Final Project Tracker PLEASE COME BACK TO ME LATER

Prototyping

I want to make a pair of moveable wings for MIT’s Infinite Gala!

I plan to 3D print the appendages of the wings, with Sirvo motors attached for movement.

Using a joystick, the user would be able to control the movement.

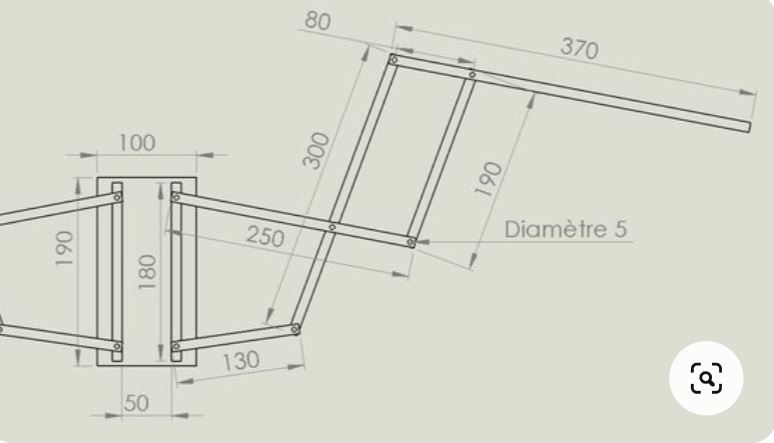

From BlackOwlStudio, I found a prototype for a wing design that I want to start off testing.

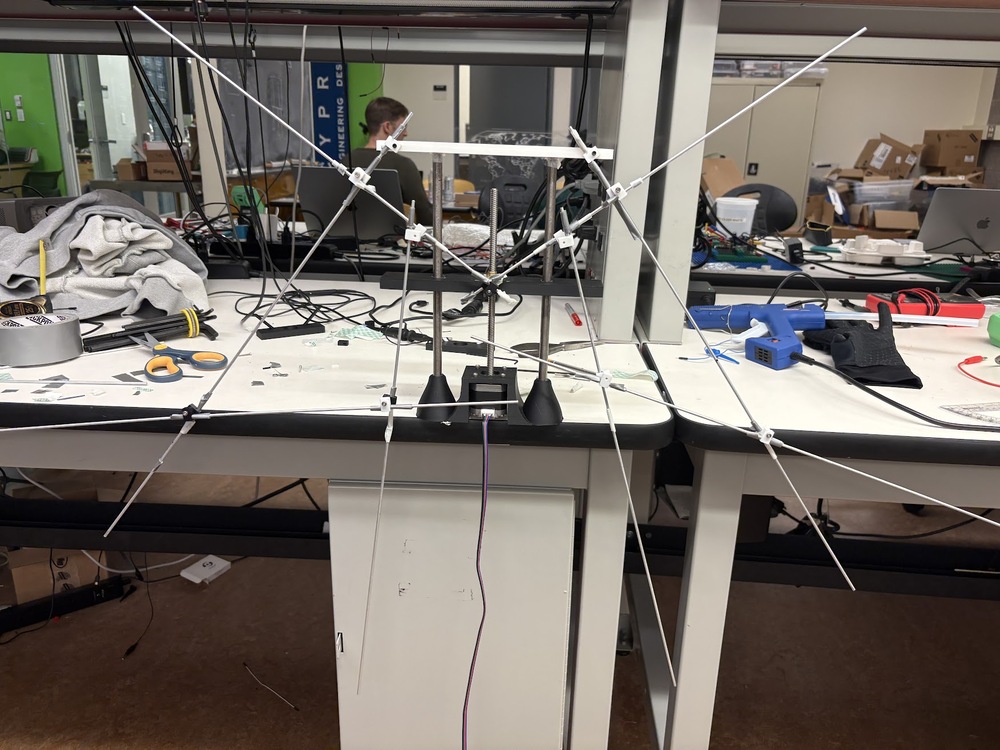

I laser-cut out cardboard pieces to test movement and used wires to connect it together.

I ended up modifying the design so that it only needs one form of motion (linearly up)

The movement was pretty good! It’s not reliably symmetrical on both sides, and doesn’t hold itself up, but it’s a good start.

