HTMAA 2024 - Jonathan Cohen

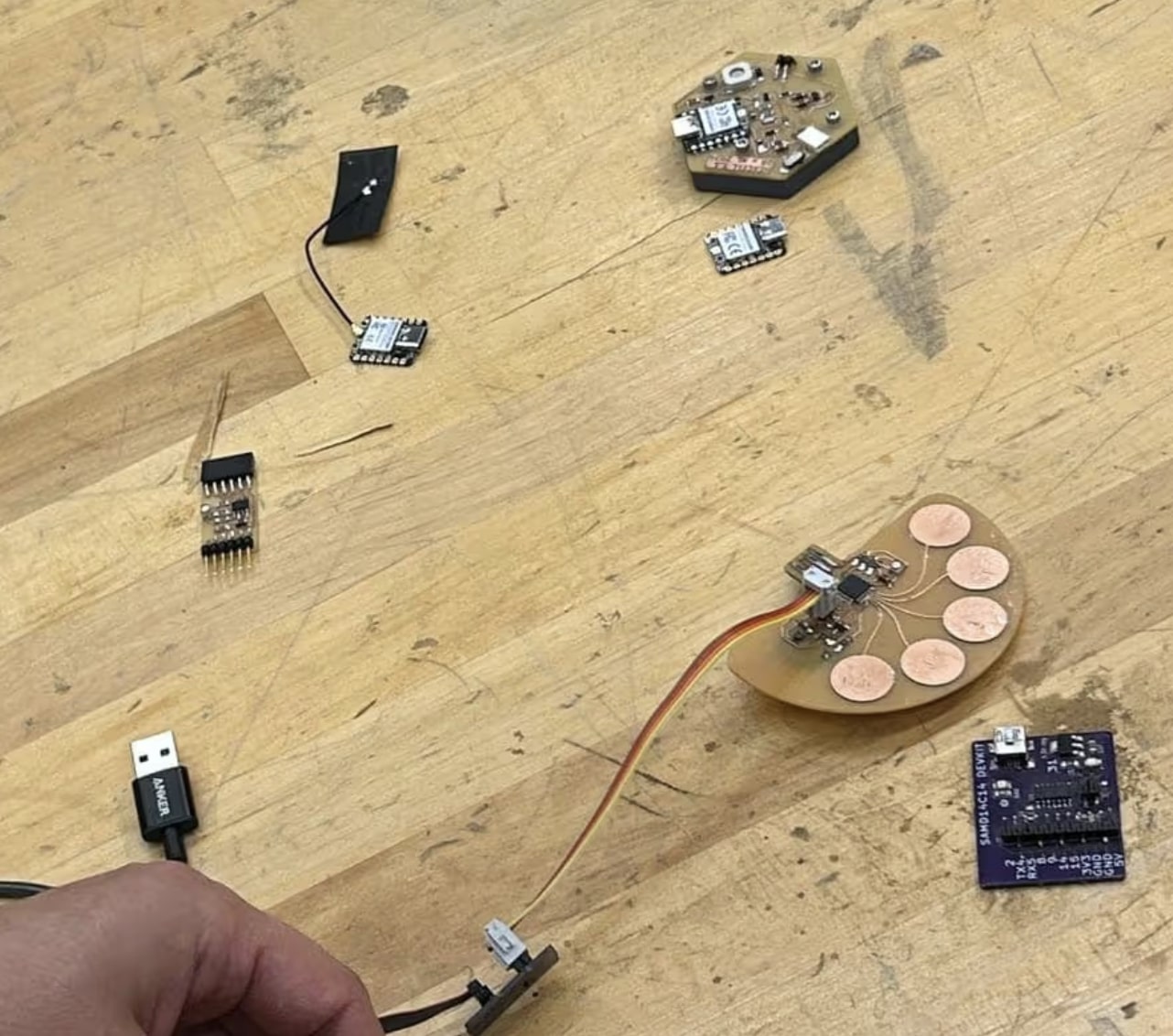

For the group assignment Quentin led the discussion into various chip architectures (see below), peripherals, adding board support to arduino ide, programming interfaces, debuggers, and how to burn a bootloader.

