HTMAA 2024 - Jonathan Cohen

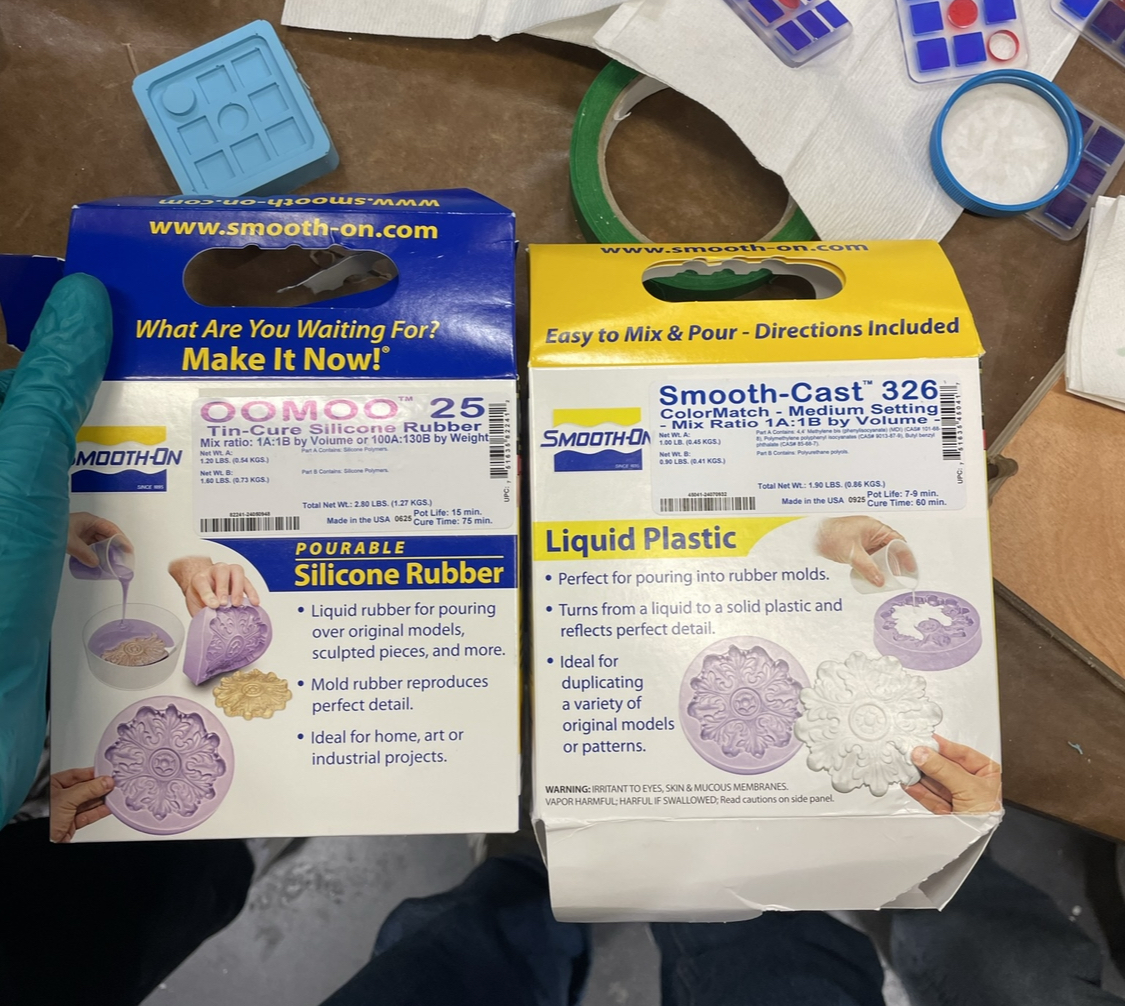

Since CBA is short staffed we focused on milling and SLA processes for creating the mold for the silicone mold. We learned about the safety hazards of the mold process. For the Silicone mold wear gloves and for the 2 part plastic we should work under ventilation with gloves. It is quite toxic so be very careful when handling. (Smooth-On SDS) and (Smooth-Cast SDS).

Pot life = Time before you need to pour and Cure time = time before part is ready to use.

