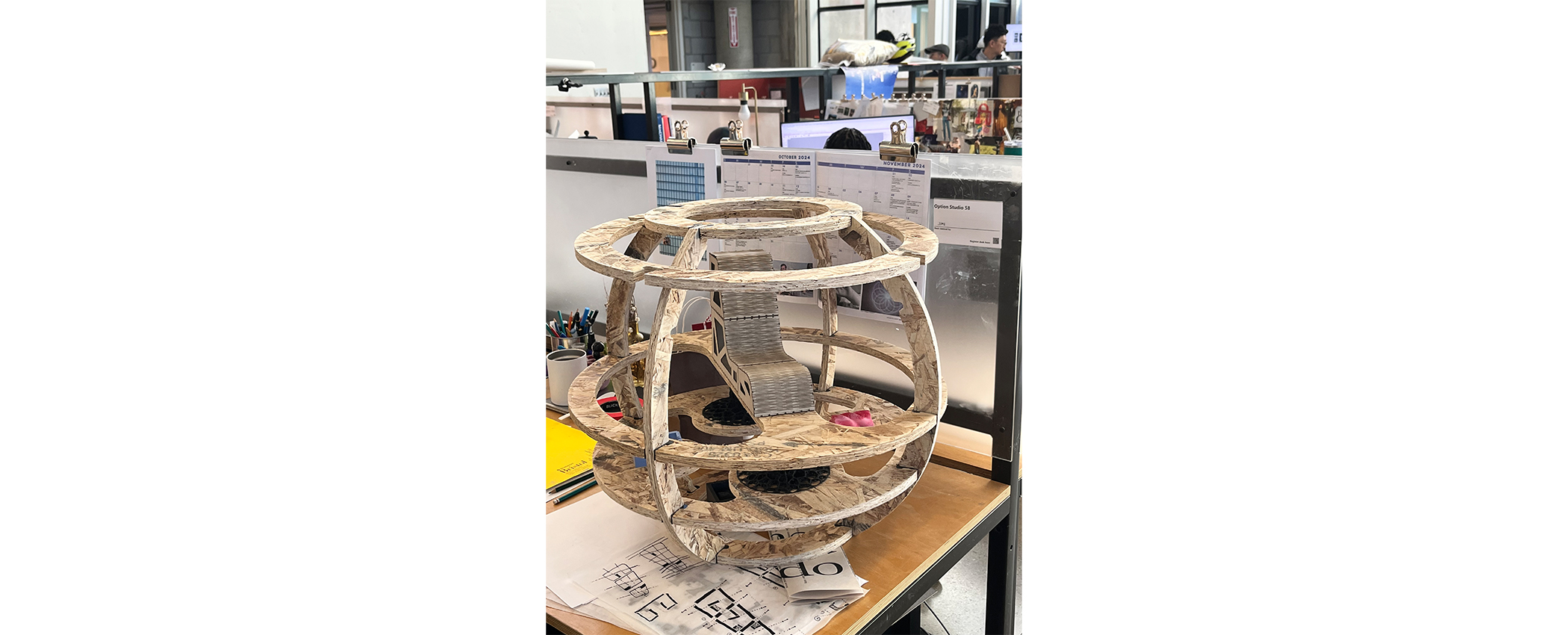

When we were calibrating the CNC to the stock, Joe had mentioned that my stock was a little thinner than the nominal 5/8". I had a feeling this would be a problem for the

press fit joints i had designed and i was right. The notches were now too big. I measured the gaps and modeled some fitouts that i printed. Hilariously, the time to print these

little guys was about 5-6 times that of the CNC job. 8 hours! I could have cut 6 more big spheres in that time, but I stuck with them because i thought they'd make a really nice

joint detail.

The pieces came together by simply cranking each vertical in between the PLA fitouts. Friction does the rest. No glue or screws needed. The order you assmble the disks is important here,

so i started with the largest center disk and assembled towards the outer smaller ones. If i had done vice versa, i would have made it impossible to fit the larger discs as the sphere becomes defined.

While assembling, i decided to omit one of the disks where my modular chair would be, since it would prevent you from reaching in and toying with the model. I keep it on top like a halo.

Big Sphere is alive and well! And the crossover episode is complete!