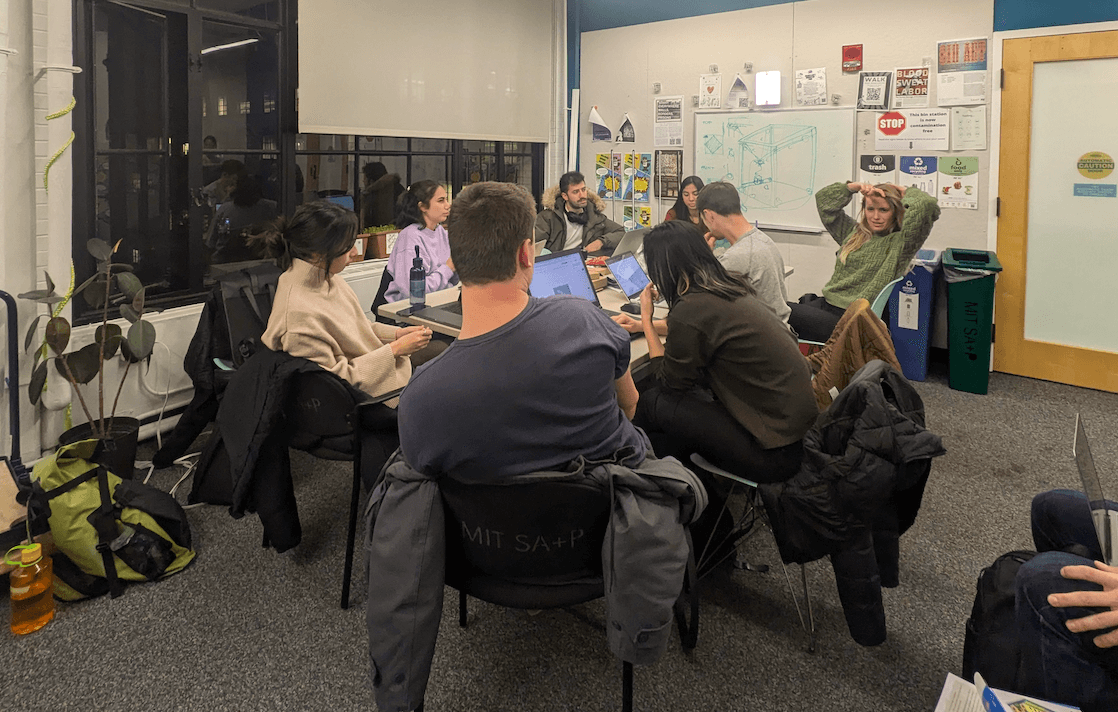

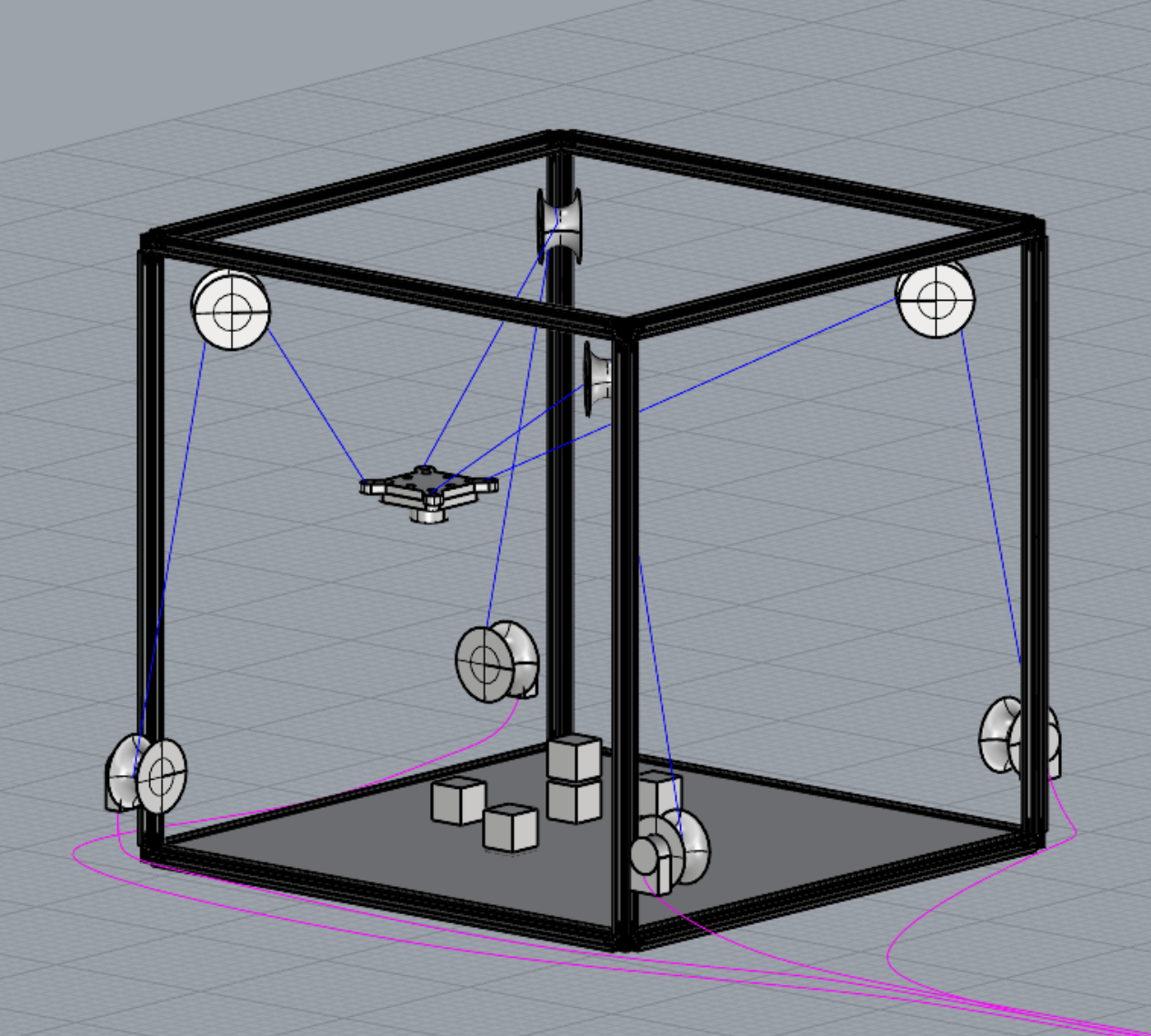

It's machine week!! We decided to make a machine capable of picking up blocks and dropping them off at a particular location. This started as something Sergio had been thinking about, and it was amazing to see it to fruition! We started with a brainstorming session where we committed to this idea.

