Snore Monitoring Final Project

My final project involved creating a device to monitor snore intensity, a solution aimed at improving sleep tracking and identifying patterns in noisy nighttime breathing. The core idea was to develop a system capable of capturing and analyzing snore levels while integrating a functional and aesthetically pleasing design. The designing process began with crafting a headboard that would incorporate the functional components while serving as the physical structure of the system. To give it a unique visual appeal, I designed the headboard with a crescent fractal pattern, blending artistic elements with the project's functional requirements. Beyond the headboard, I worked on the design of a printed circuit board (PCB) to interface the microphone and processing unit, as well as creating CAD models for custom 3D-printed connections to hold the headboard securely together.

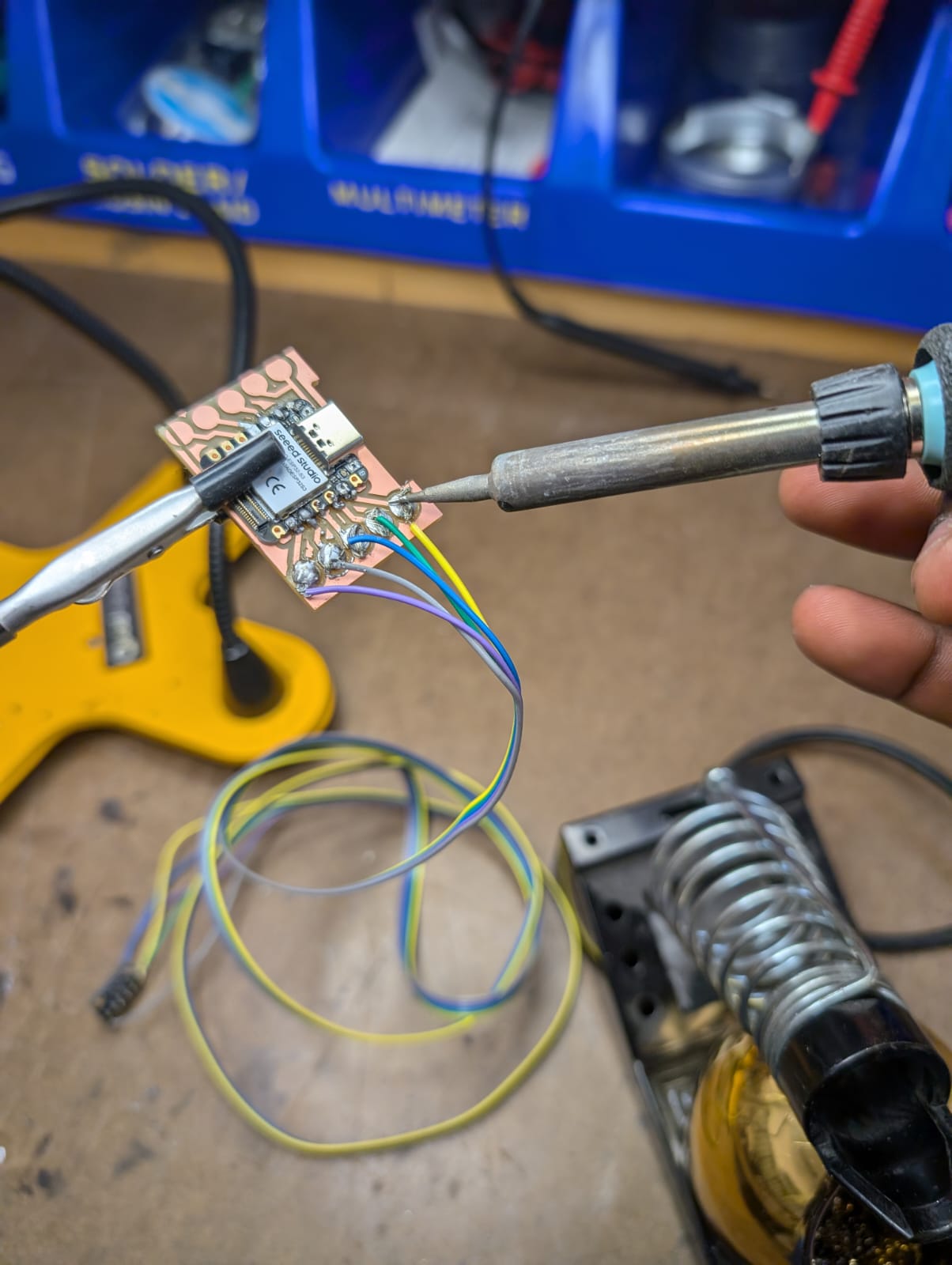

The materials and components for the project were carefully selected to balance functionality, availability, and cost. Oriented Strand Board (OSB) was used for the headboard due to its structural durability and affordability, providing a solid base for the design. For the custom connectors, I used PLA filament, which was ideal for 3D printing lightweight, precise parts to ensure everything fit together seamlessly. The electronics at the heart of the snore monitoring system included a copper plate for the milled PCB, an Adafruit MEMS I2S microphone for audio capture, and a Xiao ESP32-S3 Sense microcontroller for processing and transmitting data. These components were provided by the class, which streamlined the development process and allowed me to focus on integrating everything into a functional system.

In bringing the project to life, I fabricated several parts and systems, both physical and electronic. The headboard was CNC-machined using an Onsrud machine, precisely cutting the OSB to achieve the crescent fractal design. The PCB was milled on the Roland SRM-20, which allowed for accurate production of the custom circuitry needed to connect the microphone to the ESP32-S3 microcontroller. To ensure the headboard could be assembled securely, I modeled and 3D-printed the connections using a Bambu X1 Carbon printer, resulting in robust PLA components that held the structure firmly. This combination of machining, electronics fabrication, and 3D printing demonstrated the integration of multiple fabrication techniques to create a cohesive final product.

.jpg)