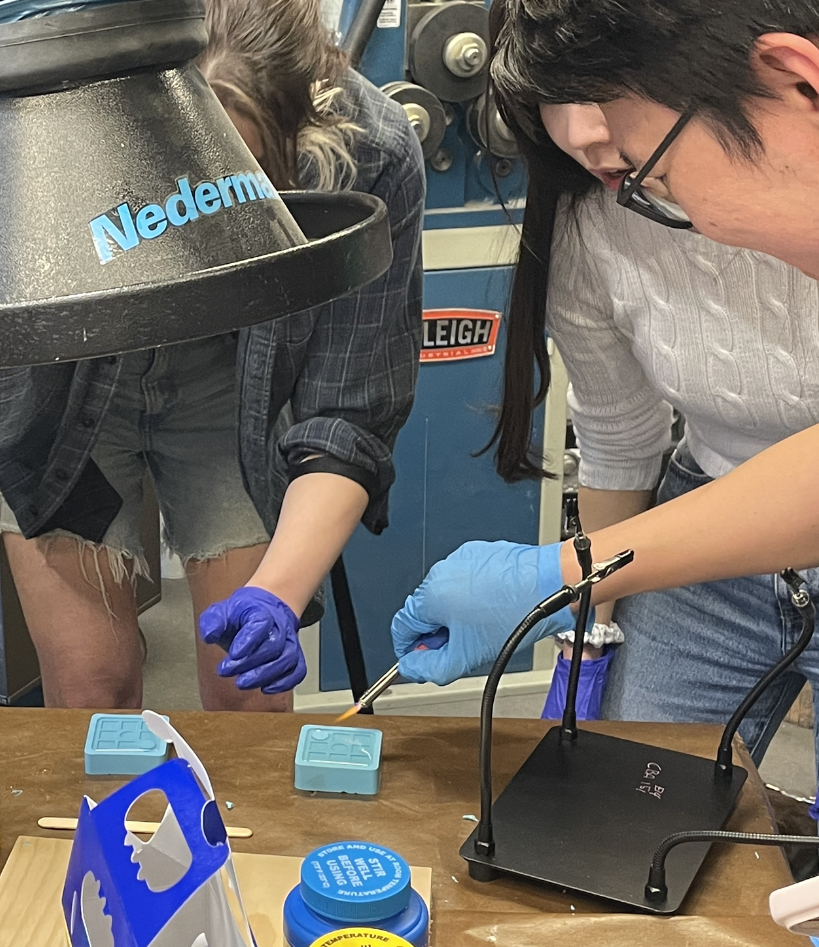

We made some CBA keychains and got a lot of tips from Marcello

I did originally design a cup with a lil hole for air assisted release of the part/mold but then I decided I needed to make something a bit cooler.