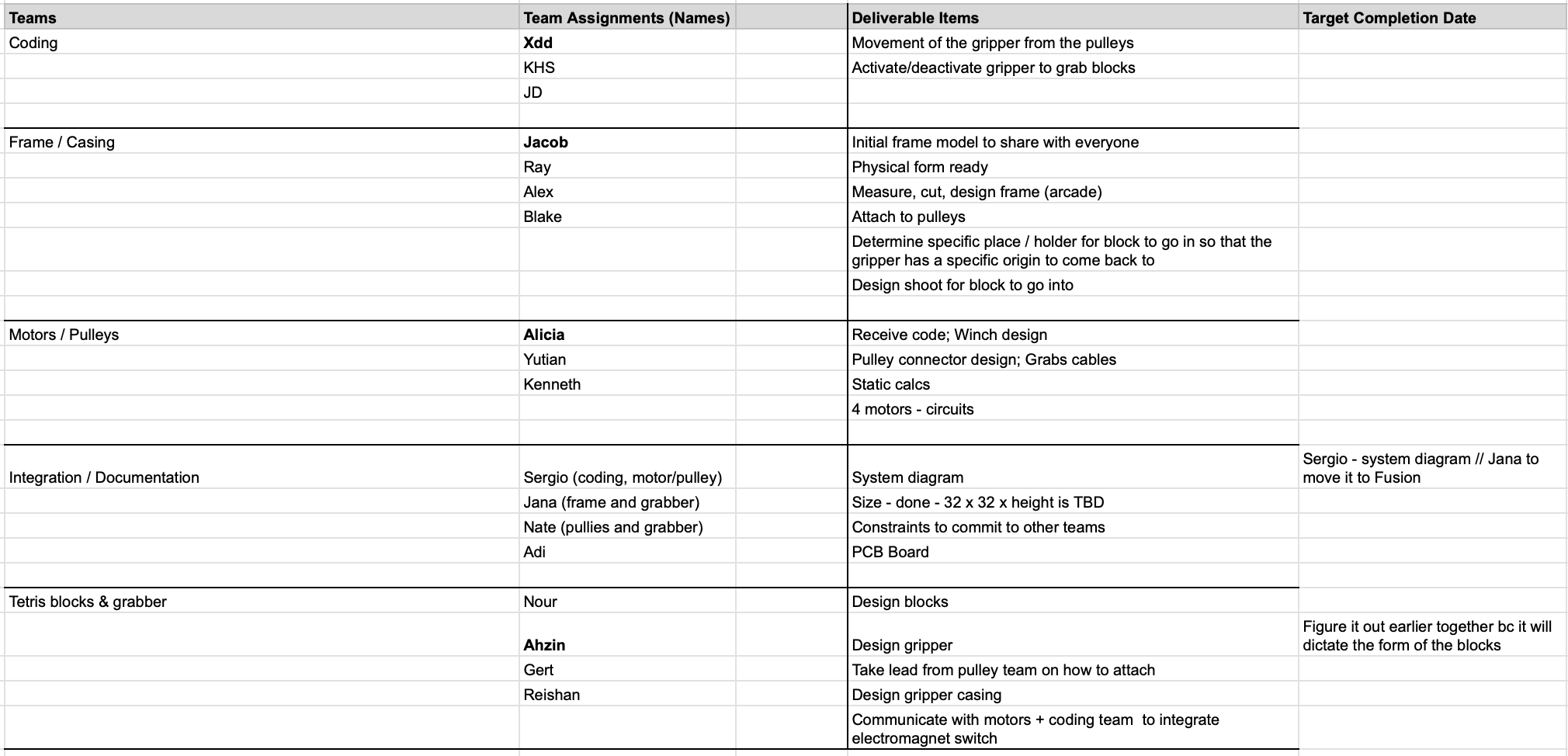

We also split up into teams:

As you can see, I was part of the Blocks and Grabber team. We were responsible for designing the blocks such that they are stackable and grabbable, as well as the grabber to electromagnetically pick them up. We started with a team meeting and talked about potential designs.

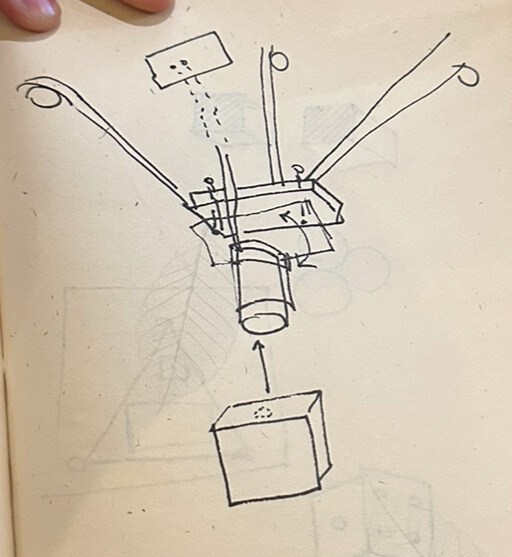

We also asked ourselves questions like how many blocks do we need? Should they be actual blocks, or a different shape? What if we made them spheres? Ahzin made a quick Rhino sketch, and it helped us visualize it, which made it easier to make decisions.

We then thought about the grabber-to-block and block-to-block connections. None of us were too familiar with magnets, so multiple worries came up. Will we be able to pick one block up without affecting any of the other blocks? How strong of a magnetic field should it be? What voltage do we need? Everything was answered in due time!

