Machine Building Week

During machine-building week, I was part of the architecture section team working on building a claw machine that can stack cubes using a "claw"/ grabber suspended by wires

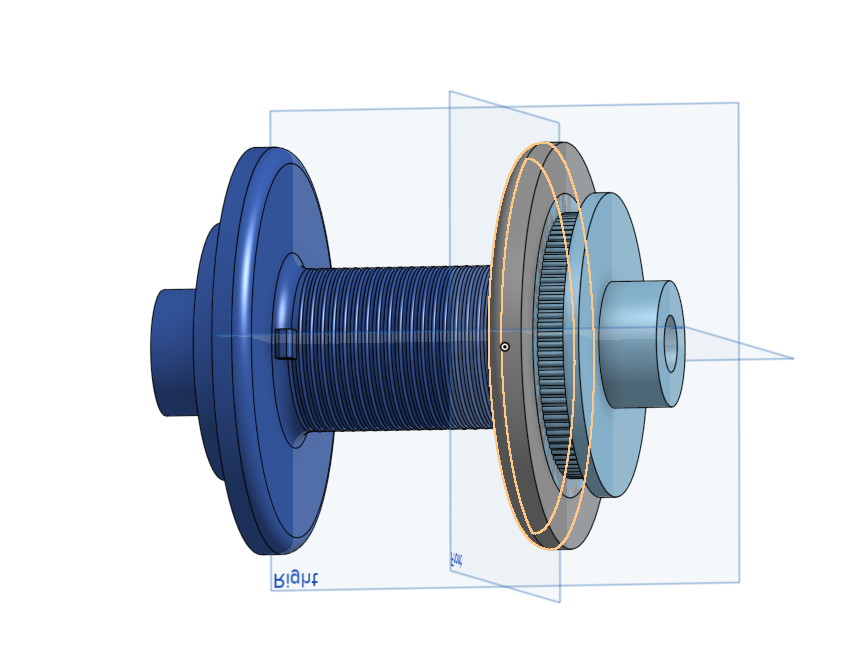

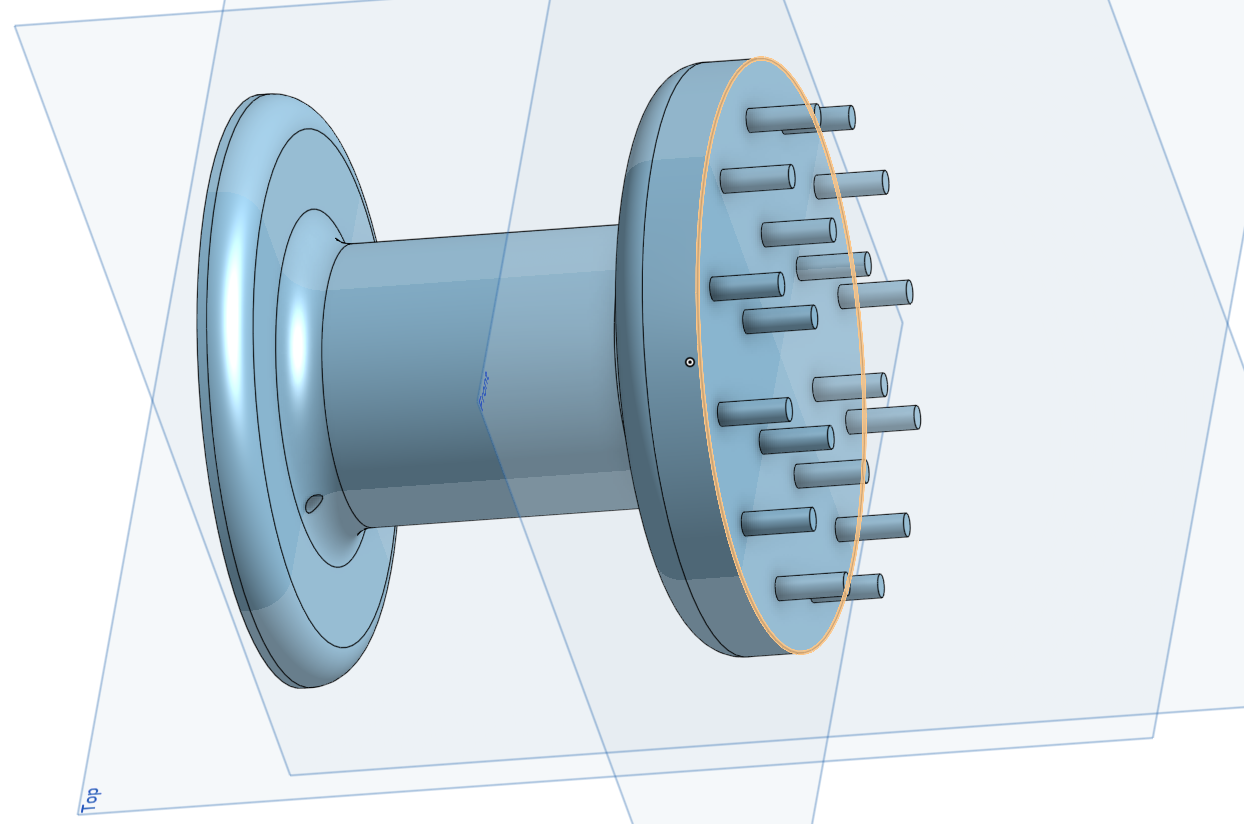

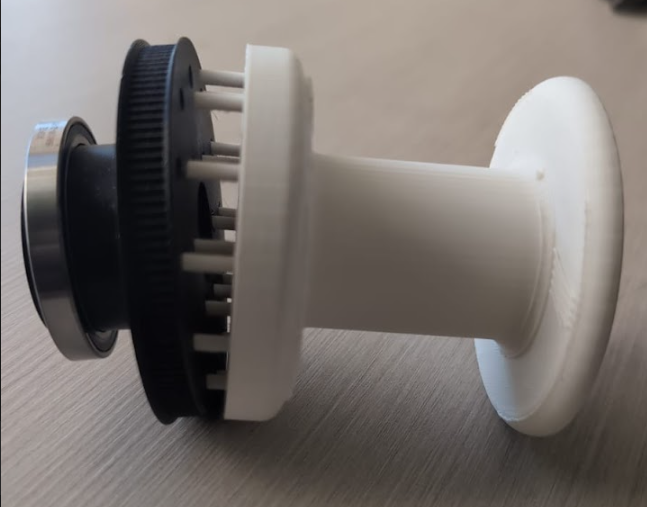

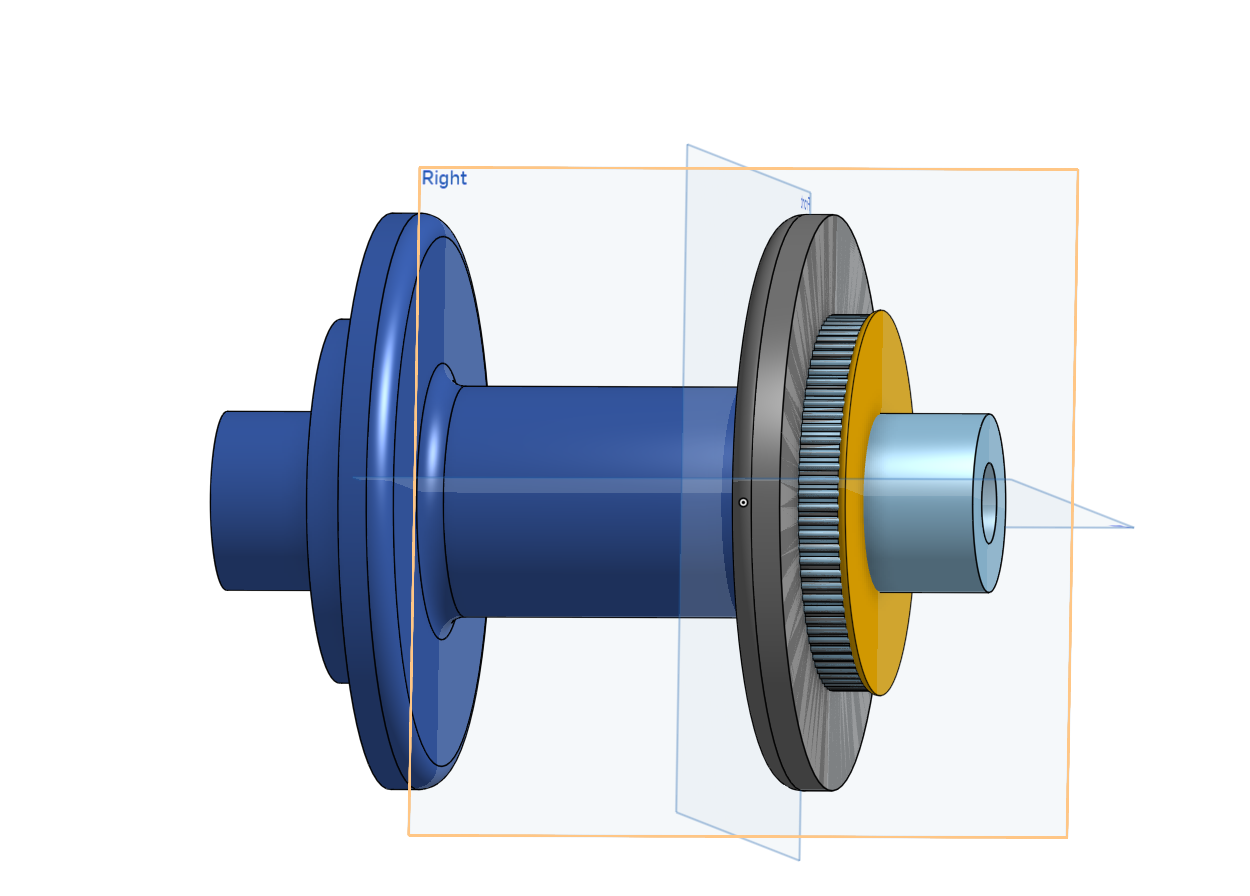

I took charge of designing and fabricating the spool responsible for managing the wires that would operate the grabber mechanism. The spool needed to interface seamlessly with a pulley to enable rotation and with a winch to secure it firmly to the machine’s frame. The initial design featured a spool with extended components allowing it to connect to the pre-existing pulley