GROUP ASSIGNMENT

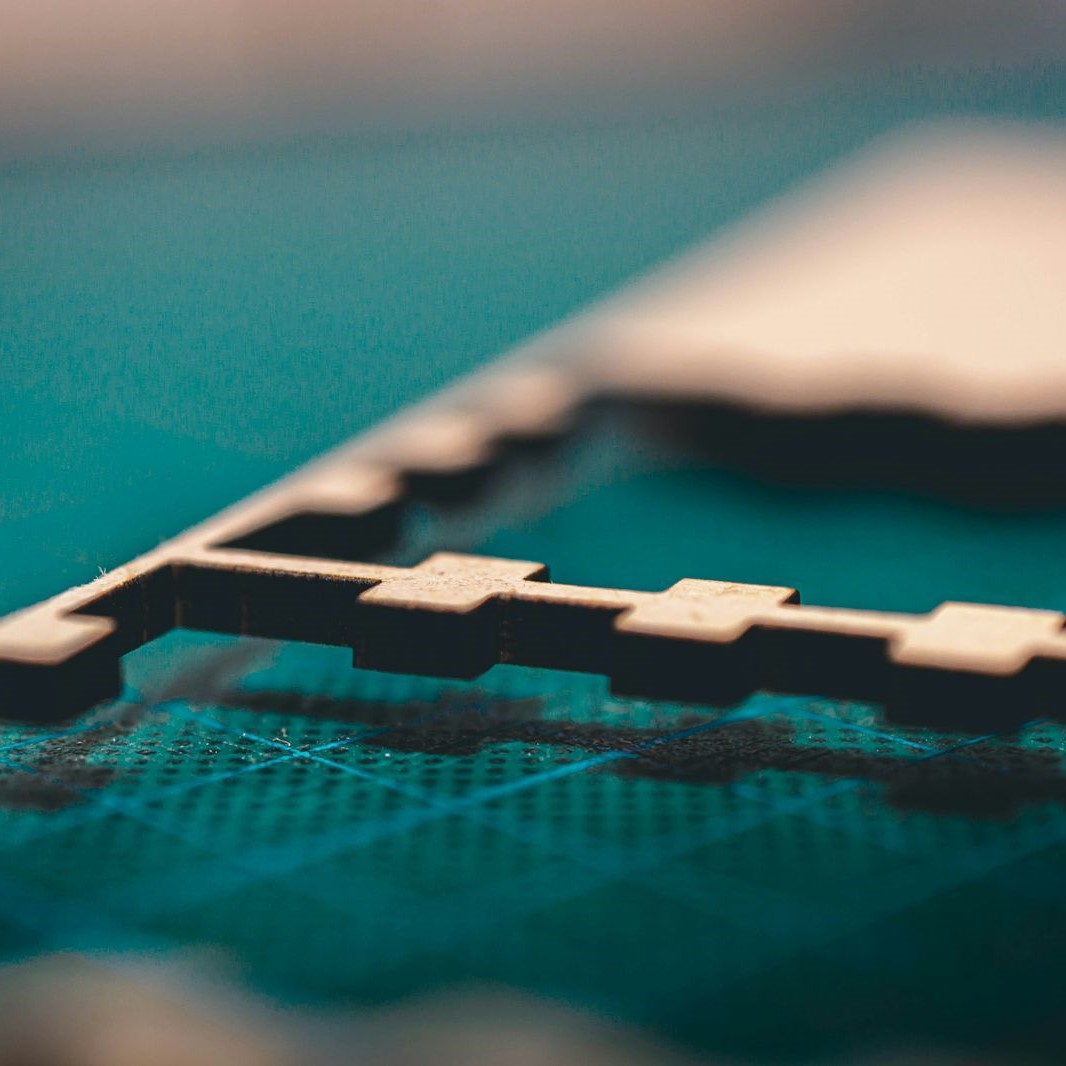

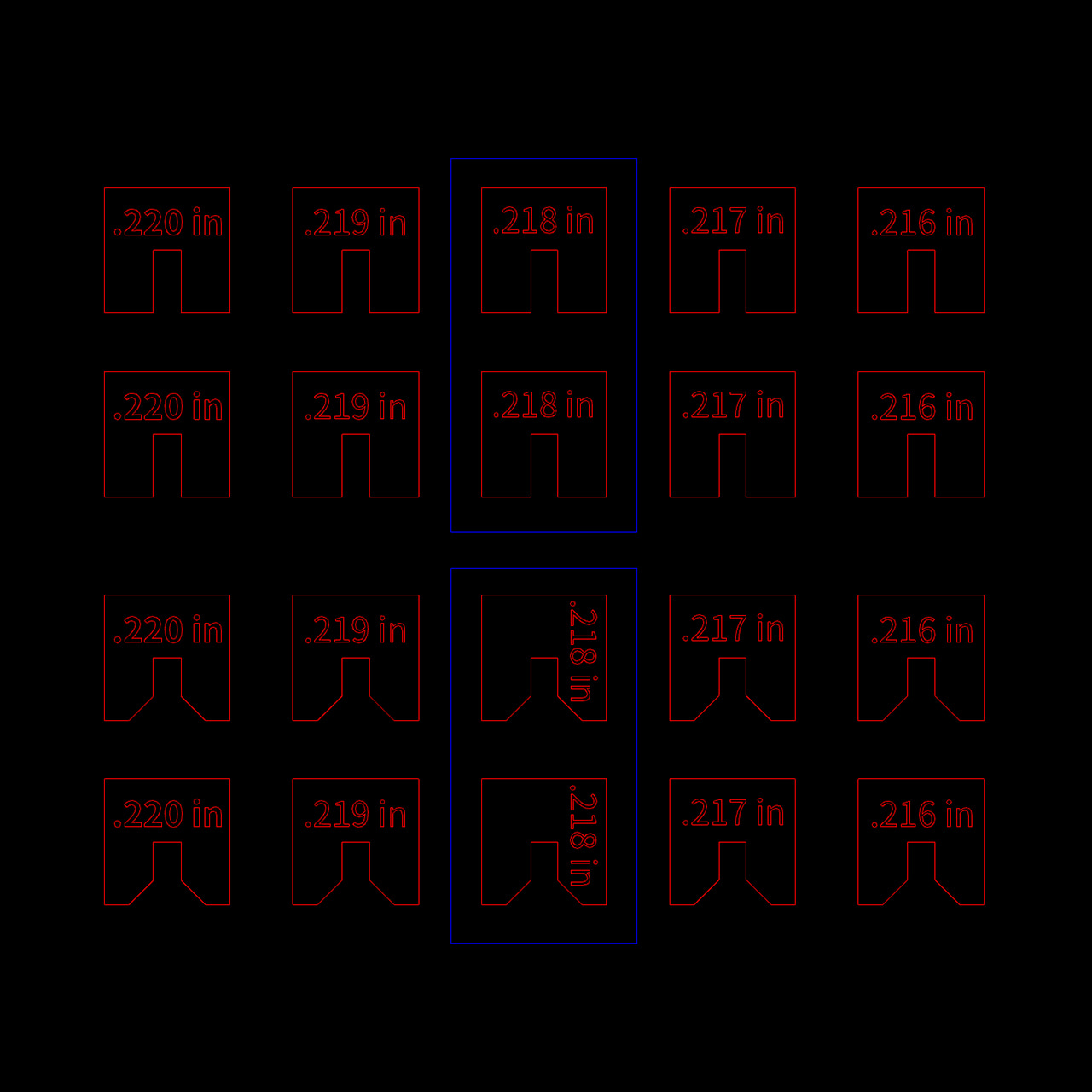

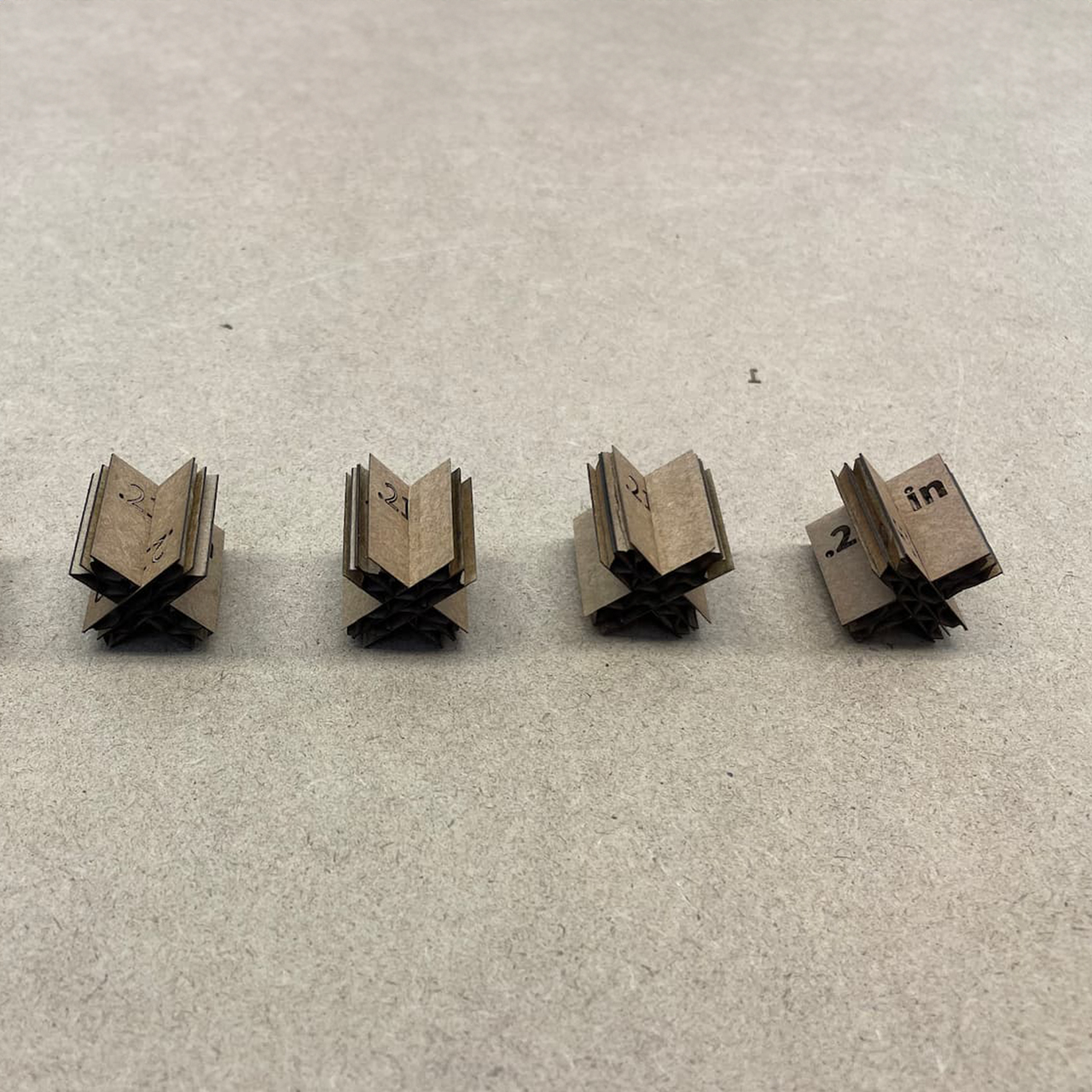

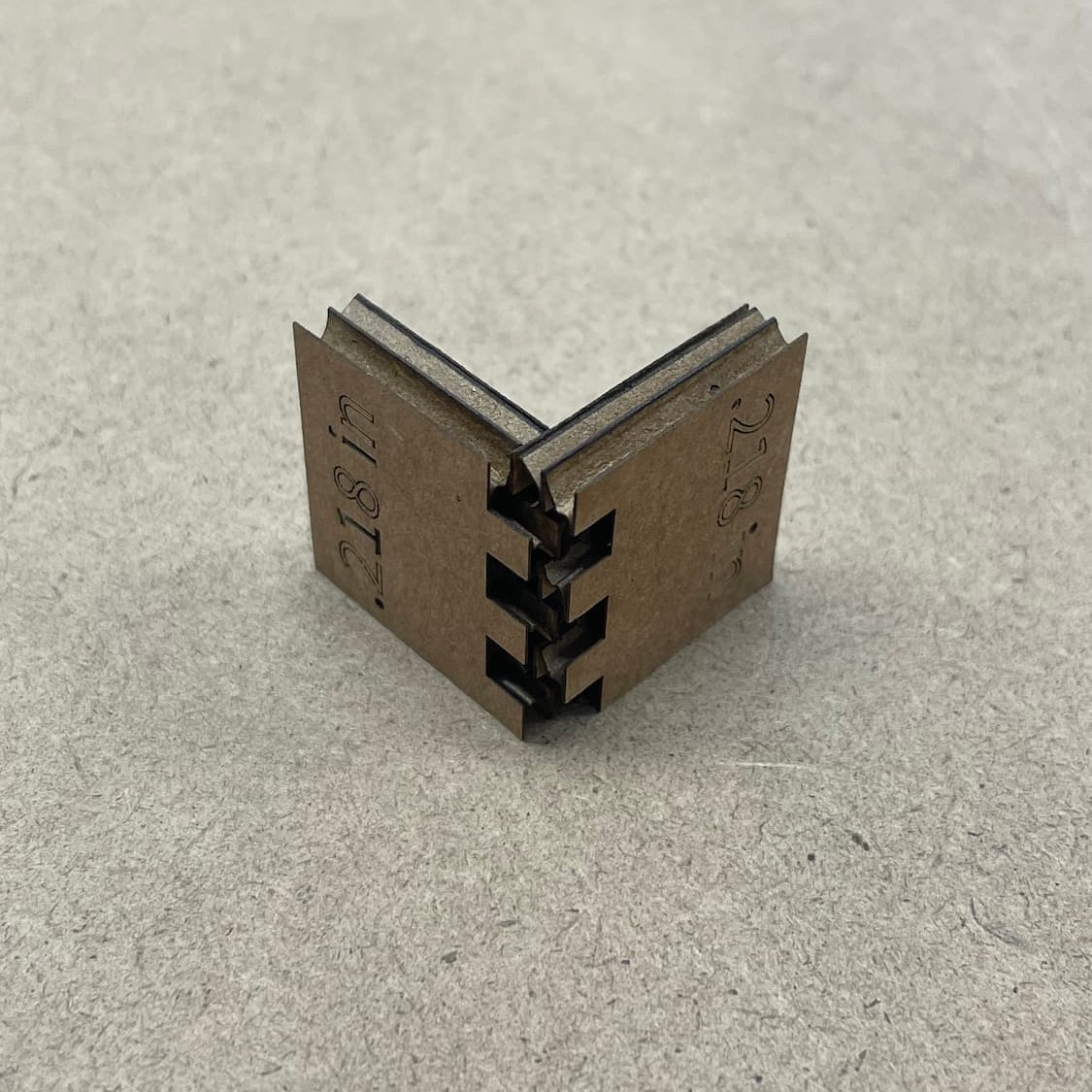

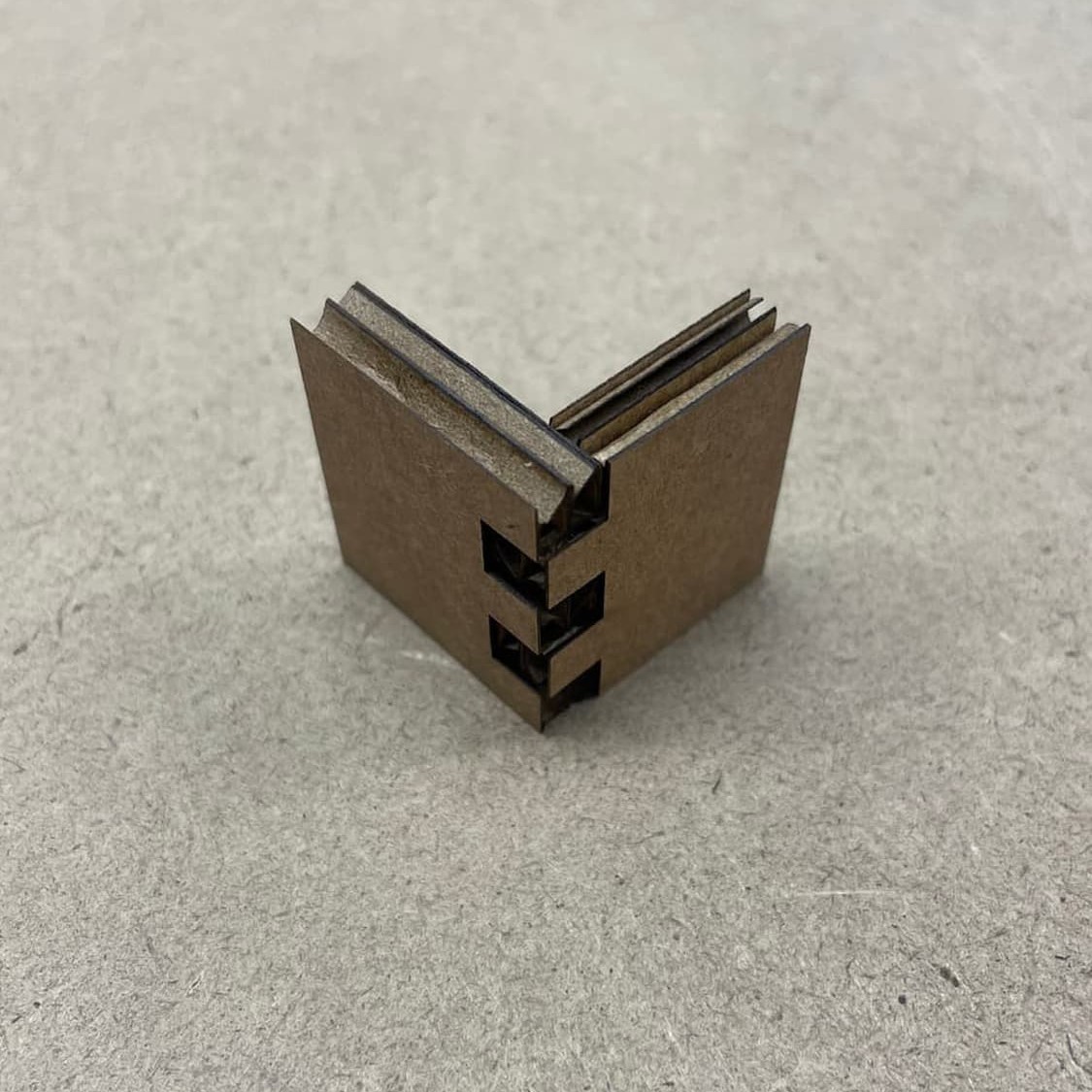

