MAKE SOMETHING BIG!!!

I’ve been really excited for this week, since my apartment is in dire need of a chair. Our living room just has 1 sofa for 4 people, so it’s often a tight squeeze.

Design

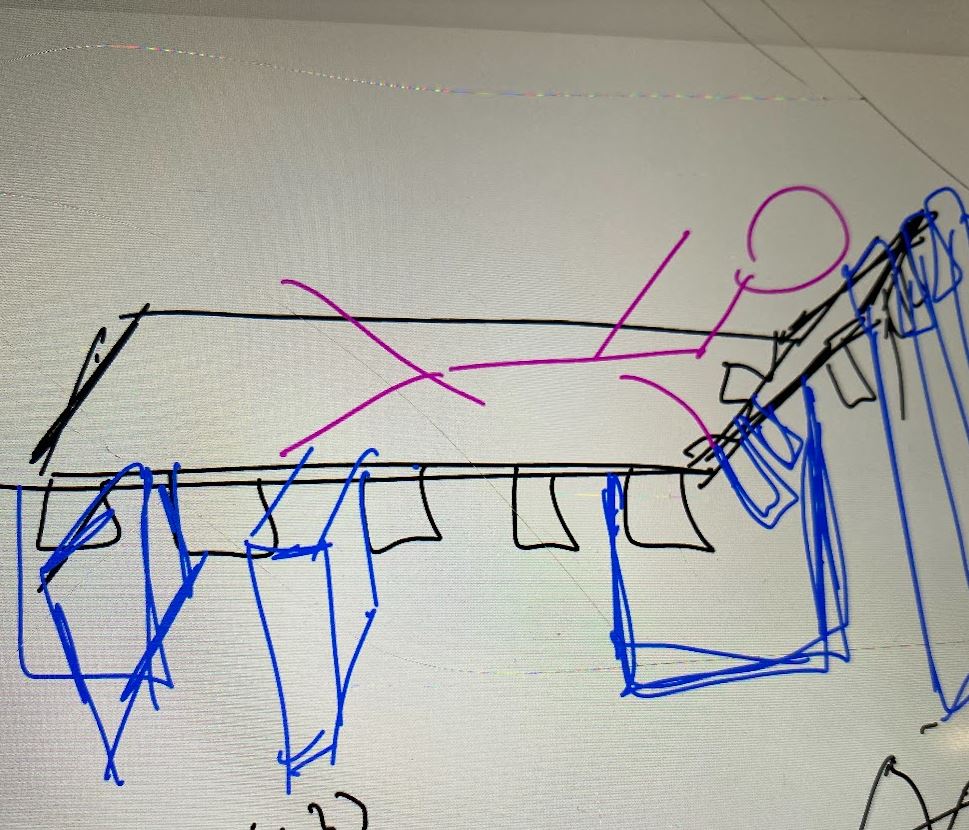

I wanted a lounge chair, so I first sketched it up.

