Group Assignment

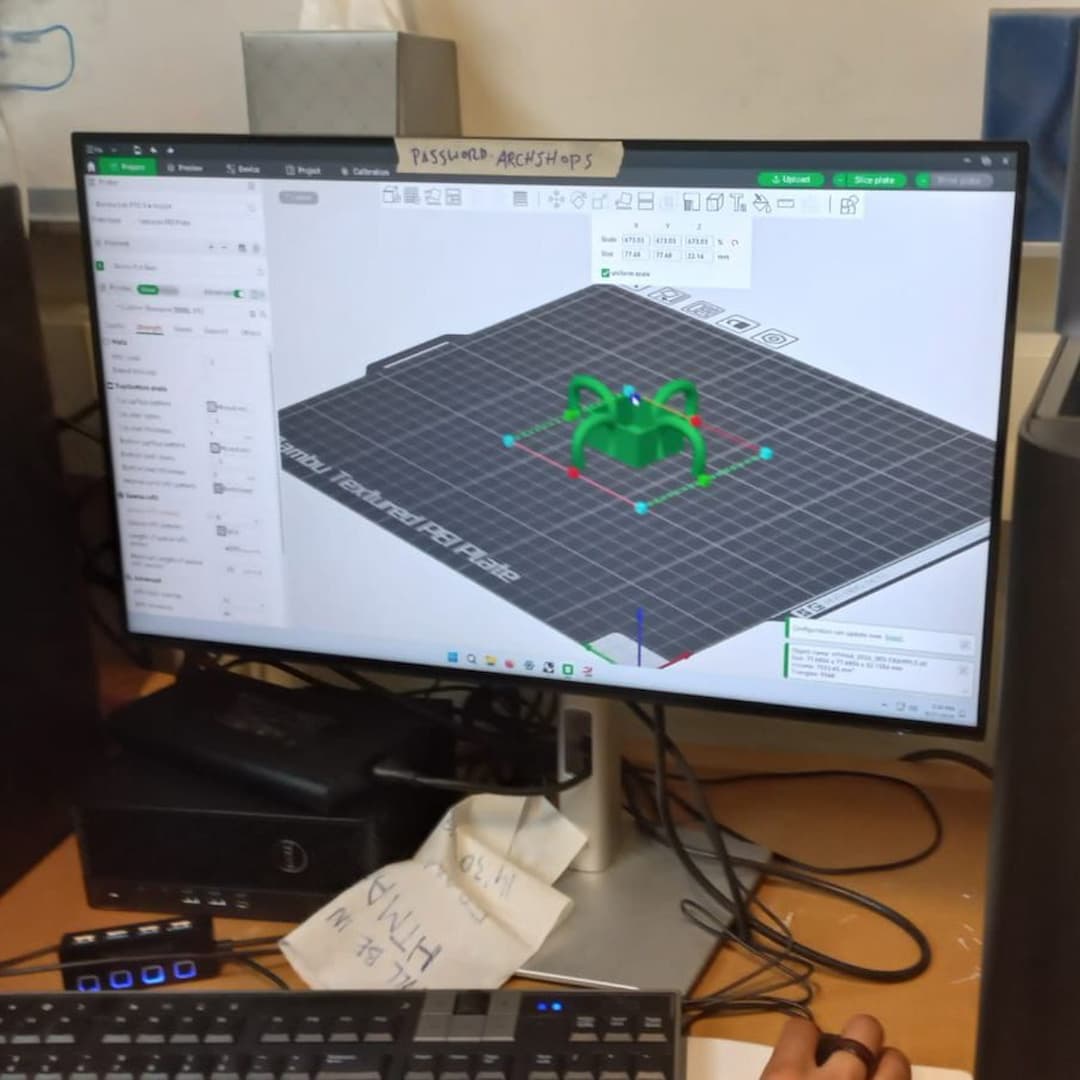

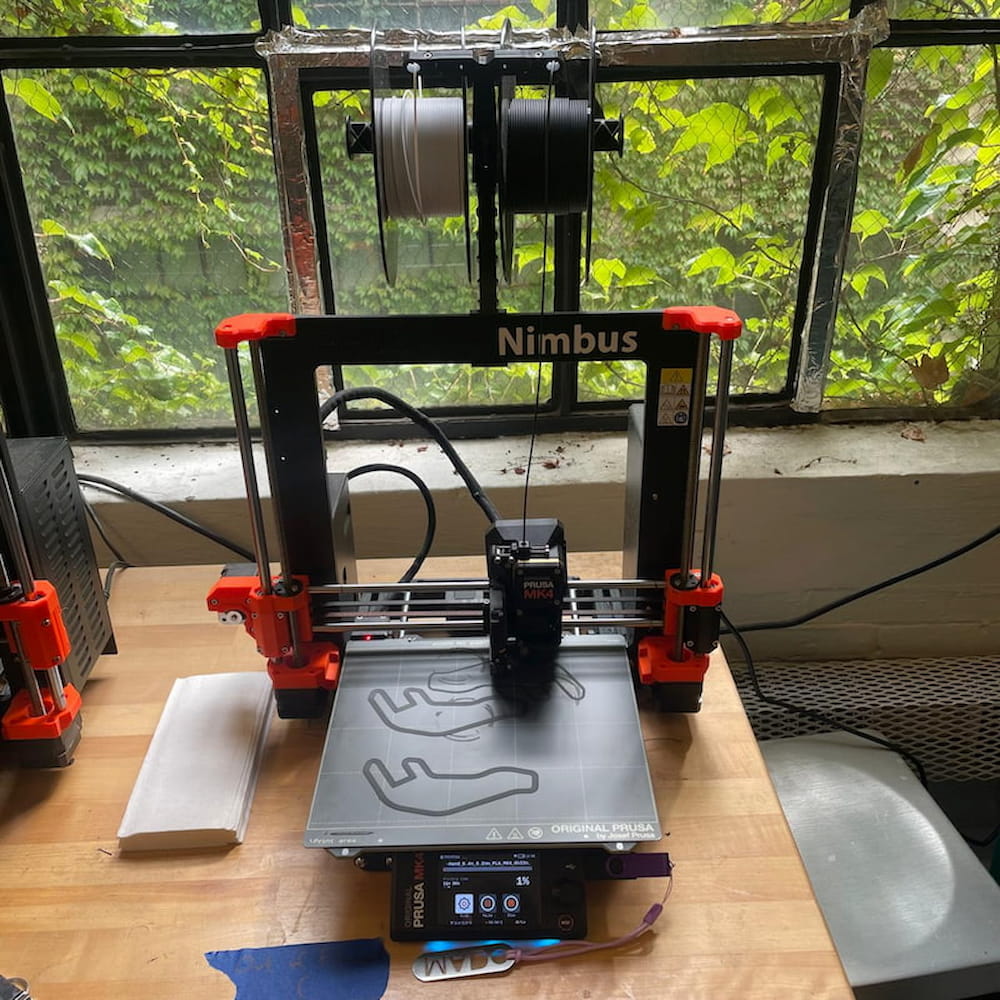

For our group assignment in the architecture section, we went over 3d-printing and 3d-scanning. For 3d-printing, Diana explained to us a basic workflow for our Bambu printers, as we did a quick test together: Rhino model -> OBJ/STL -> Bambu Studio -> Gcode -> the Bambu printer

For 3d-scanning, we used the Creality app to scan Kareem's hand and we discussed other scanning options with different setups and requirements. As it is, there already exist good 3d-scanning tools you can run on your phone.