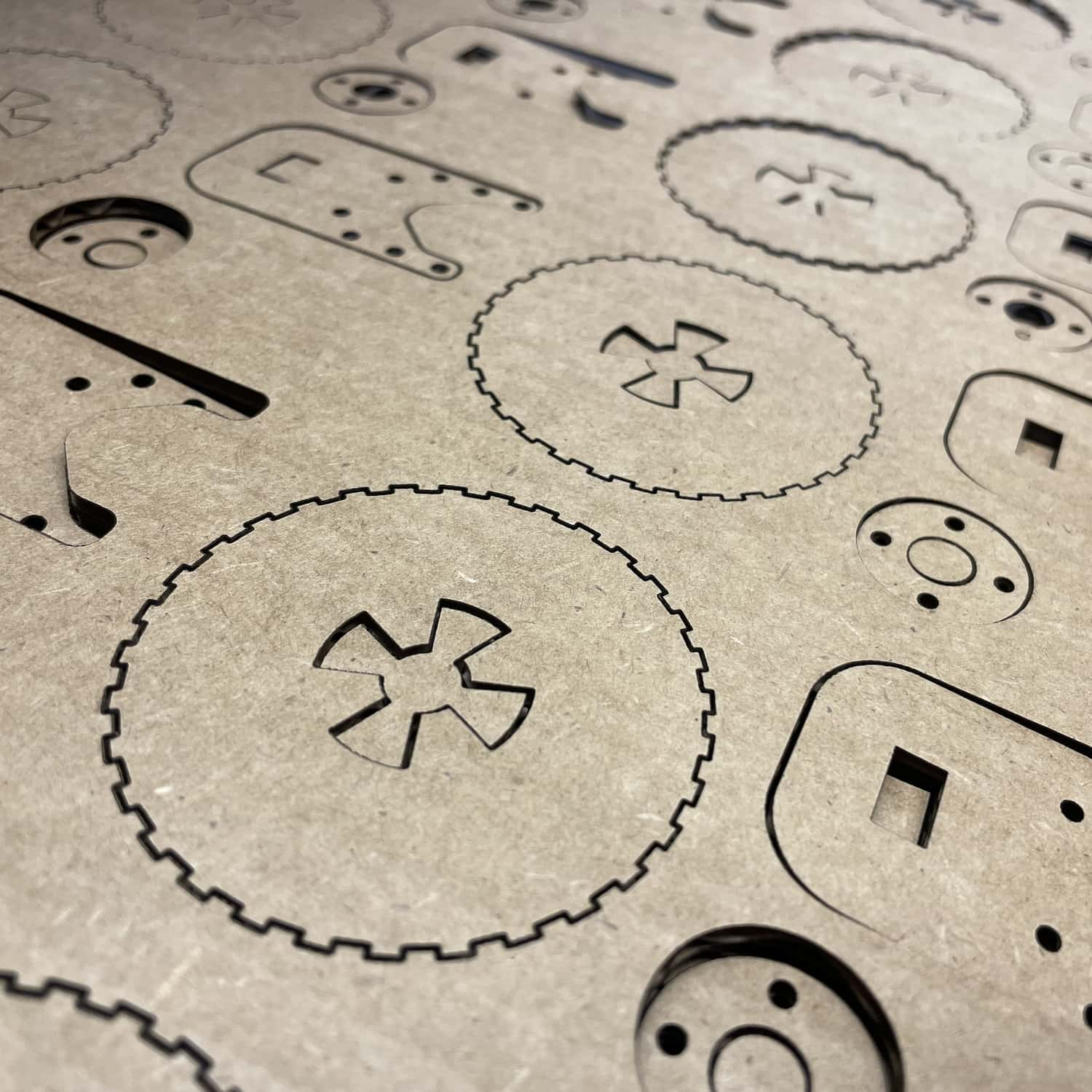

After completing the Fab Lab's safety training, we characterized our laser cutter's settings and identified the ideal cutting data for the material by cutting a series of press-fit joints and testing their strength. These are our results: focus (2 inch), power (57% of wattage), speed (35% of max speed), rate (500 ppi), and kerf (0.04 inch).

MODULAR WHEEL BOTS

Design to Fab

First, I had a series of AX-12A servo motors lying around and decided to use them from this project. Thn I searched for a 3D model of the motors online to be able to CAD my carboard pieces arond them.