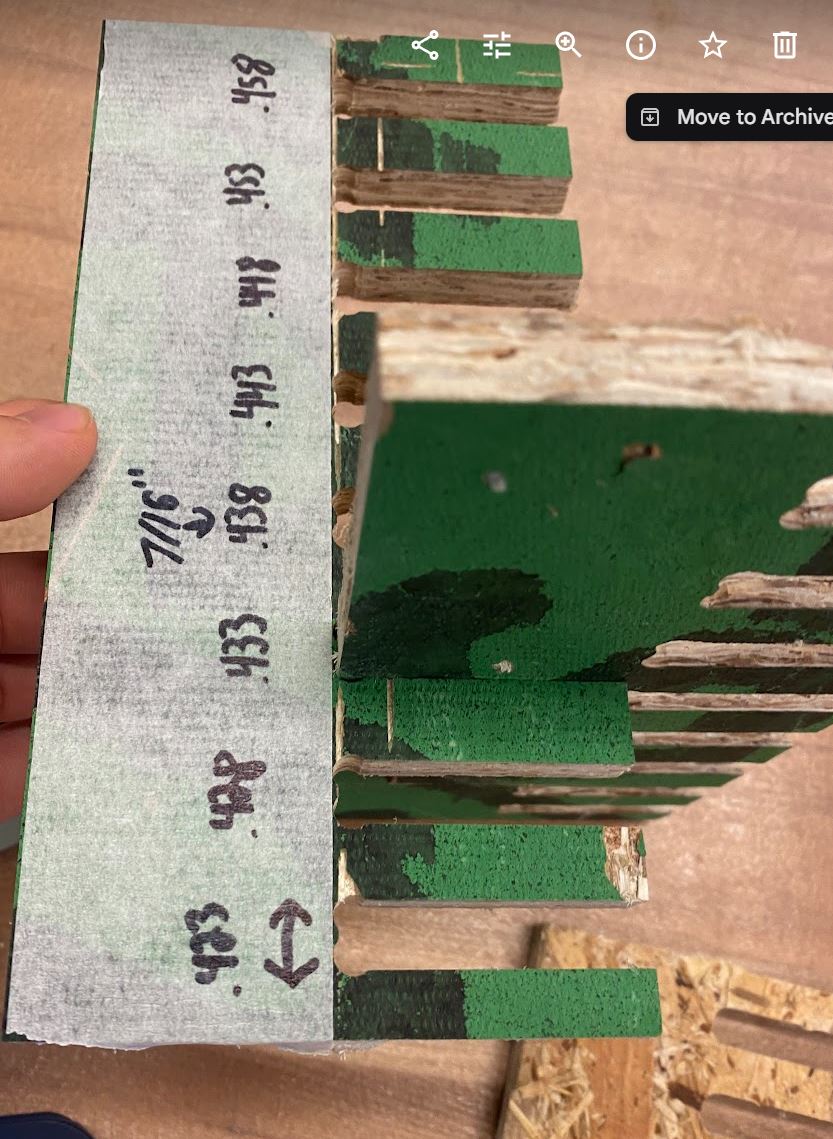

Anthony printed out these test joints, which helped me decide to use 0.433 inches as my gap width.