Linear Actuator Development

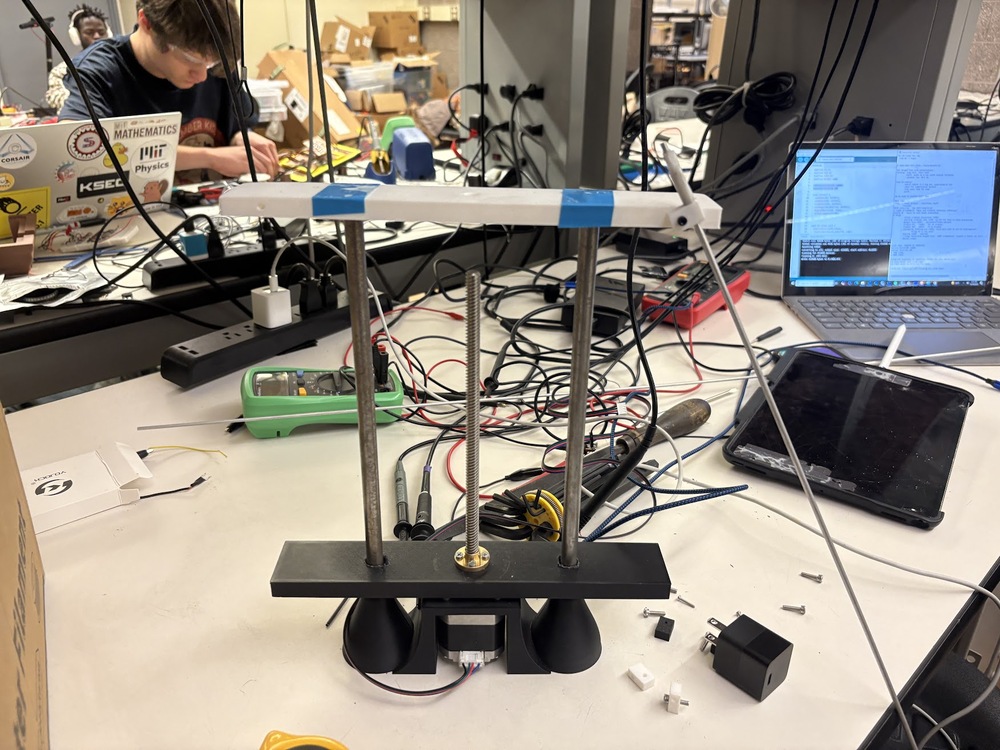

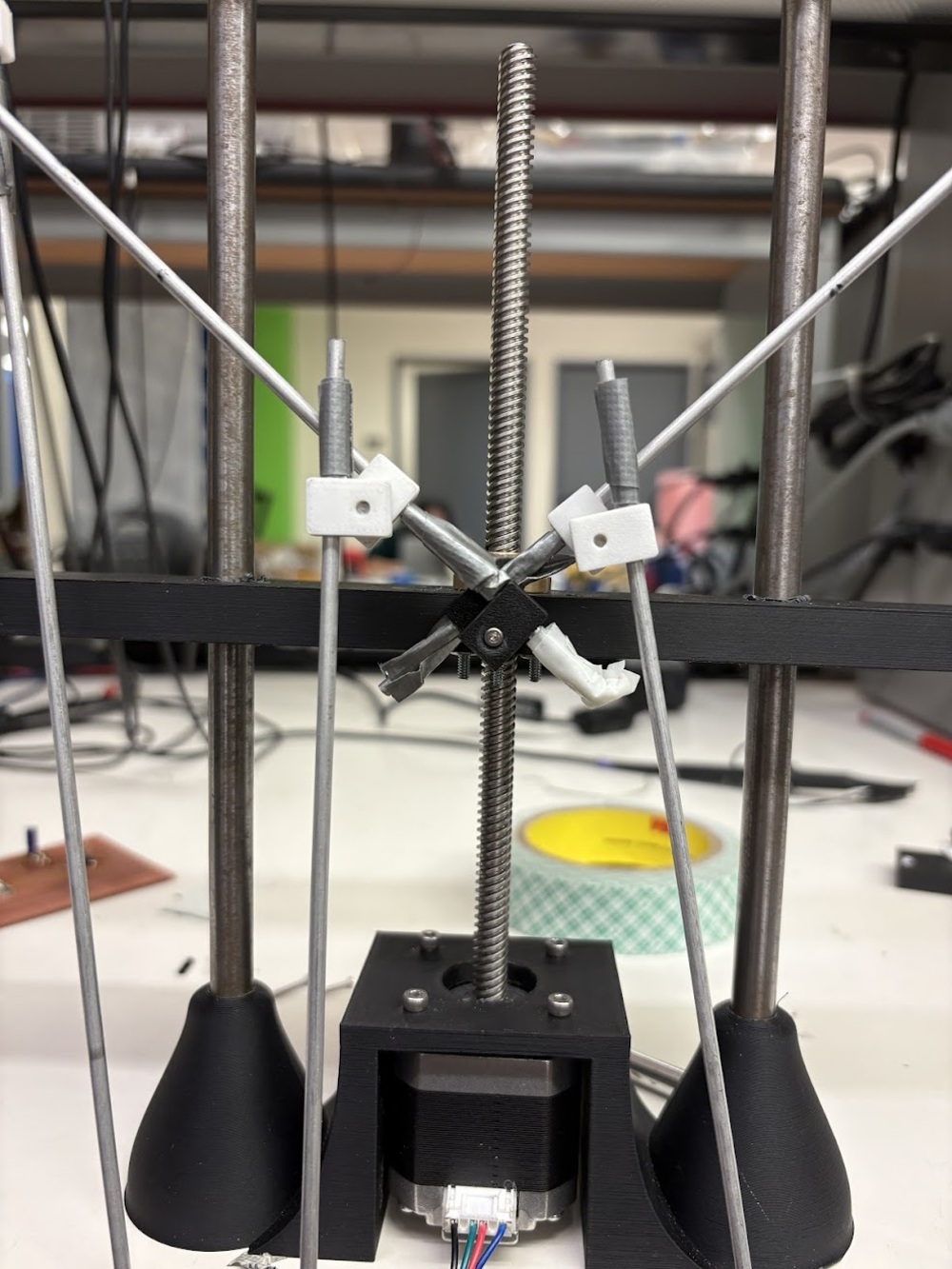

Knowing that I need just one form of motion, I went ahead and designed a linear actuator.

Electronics of Linear Actuator using Stepper

Essentially, the stepper holds a long rod with a brass piece that can rotate and “climb” up the rod.

However, on its own, gravity just causes the piece to swivel down, as shown by the video above.

