Week 2

Laser Cutting

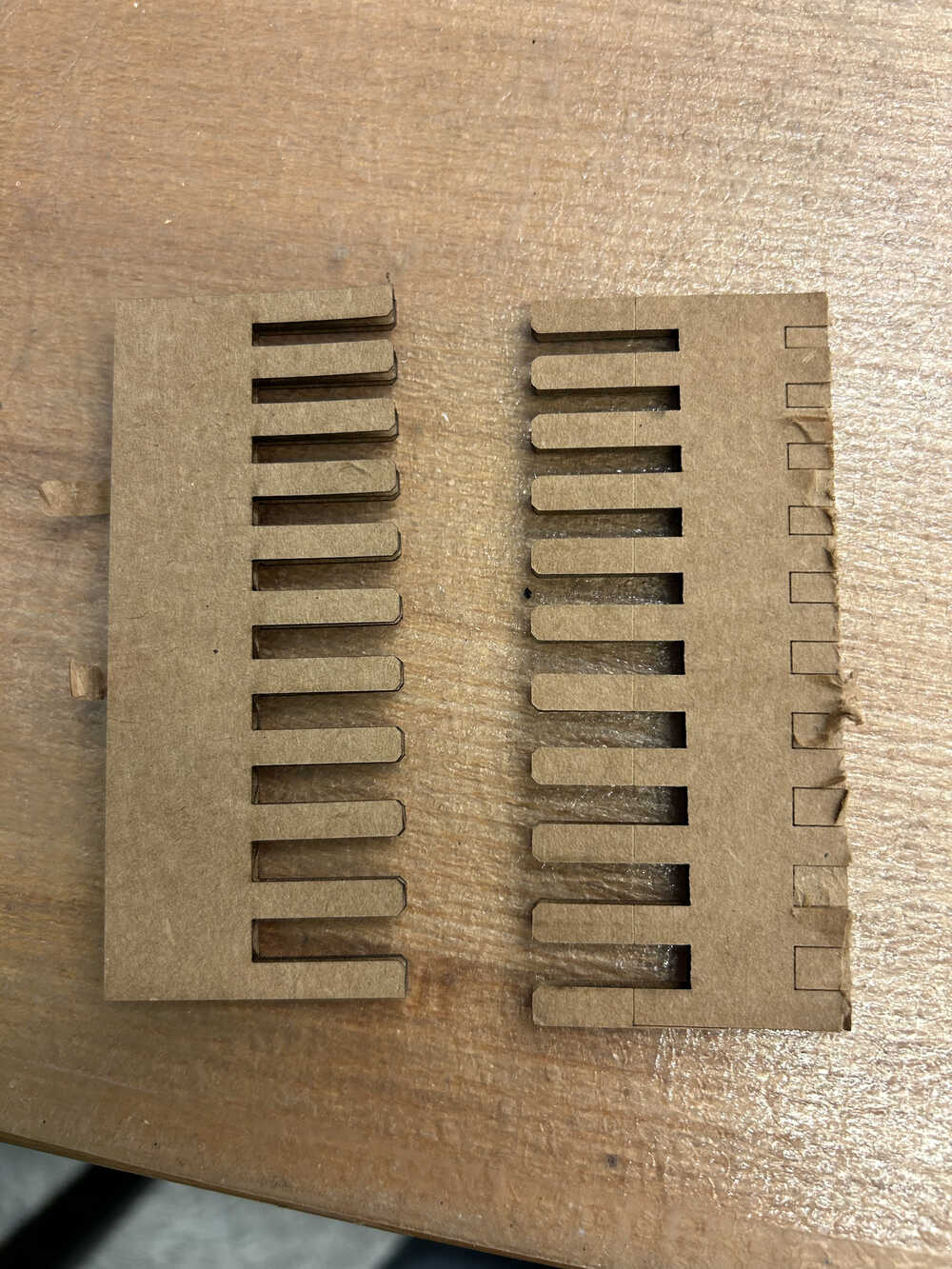

I wanted to make something that could move so I decided on making a windmill. I used images of windmills from holland as inspiration. Before starting on the windmill I had to determine the kerf of the laser and what size the cutouts should be for the cardboard to hold together. I CAD-ed and printed two copies of a comb design and saw where they fit together. I found that 3.5mm worked well.

