Week 2: How to (try to) compute with cardboard - Sun, Sep 15, 2024

This week our assignment was to design and cut a parametric construction kit. Our class maker spaces were going to be stocked with mountains of cardboard, and it was up to us to figure it out from there. For some reason my mind immediately jumped to the large scale replica of the Digi Comp II in the Stata center, a mechanical computer that does calculations by balls falling through it and passing by track changers. After a little research I found that the Digi Comp II is not turing complete, but a closely related toy called the Turing Tumbler is turing complete. While I initially sought after creating a kit that was turing complete, time constraints only allowed me to make something that could compute like the Digi Comp II.

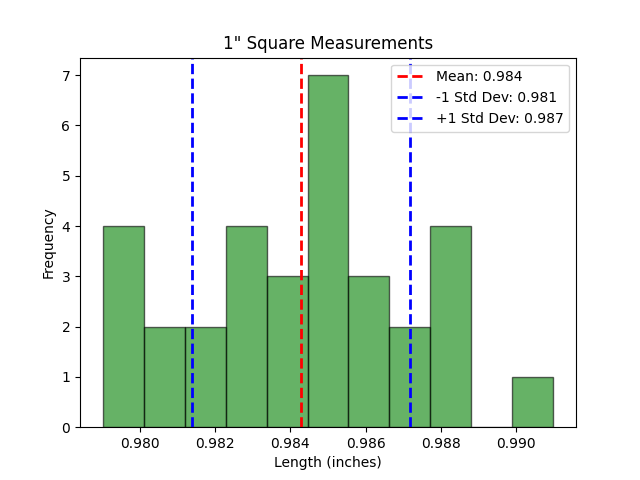

I began the week by characterizing the laser cutter I was going to be using. By cutting out 1 inch by 1 inch squares I characterized the curf of the laser.

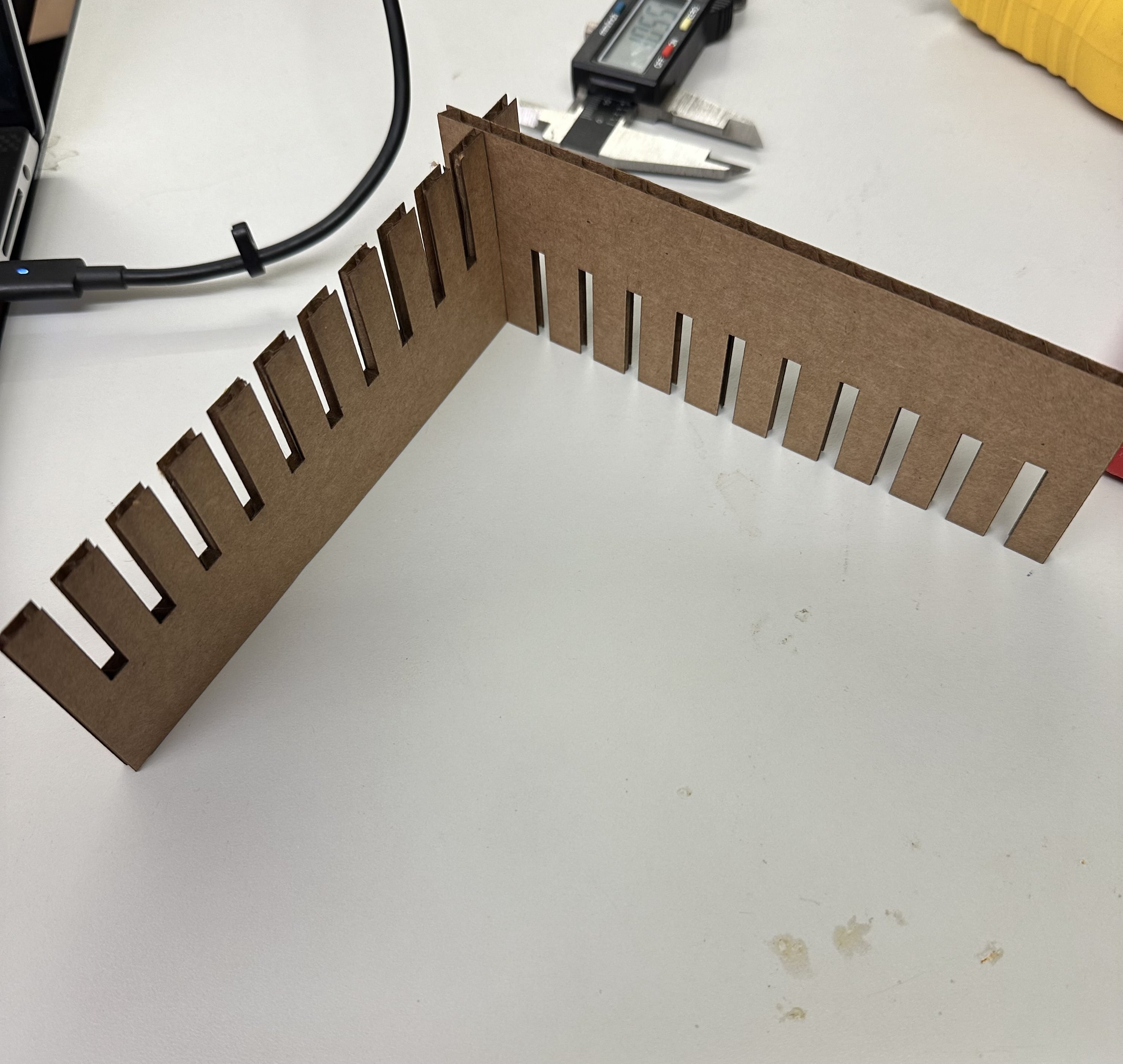

I then printed two comb-like structures to figure out how to get a solid joint between two pieces of cardboard. I found that creating 3.5mm wide gaps makes for a solid fit.