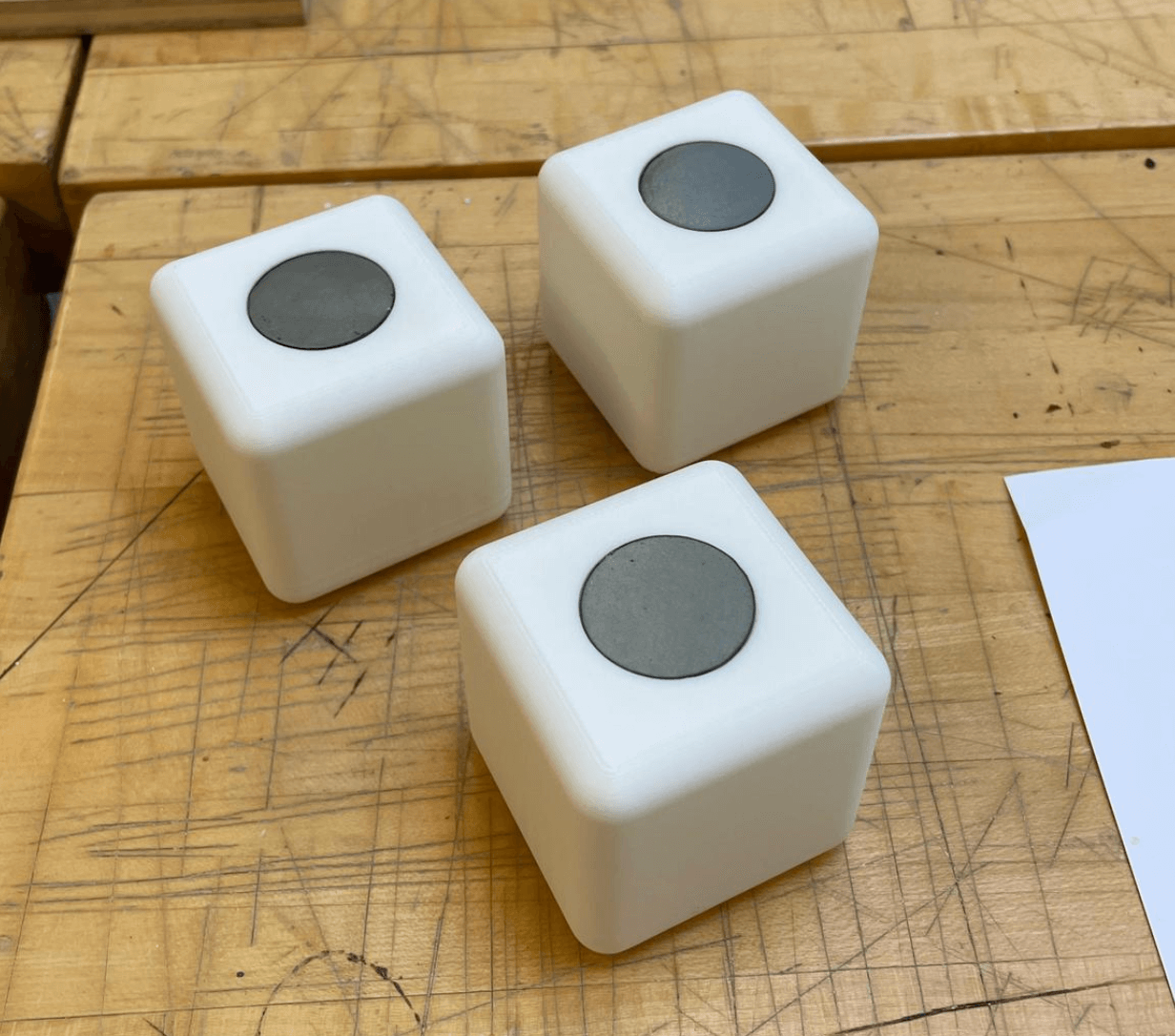

We started sending example blocks to the Bambu prints right away! We settled on a simple block design with a divet that fits a 1 inch diameter disk of steel.