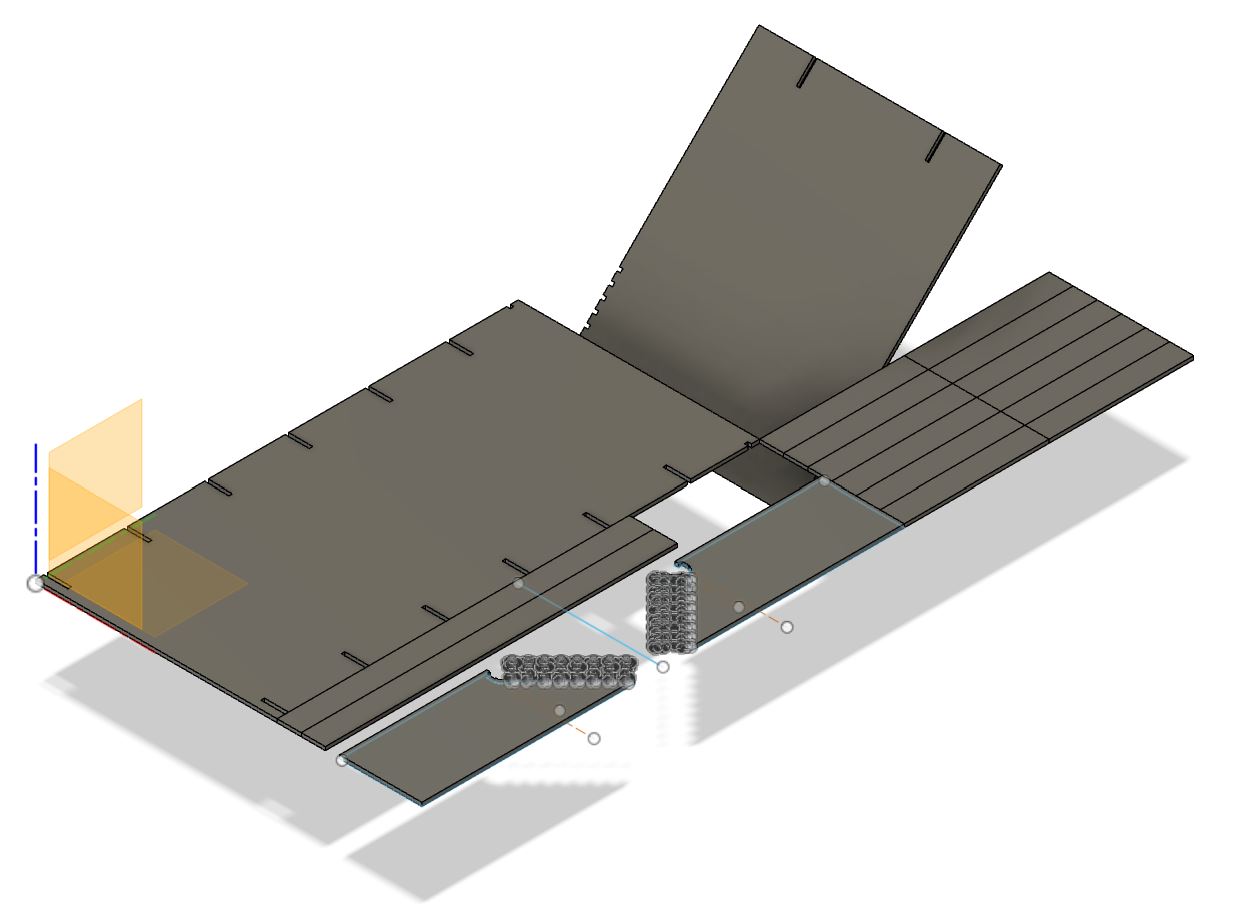

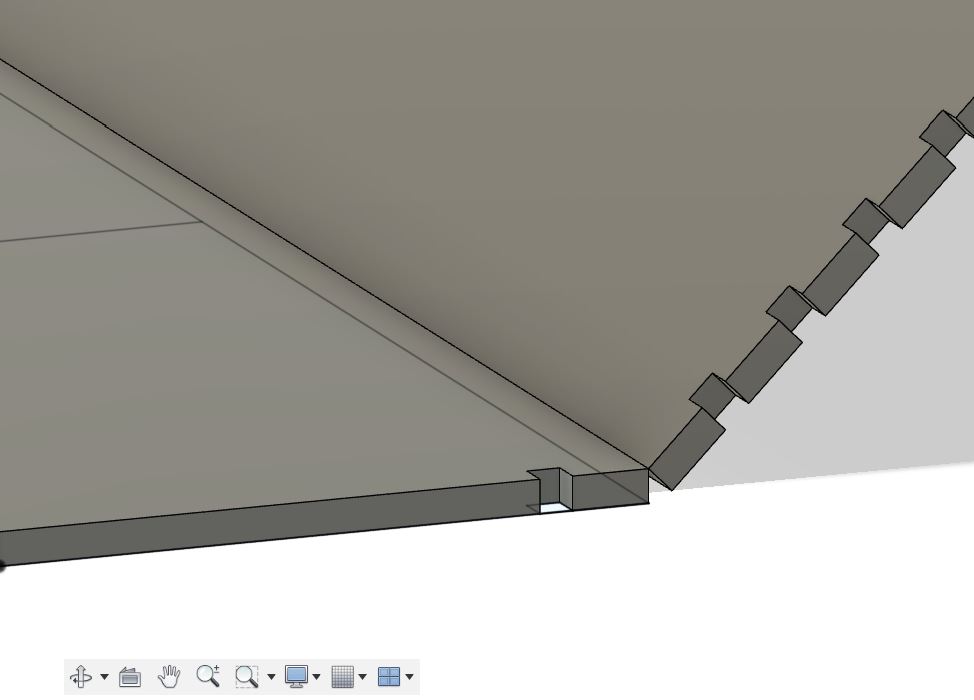

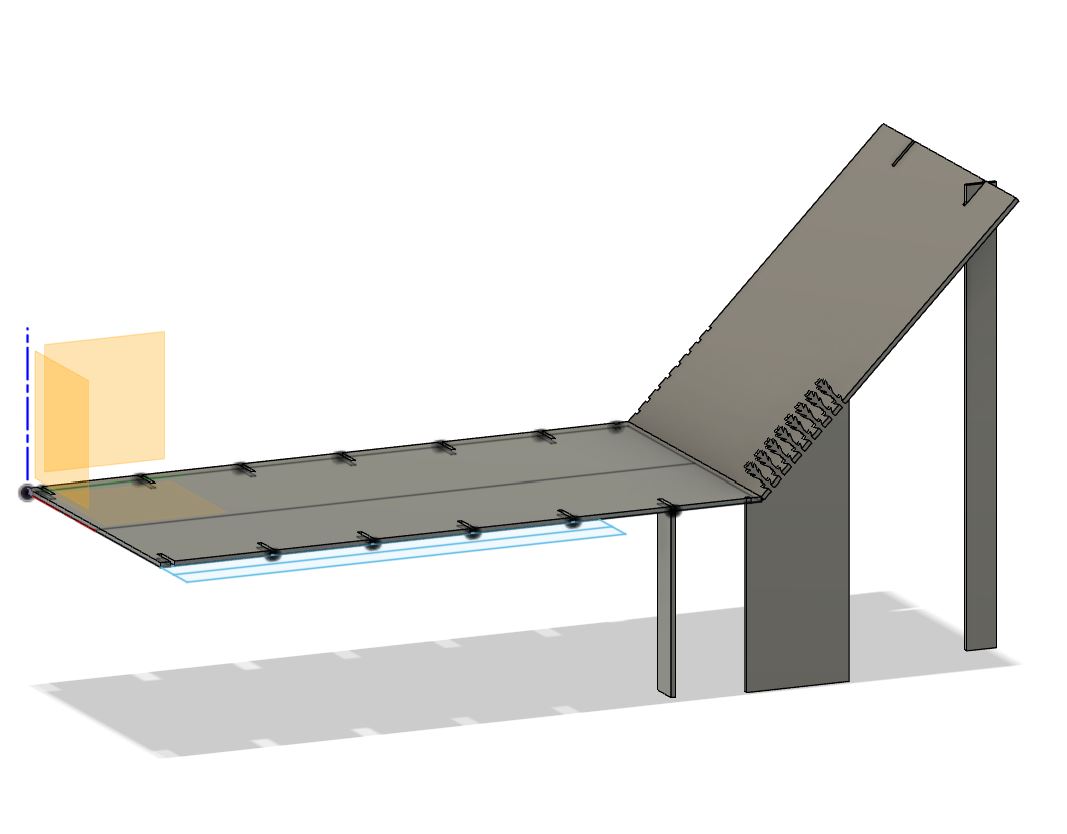

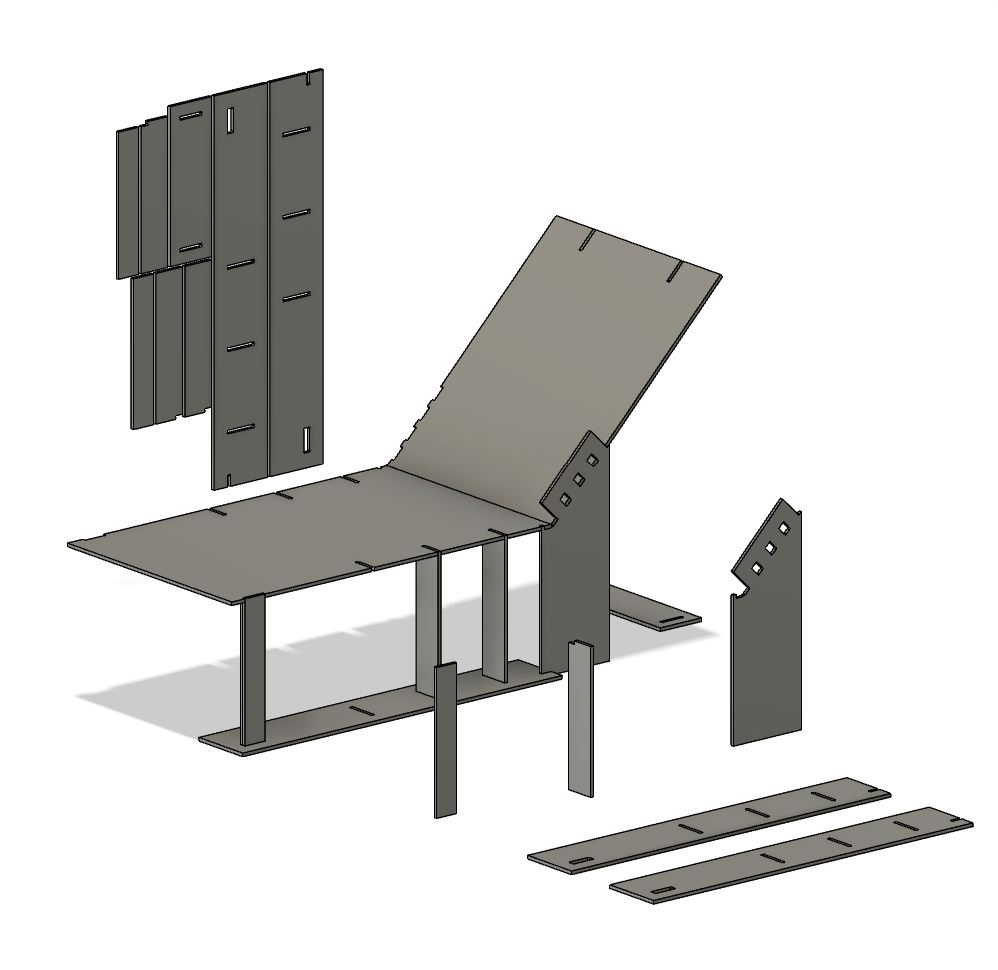