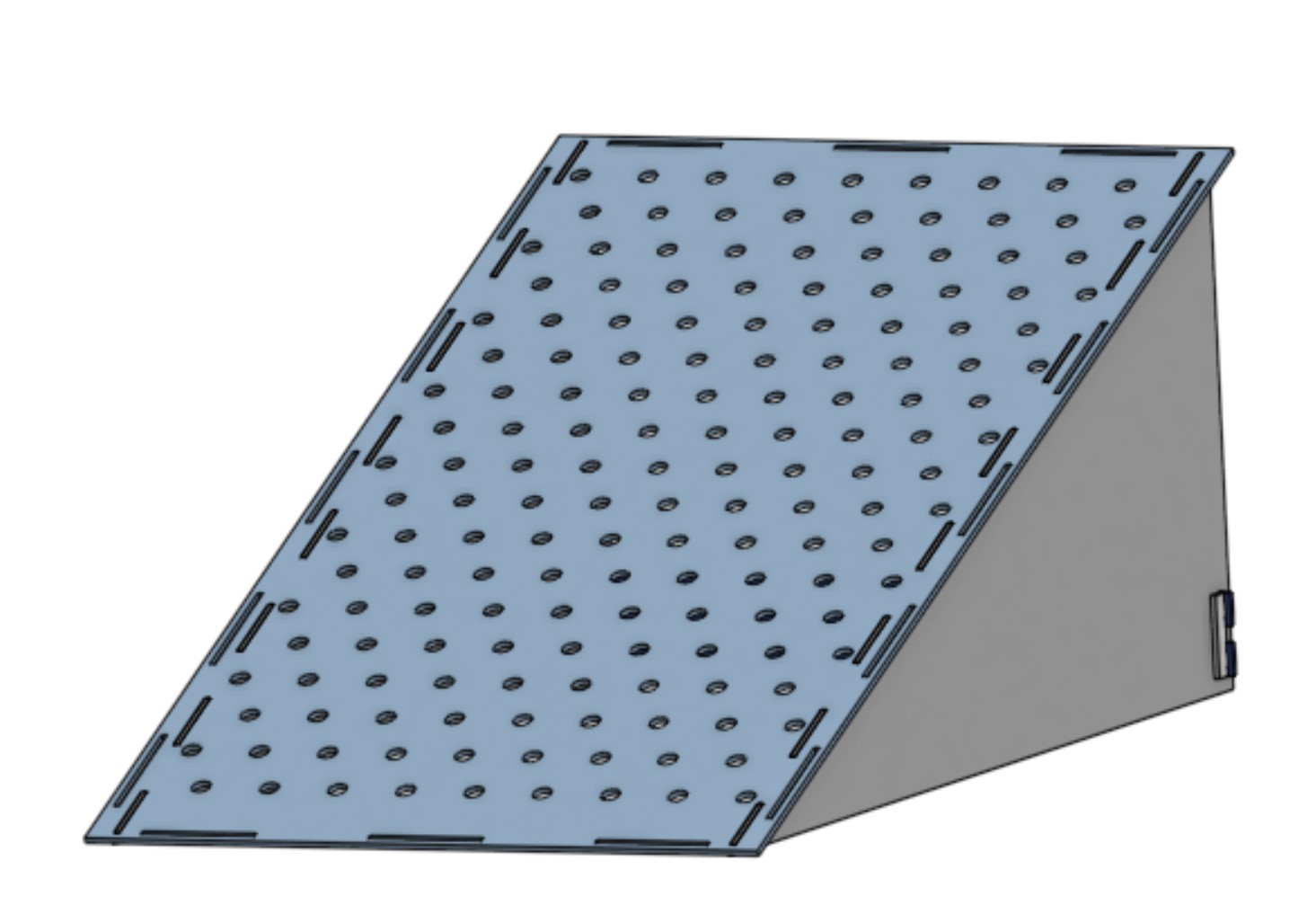

Now it was time to hop in cad and start designing. My cad of choice: Onshape. You can view the cad here, but my main goal was to first make a board that tracks and track direction changers (that I called flip-flops) could fit on. I went with a hexagonal hole structure on the board to make the implementation of flip-flops easier.

