Week 7 Molding and Casting

✅ group assignment:

review the safety data sheets for each of your molding and casting materials,

then make and compare test casts with each of them

compare mold making processes

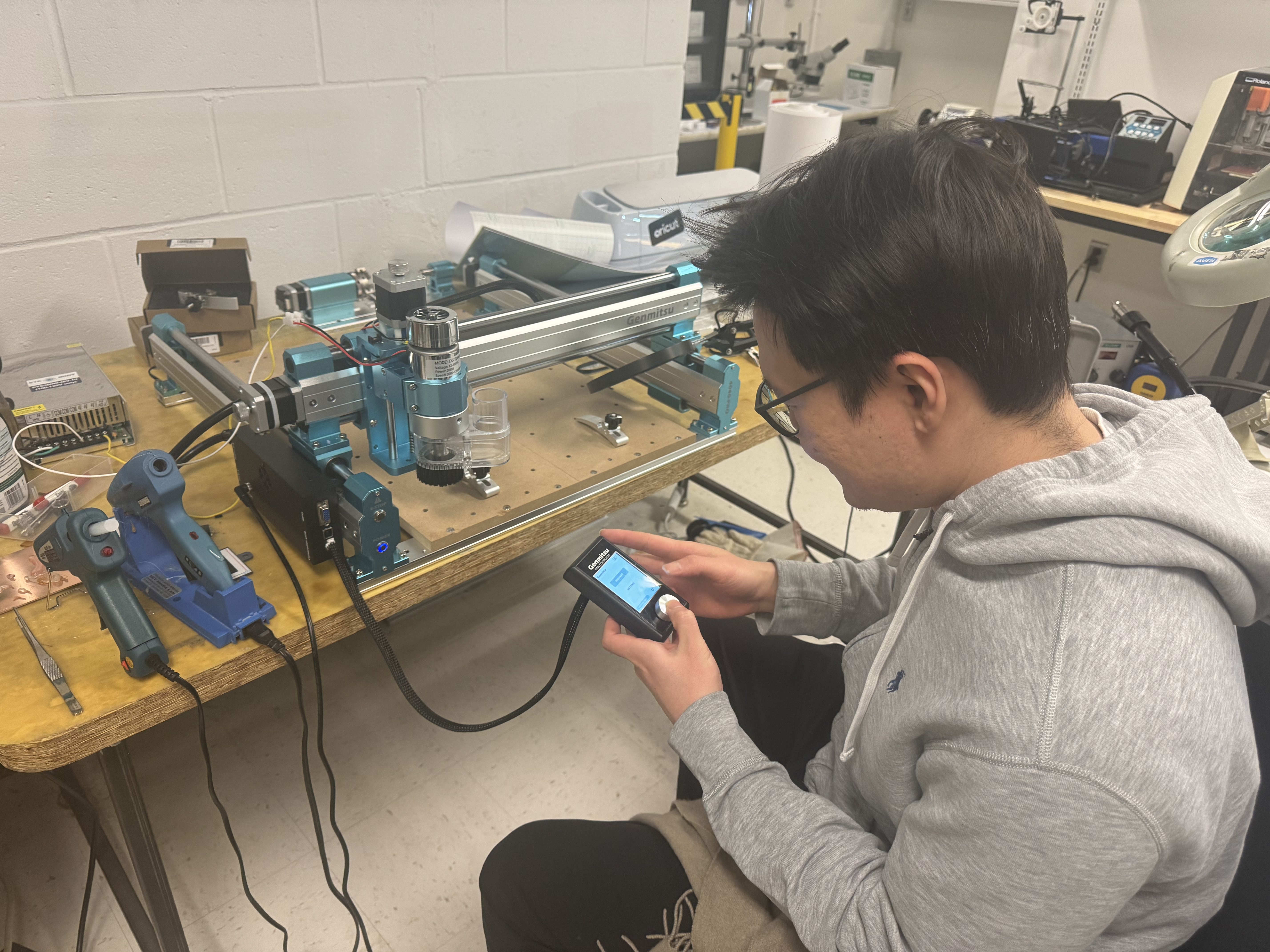

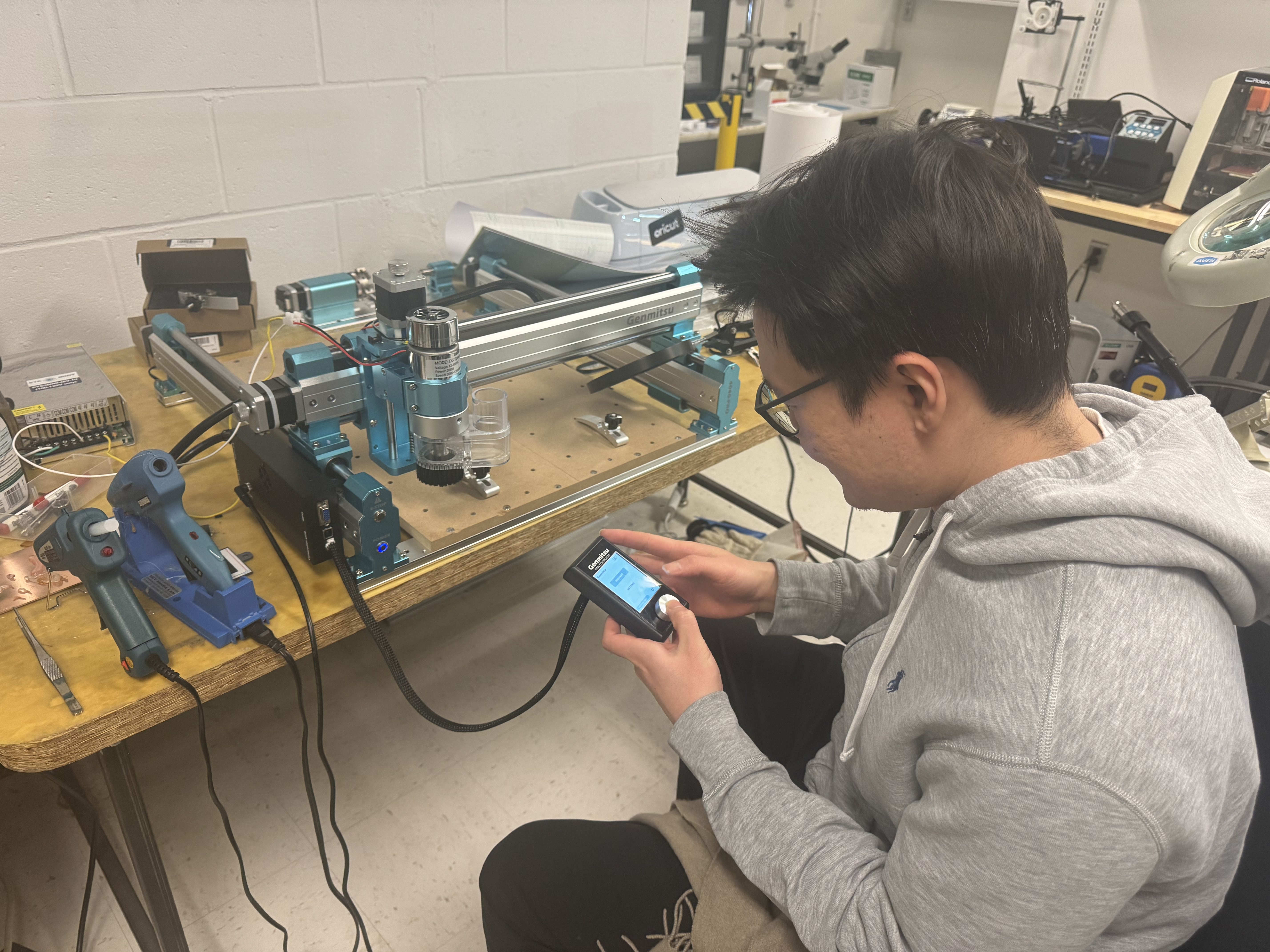

Marcello teaching wax machining and molding with OOMOO silicon