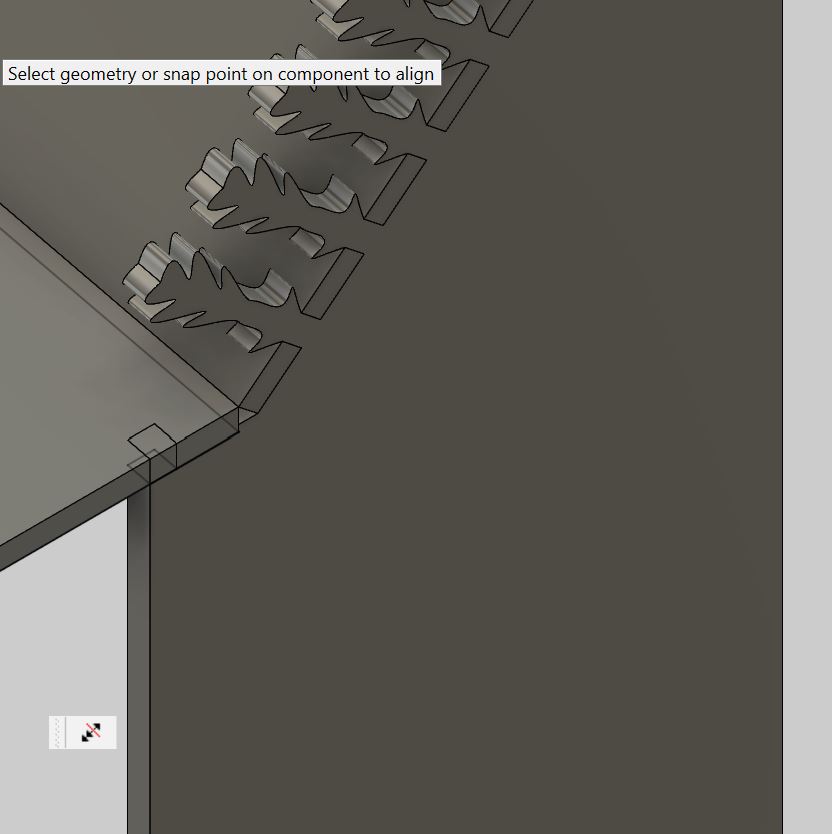

Upon CADing, I tried aligning the pieces together to see if everything fits together. Trying to figure out how to connect this diagonal facing seat back with the actual seat was difficult, due to the extra spacing created by the diagonal.