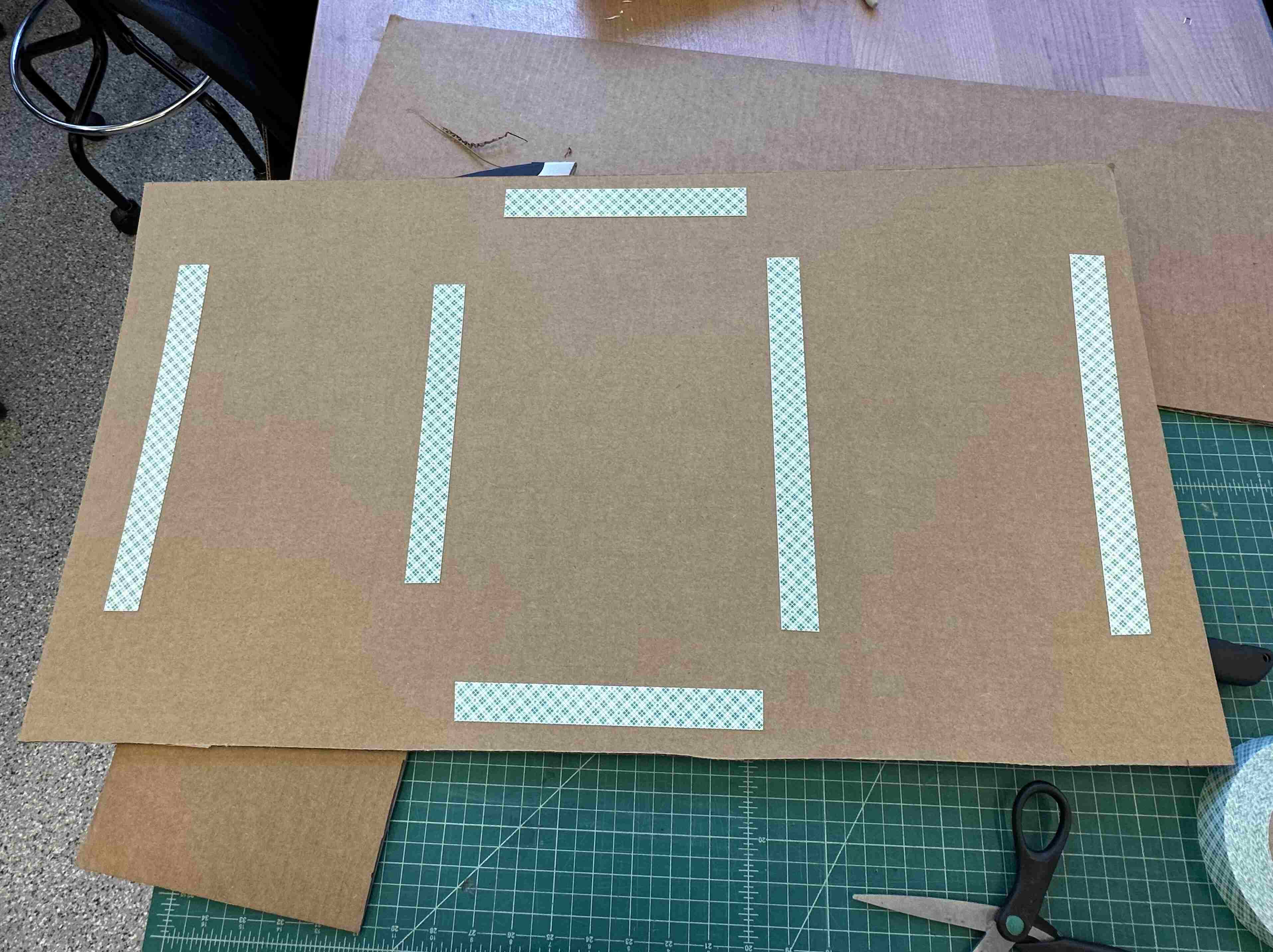

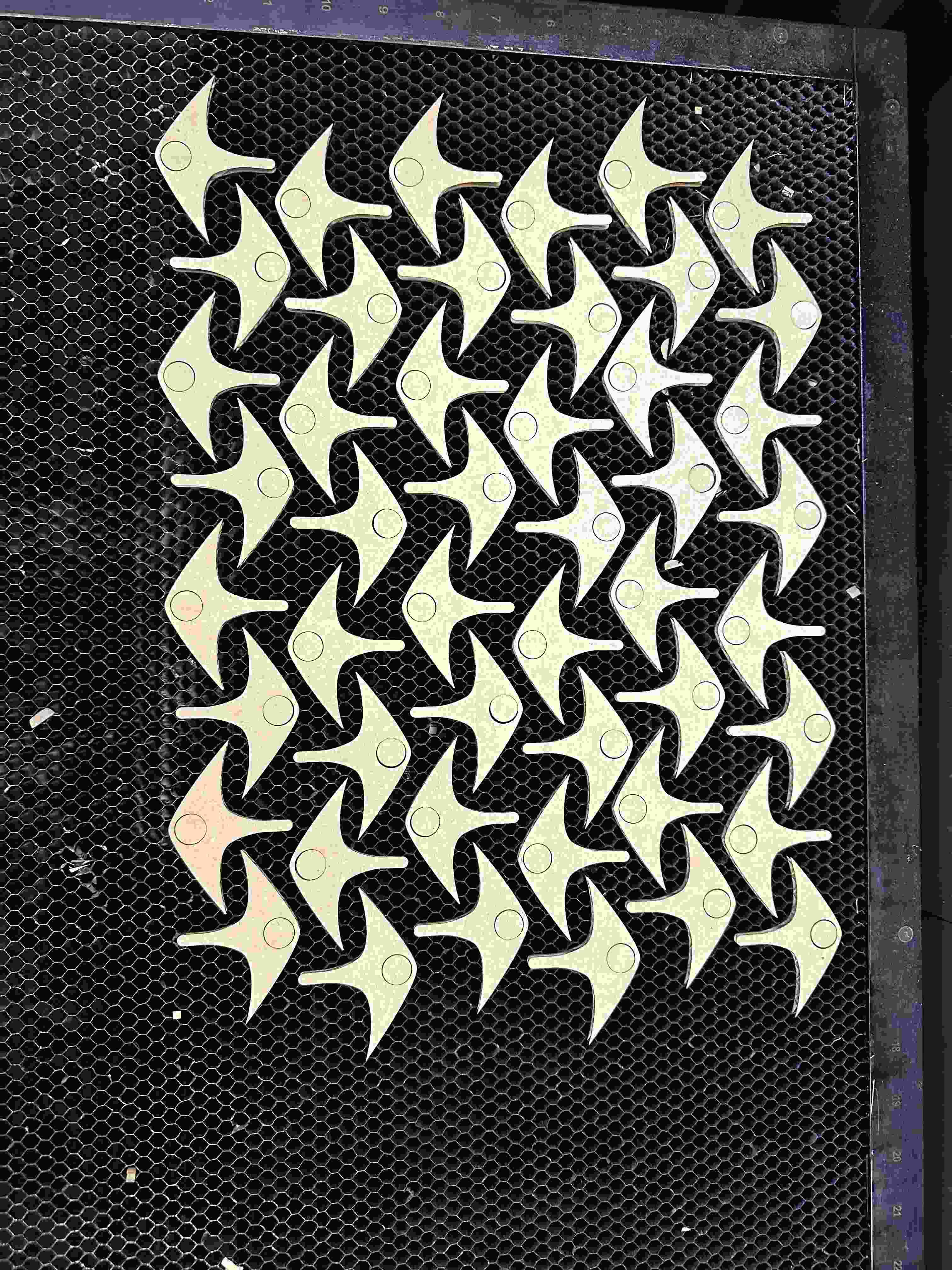

It was now time to laser cut this out. One of the biggest challenges I ran into was the bow that most pieces of cardboard had. When I tried to cut out the main pegboard of my device the non planar nature of the cardboard caused the laser to become unfocused and lead to an incomplete cut. No worries through, a little bit of nuance in selecting the right sheet of cardboard and double sticky back tape did the trick.

After some laser cutting and minor assembly I was left with the main board that I would design everything else around

