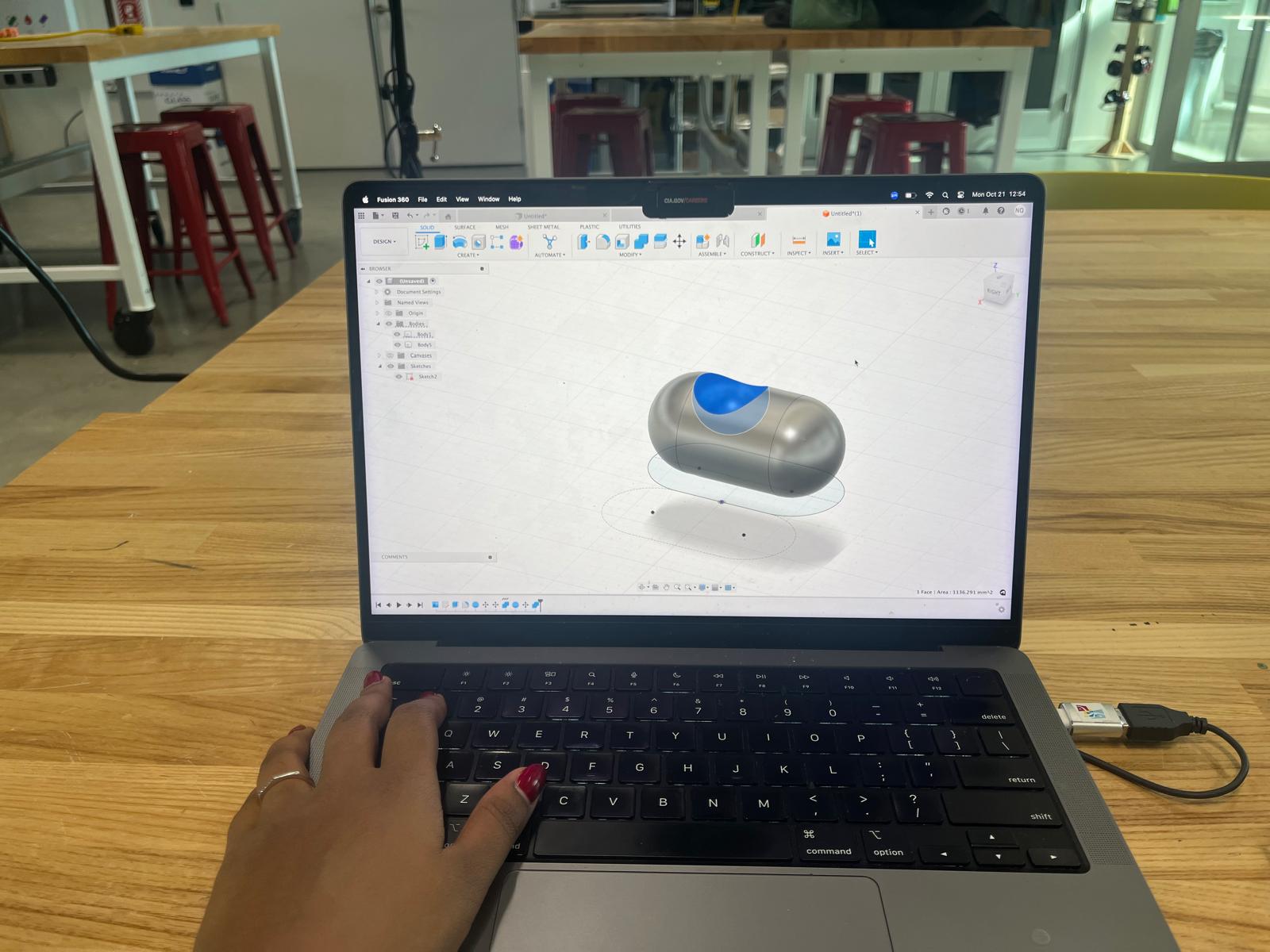

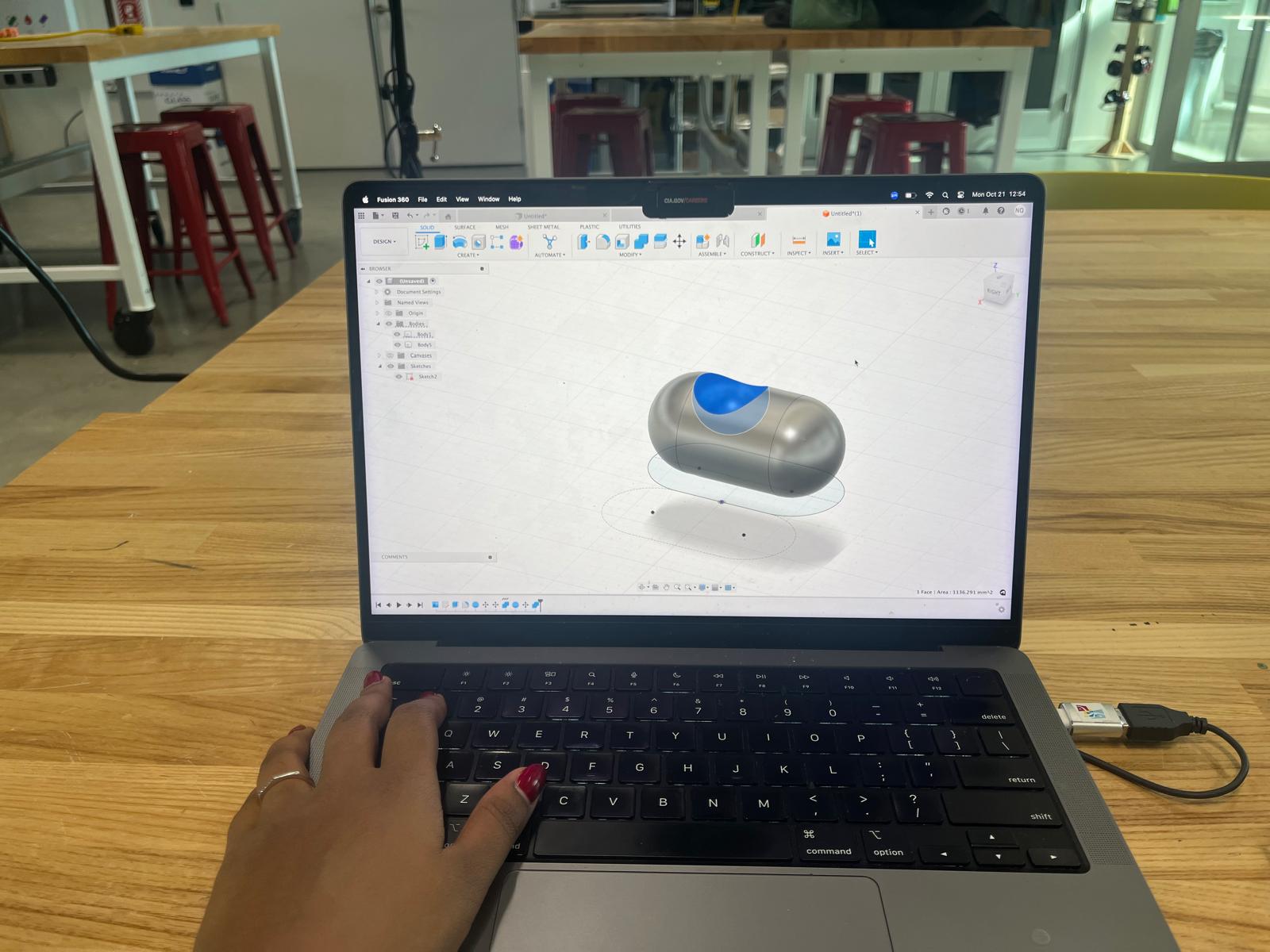

The 3D design process in Fusion 360 - getting the right curvature took many iterations!

Design and create a mold, then cast parts from it

I worked with Alex and Anthony to test various Silicone-based materials. We created small test molds to understand how different materials would look and feel. This was really helpful for learning proper mixing techniques!

For my individual project, I decided to create a mold of Clammy - the logo of a startup I've been working with. I chose to focus on the eyes because they have such fun details, and it would be a good challenge for molding.

The steps involved were:

The 3D design process in Fusion 360 - getting the right curvature took many iterations!

Getting there... this was a couple hours of work with lots of help from Joe/Jeff at the SEC!

Printing the mold on the Prusa MK4

The final mold (had some small holes but still usable)

The cast model in purple silicone

Adding the white and black details with paint

The completed Clammy logo!