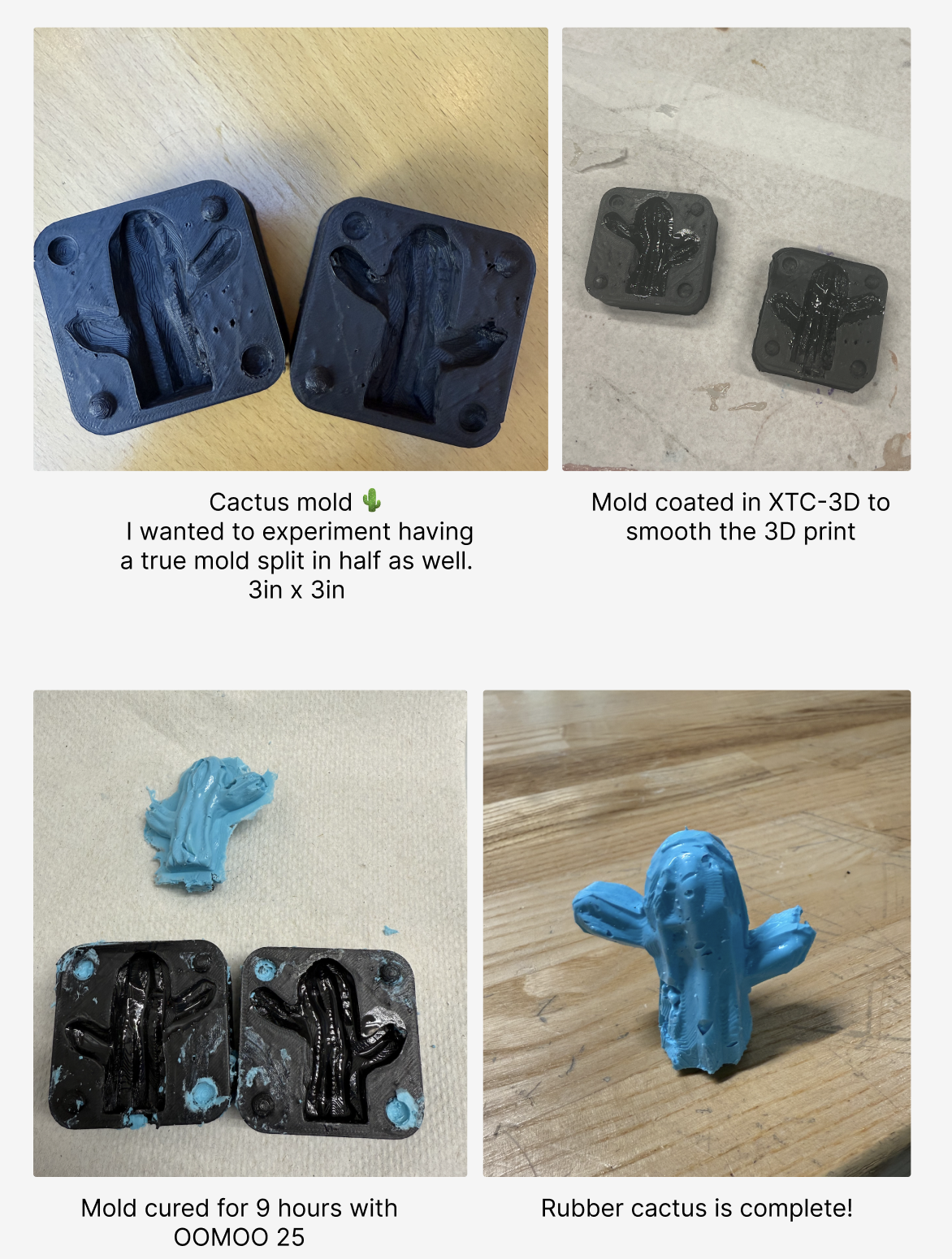

Cactus Molding Process ✏️

For this project I decided I needed more succulents around my house. so I thought it was a great opportunity to create a mold of a cactus. At first I wanted to create a

mold from a model however I thought this strategy would be more effective in being able to produce more at a faster speed. so I created the cactus and split it in half.

I used XTC-3D as a protective coating for smoothing and finishing 3D printed parts that does not melt plastic. XTC‑3D™ fills

in 3D print striations and creates a smooth, high gloss finish. The need to post finish is almost eliminated. XTC‑3D™ can be applied

to both SLA and SLS prints. It works with PLA, ABS, Laywoo, Powder Printed Parts and other rigid media such as EPS, EPDM and urethane foam as

well as wood, plaster, fabric, cardboard and paper.

Once that cured for 4 hours, I used Oomoo 25 to fill the mold. It was surprising to see how vicious the Oomoo was as it went into the mold.

I originally drilled a hole in the middle to try to keep it through each half but it was too thick. so we let it cure for 9 hours and then I went in over the moon and

cut around some of the rough edges.