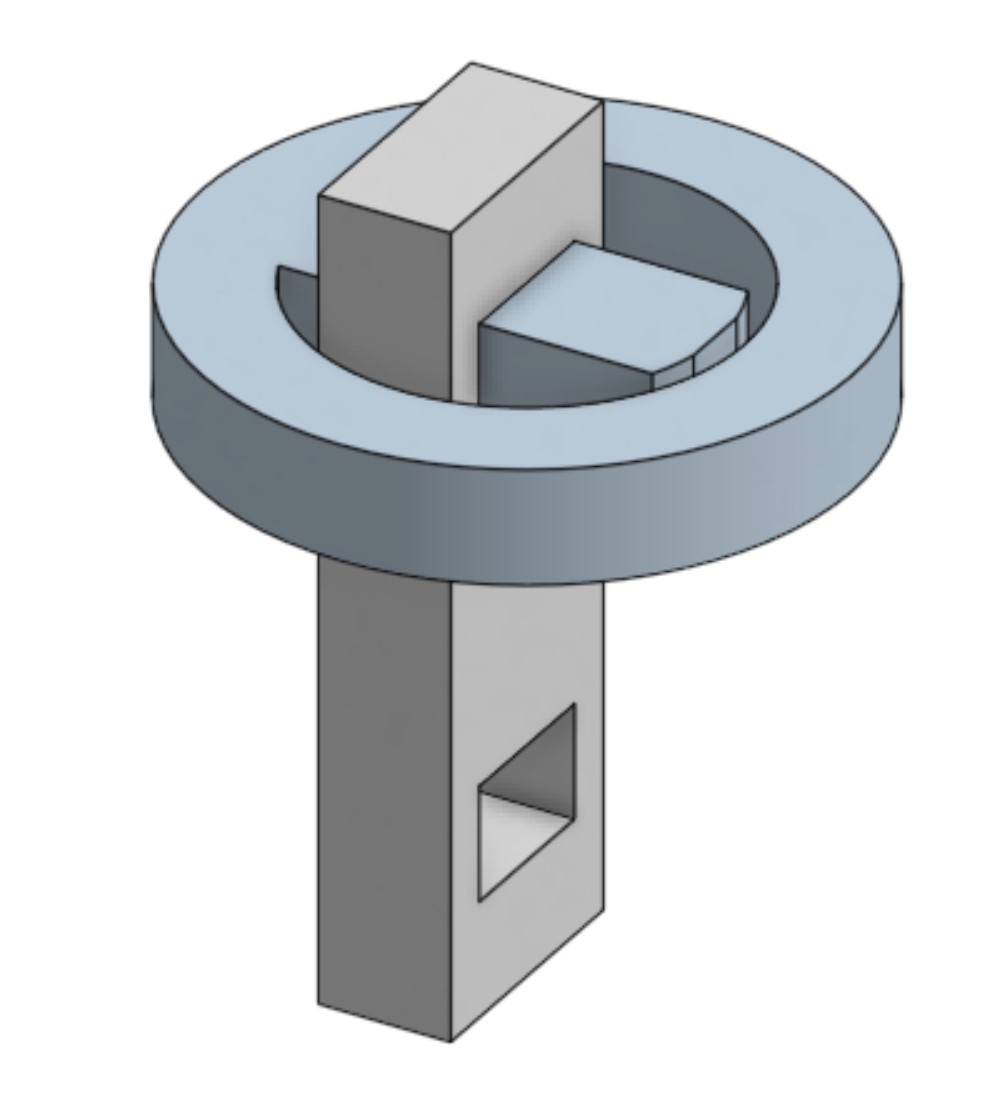

Now it was time to implement the tracks and flip flops. I needed a way to attach them to the board, so I designed a small peg.

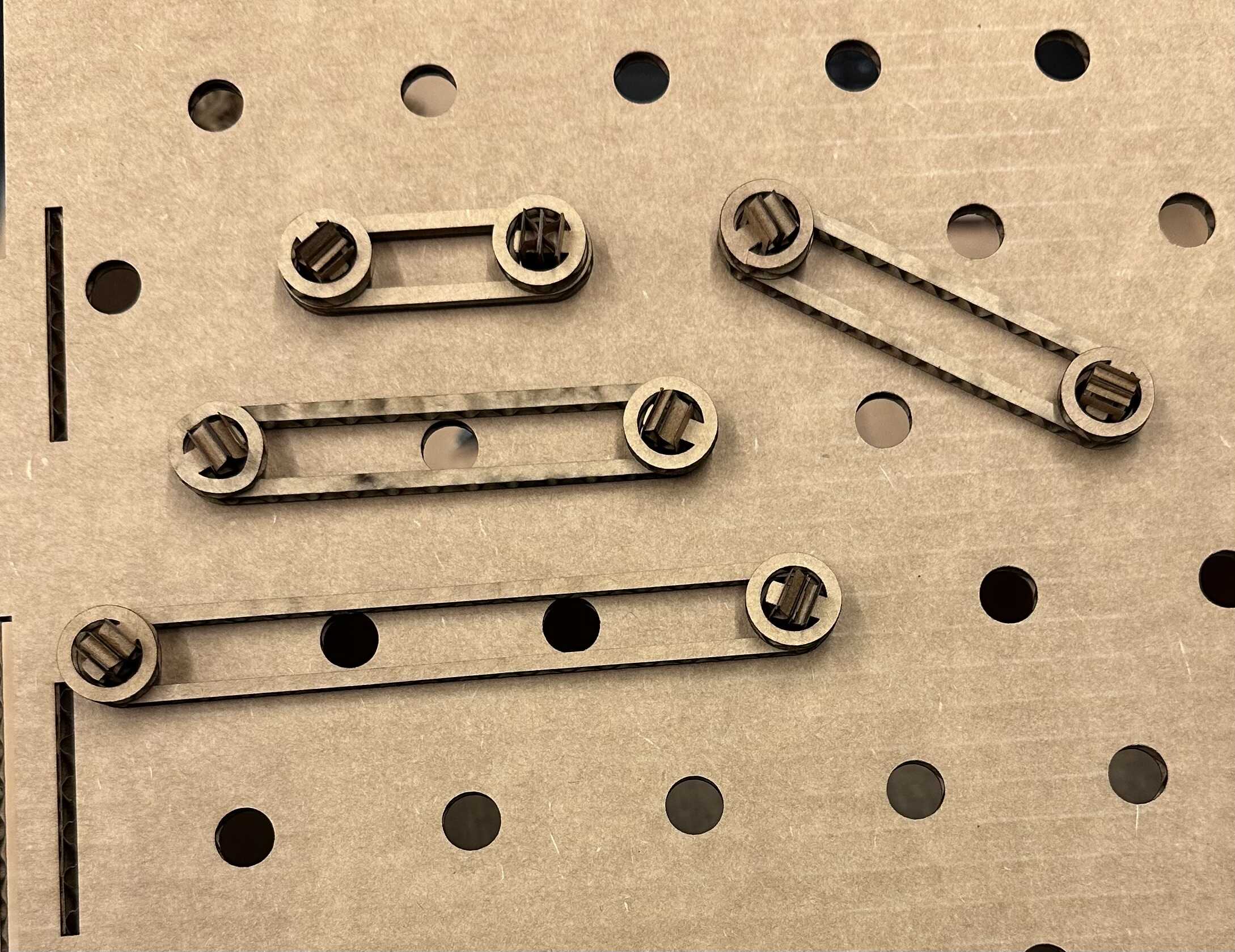

After this I designed some tracks and flip flops.

After this I designed some tracks and flip flops.