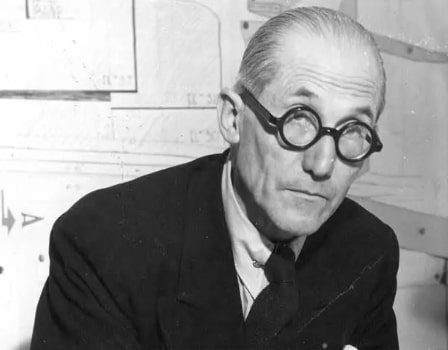

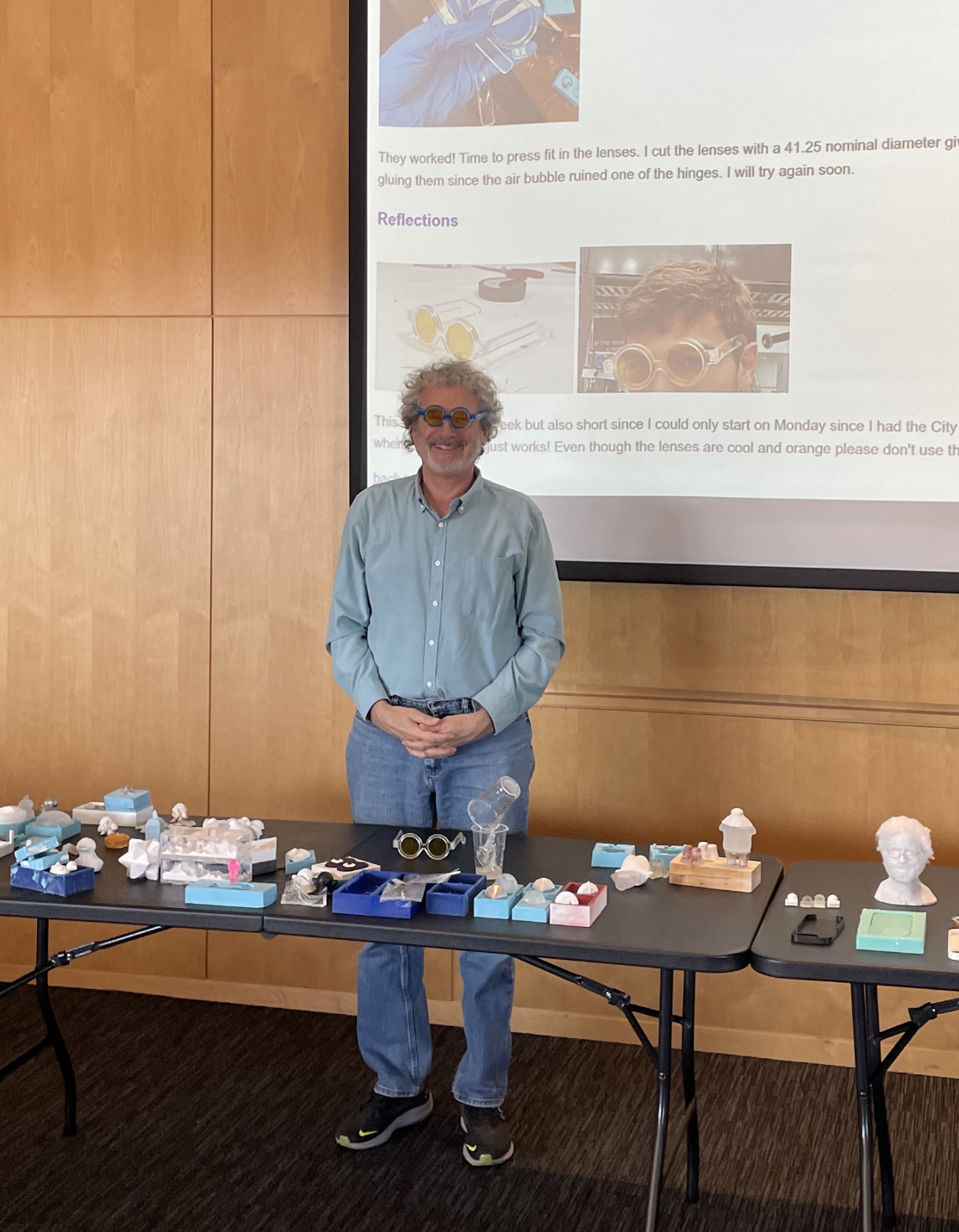

Drawing inspo from some architects and minions

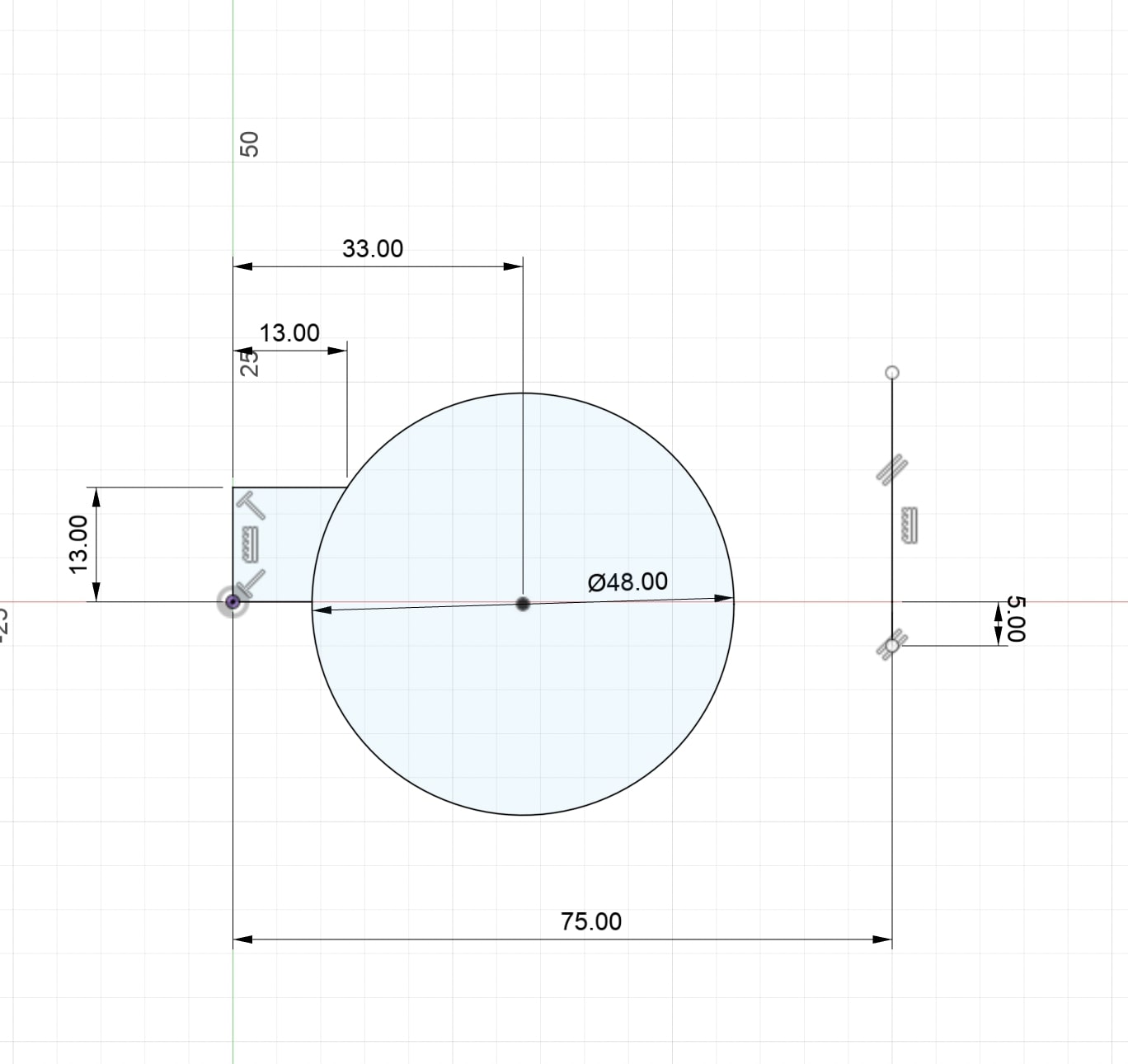

I designed the glasses in Fusion360 as individual parts and then made an assembly to test the hinges to make sure they would work