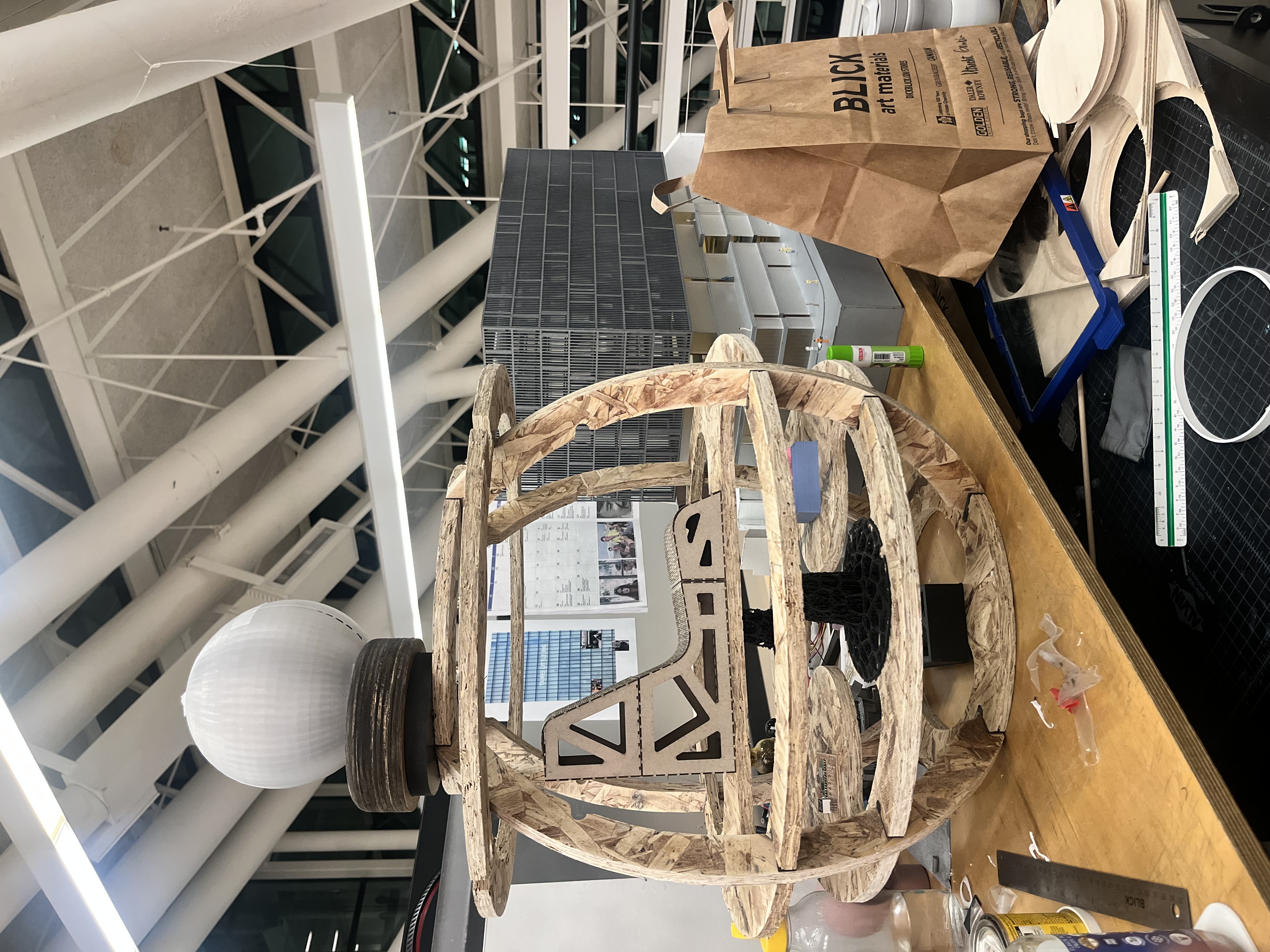

While I waited for orders to arrive, I began assembling the base. I CNC'ed plywood sheets into several ring sections and then laminated them together with wood glue. Once the glue set, I stained the base to give it the Walnut texture I was dying for.