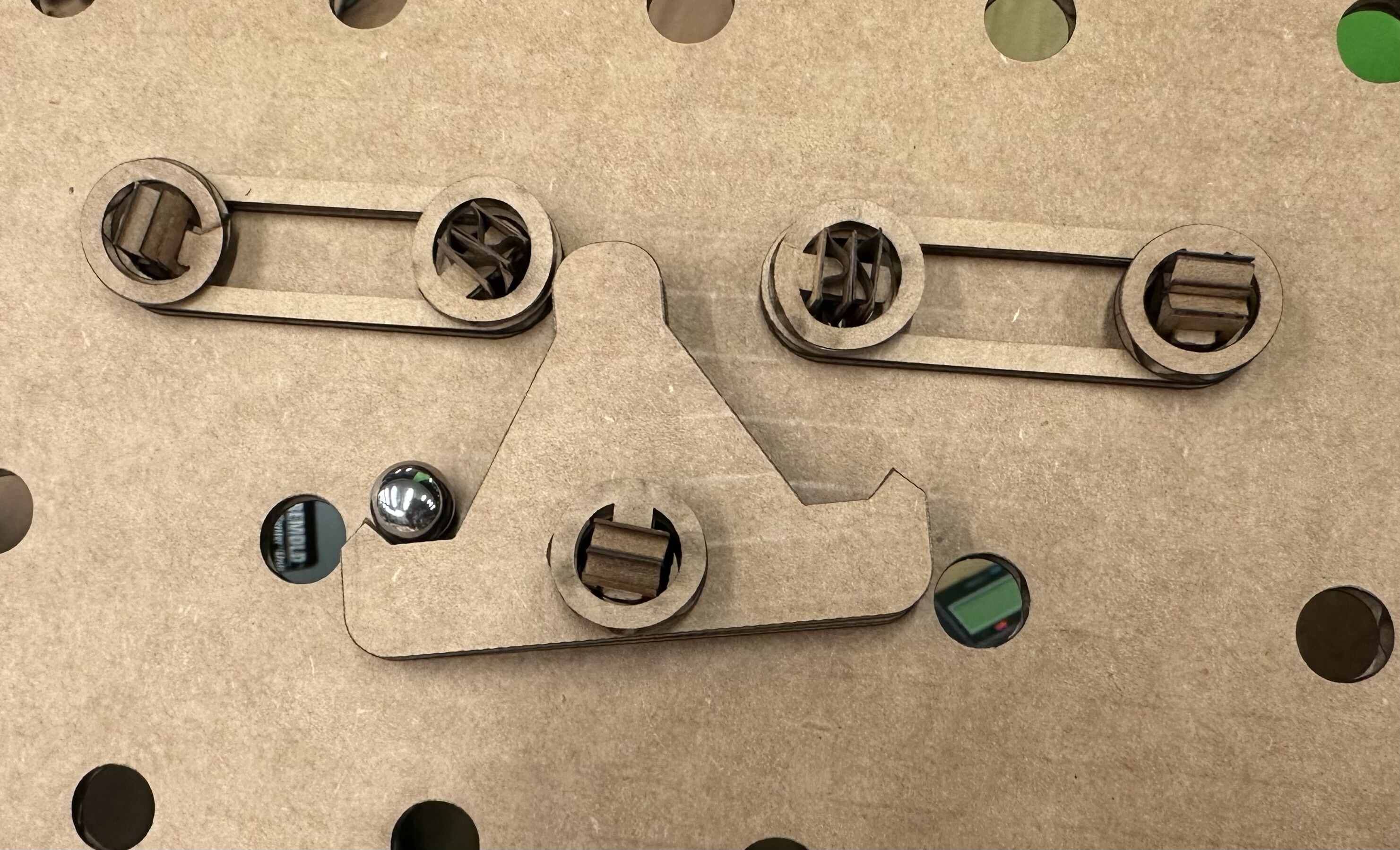

I had to redesign the flip flop over 6 times before I got a shape that worked. The ball kept getting stuck. I eventually got a design that worked.

I had to redesign the flip flop over 6 times before I got a shape that worked. The ball kept getting stuck. I eventually got a design that worked.

While I was at it I also designed a track that follows a quadratic bezier curve. I then assembled everything and was ready to test.

While I was at it I also designed a track that follows a quadratic bezier curve. I then assembled everything and was ready to test.

How satisfying. I ran out of time to program anything on the computer, but the idea is that you can represent a number in binary as the long string of registers in the video. I did have time to make this interesting looking track though.

