CNC Machining

For the group assignment, we received essential shop training from Chris to ensure we could use the woodshop safely and effectively. This training emphasized proper handling of tools, understanding shop protocols, and recognizing potential hazards. Following this, we conducted a test piece using the CNC machine by cutting various widths to determine the optimal conditions for both press-fit and friction-fit joints. This initial experimentation allowed us to gauge precision and understand how the material responded under different tolerances, ensuring a reliable fit for our final designs.

My headboard design featured a unique fractal-inspired element—a crescent shape that repeated in diminishing sizes, creating a visually intricate and harmonious pattern. I meticulously crafted the design in Rhino, ensuring every detail accounted for the thickness of the OSB plank to facilitate precise and sturdy joints. This step was critical in maintaining both structural integrity and aesthetic quality, as the design's complexity required careful consideration of the material's dimensions and how they would interact during assembly.

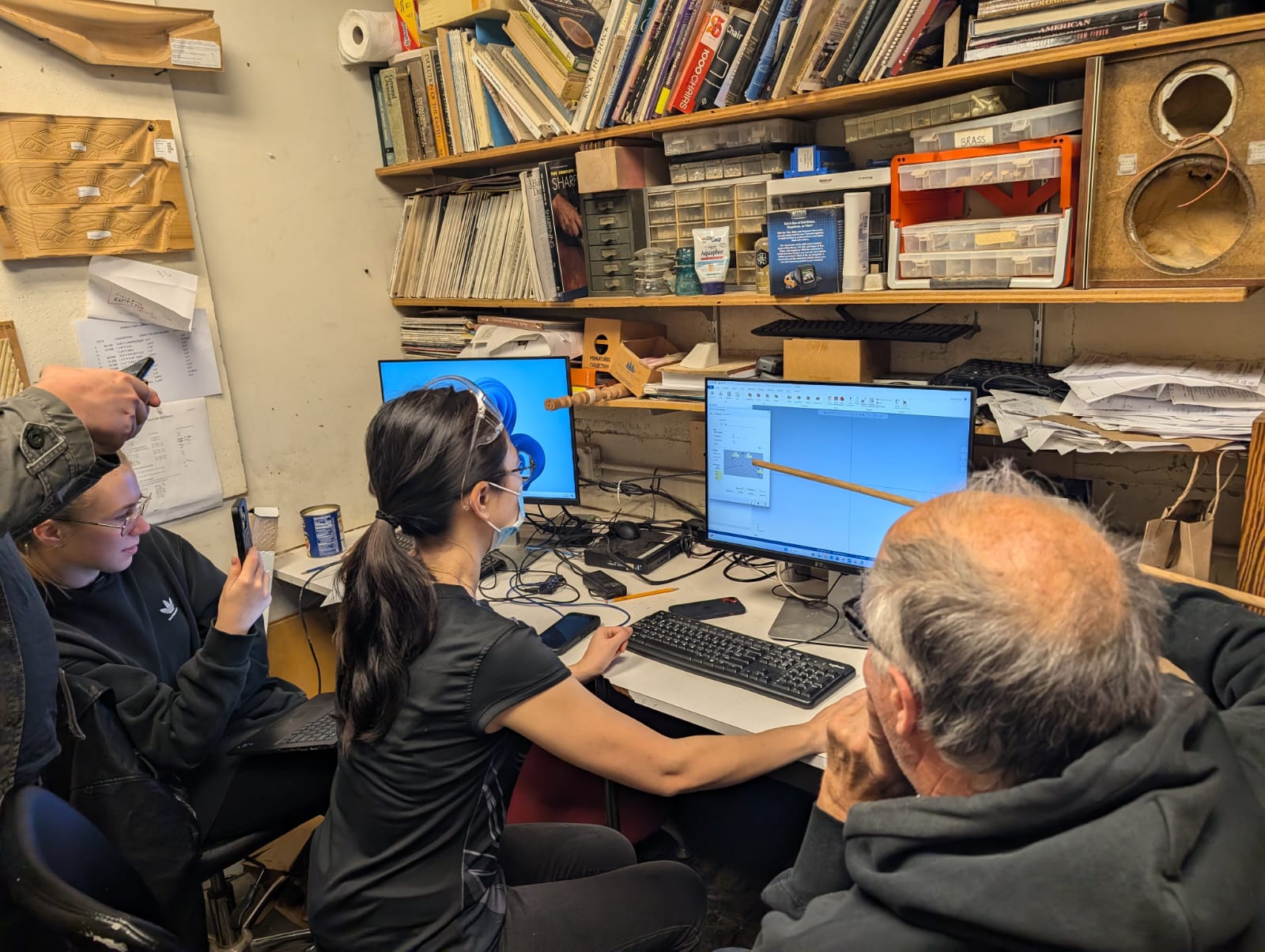

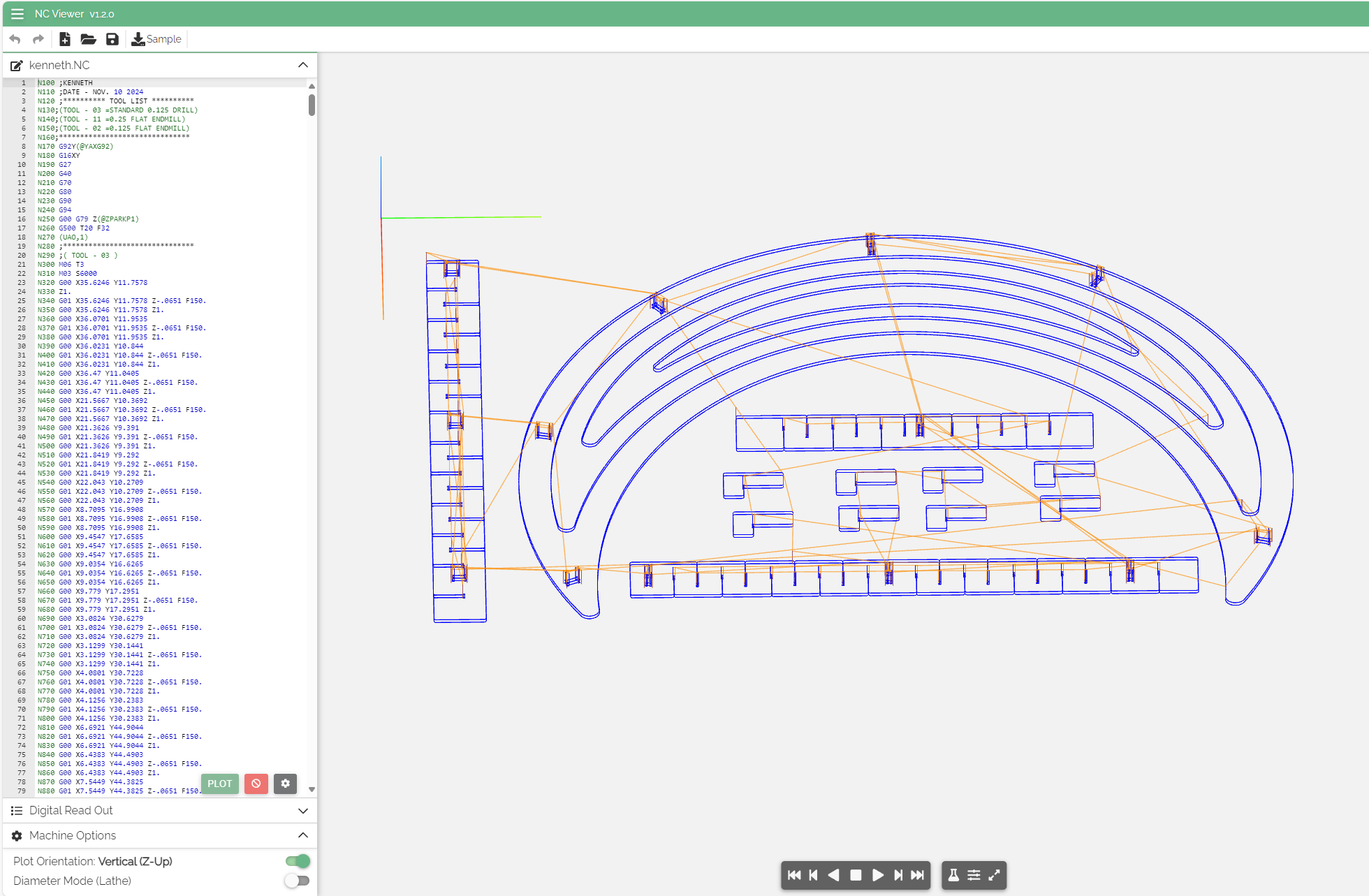

Jacob P. played a pivotal role in helping me prepare my file for CNC cutting by setting it up in Mastercam. He guided me through adjusting the appropriate tools and toolpaths to achieve the desired cuts while ensuring accuracy and efficiency. His expertise was invaluable in configuring the parameters for the CNC machine, such as selecting the right end mills and fine-tuning feed rates, which are crucial for achieving clean cuts and preserving the material's integrity.

After cutting my board on the CNC machine, I realized that the OSB material was too weak to bend or make reliable connections. I decided to design and 3D print the connectors instead, which allowed me to create more durable and precise parts for my project. Once the connectors were printed, I simply attached them to the board, ensuring a solid and functional setup