MCUs Discussed

We discussed the pros and cons of various board and why we would select a specific board for a design. We learned what programming a board looks like and how boards with a usb interface don't need a seperate programmer (i.e. esp32) but simple boards (think: ATtiny etc) need a programmer to be flashed with a JTAG (4 pins) or SWD (2 pins) interface. Some of the devices have amazing built in peripherals like the ESP32 that has wifi inside. Complex micro controllers like the ESP32 expose a subset of their pins in each package and vary across the product line. We also learned about the pinout of a USB A connector (Vbus, D-, D+, GND) and I also learned that USB uses a differential signal. At the end of the session we interacted with the esp32 board with MicroPython over usb.

(image credit: Kye Shimizu)

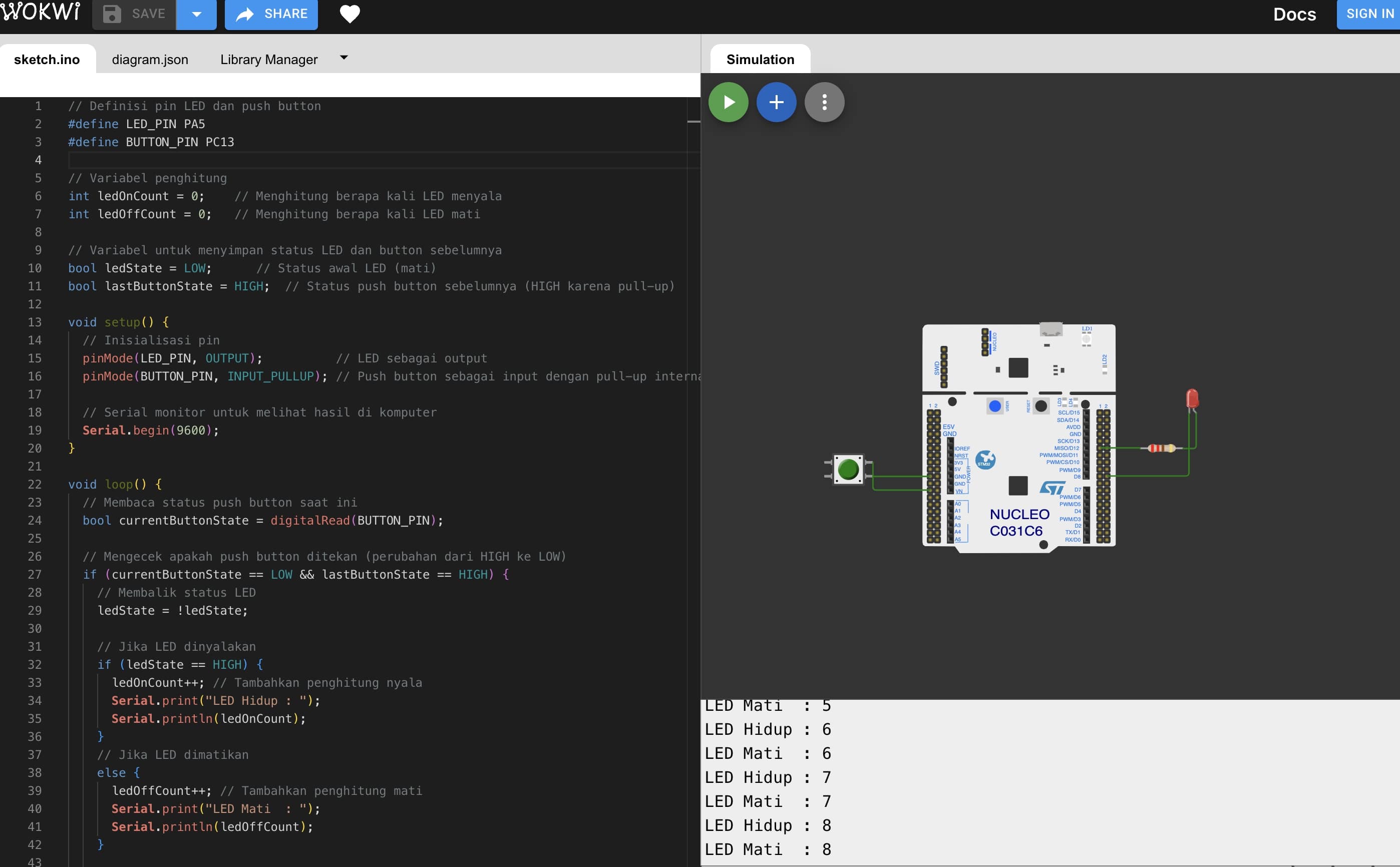

I will be using Wokwi.com to test out embedded programming on embedded devices.