Vinyl Cutter

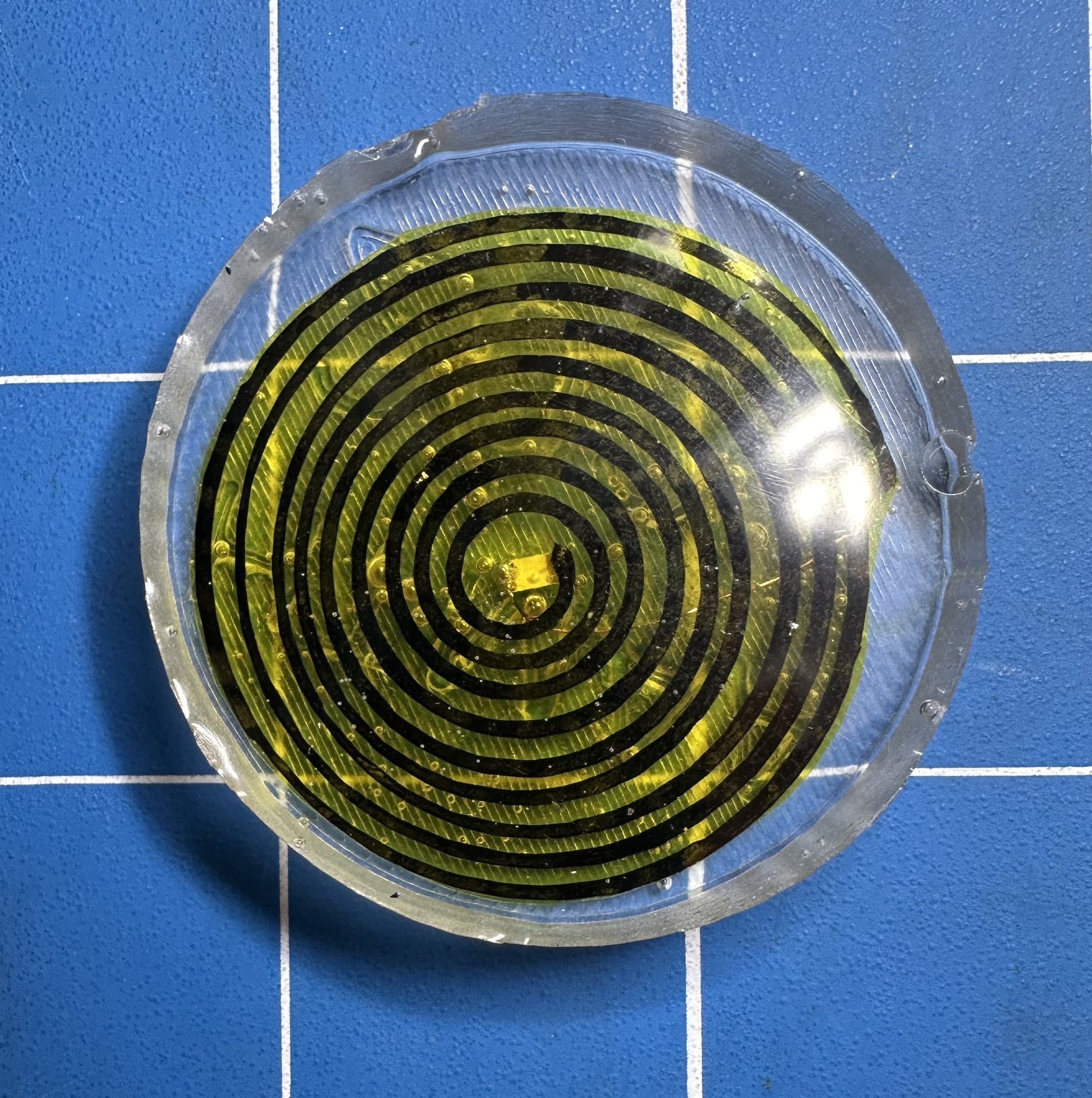

This week we also had to cut something on the vinyl cutter. I am very interested in transmitting wireless power, so I decided to cut out an antenna from copper tape. I used SVG-PCB to make a wire archimedean spiral. After processing the design in mods, I put some copper tape on top of a vinyl roll and let the machine do the work. I was very surprised that I got a clean cut on my first try! The weeding process wasn’t too bad with a pair of tweezers and a microscope.

I then transferred the antenna to some kapton and soldered a red LED in. I chose red because it should take the smallest voltage to light up.

