For make something big week, I decided to make a small table! Originally, the plan was to make a stool and a small table for an art setup, but making the stool took extremely long, and it ended up being too tall so it became a table in the end.

I looked for stool inspiration online and ended up finding this modified Z-frame, which I thought was really cool! I decided to make a stool by cutting a few of this hourglass-like profile, then creating some panels to lay on the top and bottom to connect the profiles.

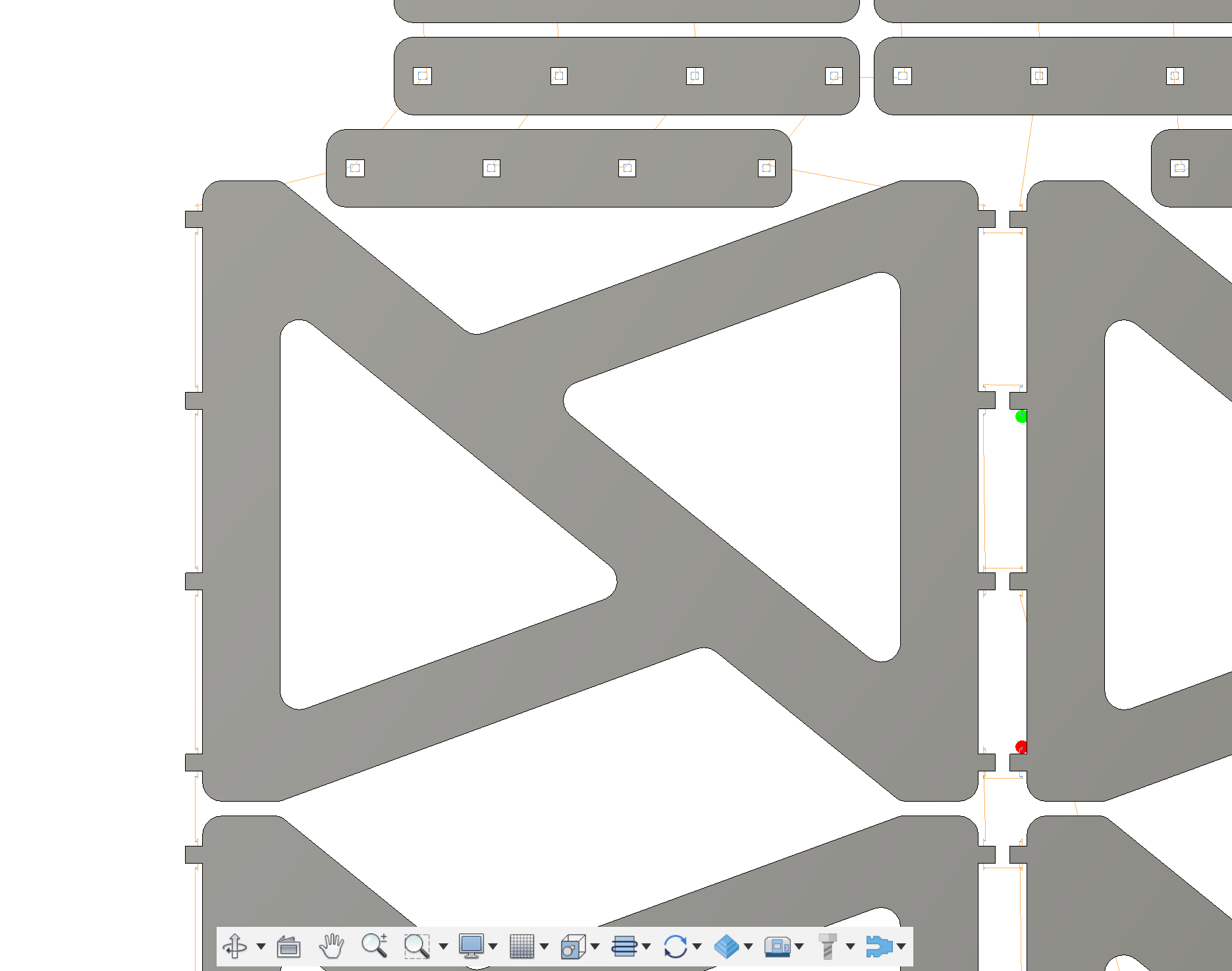

I created a simple CAD model of the profile, making the stool 16x12x20in based on some dimensions I found online (in hindsight, I really should've checked with a tape measure when I got into lab since I made all the dimensions parametric anyways). The panels I created were a simple 2in x 12in, with rounded corners.

When I got to lab, Anthony let me know that I wouldn't be able to drive screws into the side of OSB, so I begrudgingly added press-fit joints to my design. I did make the mistake of not giving myself any clearance, so there was a lot of filing and sanding post cutting...