I thought walnut would give the base a rustic feeling that would contrast the transluscent smoothness of the ball. It looks like I chopped a tree down! Such a natural effect to something machined.

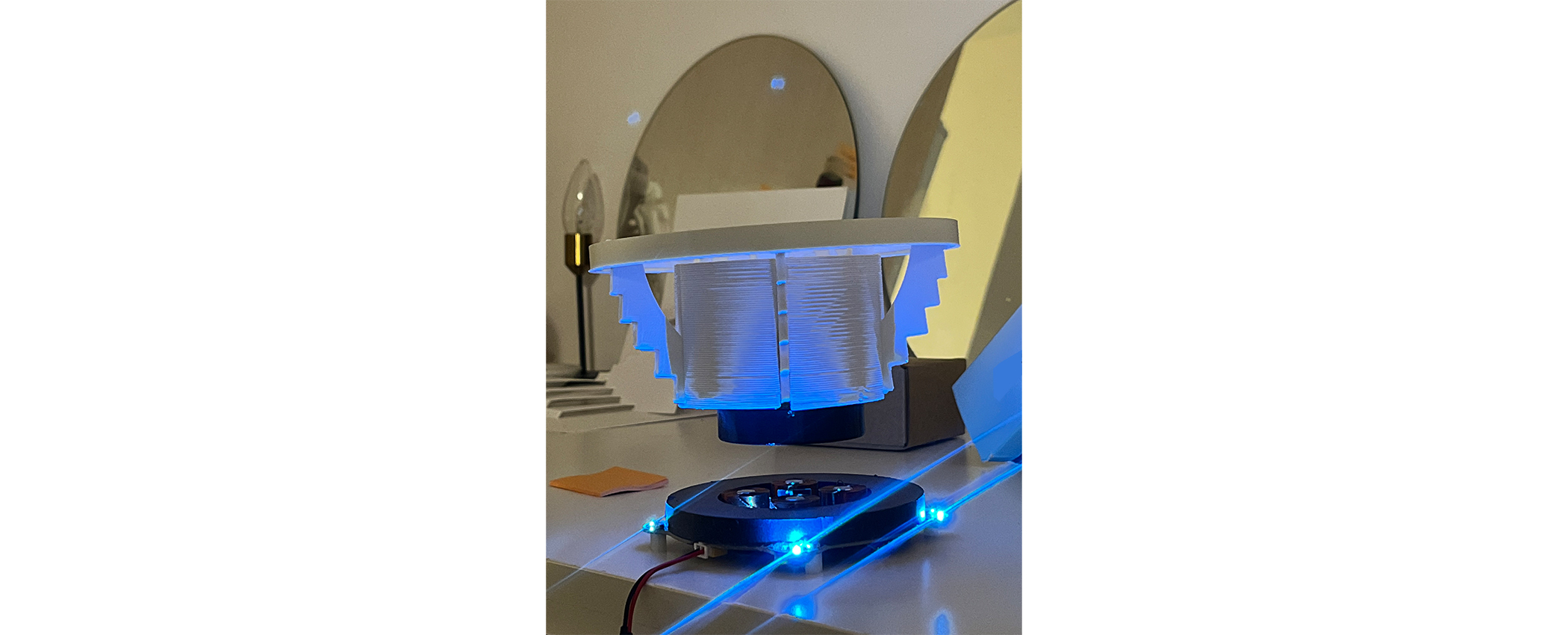

The MagLev platform is an analog system that I purchased parts for. I would have liked to reverse engineer the whole process, but I knew time was short with a lot still to do. I tested out the system with an older version of my Interior core prototype, and it floats!

The electromagnets are controlled by a potentiometer, and the ring magnet is strong enough to hold the sphere in place. The Hall effect sensors are sensitive enough to detect the sphere's position and adjust the electromagnets accordingly. You need to find the sweet spot in the center to keep it intact for the initial float.

As I began to fabricate the frame for the sphere, I tested out the verticals on the base:

Initially I thought I would have to incorporate a motor to the base to achieve the slight rotation that I sketched out earlier, but the physics of the magnetic field trying to gain stability actually causes the sphere to rotate by itself.

The more stable the sphere becomes, the less it rotates over time. A happy surprise! Go physics.