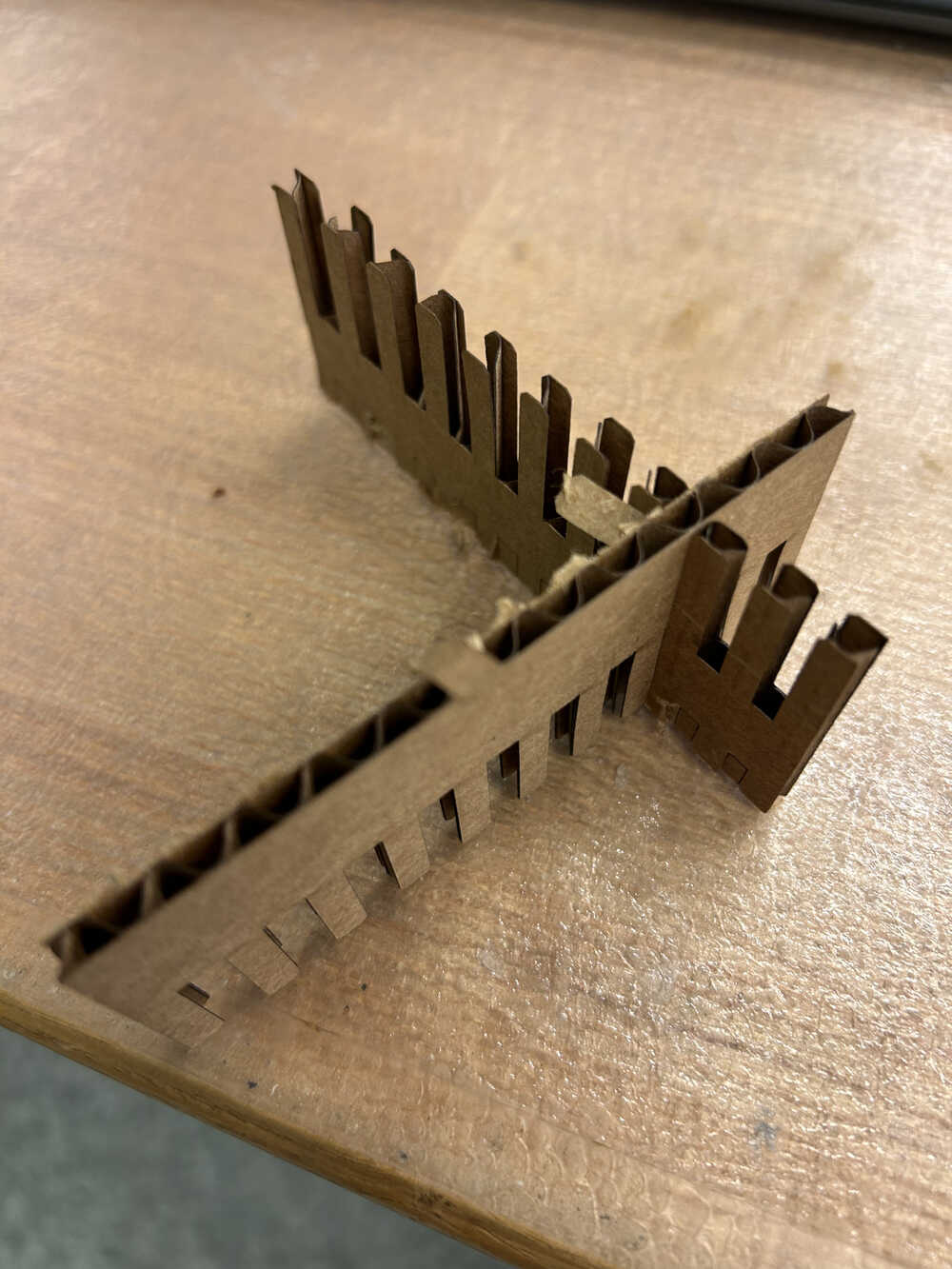

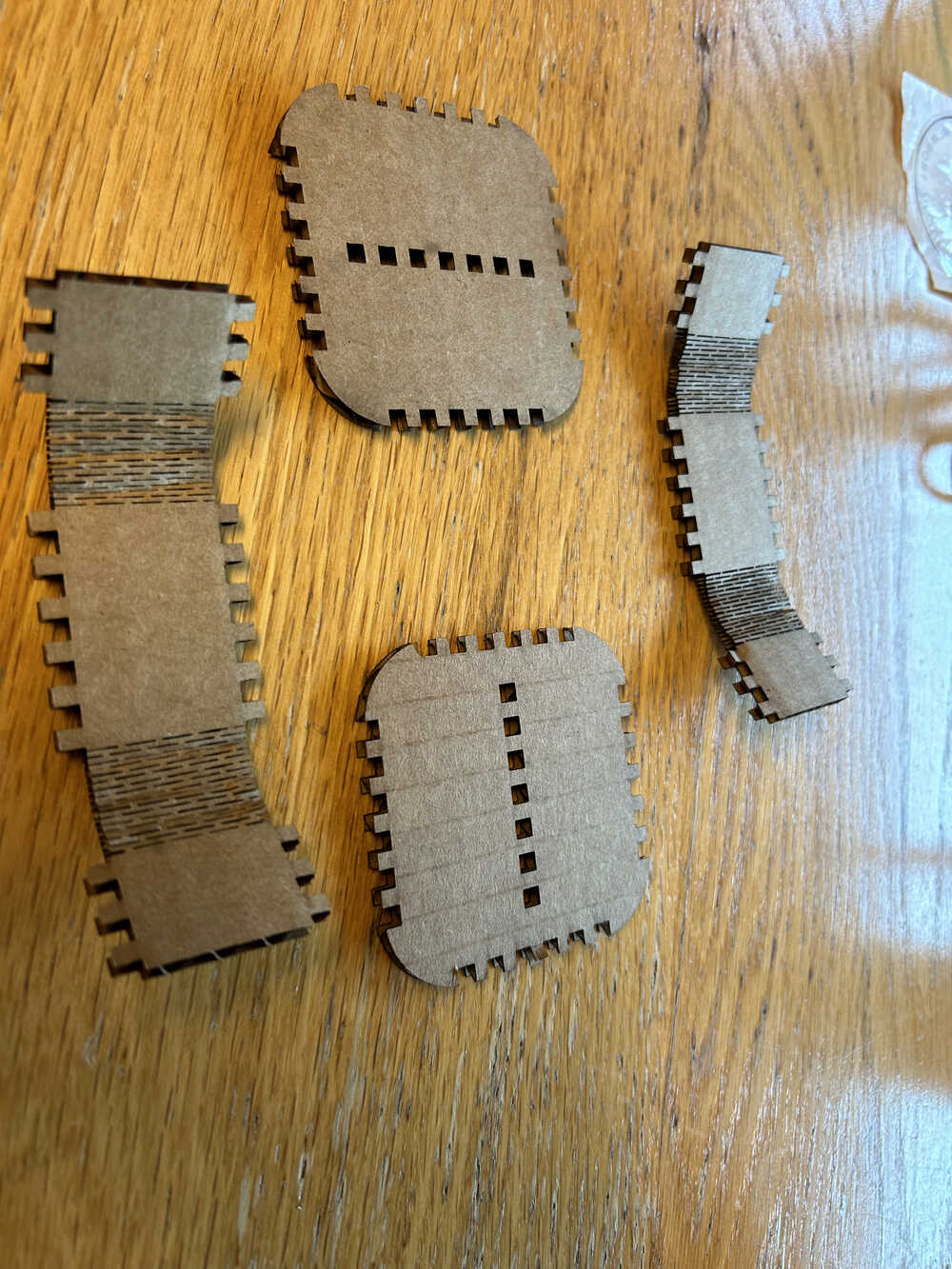

This is the comb I made. ignore the rough edges, I was having a battle with the laser cutter. you can see where the pieces fit together.