INDIVIDUAL ASSIGNMENT

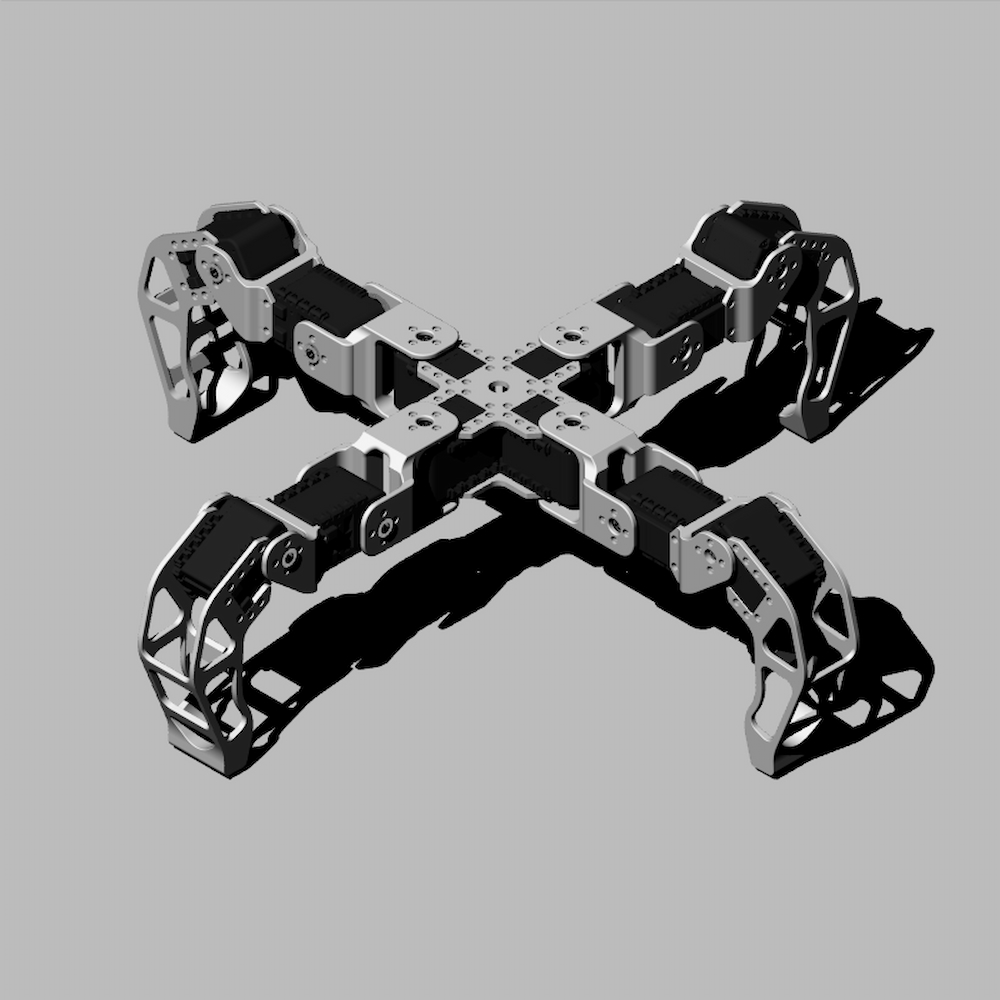