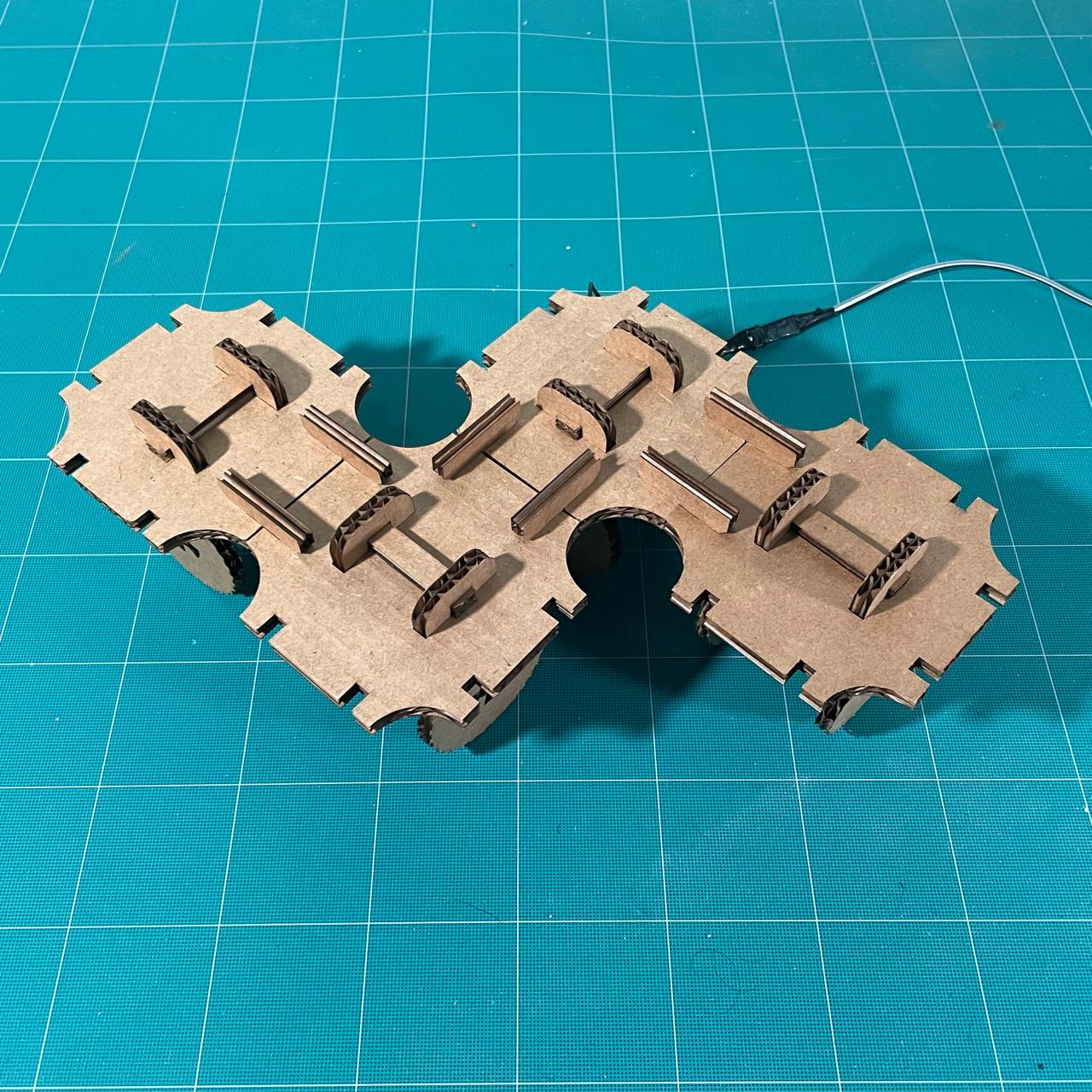

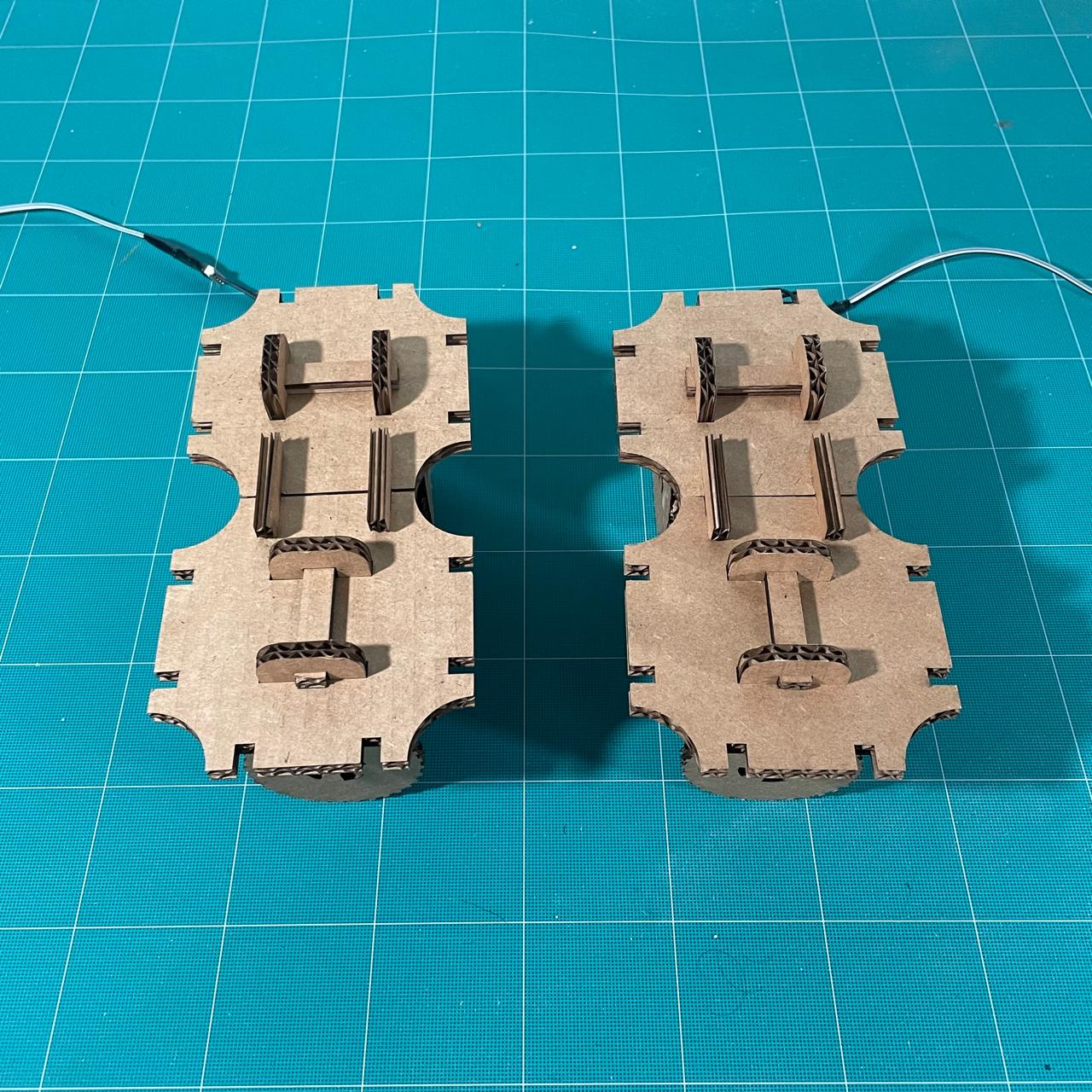

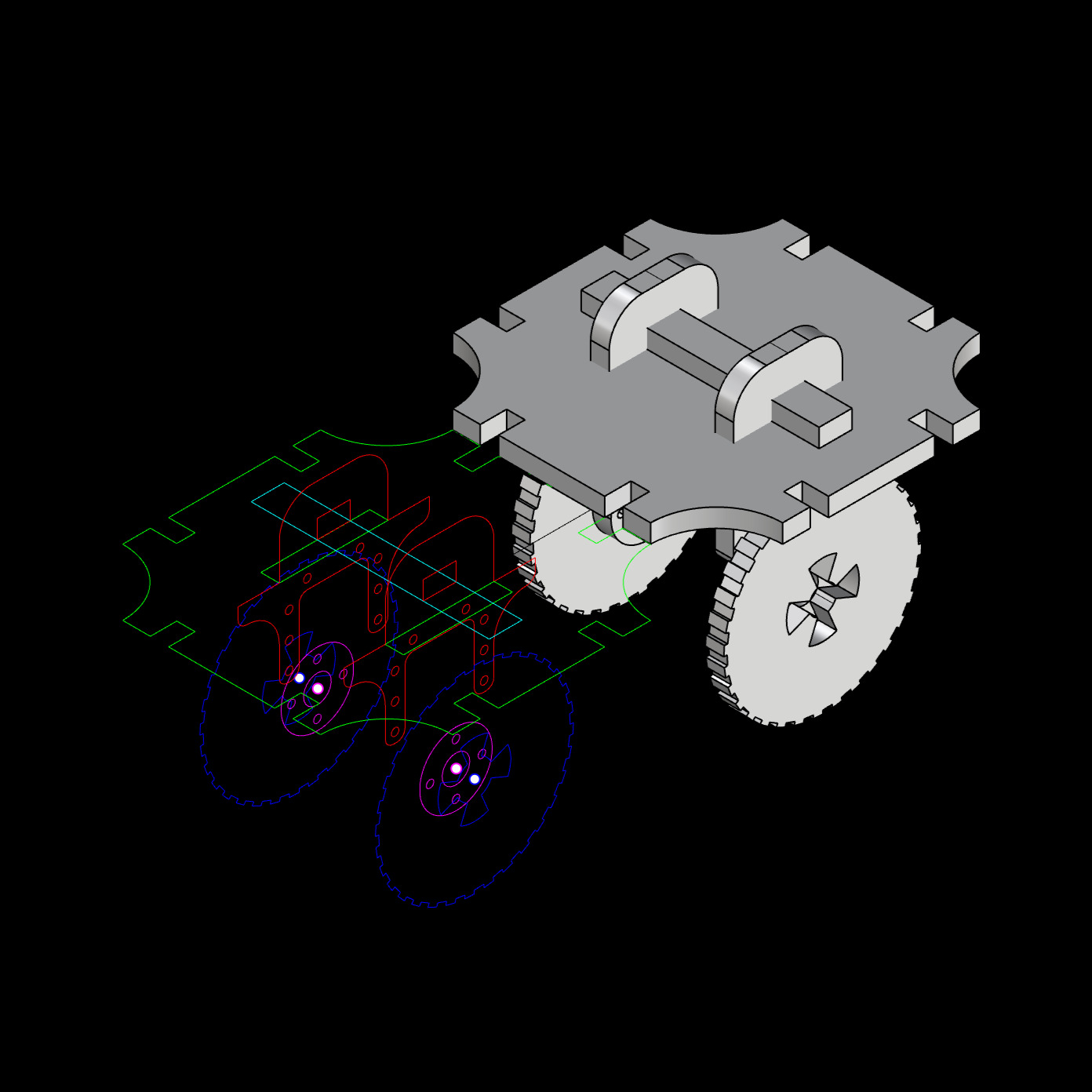

Inspired by bottom-up natural systems, my idea was to have a series of modular wheel robots that could be assembled in multiple ways, or bodyplans, to achieve different objectives / showcase different behaviours.