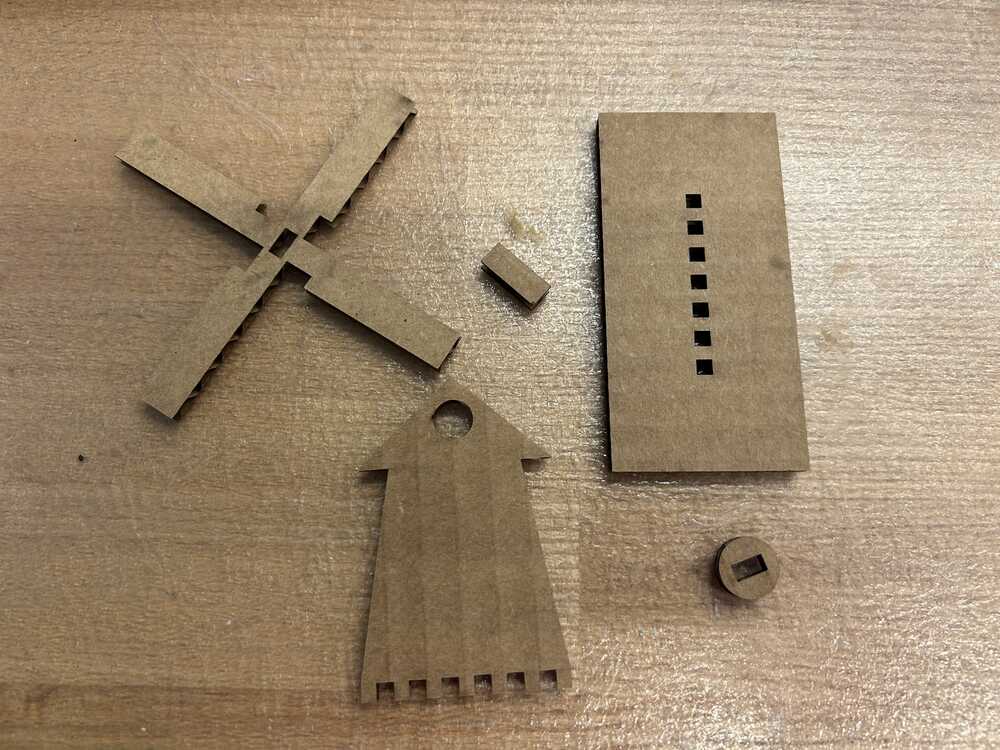

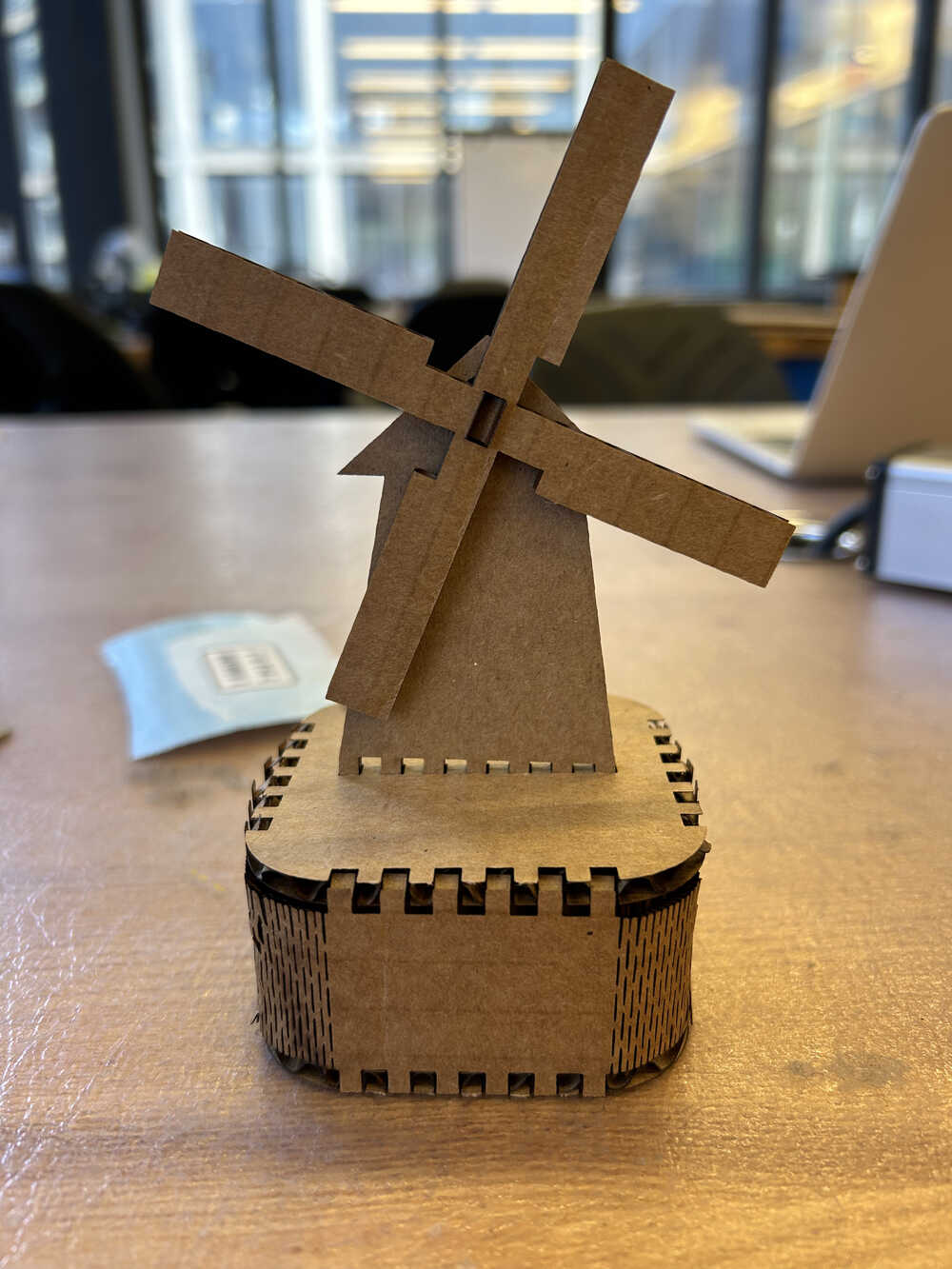

I then designed and printed the pieces for my windmill. I used a finger joint to make the windmill stand vertically on a base. For the axle, I started simple by making it fit snugly into the windmill blades and loosely into the building part so it could rotate. this ended up being sufficient, though I did have to mess around with the sizing a bit. I tried to originally make it a square prism but that was two thin and fell apart so I had to make it wider. I then assembled it and it came together well.

the pieces for the windmill

the assembled windmill

I want to try to incorporate curved surfaces into my design and make it a little more complex so my next step is to build a better base box.