with an m2 or m3 screw. I then made another assumbly to create a mold to SLA print (Glasses File Mold in Fusion360).

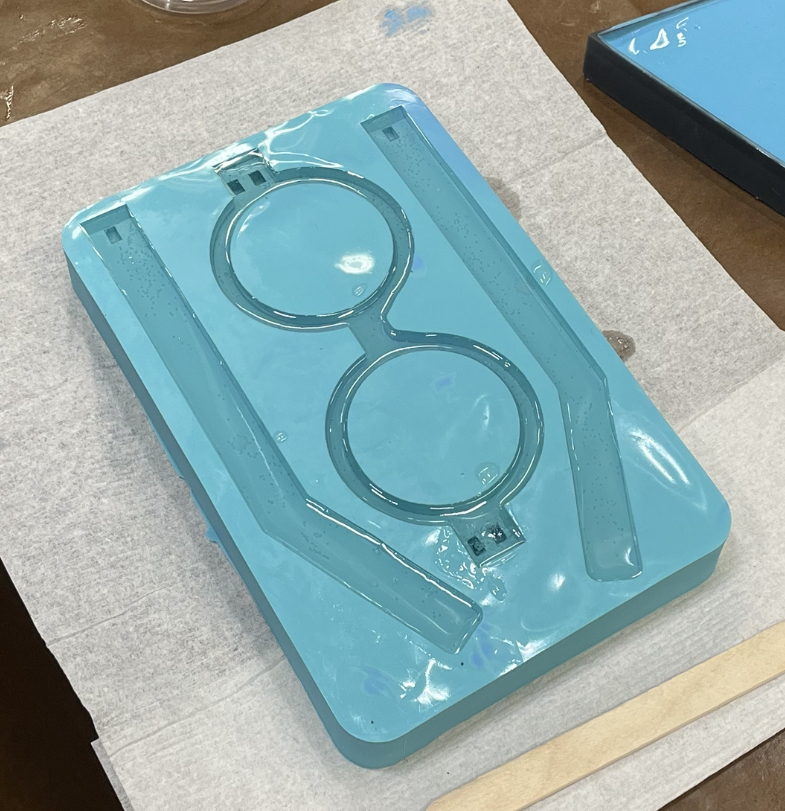

Print out the mold to make the mold on the Formlabs 4. This is a very cool printer with incredible industrial design and so easy to use. Wow!