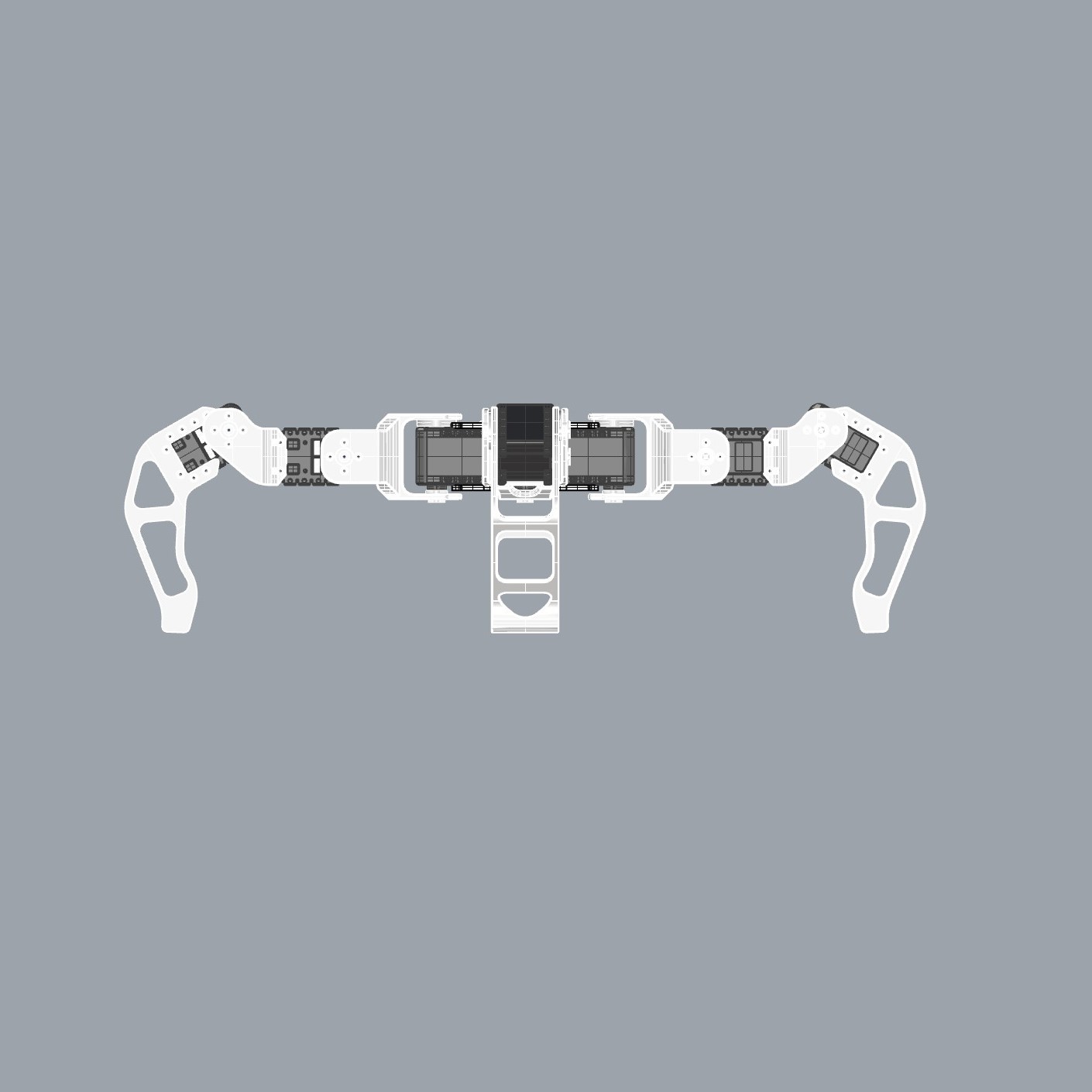