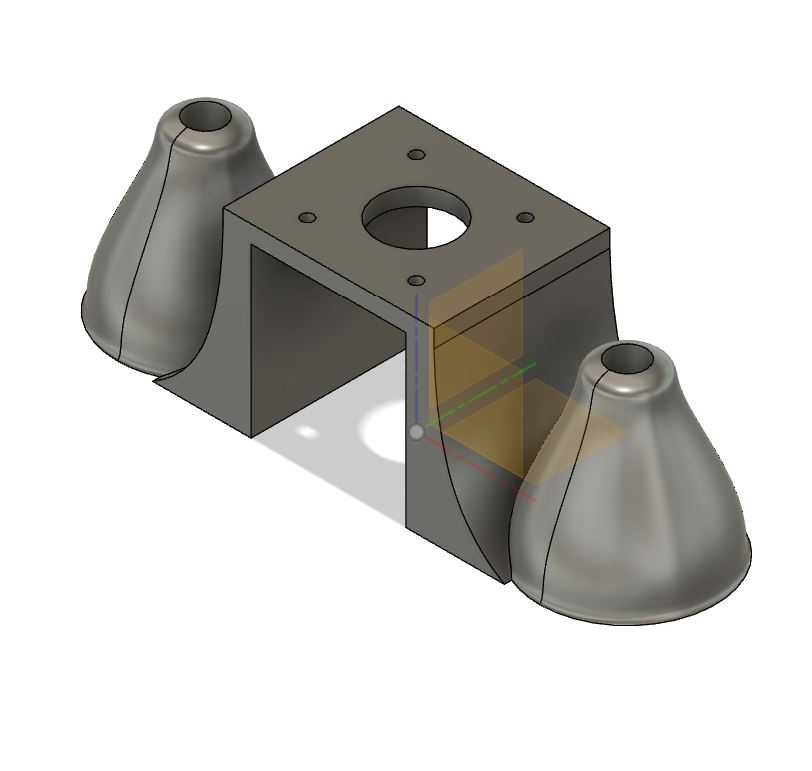

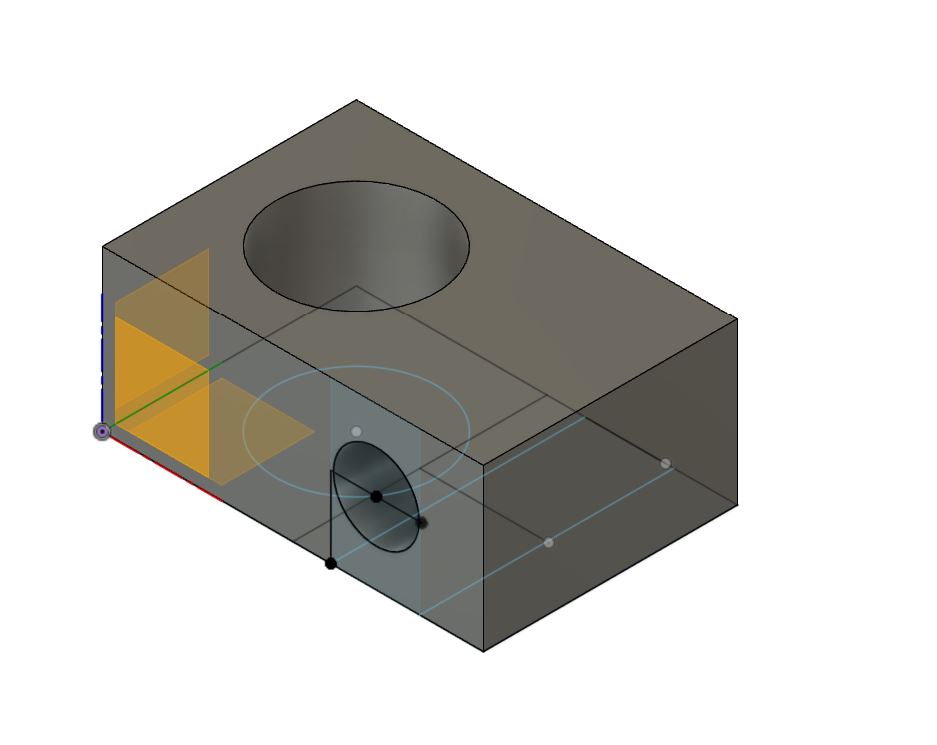

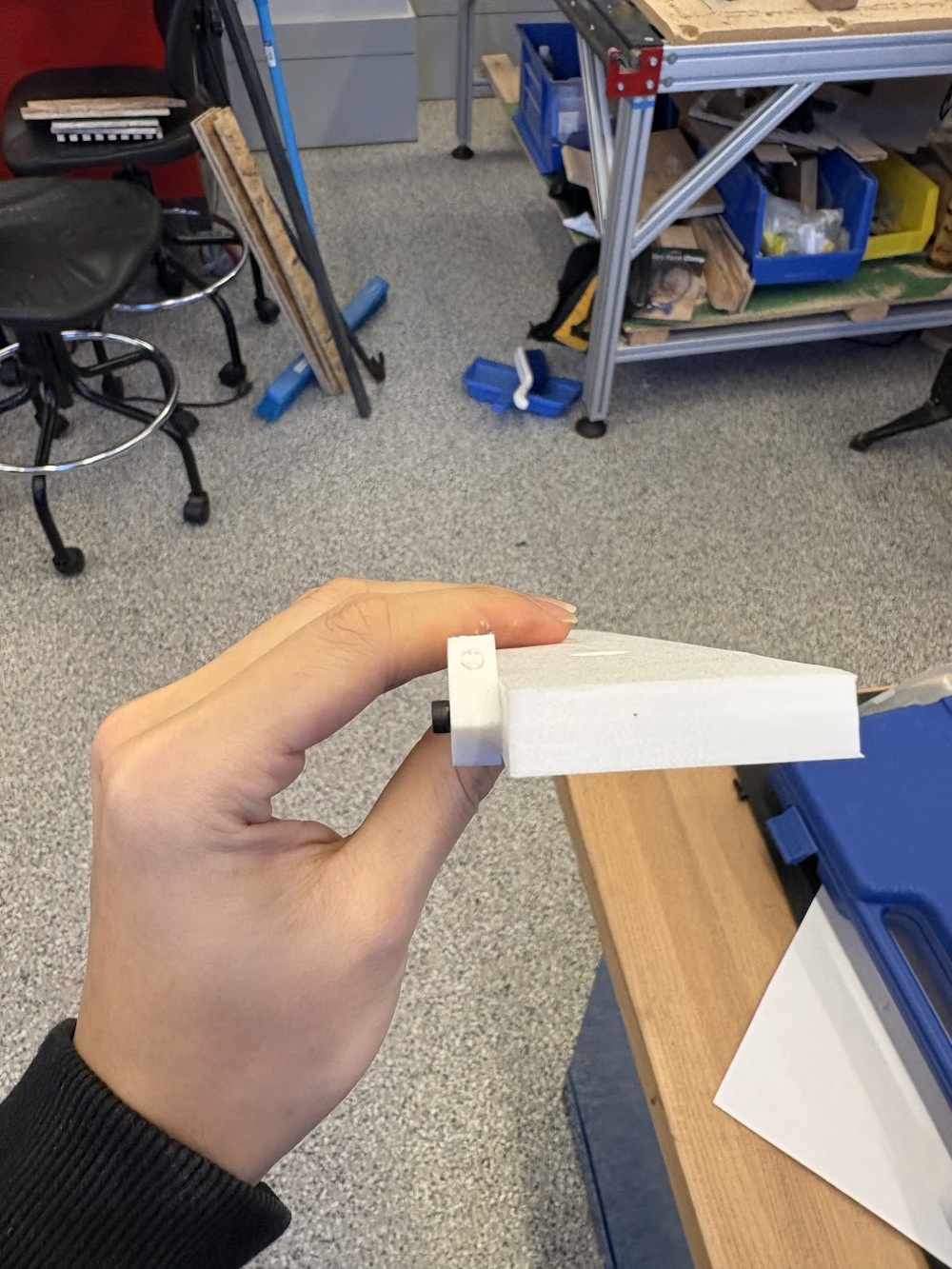

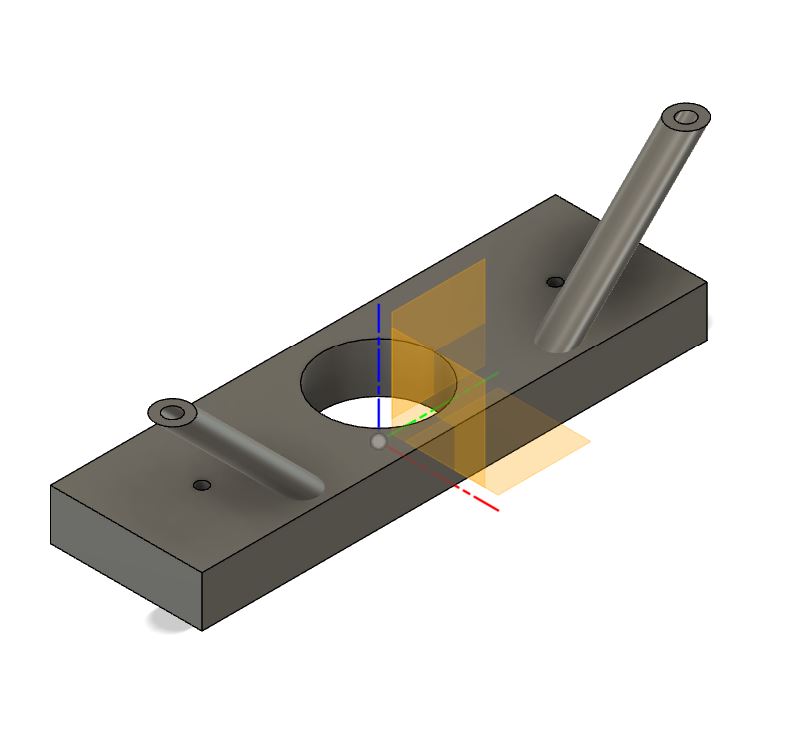

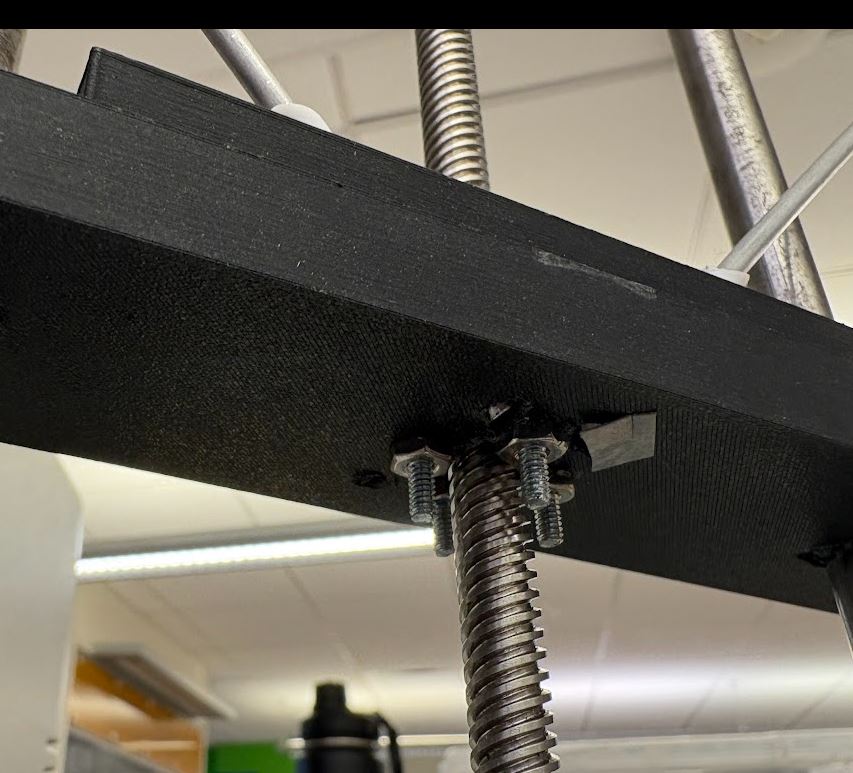

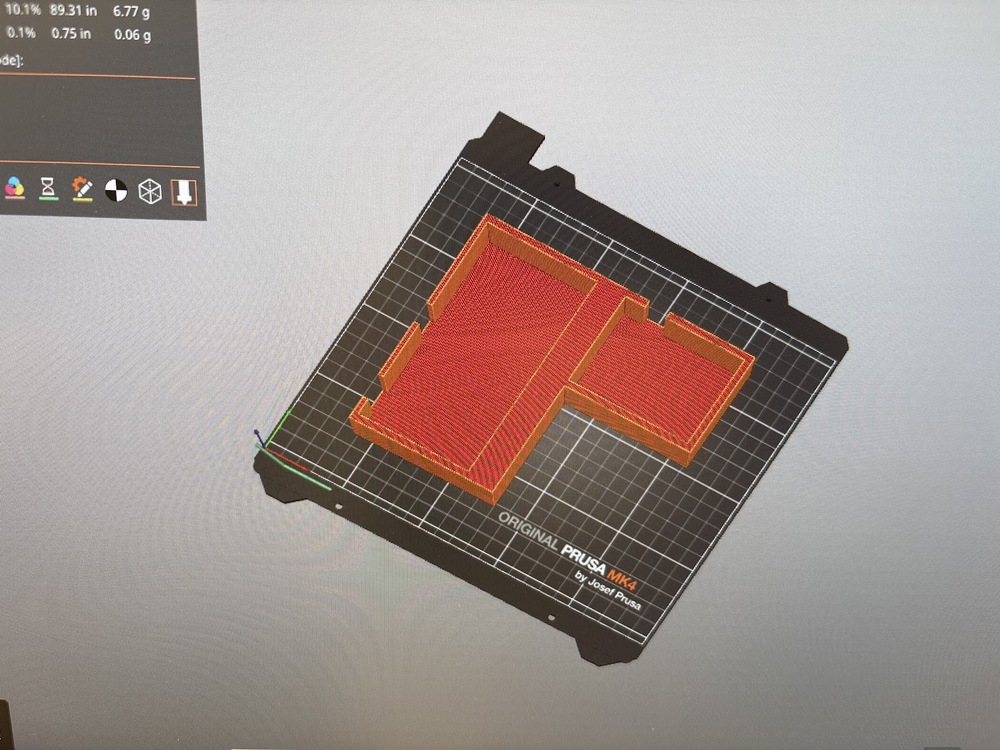

To fix this, I made a 3D printed part that has holes for the brass piece to screw into, and two other holes where I’ll fix metal rods.

The metal rods will limit rotational movement, forcing it to climb vertically up and down.