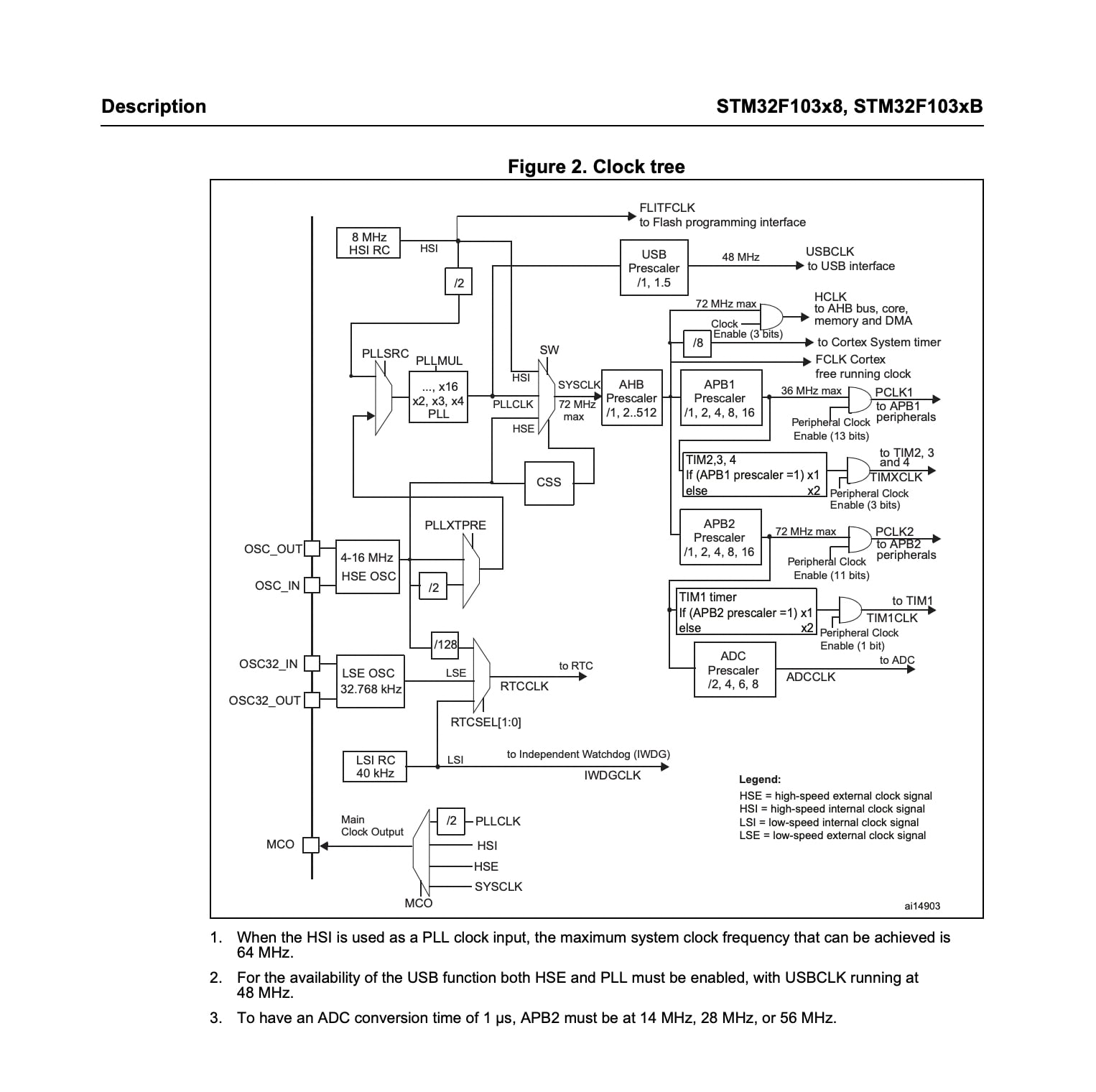

I went through a data sheet! Look at these nice clocks :) I selected the stm32 since I have to use it a bunch in another robotics course using the nucleo family that I am also taking and want to get really good at programming them.