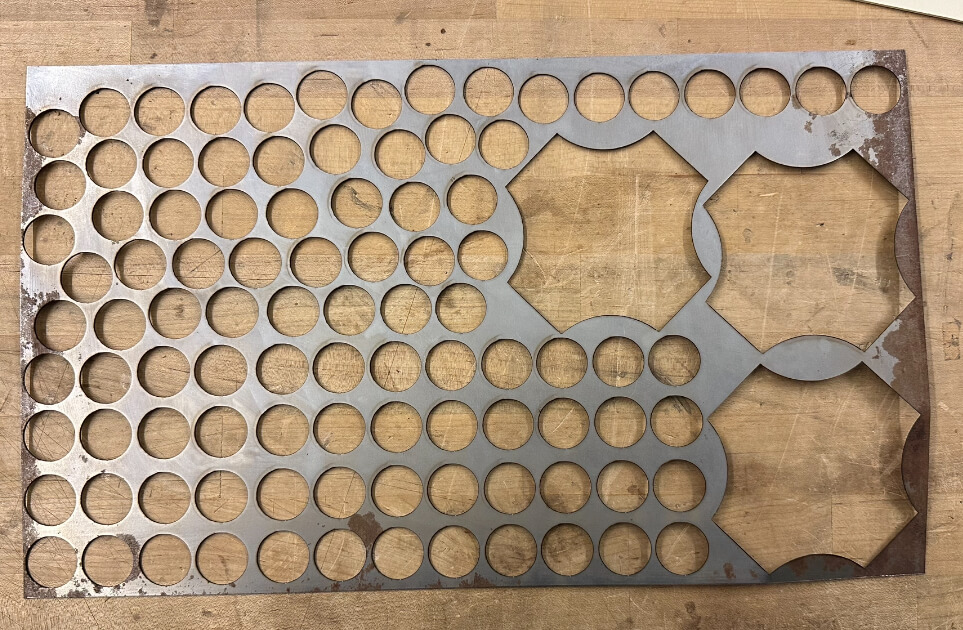

We also designed weights for the grabber. The metal disks and weights sent me on my first solo mission: to use the metal laser-cutter in N-52.I talked to Bill and Chris, and they introduced me to the shop monitor that would be helping me (shoutout to Awen Gronda!!). They were also kind enough to give us some sheet metal they had left over. I tried fitting as much as I could on that sheet:

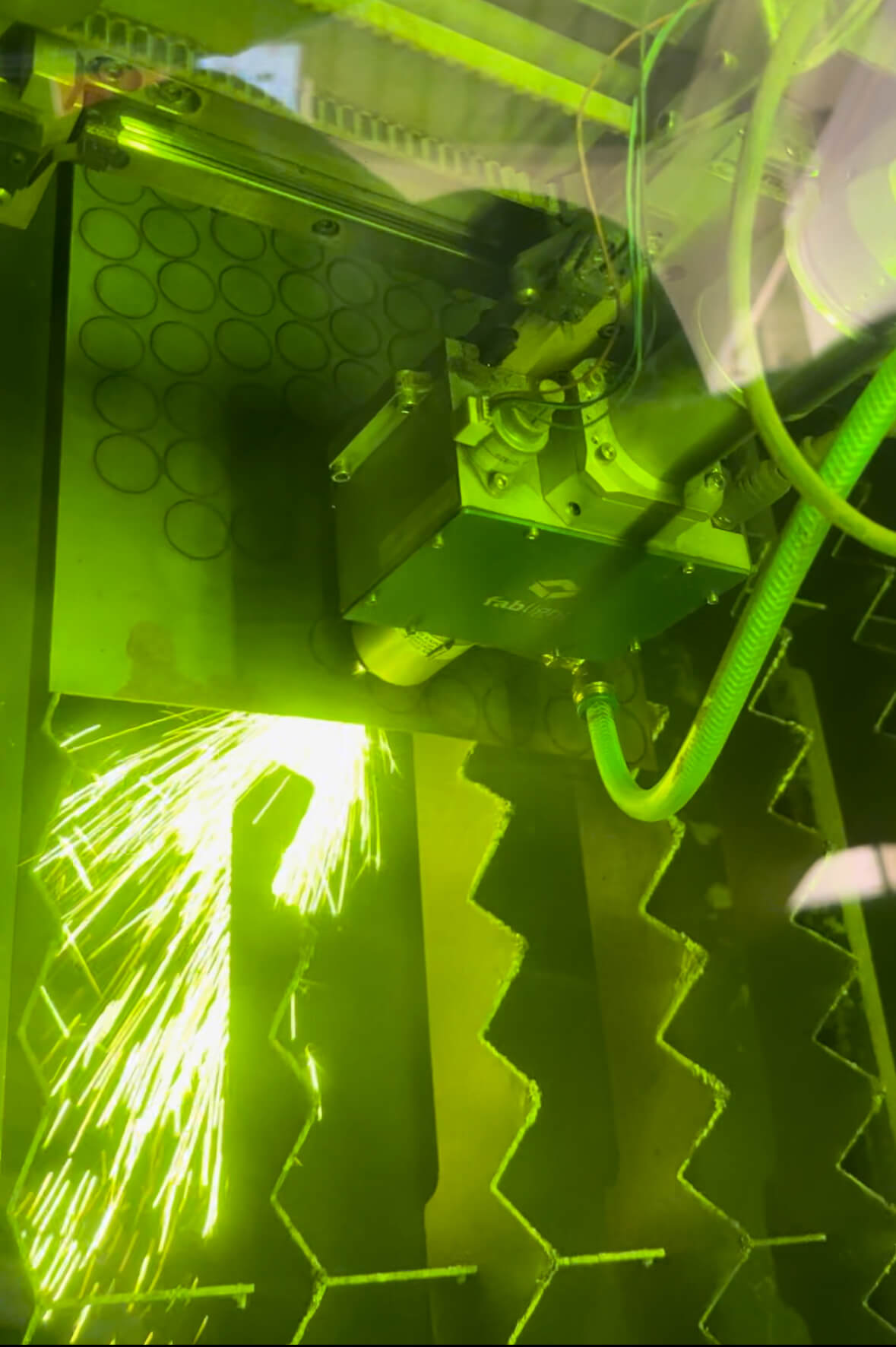

Awen had never used the FabLight cutter by herself before either, so it was an adventure for the both of us. First, we prepared the file. The program takes .dxf files, and you just need to reorder the cuts such that the inner cuts get done before the outside one. This is because when you cut an object's outer layer, it might move, and any inner cuts you would need to make after might not be in the right place. We then measured the material thickness and inputted that on the computer. We were using 0.03" Steel CRS. Then, I cleaned the sheet with IPA and was surprised with how much came out.

We didn't clamp it before starting the laser-cutter. This resulted in a lot of spray:

This was not the only mistake we made. We did not add tabs because we did not know that we were supposed to tab everything. So, one of the weights fell through the cracks as soon as it was cut. So, we decided to restart, "for real this time". We tabbed everything, clamped the sheet down, and even put a weight on the other side. It worked great! I used a mallet and puncher to remove all the pieces.

Next, we needed to print as many blocks as we could. I tried squeezing 12 blocks onto one plate, but around halfway through the print, PLA stopped coming out of the nozzle. It didn't run out of filament, but the filament was kind of tangled in the spool. What a waste :(