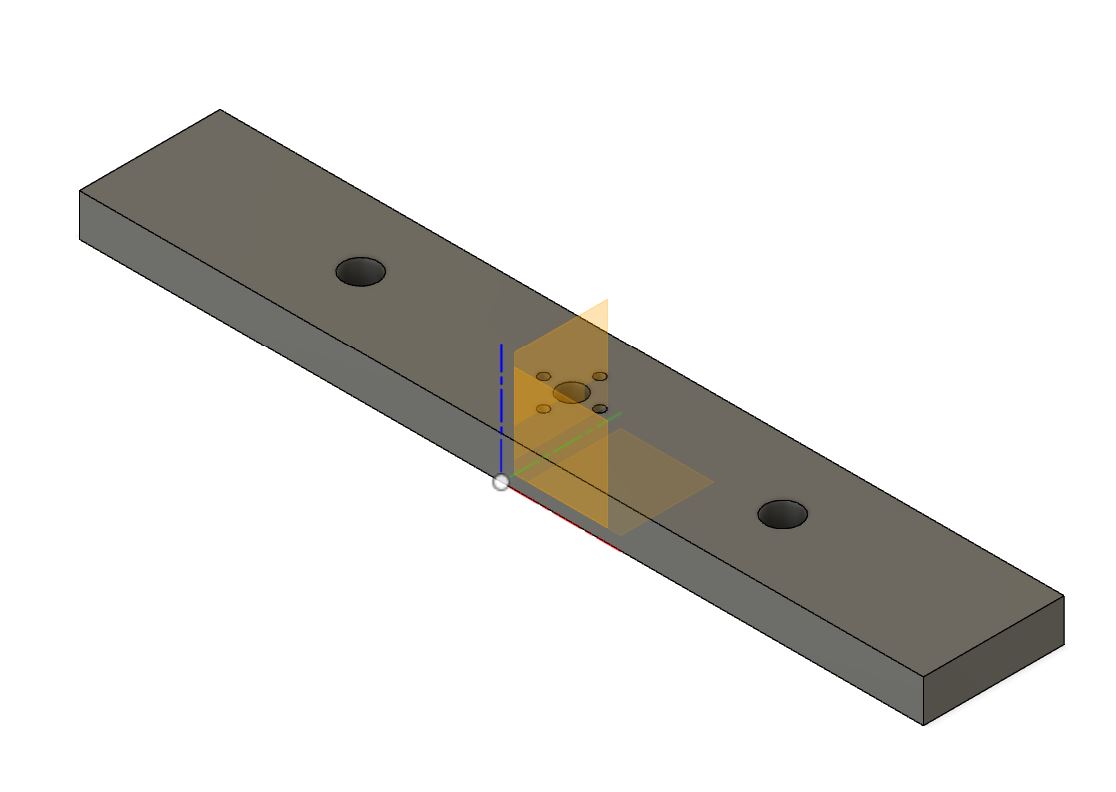

I then designed some more parts to hold the entire system of rods in place.

With everything coming together, I turned a stepper into a linear actuator!

Electronics and Networks

Input devices week, I used an accelorometer, and output devices week, I drove a stepper for the actuation movement. Why not combine the both?

Accelerometer Electronics

Stepper Motor Electronics

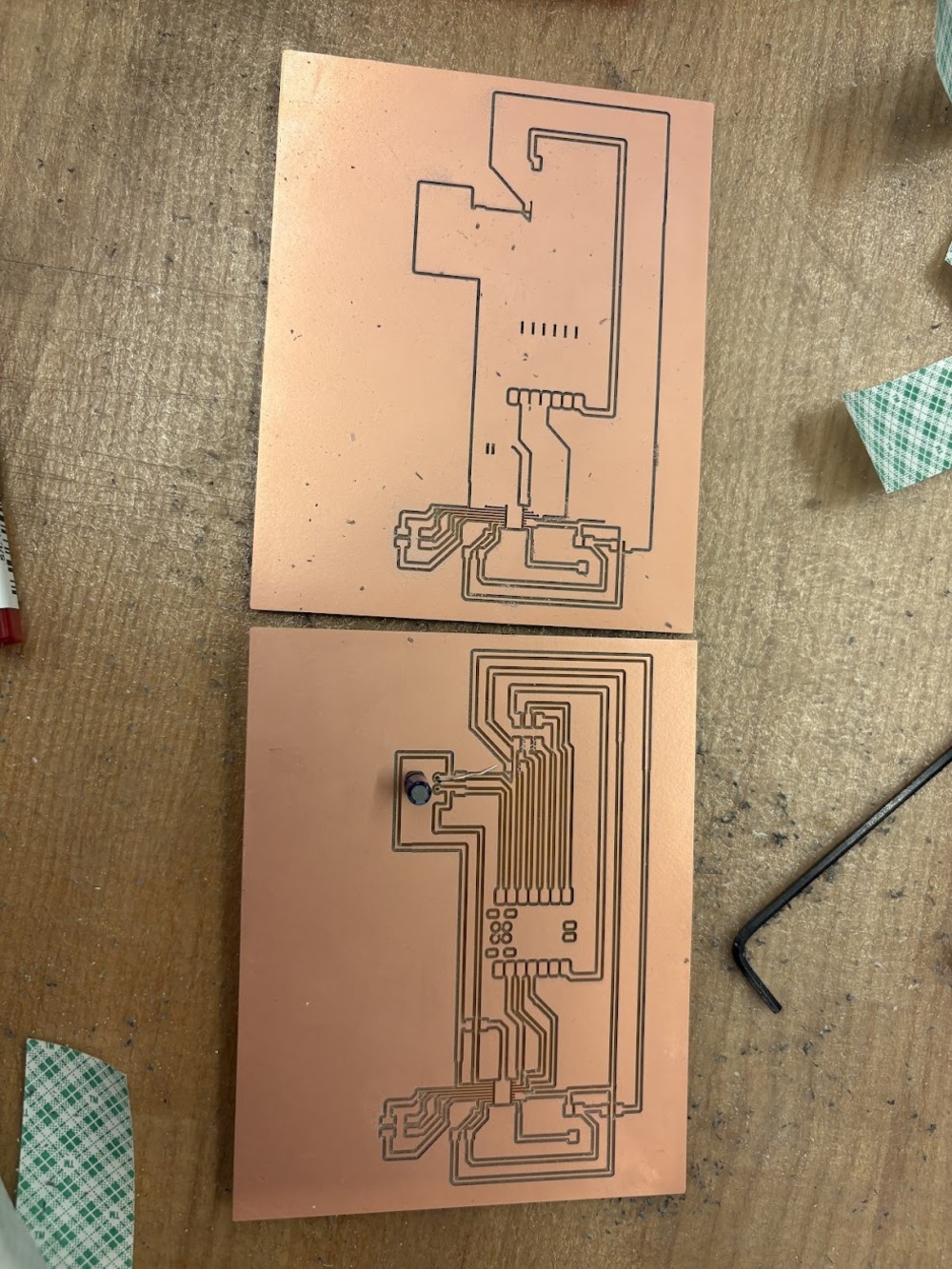

Due to traces being ripped off, I decided to isolate the two onto different boards and use SPI connections to communicate.