/TRACKING 12.14.24/ THE SPHERE

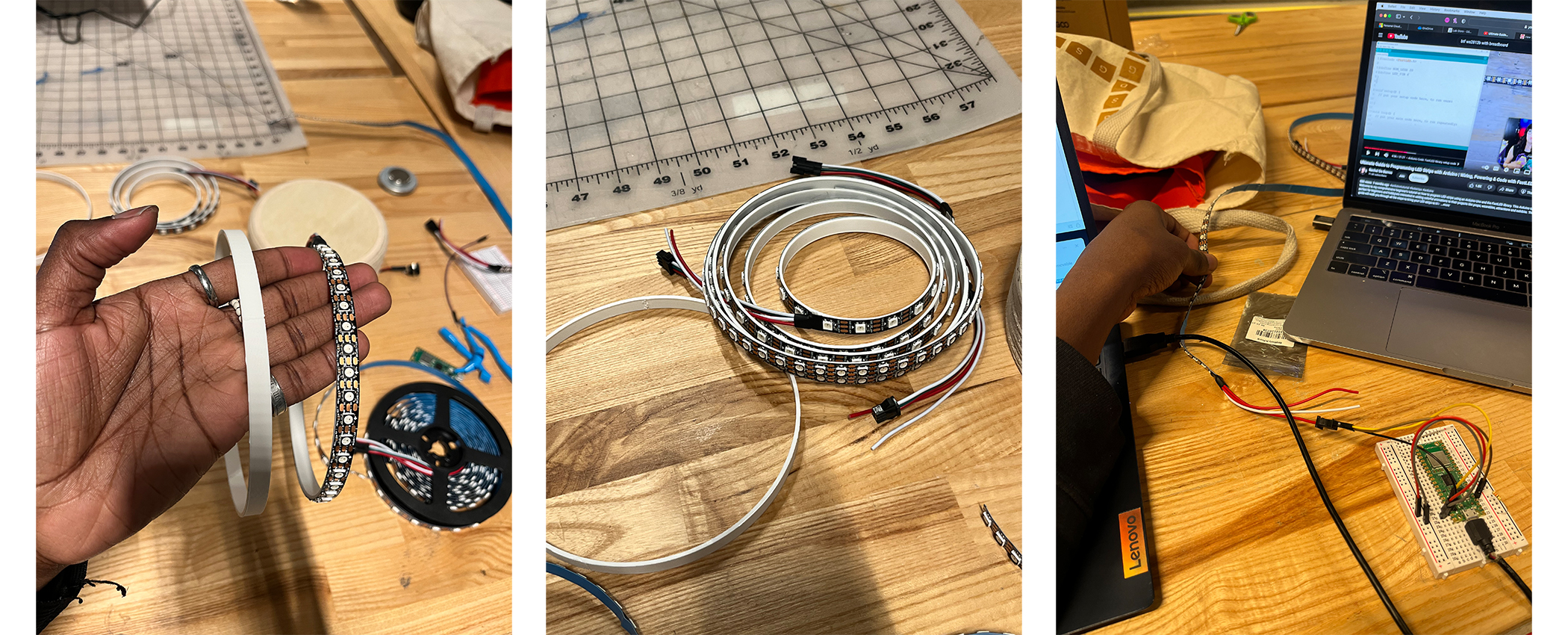

Eventually the LED Rings arrived, and I could start assembly on the sphere. I started prototyping with a Raspberry Pi Pico because initially i thought i would need a lot of pins because I had a lot of rings, but the logic of the led strips actually

meant I only needed one pin for data! Since the LEDs can all be wired together and strung to a common power line, as well as only needing one data connection once they were all connected, I eventually moved to the Xiao to keep the interior as compact as I can.

I then fabricated the Interior Core. Another power related thing i had to consider was how the LED's could be turned on with all the electronics locked away in the middle of the core. Luckily, the buck concerter has an On/Off switch, so i designed a switch mechanism at

the bottom of the core that could trip that switch from the exterior. This was fun to figure out.