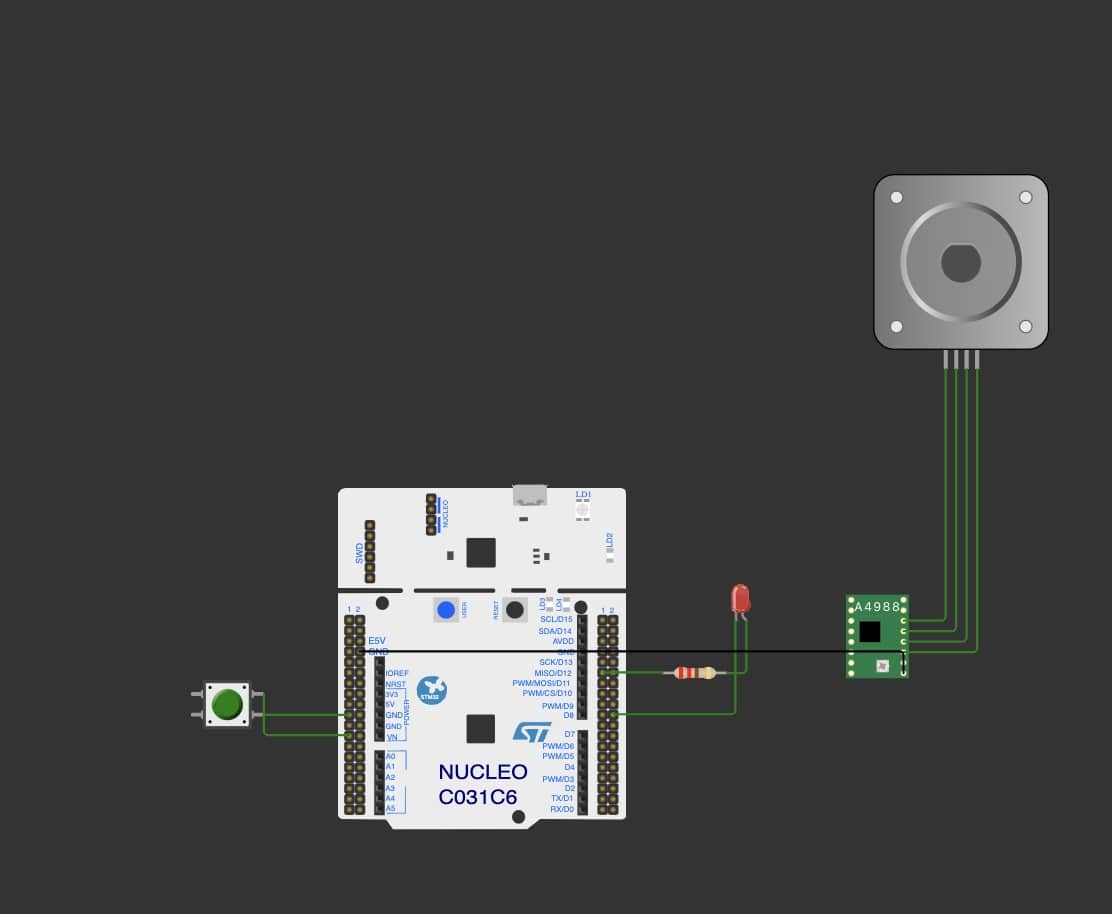

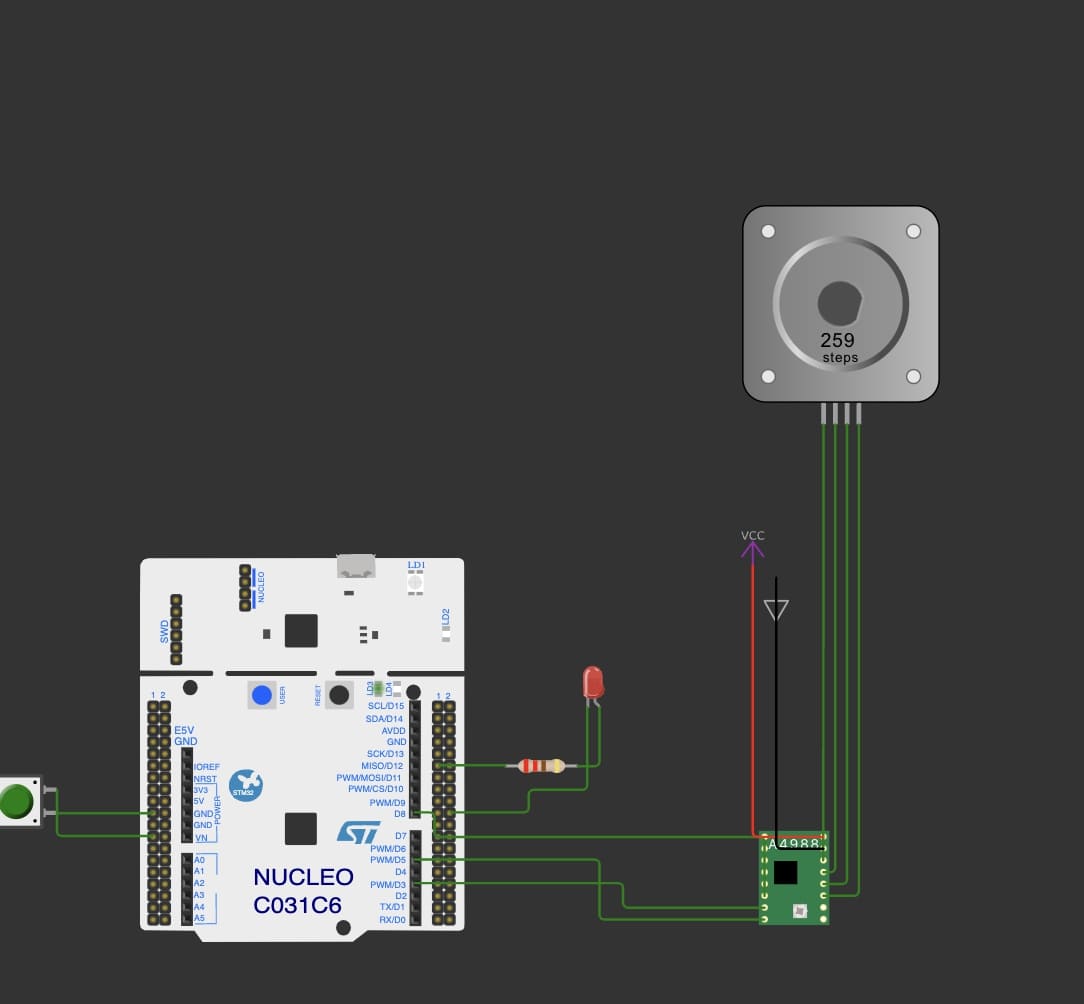

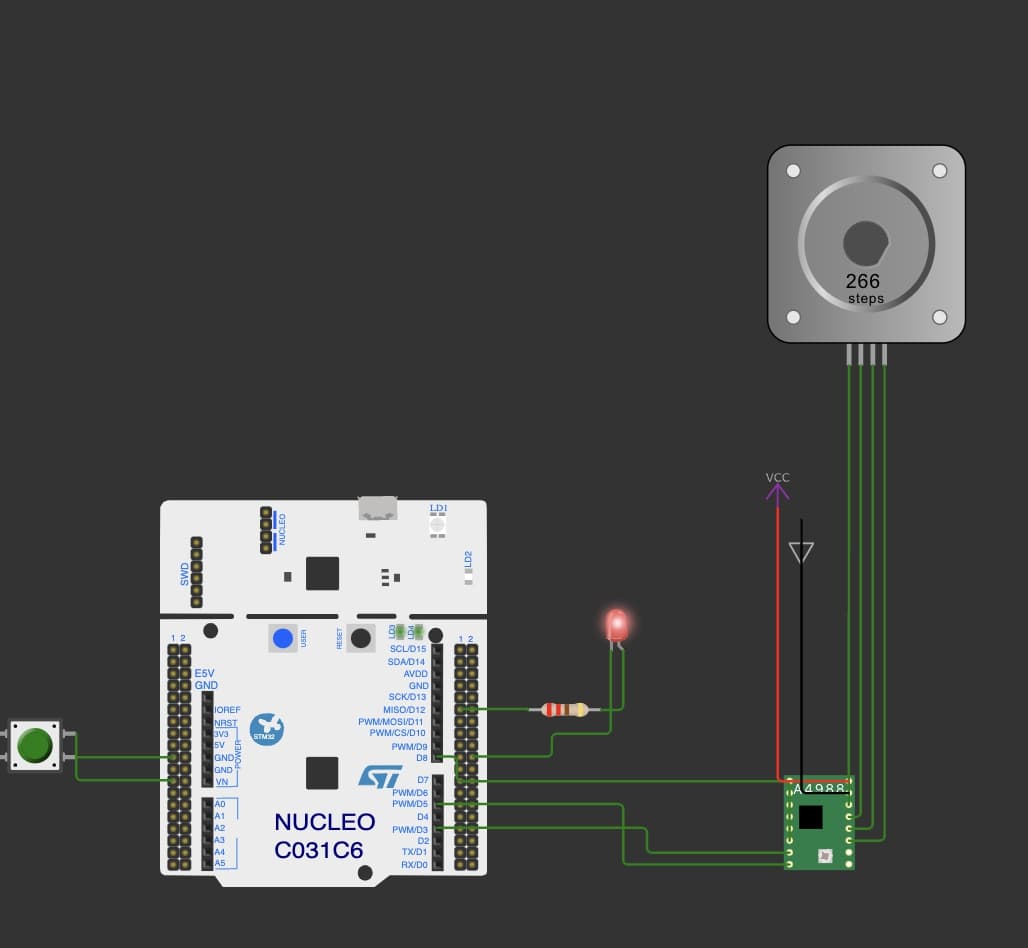

I am going to start with an example with a button and an LED but we will add a stepper motor that will step forward when the button is pressed.

Got the wiring all set up and now it is time to code this!