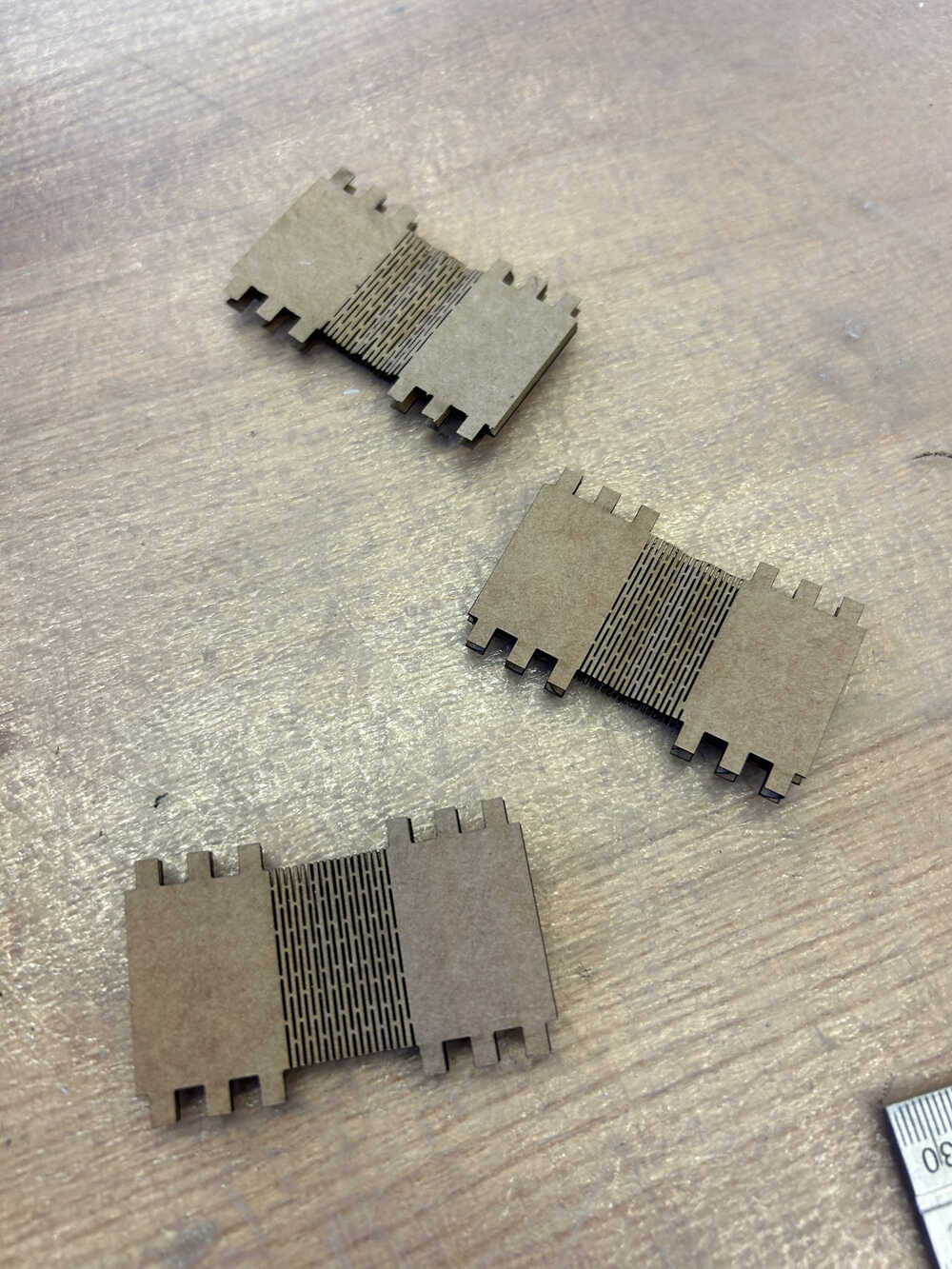

I created a cad with a lot of lines for a living hinge and finger joints to make a base box. For my first iteration, the pieces didn't fit together because I underestimated the length needed for the arc, so I widened it a bit and decided to use 2 pieces rather than 4 so it would be more seamless.