wheel, which had concentric holes. However, this design relied heavily on friction to maintain its position relative to the pulley, an arrangement that, while functional, was less than ideal for long-term stability.

Recognizing the limitations of the first iteration, I created a second design that merged the bottom pulley wheel with the spool into a single, unified structure. This integration not only eliminated the dependency on friction but also improved alignment and stability. By combining the two components, the spool became a more compact and robust element within the system, allowing for more efficient transfer of motion from the pulley to the wire that operated the grabber. This modification addressed potential issues of slippage and misalignment, ensuring that the spool could withstand repeated use without losing functionality.

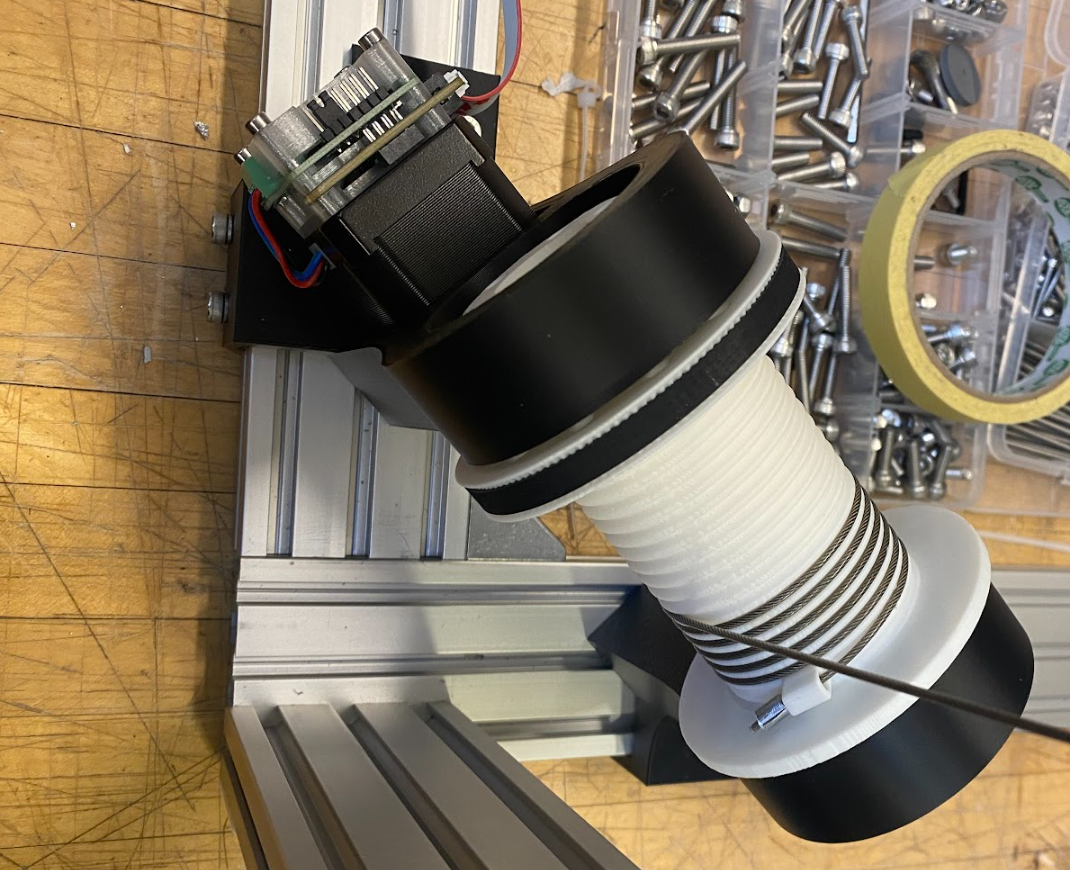

Building on the improved second iteration, I incorporated additional refinements to further enhance its performance. Threads were added to the spool’s surface to prevent the wire from bunching or overlapping during operation, maintaining consistent tension and smooth motion. Additionally, a stopper was designed and implemented at the spool's end to securely anchor the wire, ensuring it remained fixed during use. These final modifications resulted in a durable and efficient spool design capable of reliably managing the wire and facilitating the precise movement of the grabber.