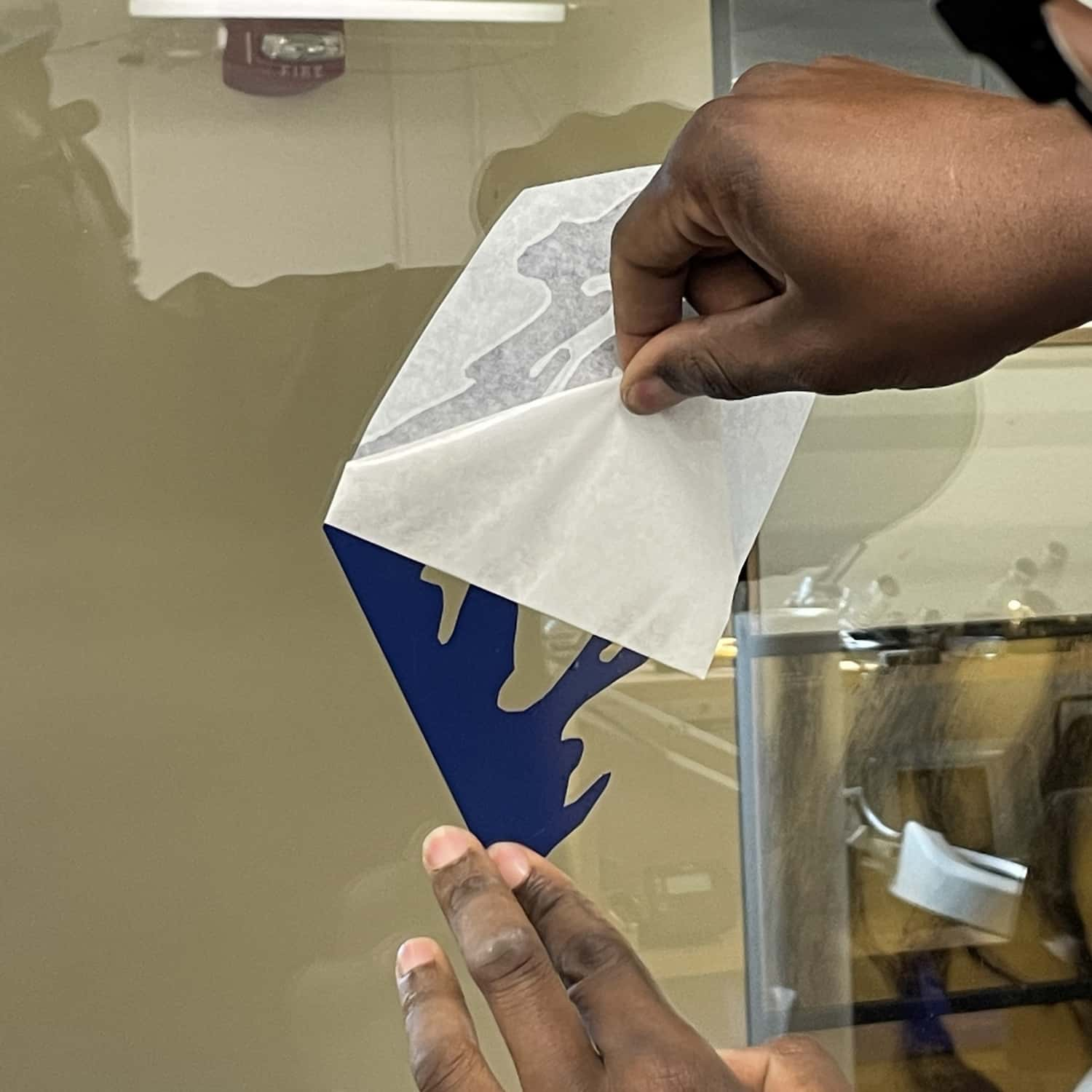

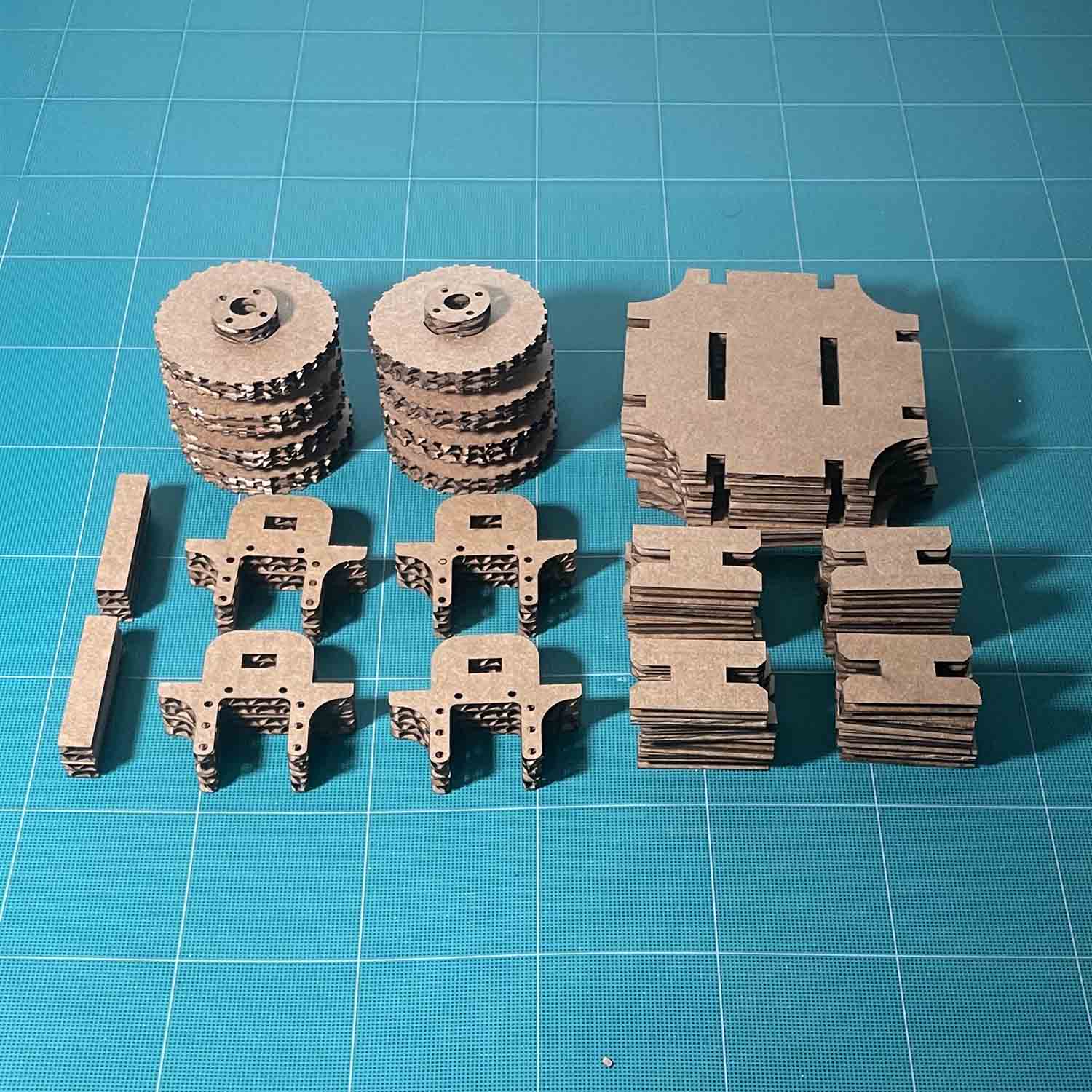

Once the design was ready, I extracted the cutting lines and went to the architecture shop. Using the material Jen saved for us, and the settings we discussed in training, I quickly cut all the pieces of my assembly. Thanks Jen!

MODULAR WHEEL BOTS

Assembly