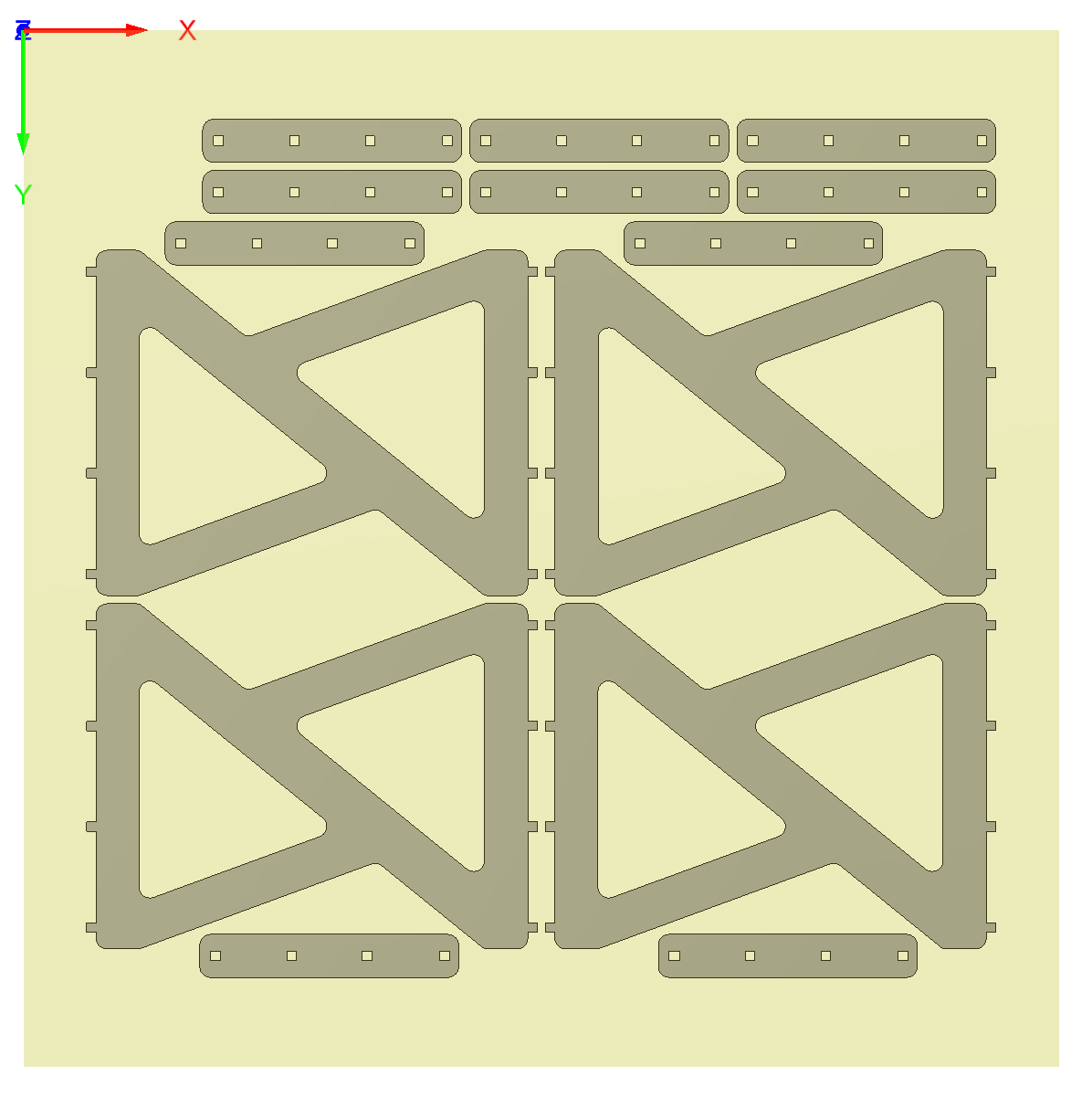

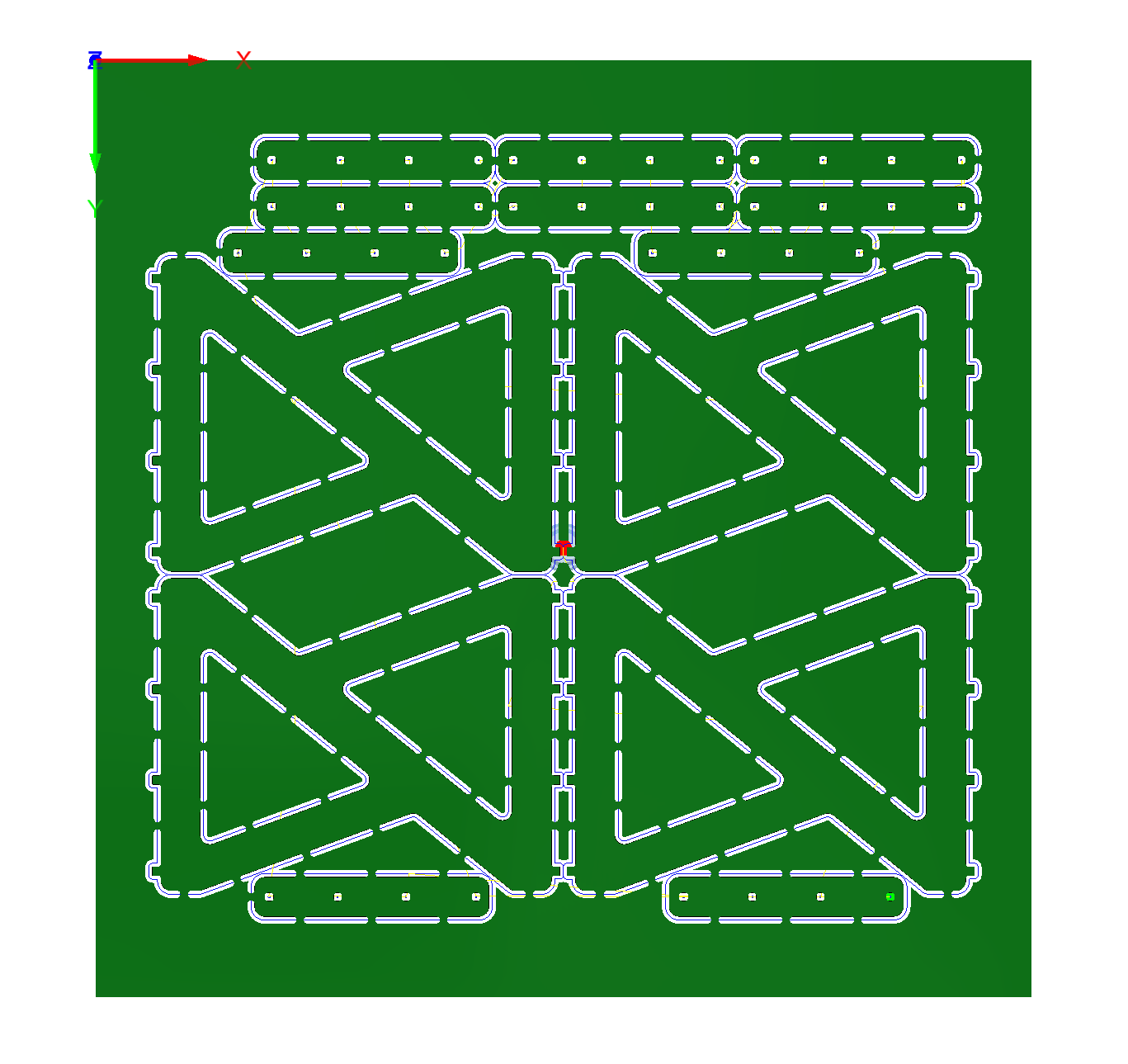

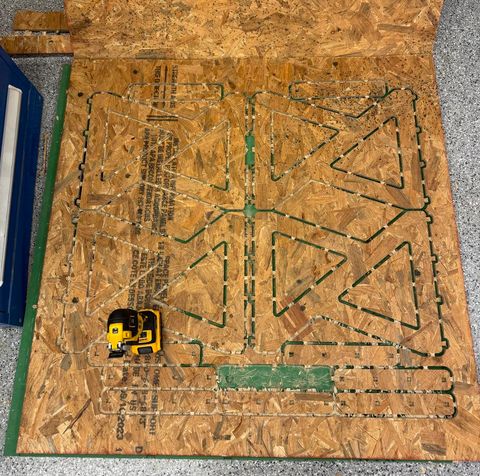

Anthony then helped me set up my CAM in Fusion, where we used a 3/8 flat endmill to clear away material and a 1/4 flat endmill to dogbone our joints. After nailing the OSB to the machine bed with plastic nails and exporting our design to G-code, we were ready to go! I don't have any photos of the milling process, but it all went smoothly, although a bit loudly.

Here is the milled board, before I cut the tabs of the pieces with the oscillating saw. The depth of the milling actually didn't make it through parts of the board (likely the board was still a bit bent because the CNC bed needed re-milling), so I had a lot of sanding and filing to do after.

Here are some progress pics of the finishing process...

And here are some pictures of the final stool-turned-table! It does hold my weight, thought it rocks back and forth in one direction. It was quite a lot of physical effort to sand it down, so I learned my lesson in designing joints and also double checking dimensions, but overall I am very satisfied that I was able to design and build something with my hands!