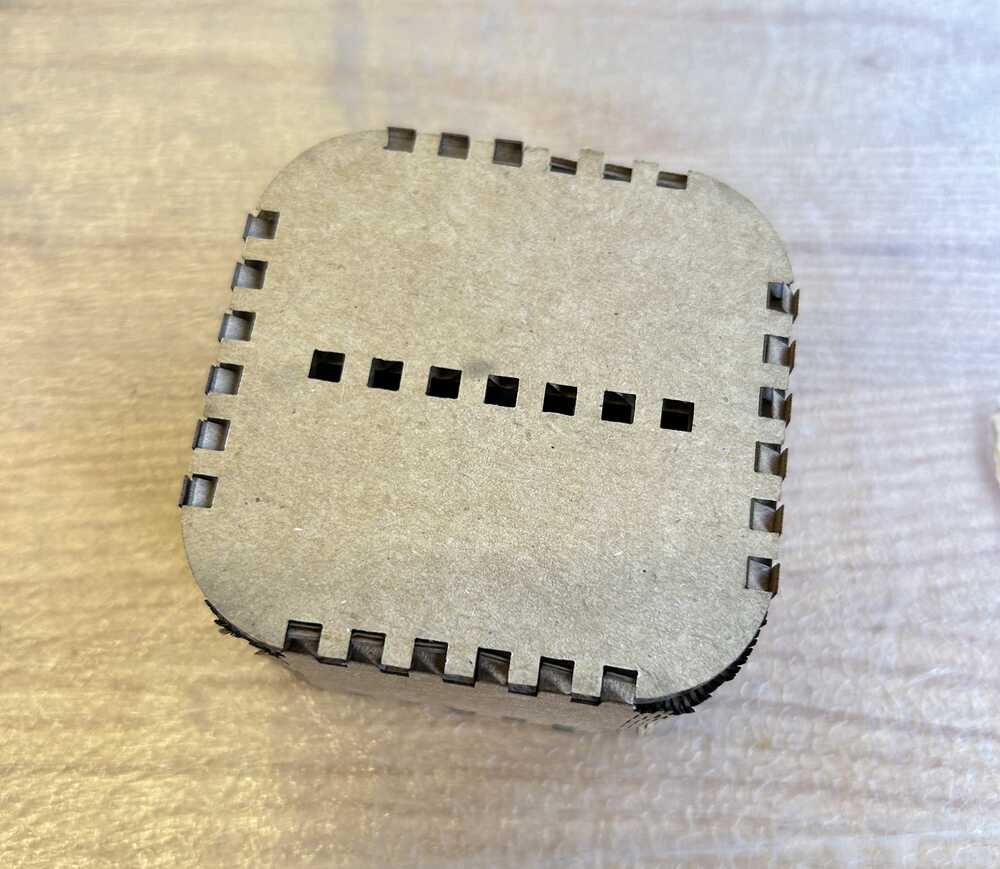

(left) first iteration of the wall pieces. (right) second iteration with the top and bottom of box

I then assembled it and added my existing windmill design on top

second iteration of windmill

I was having trouble getting the walls to stay in place with the walls. I originally thought this was a result of the curved part being too springy, but I realized that I did not properly account for the kerf in this joint, so I CADed a new version. I have not had the chance to print and test it, but I'll update this here when I have.

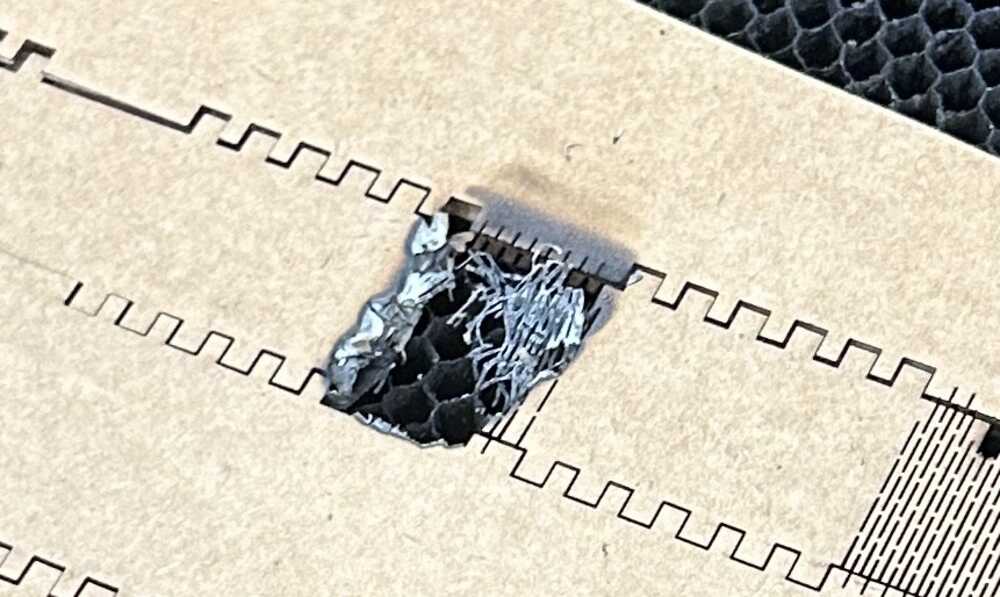

I recut it and it was better, but still not quite as snug a fit as I wanted. So I tried making the spaces smaller on the box top and bottom. This didn't work because the pieces wouldn't fit together at all. Maybe chamfering would've helped but instead I decided to combine the two wall pieces into one wall piece to see if it fit better. I ran into an issue because the setting on the laser cutter was changed since I had last cut and I forgot to check it. So I was cutting at a much lower speed and got a small fire. I paused the cutter and kept an eye on it and the fire went away. I fixed the speed and recut it and it worked out much better. That worked really well and I was pretty satisfied with the overall product.

(left) is my piece that got burnt :( . (right) wall for the box that is one piece.

(left) box with the singular wall piece. (right) full windmill on new box. Not super obvious in the picture but the wall on the box was much more flush and held together better.