Networking between the two

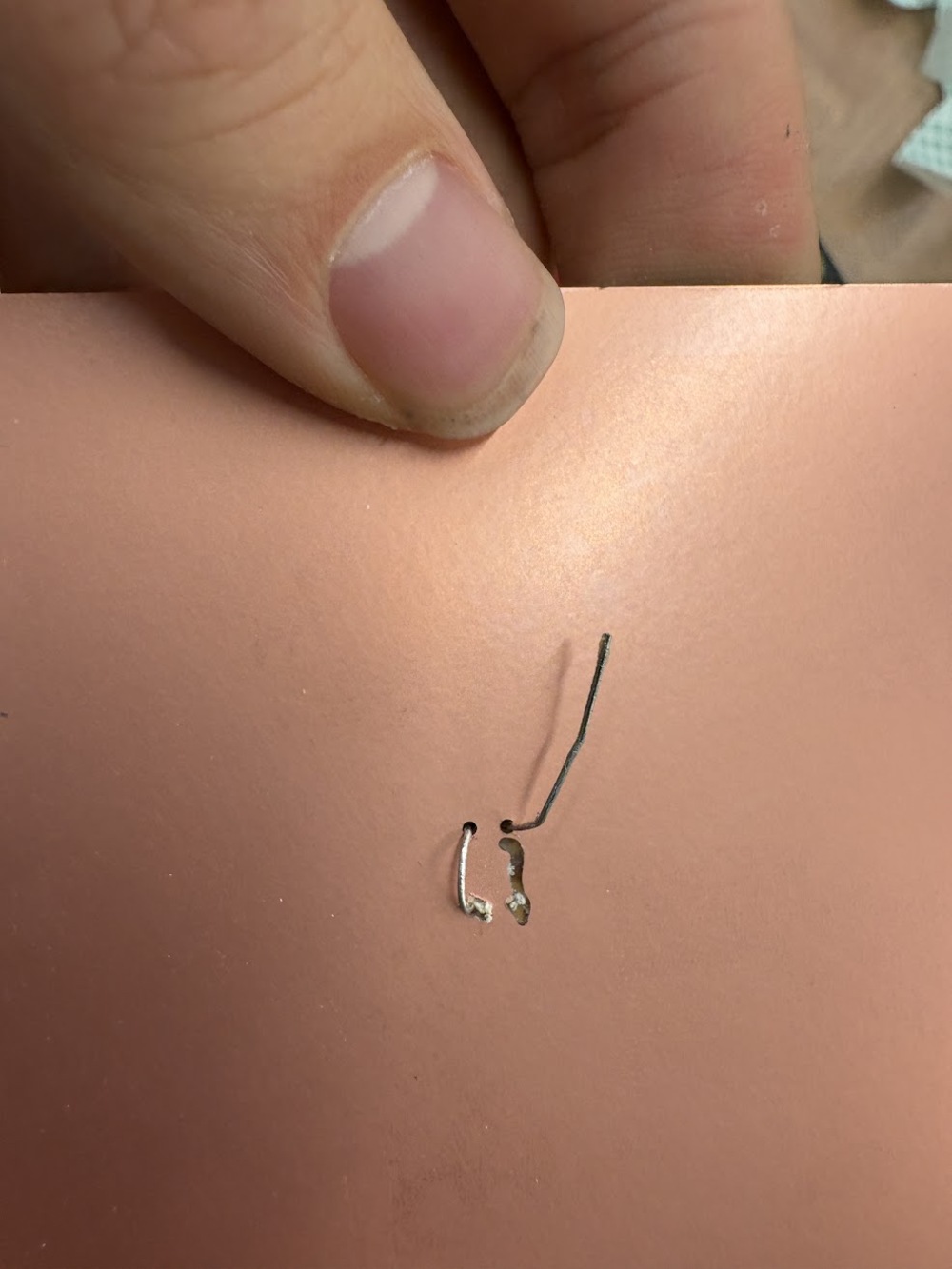

One of the biggest reasons for traces being ripped off is the 100 microFarad capacitor, which is not surface mountable. I had a makeshift solution of directly soldering the leads onto the board, but Alec told me a better way to do so is using througholes and a double sided board.

This took a couple tries to get right.

The second one was so close to being good. On the back side, I didn’t tape it down well enough, causing the mill to go crazy.

All the integrated electronics together can be seen in my networking week page.

Assembly/System Integration

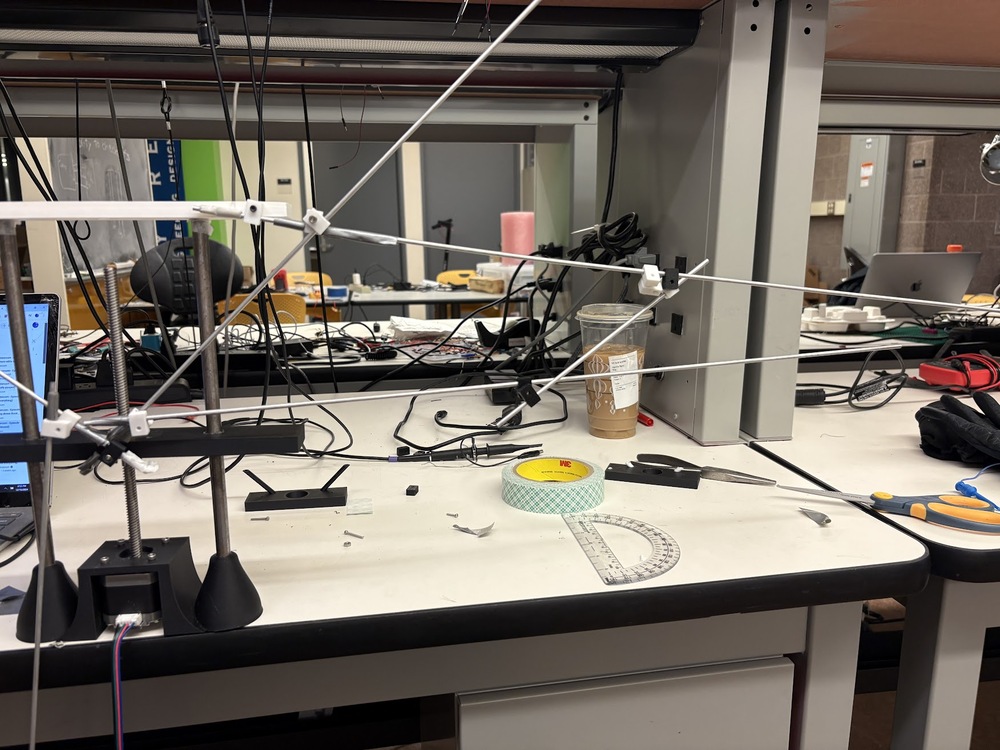

Now for the main part of the project: actually building the wings themselves.