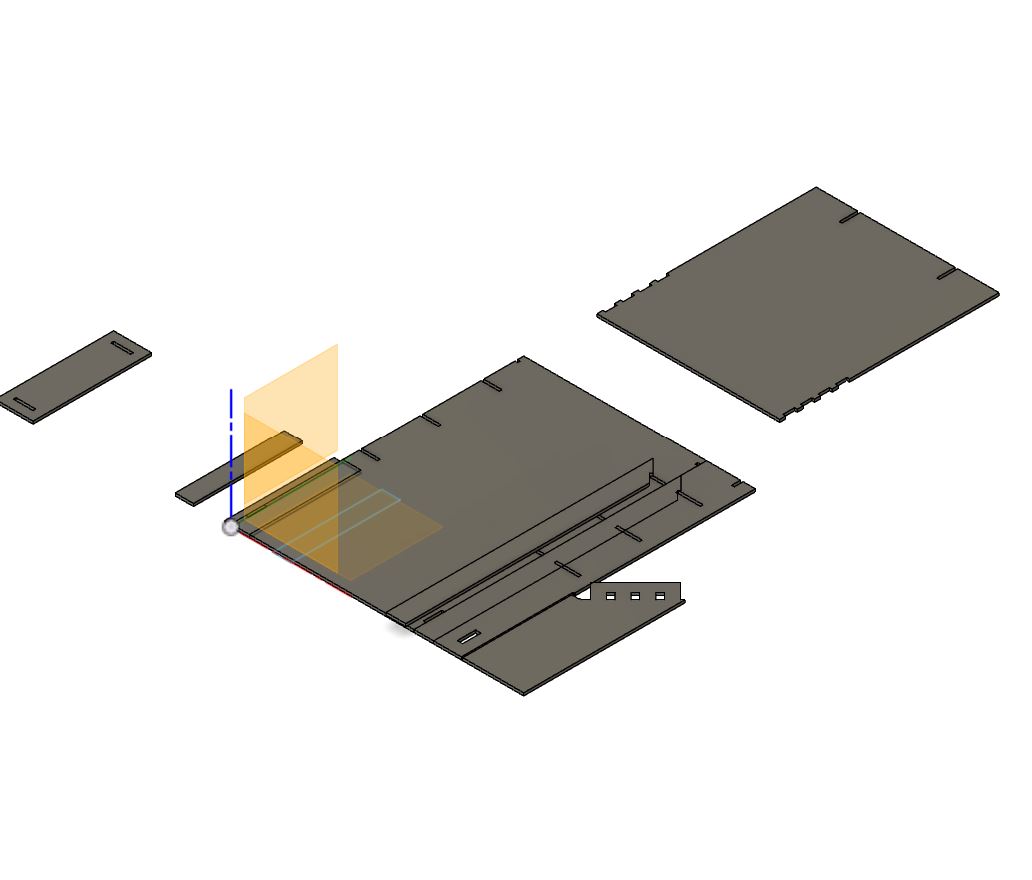

I then went into manufacturing mode, and created a manufacturing model where I could arrange my parts onto a … 4 x 8 foot sheet.

I completely forgot that the EECS shop only handles up to 4 x 4 sheets, and designed everything with 4 x 8 foot specs.

Fortunately, Anthony told me that there was still hope! The architecture shop could handle 4 x 8 sheets, so he gave me their contacts to see if I could go over to their studio.

UPDATE:

The architecture mill wasn’t doing so hot, so I redesigned my pieces to all fit within multiple 4x4 sheets. I also redesigned the chair to be more stable by adding a base for the legs, and removing the thin decorative arms.

CAM TIME!:

Anthony took the wheel on the CAM-side, but essentially:

Watch out for pieces that could fly off during milling, and fix them with small bridges to bigger parts.

Add dog bones to sharp corners, since a round tool can’t make a perfect 90 degree cut.