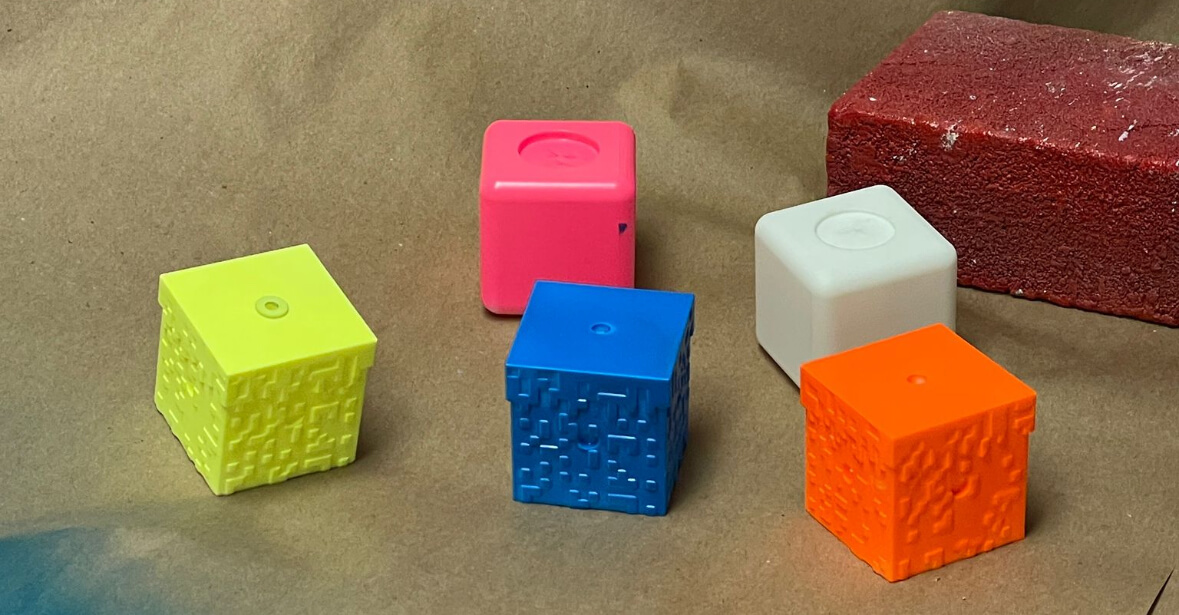

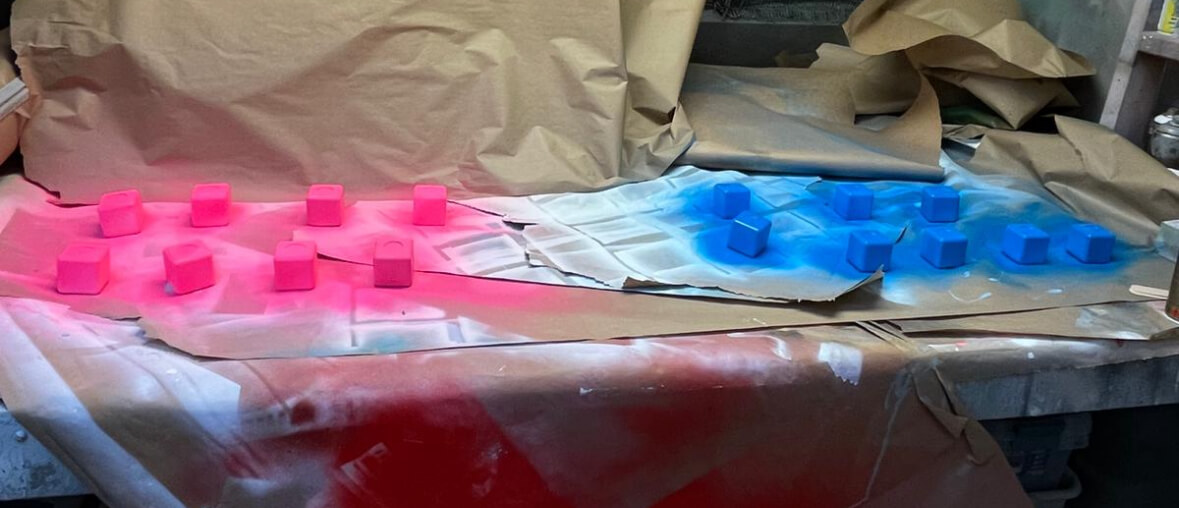

I sent another 12 to print, and those worked! While I was there, I also printed Jana's frame prints. After that came the most fun part: spray painting! We tested a few fluorescent colors, and settled on pink and blue. Our team split up the painting, and each of us would continue where the other left off.