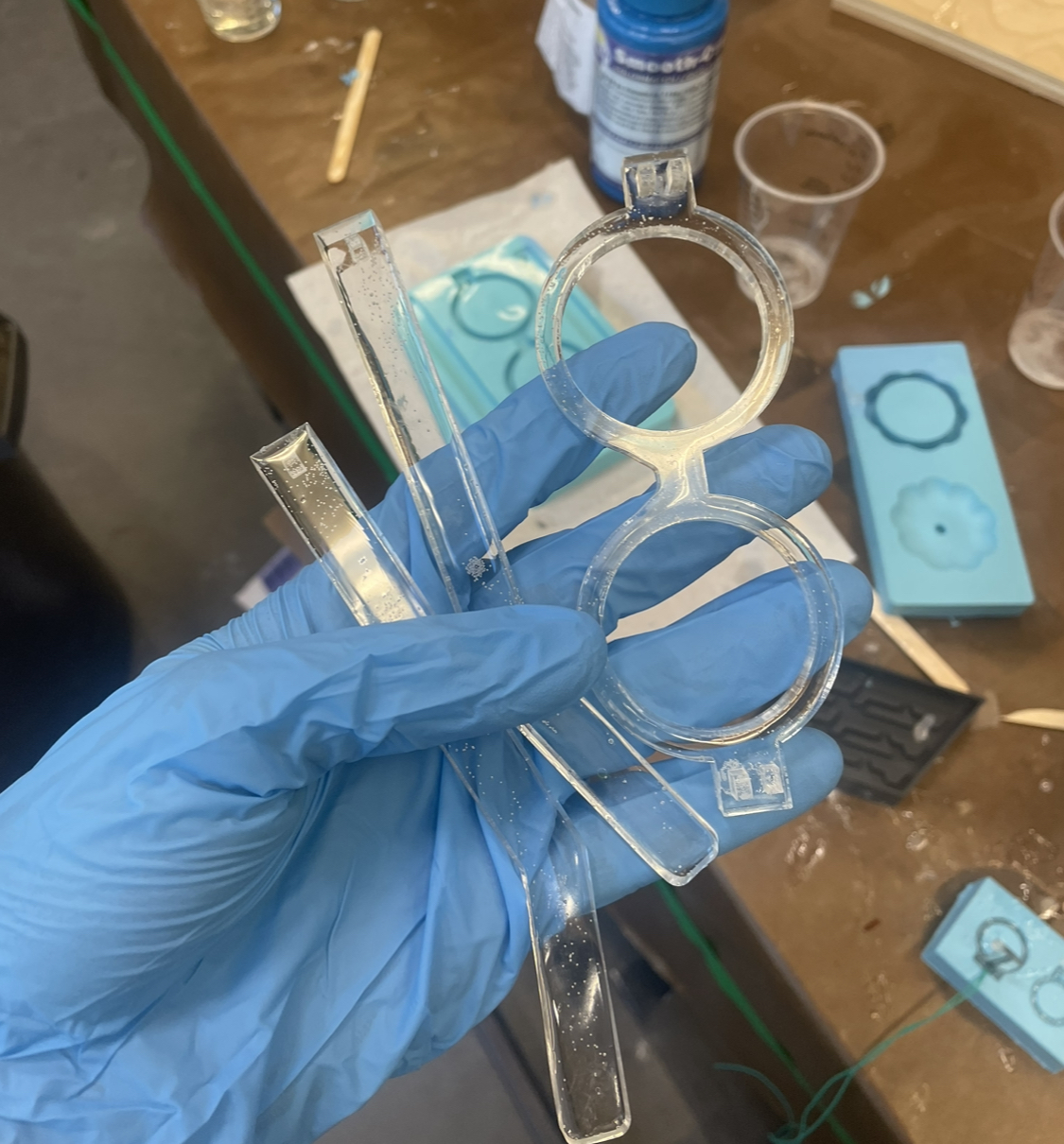

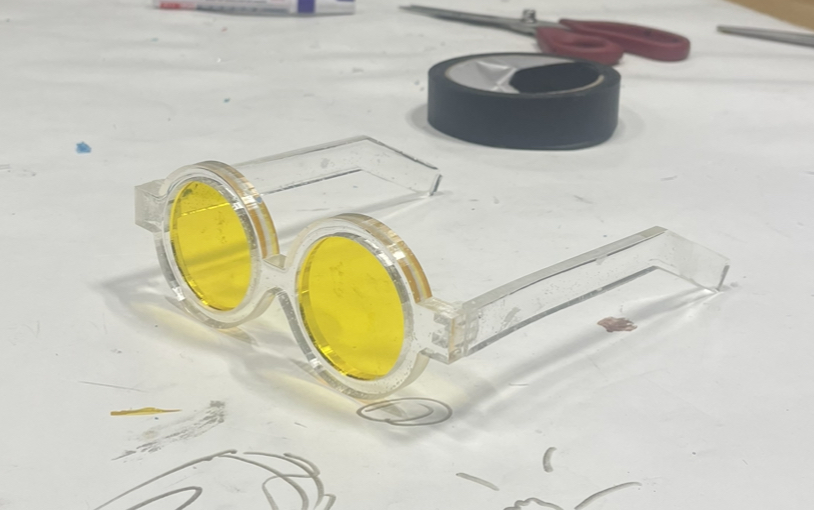

First step was making the mold and then I poured the glasses and will wait overnight for them to cast. There is an air bubble in the hinge tab and it will definitely be a problem...

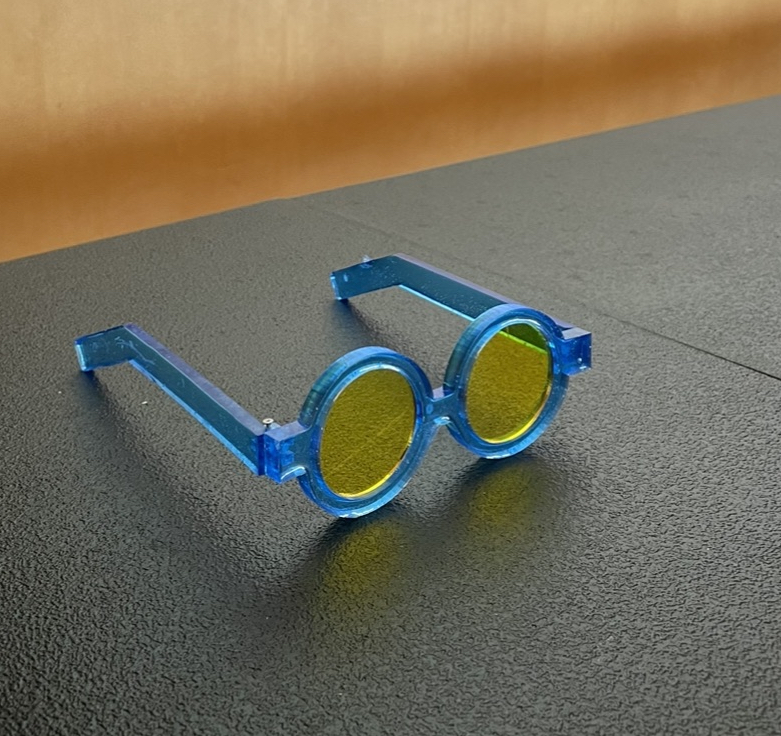

They worked! Time to press fit in the lenses. I cut the lenses with a 41.25 nominal diameter giving me something near a 0.05mm annular press fit after kerf. The hinges got messed up so I just ended up gluing them since the air bubble ruined one of the hinges. I will try again soon.

This was a very fun week but also short since I could only start on Monday since I had the City Science 2024 summit in Andorra and returned to Camrbidge on sunday. There is something wildly satisfying when your press fit just works! Even though the lenses are cool and orange please don't use them to protect you from lasers, the UL cert will only protect you from looking uncool.

In the final moments before class I grabbed my second pair of glasses, drilled the hinge holes, screwed it together and then popped in the lenses right before class.