The intention for this project was to design and lasercut a kit that could be assembled in multiple ways, without glue or fastener. When all else fails, an architect will make a chair.

STEP 1:

Rather than develop a system of interchangeable joints, I opted to make a modular chair whose secondary system could be reorganized. Less hassle, More fun.

STEP 2:

I modeled three interchangable modules with surfaces that clip together with a finger joint.

The plane of curved surfaces is given primary attention (extra credit = overachiever)

STEP 3:

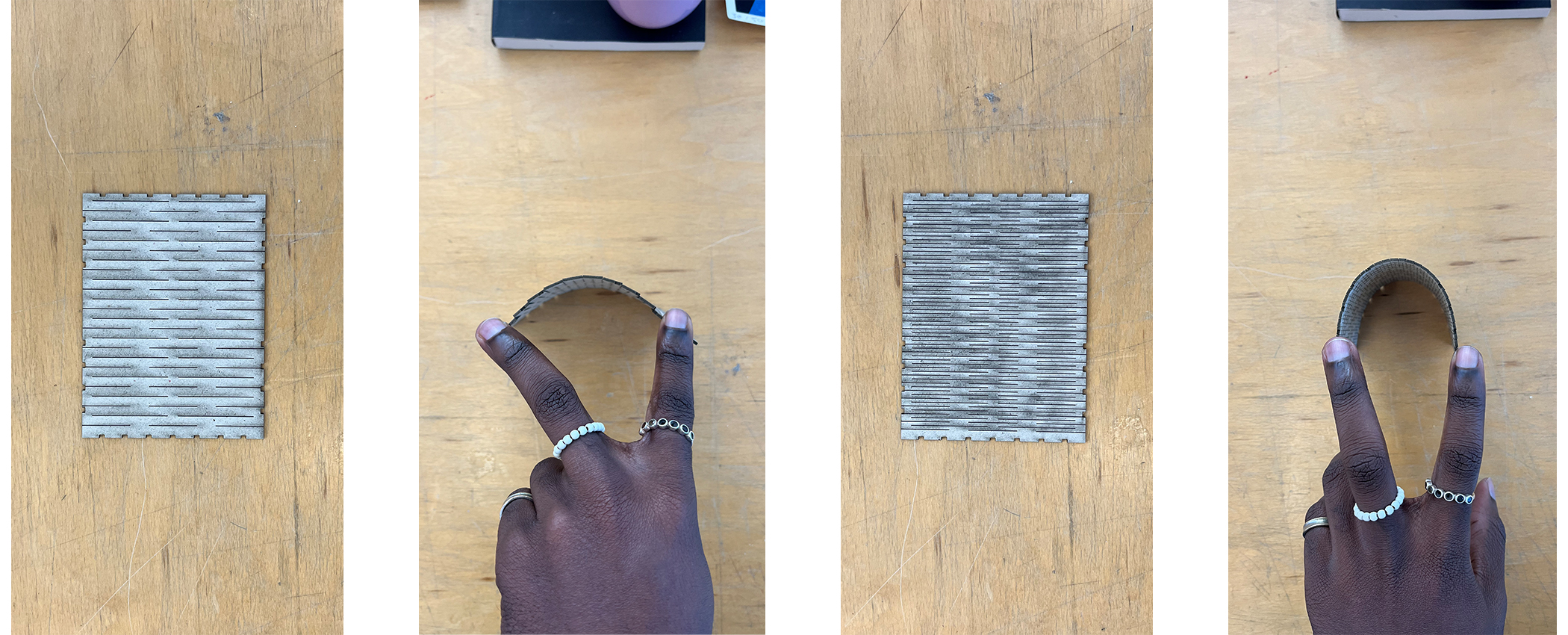

Once it was time to start fabricating, i had to do a couple of tests with the joints & curved surfaces to attune the tolerance

-

At an offset of 0.0075", the chipboard entered compression when clipped together, offering greater structural integrity as seen in the sharp angle of #2

-

I used a straight living hinge pattern that would be continuous along the entire curved surface. A spacing of 2.5mm vertically offered the desired elasticity (i know i suddenly switched to metric. i'm a dual citizen)

STEP 4:

When all had been said and calibrated, all that was left was the fun part

Assemble!

FINAL PRODUCT:

For the Vinyl Cut part of the week, I used the Zund at the GSD to make this pop up stair card. The Zund has changeable heads, and to make this i used a knife head to cut and score the Bristol.

STEP 1:

You first need to prepare a vector file to send your job toe the Zund. The machine at the GSD uses Illustrator files, so i prepared a file to signify where to cut through (magenta) and where to score (blue).

You'll notice that the cuts and scores are directional (cuts are vertical, scores are horizontal). This is what will give the card its pop-up effect.

STEP 2:

Send file to Zund!