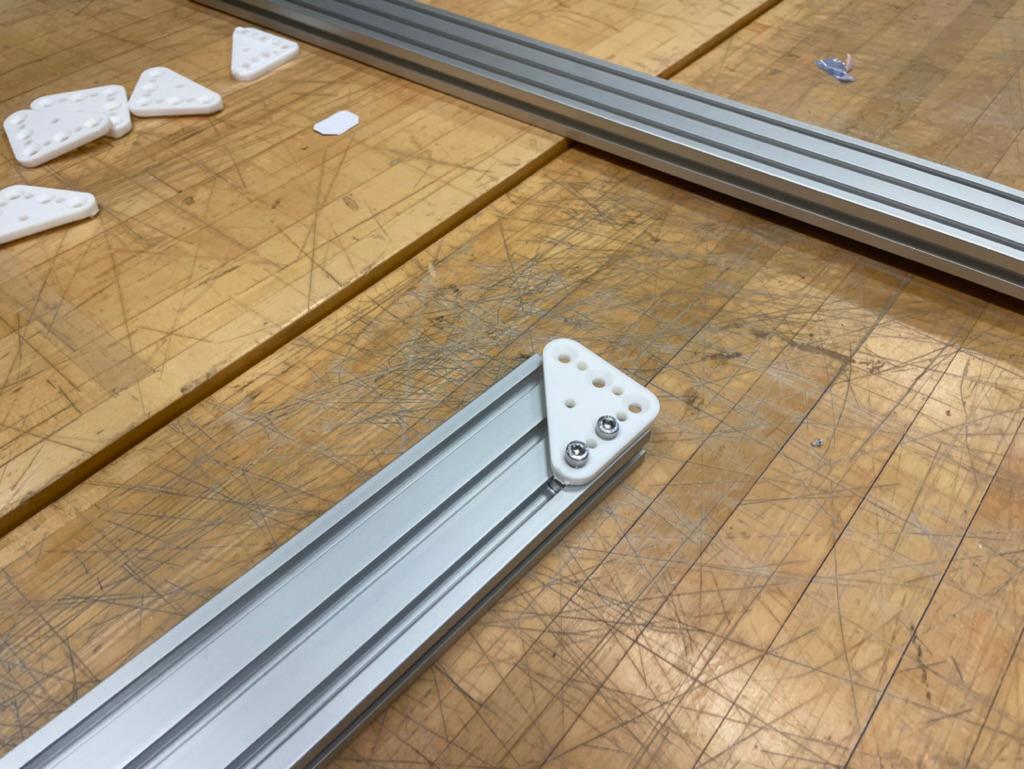

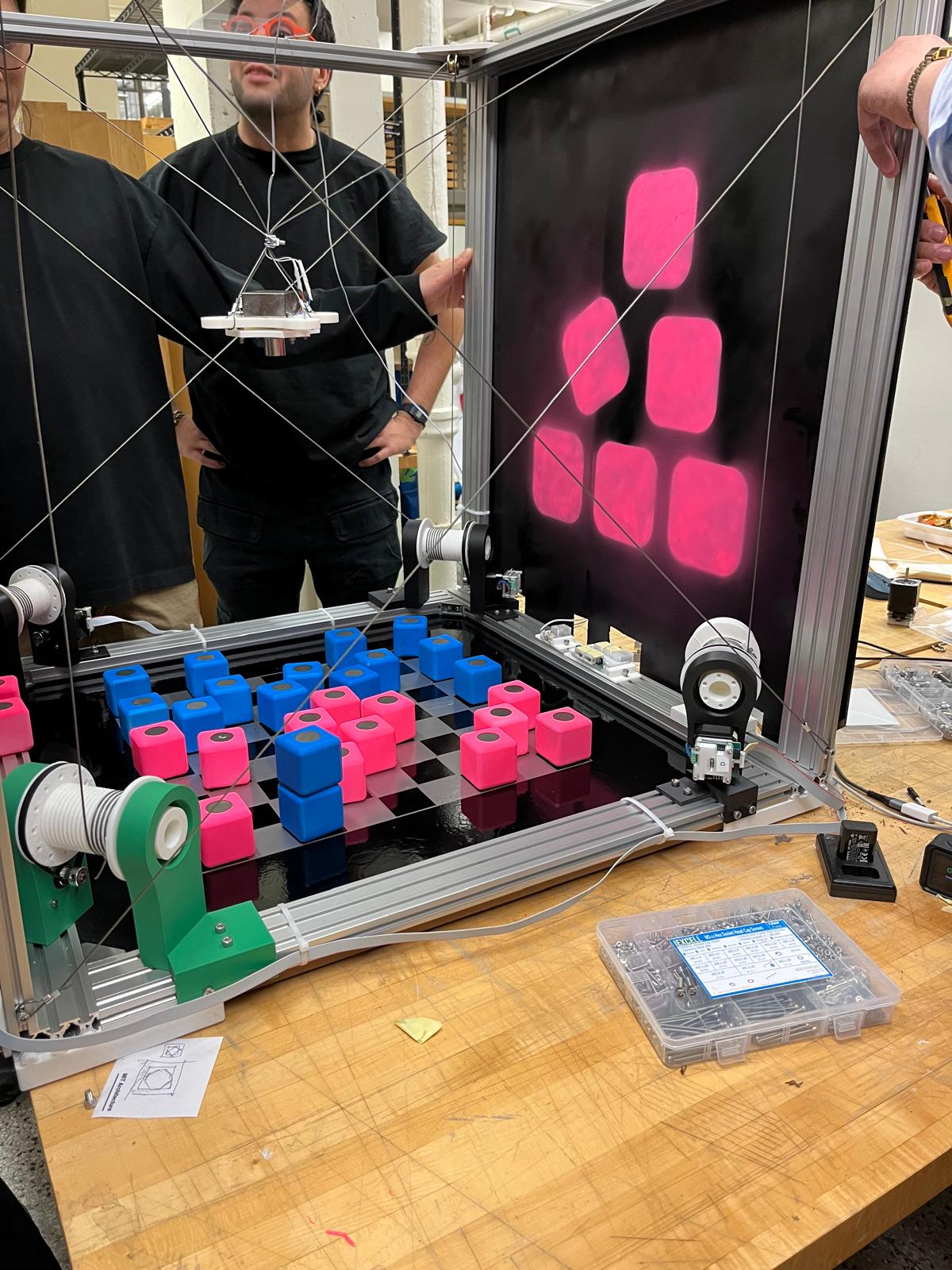

Machine week! Arch section ATE this week. We built a cable-guided grabbing machine. I was a part of Team Frame, helping with designing and building the enclosure for our machine. We received extra aluminum extrusion from Jake and cut it in the RPL shops using the chop saw to length based on our CAD drawing in rhino. We 3D printed 90 degree brackets from the files provided to us. I was tasked with ensuring that the basic cube of our frame got built ASAP so other groups could work off of it. So we had the whole frame fully assembled by Thursday night - the day after lecture. I also assisted in cutting and finishing the MDF base and defining the playable area with vinyl grid design. First I covered the MDF entirely in black vinyl. For the 2"x2" (same as block size) silver grid, the large Roland vinyl cutter was having communication issues, so instead I cut and patched together several smaller stickers cut on my desktop Cricut. We slotted the finished base into the frame using 3D printed slots that fit into the aluminim extrusion and hug the corners of the MDF sheet. See my contributions in action on our team page linked below!