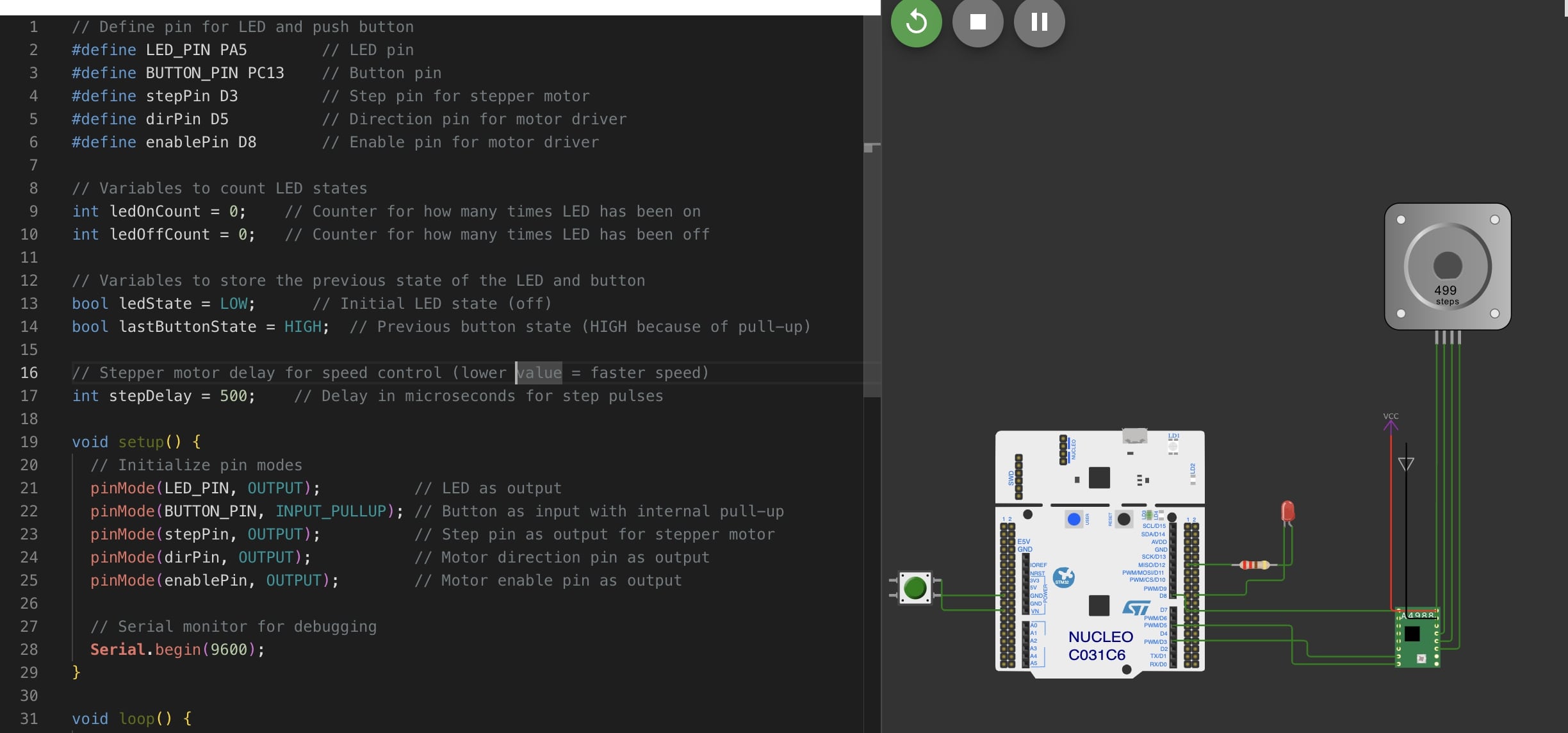

// HWTMAA WEEK 3 EMBEDDED PROGRAMMING

// Started with LED + button demo on Wokwi

// Define pin for LED and push button

#define LED_PIN PA5 // LED pin

#define BUTTON_PIN PC13 // Button pin

#define stepPin D3 // Step pin for stepper motor

#define dirPin D5 // Direction pin for motor driver

#define enablePin D8 // Enable pin for motor driver

// Variables to count LED states

int ledOnCount = 0; // Counter for how many times LED has been on

int ledOffCount = 0; // Counter for how many times LED has been off

// Variables to store the previous state of the LED and button

bool ledState = LOW; // Initial LED state (off)

bool lastButtonState = HIGH; // Previous button state (HIGH because of pull-up)

// Stepper motor delay for speed control

int stepDelay = 500; // Delay in microseconds for step pulses

void setup() {

// Initialize pin modes

pinMode(LED_PIN, OUTPUT); // LED as output

pinMode(BUTTON_PIN, INPUT_PULLUP); // Button as input with internal pull-up

pinMode(stepPin, OUTPUT); // Step pin as output for stepper motor

pinMode(dirPin, OUTPUT); // Motor direction pin as output

pinMode(enablePin, OUTPUT); // Motor enable pin as output

// Serial monitor for debugging

Serial.begin(9600);

}

void loop() {

// Read the current button state

bool currentButtonState = digitalRead(BUTTON_PIN);

// Check if the button was pressed (transition from HIGH to LOW)

if (currentButtonState == LOW && lastButtonState == HIGH) {

// Toggle the LED state

ledState = !ledState;

// If the LED is turned on

if (ledState == HIGH) {

ledOnCount++; // Increment LED on counter