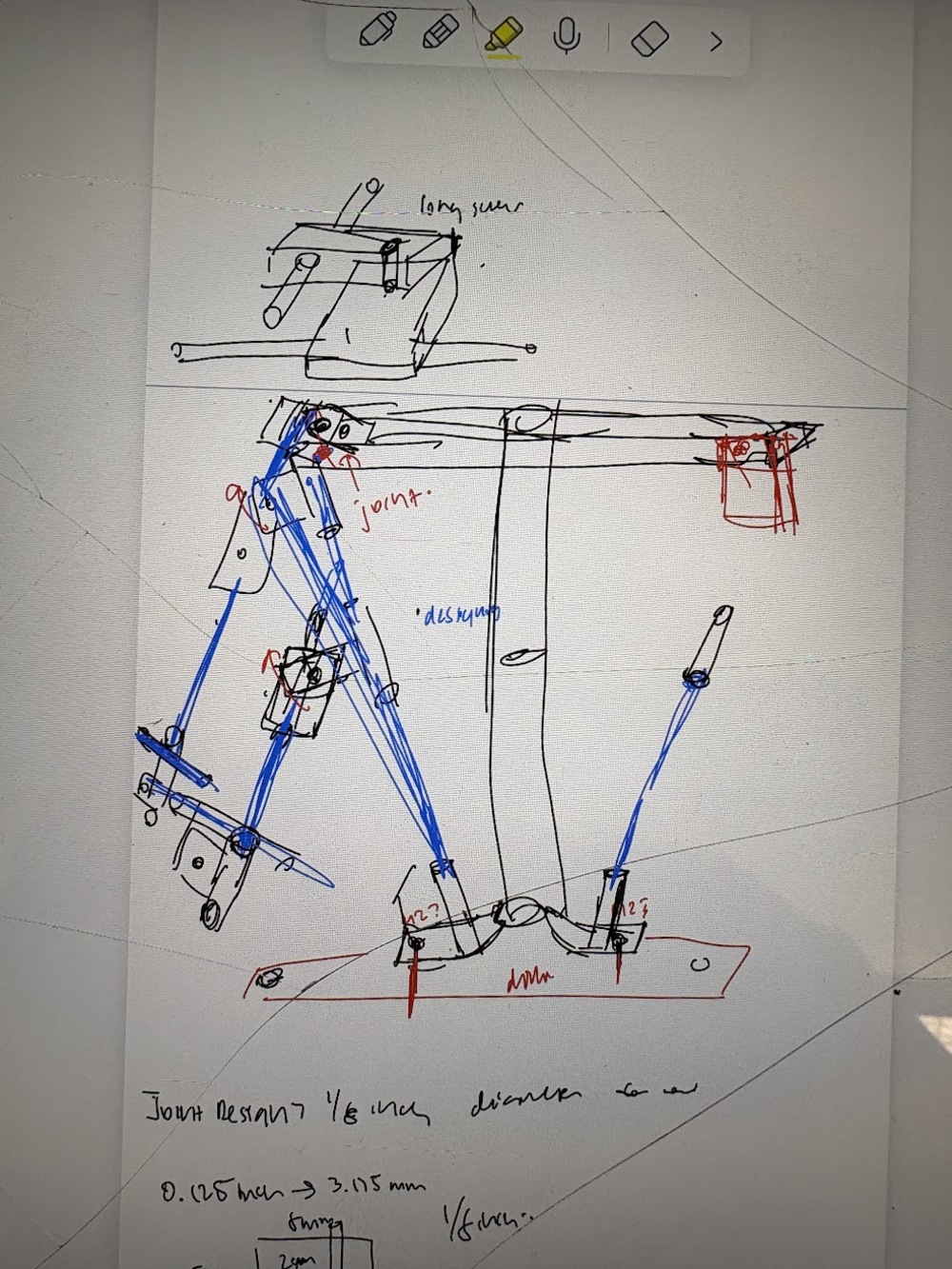

I didn’t like the look of cardboard, and wanted my wings to be a bit more life-like, so I went with thin 1/8 inch diameter aluminum metal rods, hoping they’d look like bird bones.

They were the perfect material, since they were strong but not too rigid, and very light.

I designed a similar wing design to the cardboard one earlier, except one that would allow for thin rods.

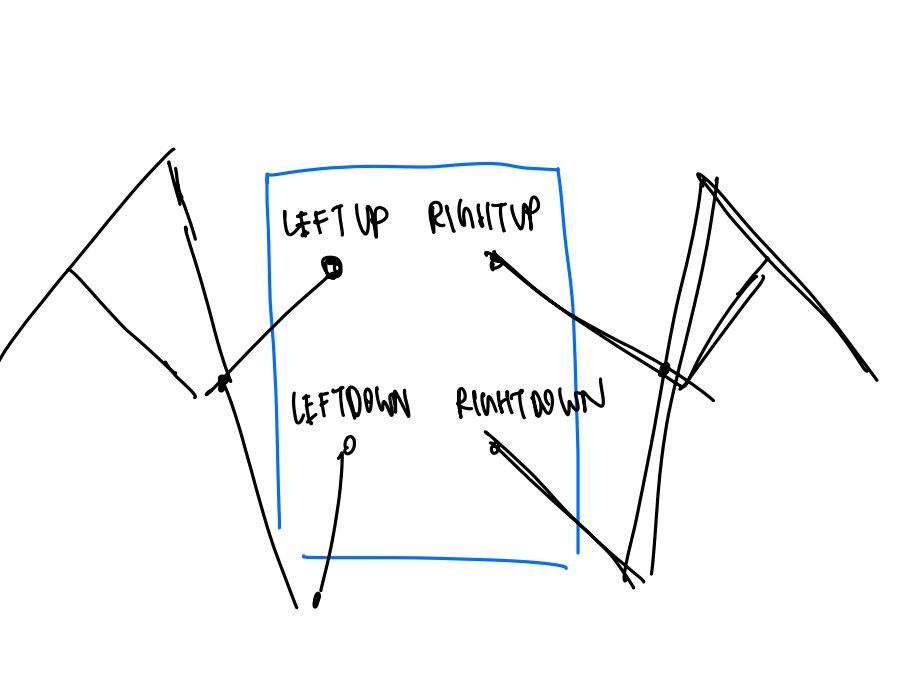

Essentially, the upwards motion by the actuator pushes the main joints affixed to the top.

That joint can rotate, so the upward motion causes it to rotate upwards. This brings up the rod, which pulls everything attached to it upwards.

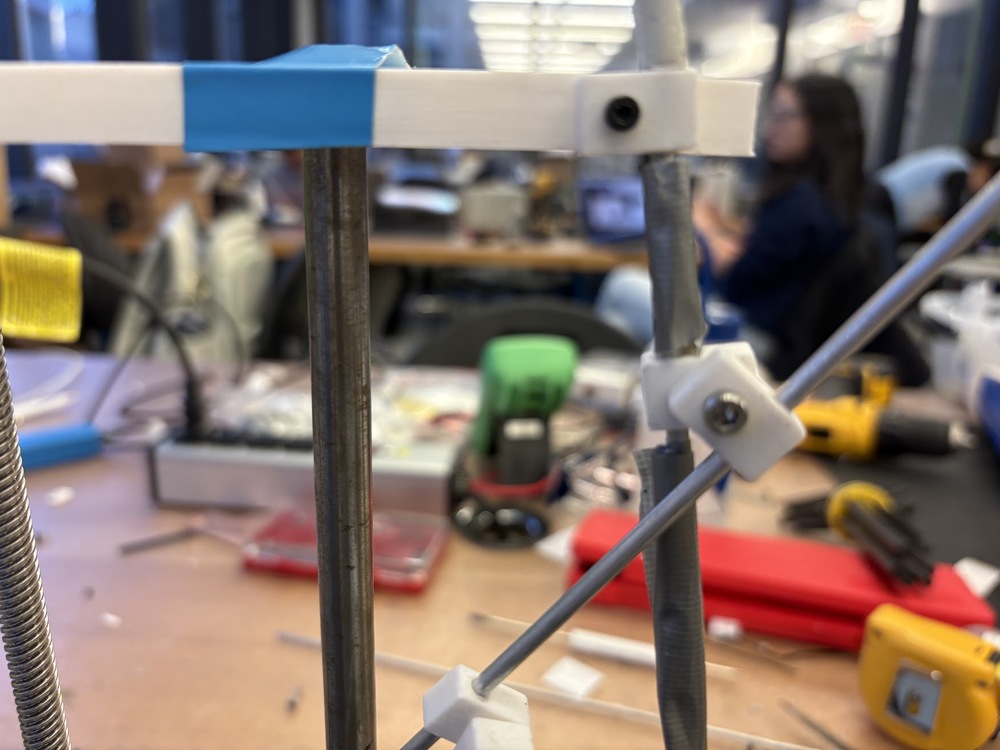

I designed and 3D printed my joints such that they’d be held together by a M-3 screw, with a loose fit to allow for rotation. The joints would have througholes where the rods would go in.