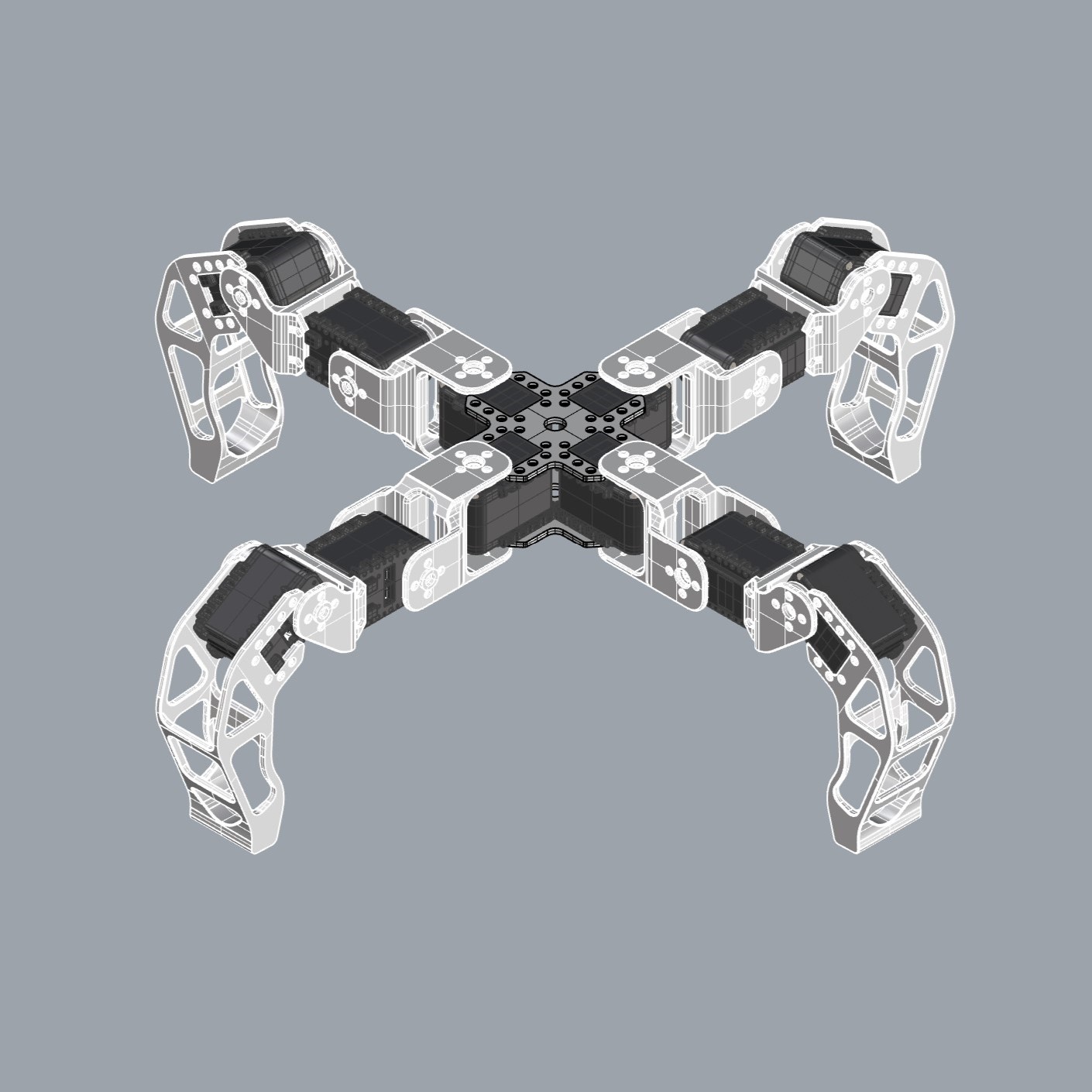