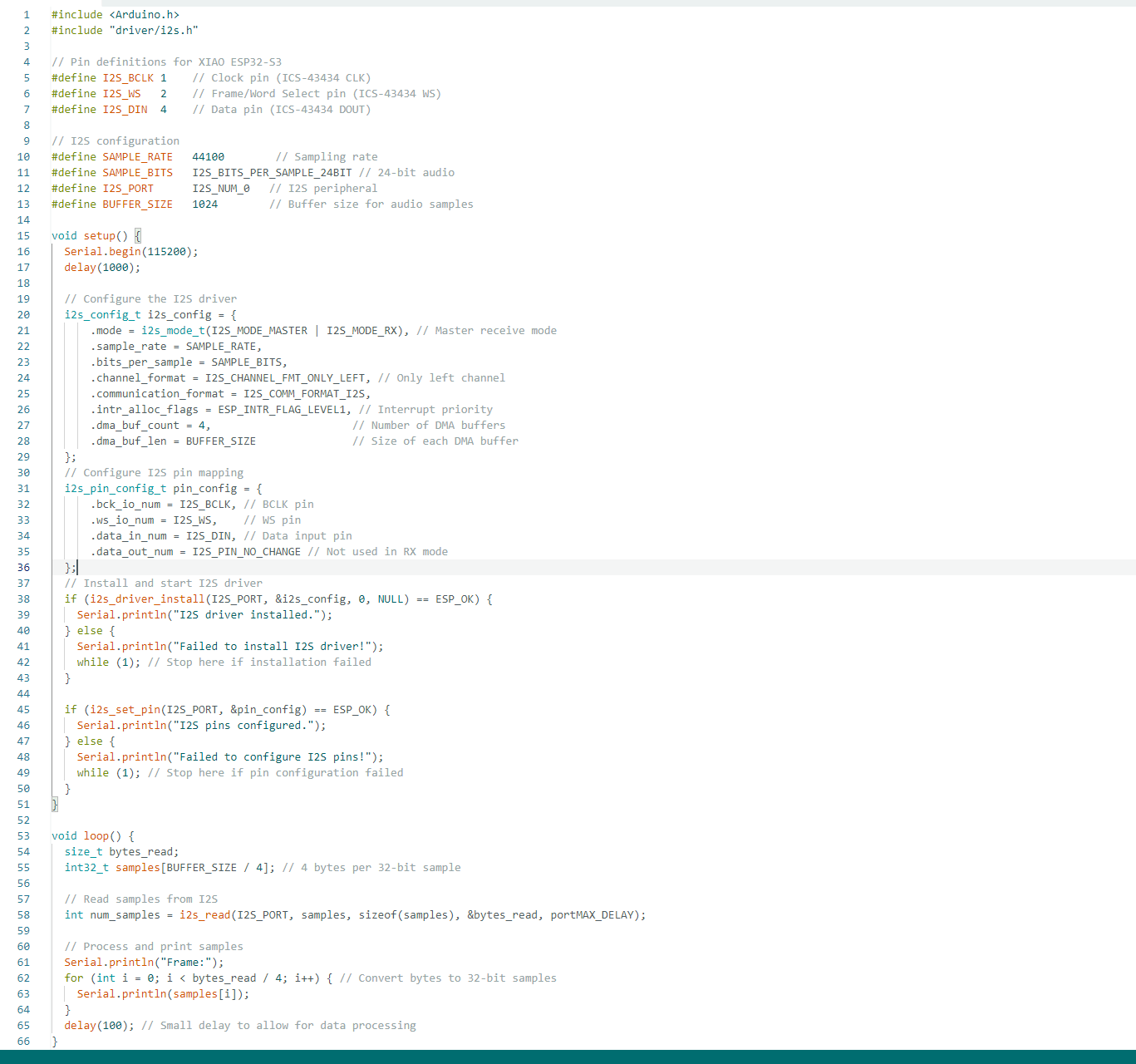

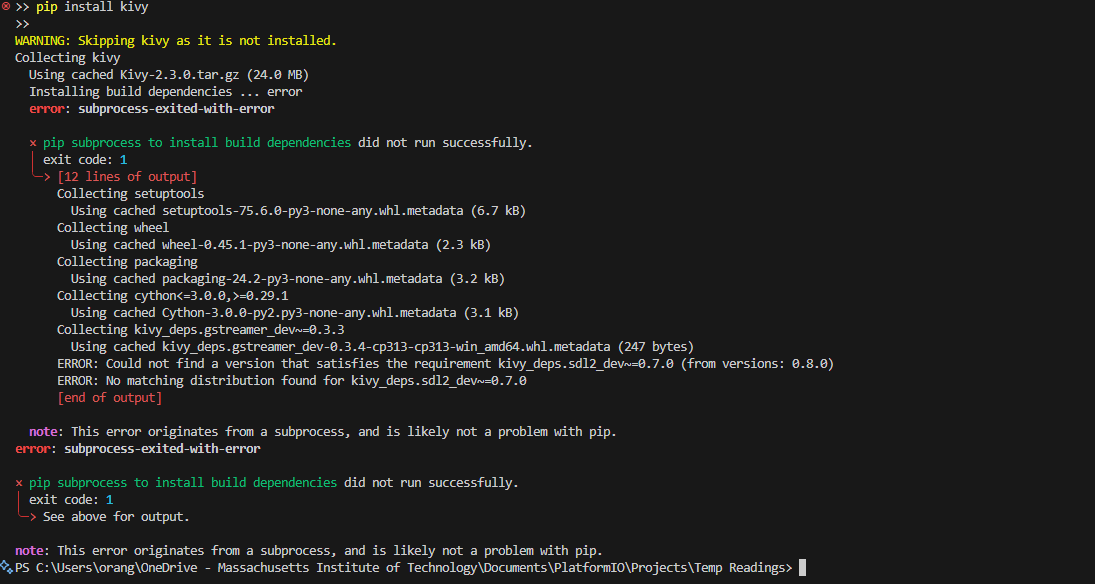

The project had its highs and lows. On the physical side, the fabrication processes went remarkably well. The CNC machining, PCB milling, and 3D printing were all executed with precision, and the parts came together as intended without significant setbacks. However, the coding aspect of the project proved to be far more challenging than expected. While the physical components worked flawlessly, programming the ESP32-S3 to read input from the microphone and reliably monitor snore intensity took a considerable amount of time. Debugging the software, calibrating the microphone sensitivity, and ensuring smooth communication between hardware components required a great deal of patience and problem-solving.

For the coding aspect, I wrote to the board using the Arduino IDE to set up the Wi-Fi connection with my computer, allowing data to be transmitted wirelessly. I then developed a Python program using Kivy and PySerial to visualize the received data in a user-friendly application. This process involved configuring the communication between the microcontroller and the application, ensuring that the real-time data could be displayed effectively on the screen. While there were challenges in establishing a stable connection and ensuring data integrity, the end result was a working system that allowed users to visualize snore intensity directly on their computer.