digitalWrite(dirPin, HIGH); // Set motor direction

digitalWrite(enablePin, HIGH); // Enable motor driver

Serial.print("LED and Motor ON Count: ");

Serial.println(ledOnCount);

// Generate steps manually with delays

for (int i = 0; i < 10; i++) { // Run for 1000 steps (or adjust as needed)

digitalWrite(stepPin, HIGH); // Set step pin HIGH

delayMicroseconds(stepDelay); // Wait for step delay

digitalWrite(stepPin, LOW); // Set step pin LOW

delayMicroseconds(stepDelay); // Wait for step delay

}

}

// If the LED is turned off

else {

ledOffCount++; // Increment LED off counter

digitalWrite(enablePin, LOW); // Disable motor driver

Serial.print("LED and Motor OFF Count: ");

Serial.println(ledOffCount);

}

// Set the LED according to its state

digitalWrite(LED_PIN, ledState);

}

// Save the button state for the next loop cycle

lastButtonState = currentButtonState;

// Delay for button debounce (to avoid reading multiple presses quickly)

delay(50);

}

When you press the button the motor steps forward! Yay! The failure here is that I first tried to PWM the step input pin on the motor driver but I could not get it to work. I wonder if I was using the wrong frequency that was far too fast and just read it as HIGH the entire time. Instead we are just using a 500 microsec delay between high and low.

Wowi is cool and easy to use but it has limitations. You can move fast but when it comes to debugging it is less intuitive than having real boards in front of you. I can imagine that wowi is very nice for documentation and also helpful for brainstorming but when it comes to debugging, its quite cumbersome.