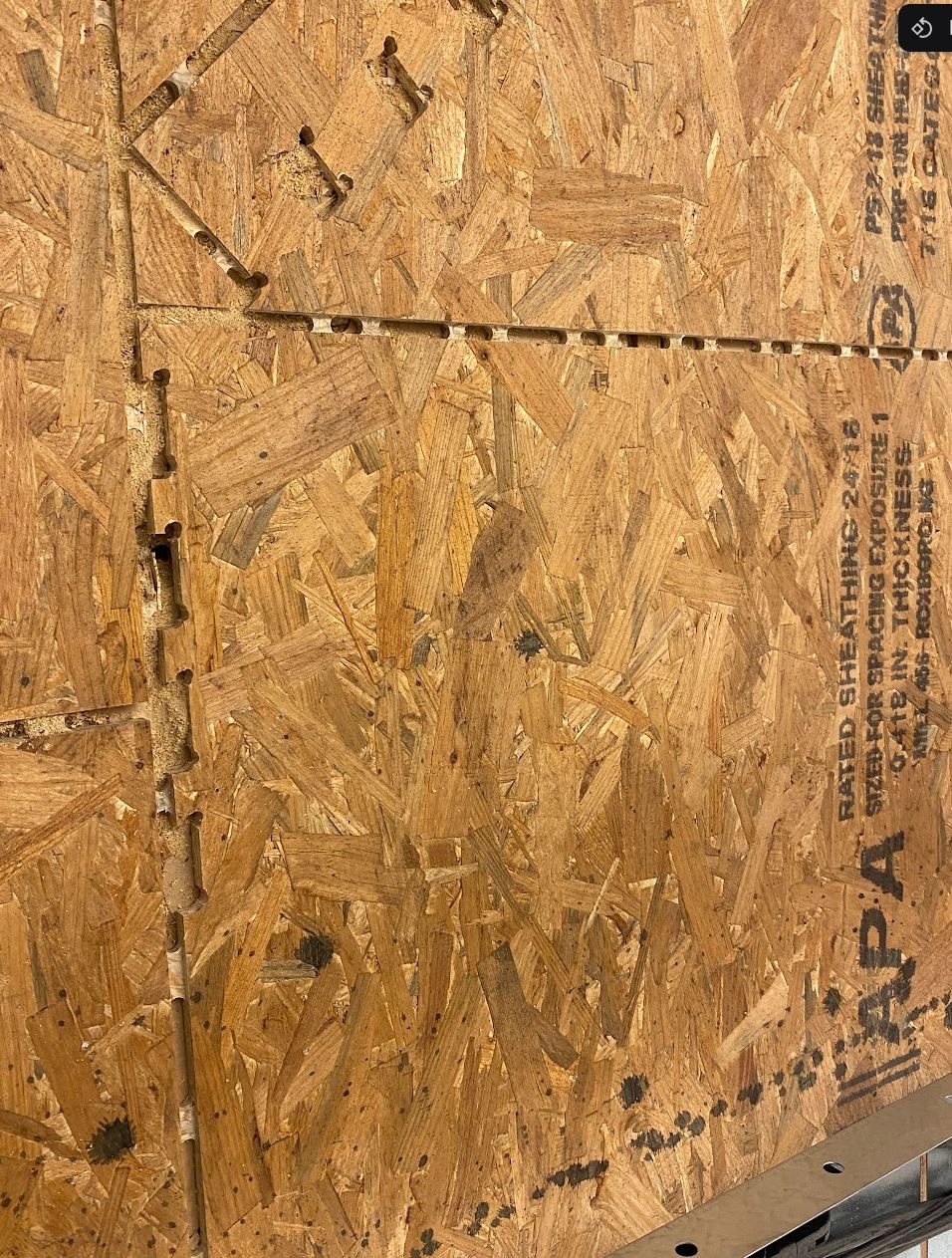

Using a nailgun, I put nails to fix the OSB to the bed.

Milling:

For one of the prints, the mill messed up halfway through, causing the job to become unaligned.

Assembly

First, I cut out all the wood bridges using the bandsaw and other.. saw (blanking on the name).

After a lot of filing and hours of assembly… all I have is this table.

I ran into a couple issues:

My CAD was designed based around the wood being perfectly 7/16 inches thick. However, there were many irregularities, so some joints were off.

My base was too thin given how big my structure is.

The milling mishap made it impossible to connect the back of my chair to the seat, since it destroyed the holders that the back of the chair was supposed to slot into.

I think it is salvable with a lot (ALOT) of hot glue but I decided to cut my losses and keep it as a table.

RIP Chair.