They fit nicely into the base, and rotated quite easily! Here’s a video of me testing the movement.

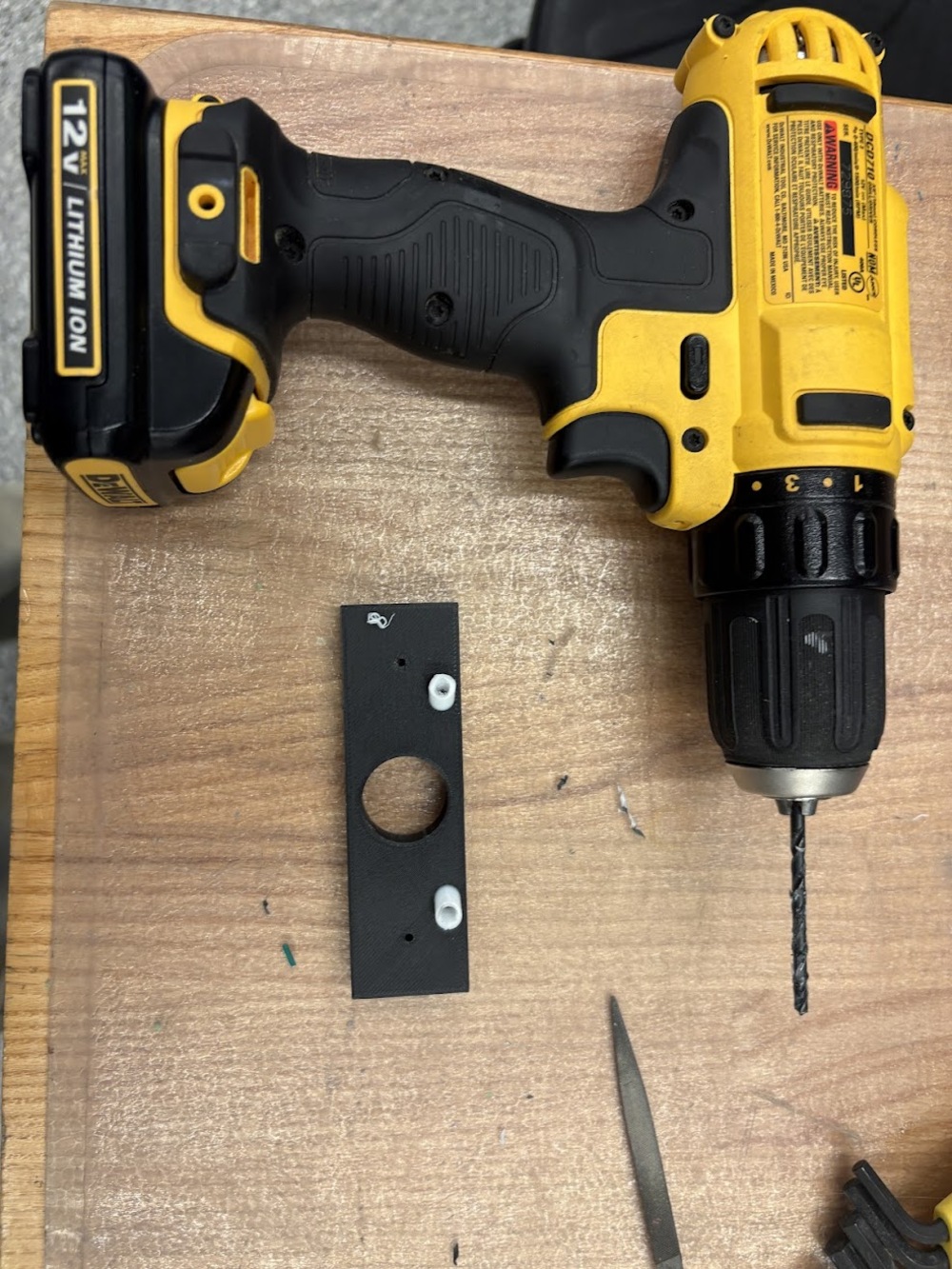

Now I had to affix rods connected to the linear actuator that will push the joints upwards. I designed this piece that fits ontop of the moving base, while affixing the rods in place.

I then drilled through the moving base, and fixed the rods in place.

Using the motor, the movement worked pretty well! The motor gets very loud, due to loose joints making things become speakers, and high power output.

Turning the pot that controls current helped a lot in reducing noise.

Here’s where things started to go wrong.

My rods were sliding along the joints, causing them to fall out. I wrapped tape around the rod to restrict their movement, preventing sliding.

However, this also lead to jamming, as seen in the video below, where the motor just can’t push the rods up.

I experimented with a bunch of different fixes, such as removing tape and making the holes smaller, but none worked.

After brainstorming with Sam, we tried changing the way my rods were affixed to the moving plate. By having them connected together at a singular point, the movement became a lot smoother.

Some pretty good movement here!

Thank you Sam so much for helping me figure out the joint jamming! I was stuck on it for so long, and he identified the central joints that had to be taped donw, which smoothened the movement a lot.

Some timelapses of assembly!

Assembly took soooooo long. 48 hours straight of fiddling with the rods.. measuring.. cutting. The more joints I added, the more complicated the force-body diagram of this thing became.

Tape became my saving grace. With so many different joints, there were many ways for the rods to move in the wrong direction. By constraining some degrees of freedom, we were able to force the rods to move cohesively.

However, this required a lot… A LOT of tape. And fiddling.

With all the rods in, I had to now deal with things being asymmetrical. Some joints were tighter than others, causing the left and the right half to move asymmetrically.

By playing around with where the joints are placed, I managed to get a semi-symmetrical looking structure.

Integrating with my electronics:

With a couple hours until the final, I quickly CAD’ed up a case for the electronics. Using the nibbler, I had to cut my PCB to make them fit (I was sleep-deprived measuring…)

And now for the final presentation! My joints were looking veryyy asymmetrical, but some more pieces of tape reinforcement did the job.

Files:

All the electronics files are in the respective weeks pages.

3D print files:

3D Designs