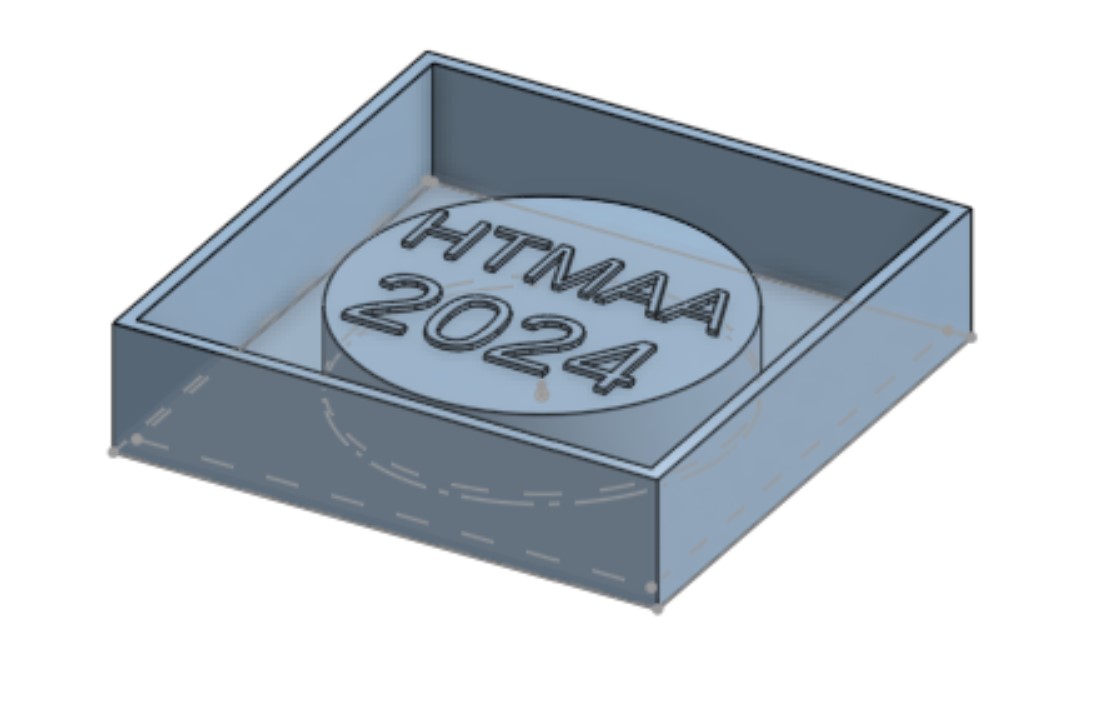

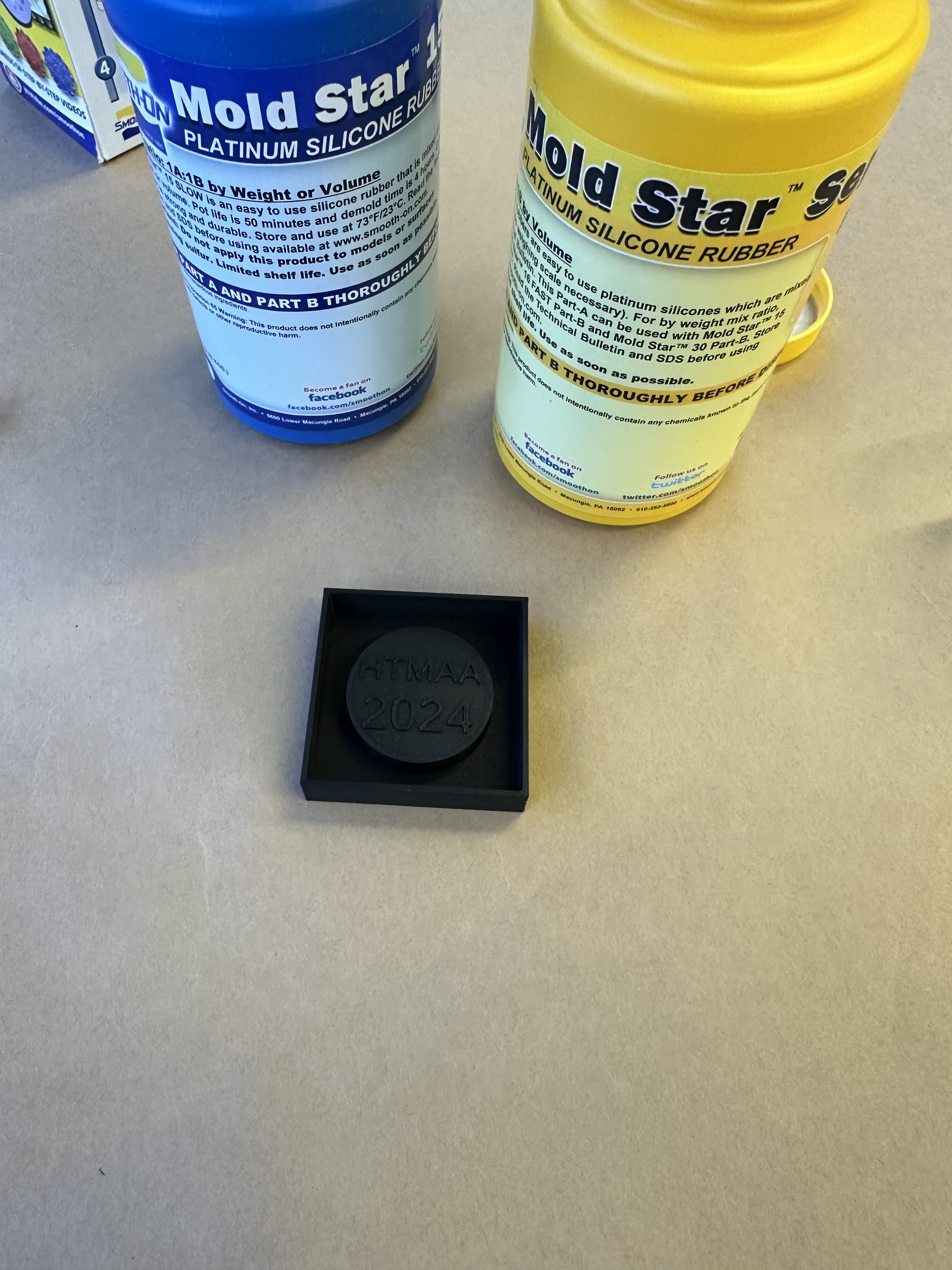

I wanted to protect this circuit by encasing it in resin, so I printed a small positive of a coin shape, used Oomoo to make a negative mold, and used some clear resin to encase the coin.

The top face of the coin was not as clear as I would have liked it to be, but this is a result of not post-processing the 3D print before creating the Oomoo mold.

While I was working on this project, Anthony told me about a HTMAA student a couple of years back, Olivia Seow, who made a project like this. She milled out a PCB with archimedean spiral antennas to light up some LEDs from NFC readers. I thought that this was really cool, and her spirals looked similar to mine. I decided to test my coin with the NFC readers we have around campus.

The LED even lights up from the NFC function on my phone. I think this is pretty neat! I now want to build a large set of Helmholtz coils that I use to make a large wireless power field.