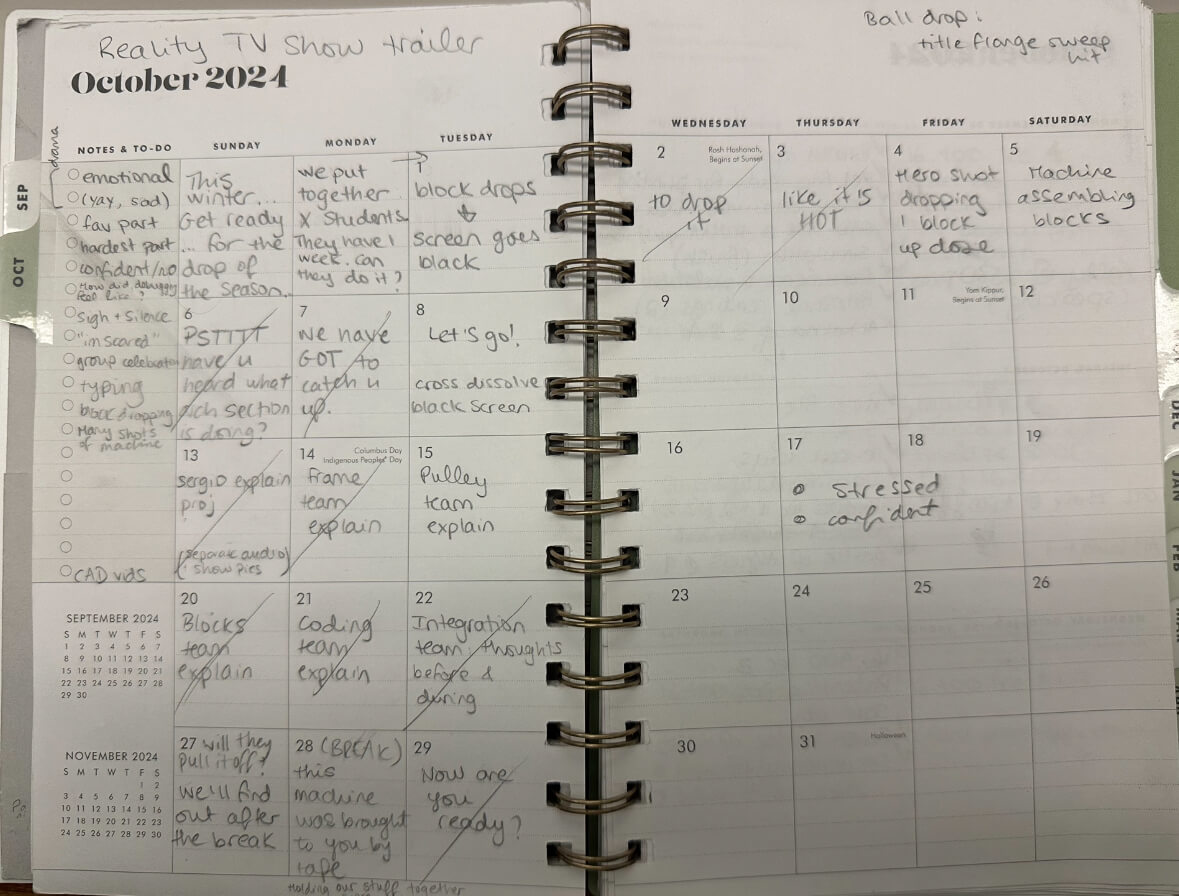

I also helped Sergio metal cut! After cutting with Awen, I felt comfortable using the laser-cutter alone. It went well! After that, my role became just to support the rest of the teams. That is, until I volunteered to make the video. I spent more than 12 hours on it on Tuesday, and if not for Javier's help, it would have taken even longer. I started by planning a general outline for the video to figure out what shots we needed to get.

The idea was to have the video be somewhat like a reality TV show, with the interviews where characters share candid thoughts to the camera. Javier and I took our teammates one by one and asked them some questions. We got some great answers! I had to delete a lot because the video would have been way too long, but I wish I could show you everything. I just used iMovie, and was very impressed with what we could do with such a simple program.

You can find the video on our group site here!