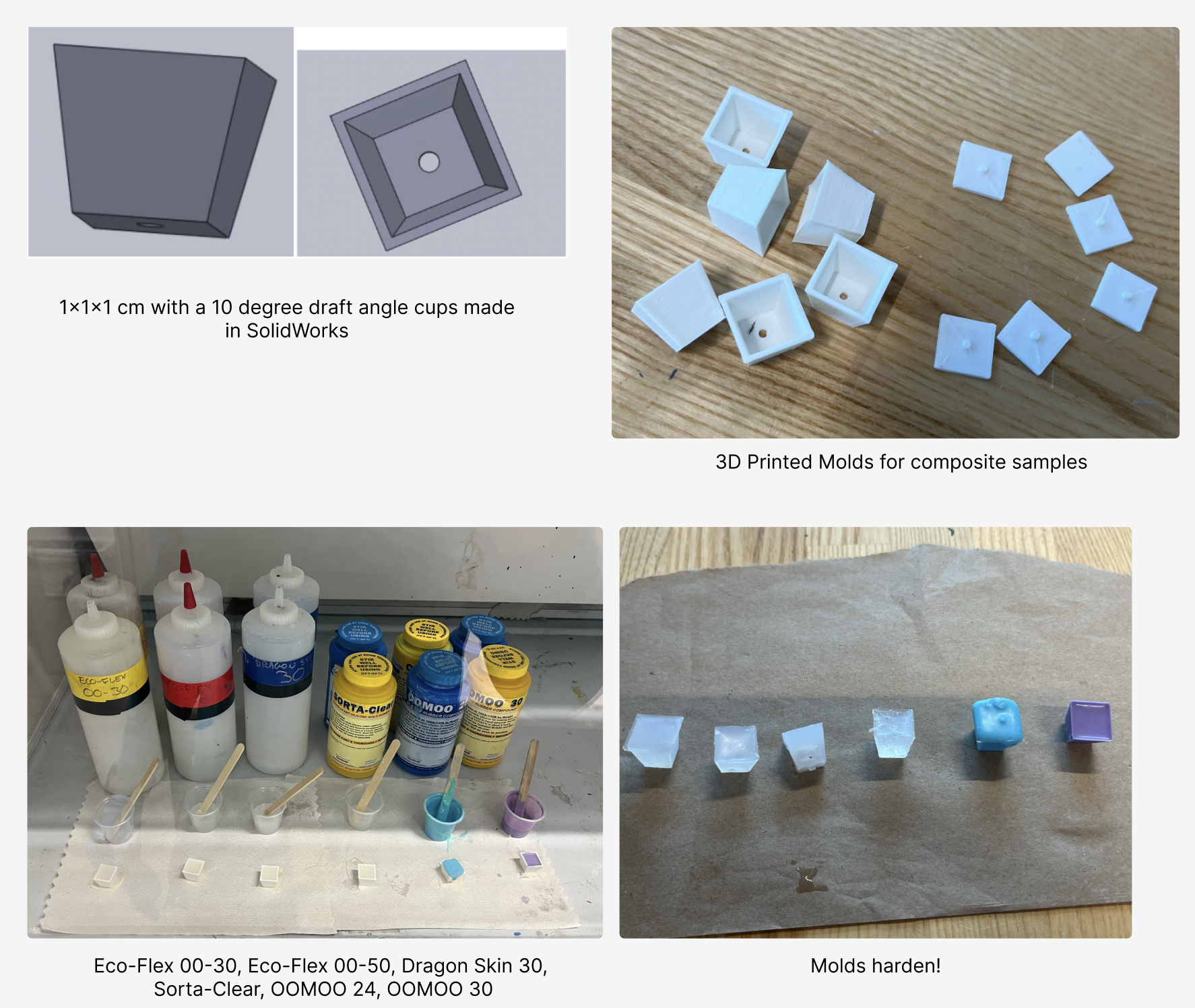

Group Assignment

We made little square cups in Solidworks with drafted walls to test the material properties of all the molding and casting materials.

These cubes are roughly 1x1x1 cm with a 10 degree draft angle for easy removal. I made little caps that fit over the bottom of the box to seal the hole.

The hole is there so that the mold can be pushed out.

We then molded little cubes of the following materials: Ecoflex 30, Ecoflex 50, Dragonskin, Sorta-Clear 37, Oomoo 25, and Oomoo 30.

Each are mixed in 1:1 ratios of two materials, and have different working and curing times.

Oomoo 25:

No Vacuuming - No Scale - Easy To Use OOMOO™ 25 is an easy to use tin cure silicone rubber compound that

features a convenient one-to-one by volume mix ratio (no scale necessary). It has a low viscosity for easy mixing and pouring

vacuum degassing is not necessary. This product cures at room temperature with negligible shrinkage. OOMOO ™ 25 has a 15-minute pot life and 75-minute cure time.

Oomoo 30: An easy to use tin cure silicone rubber compound that features a convenient one-to-one by volume mix ratio (no scale necessary).

It has low viscosity for easy mixing and pouring vacuum degassing is not necessary. This product cures at room temperature with negligible shrinkage.

OOMOO ™ 30 has a 30-minute pot life, with a six-hour cure time.

Sorta Clear 37: SORTA-Clear™ Series rubbers are premium water clear translucent silicone rubbers (platinum catalyst) which cure at room tempe

rature with negligible shrinkage. SORTA-Clear ™ 37 has Shore 37A hardness and features high tensile and tear

strength. This product also offers the convenience of a 1A:1B by volume mix