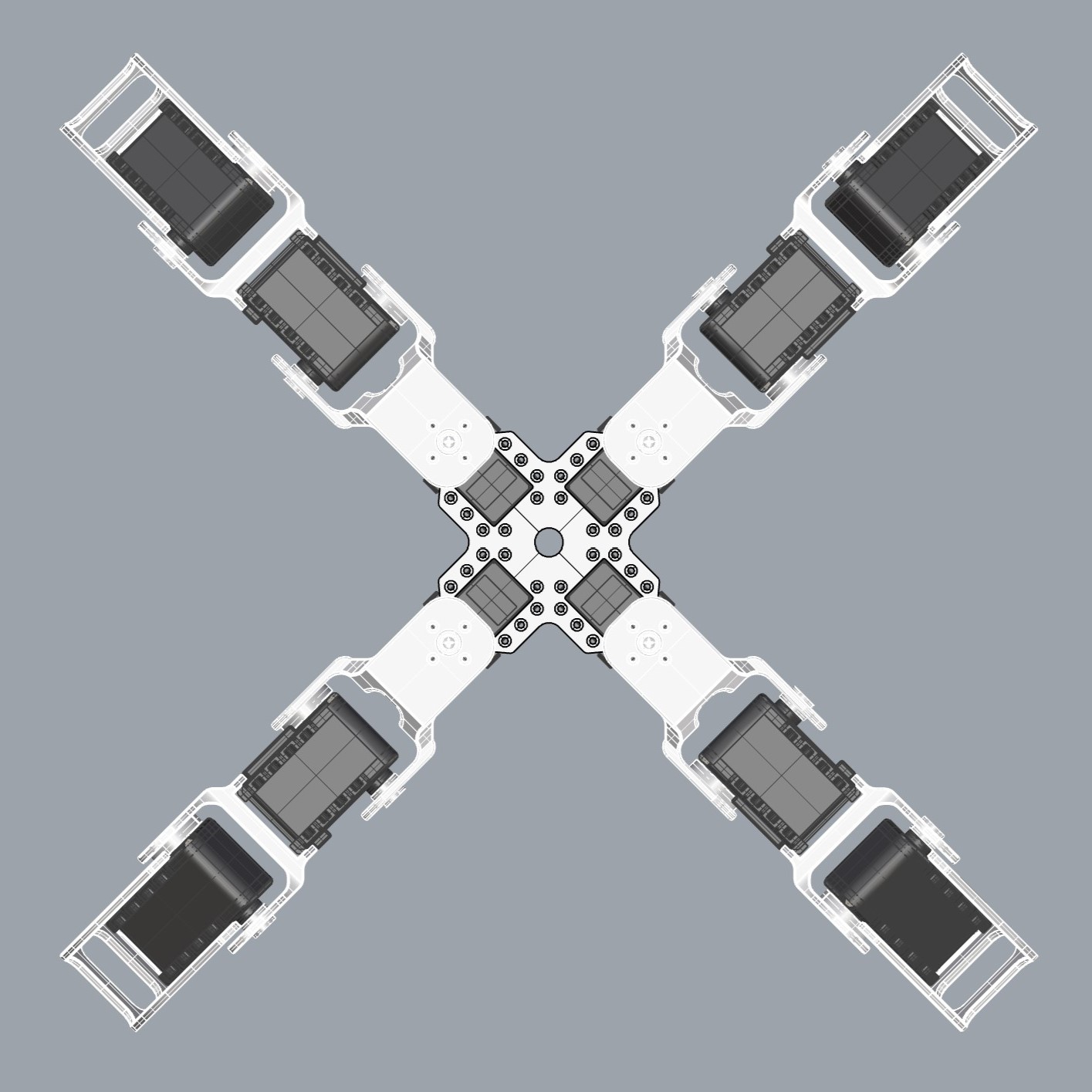

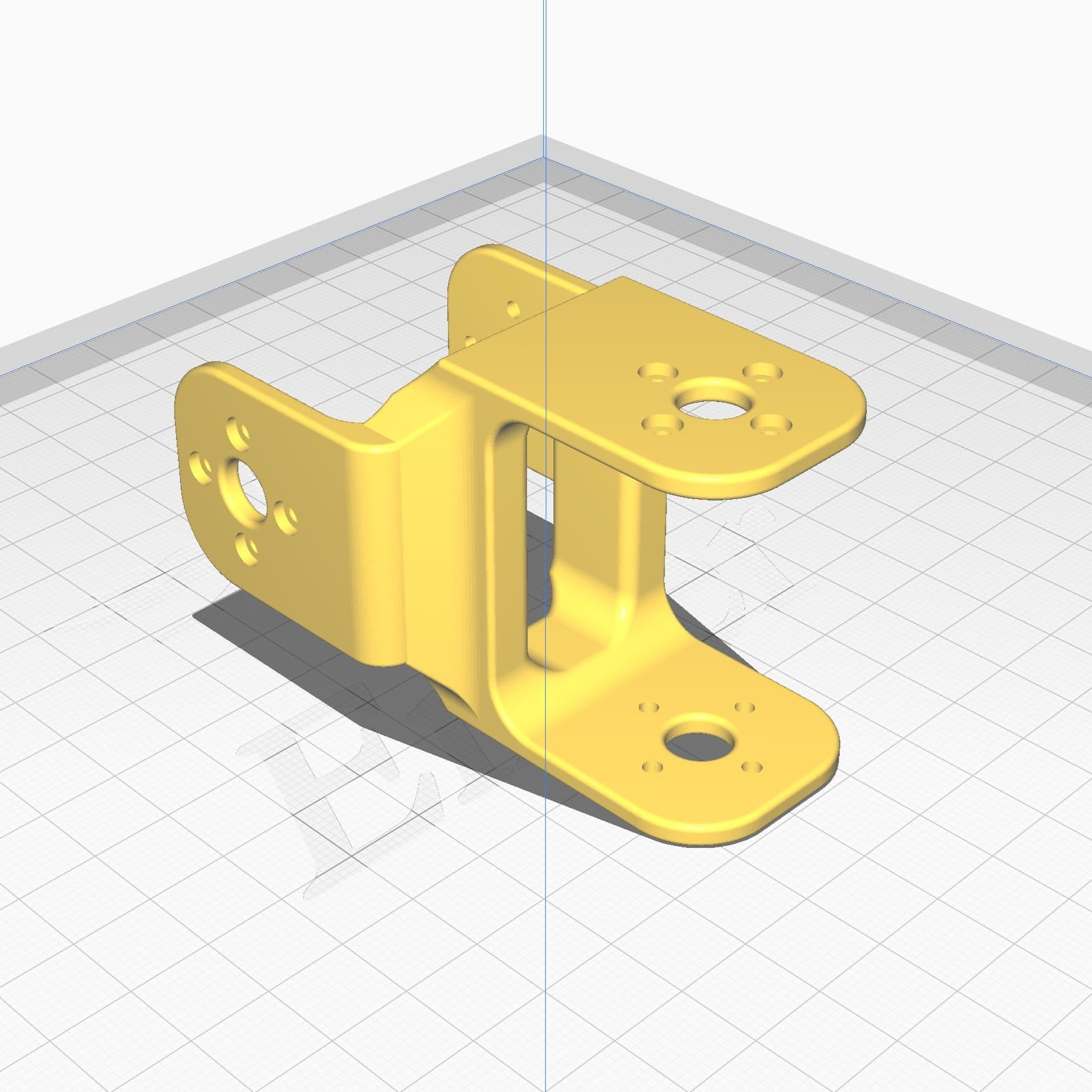