/TRACKING 12.15.24/

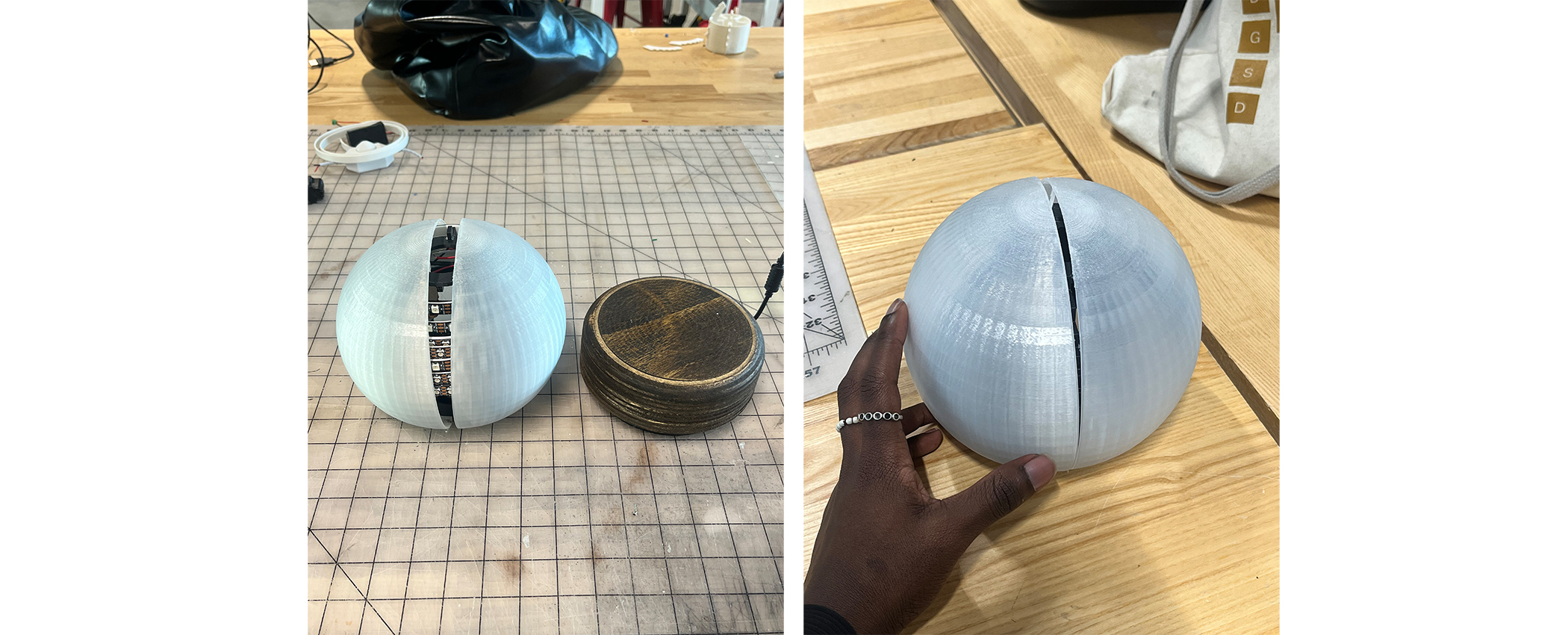

With the core ready, I could test the stability of the power system when floating, and the effect of the LED strip in space. I also printed the Outer Shell with a special PLA that i had to get clearance for. Shoutout to Joe Kyle!

/TRACKING 12.16.24/

Time for system integration. I had to drill holes in all the LED strips and wire and solder them all which took a bit of time, so I was losing confidence that I would be able to power the ball in time for review. Nevertheless, I marched on.

/TRACKING 12.17.24/

Ran out of Time. While all the functional elements of the project are present, and the product is acheiving the aesthetic qualities I was aiming for, it is not yet up to full functionality. But it will be. I feel inspired by this idea

and will bring it to full fruition next semester. Magic awaits.

Bonus: My little sphere, my big sphere housing my weekly projects, and my big building for my architecture studio at the GSD. It's been a rewarding challenge taking this class on alongside an Architecture studio, but I think i rose to the challenge and developed a body of work that i'm incredibly proud of.

I spent alot of time outside my comfort zone and honed in on my expertise. Here's to making more of anything.