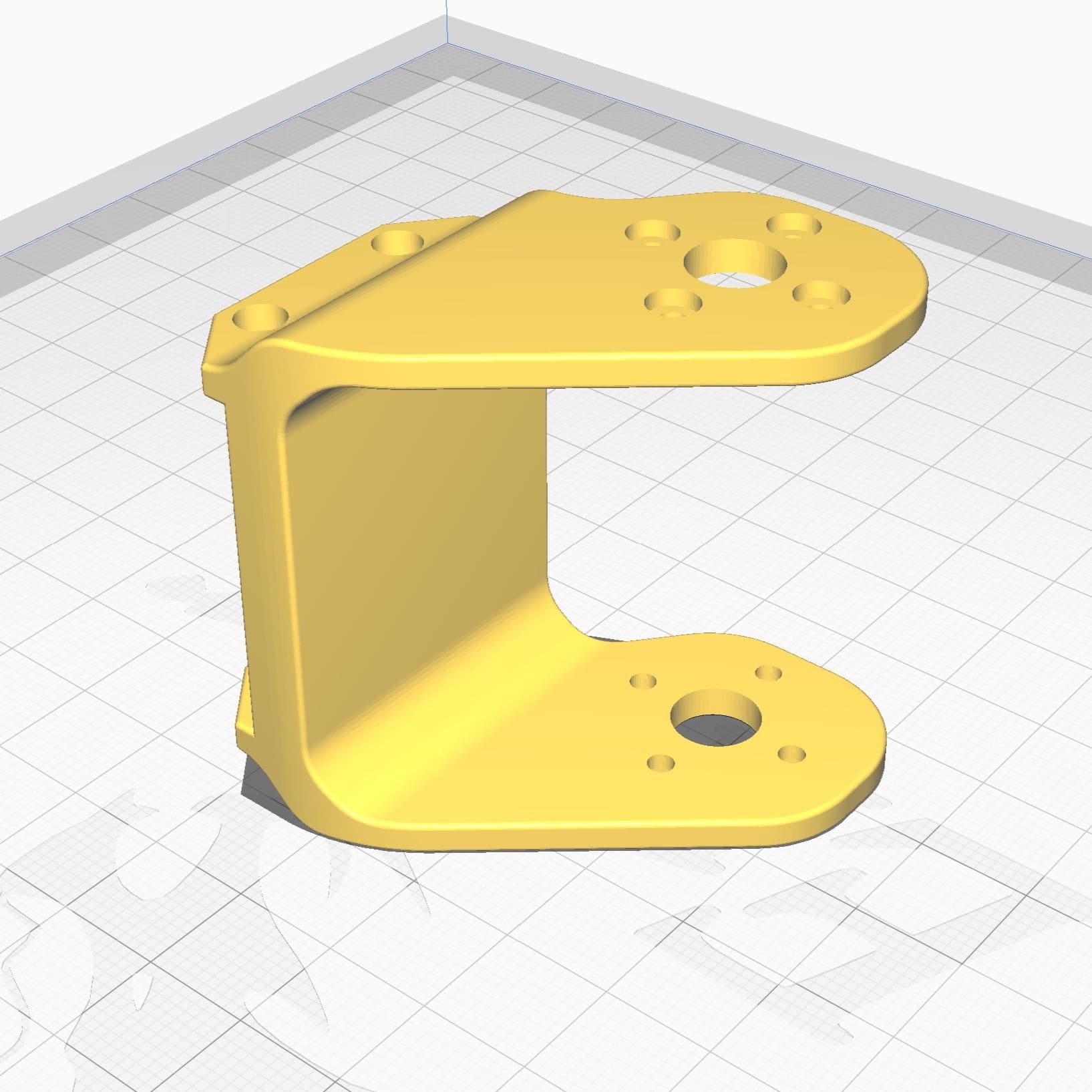

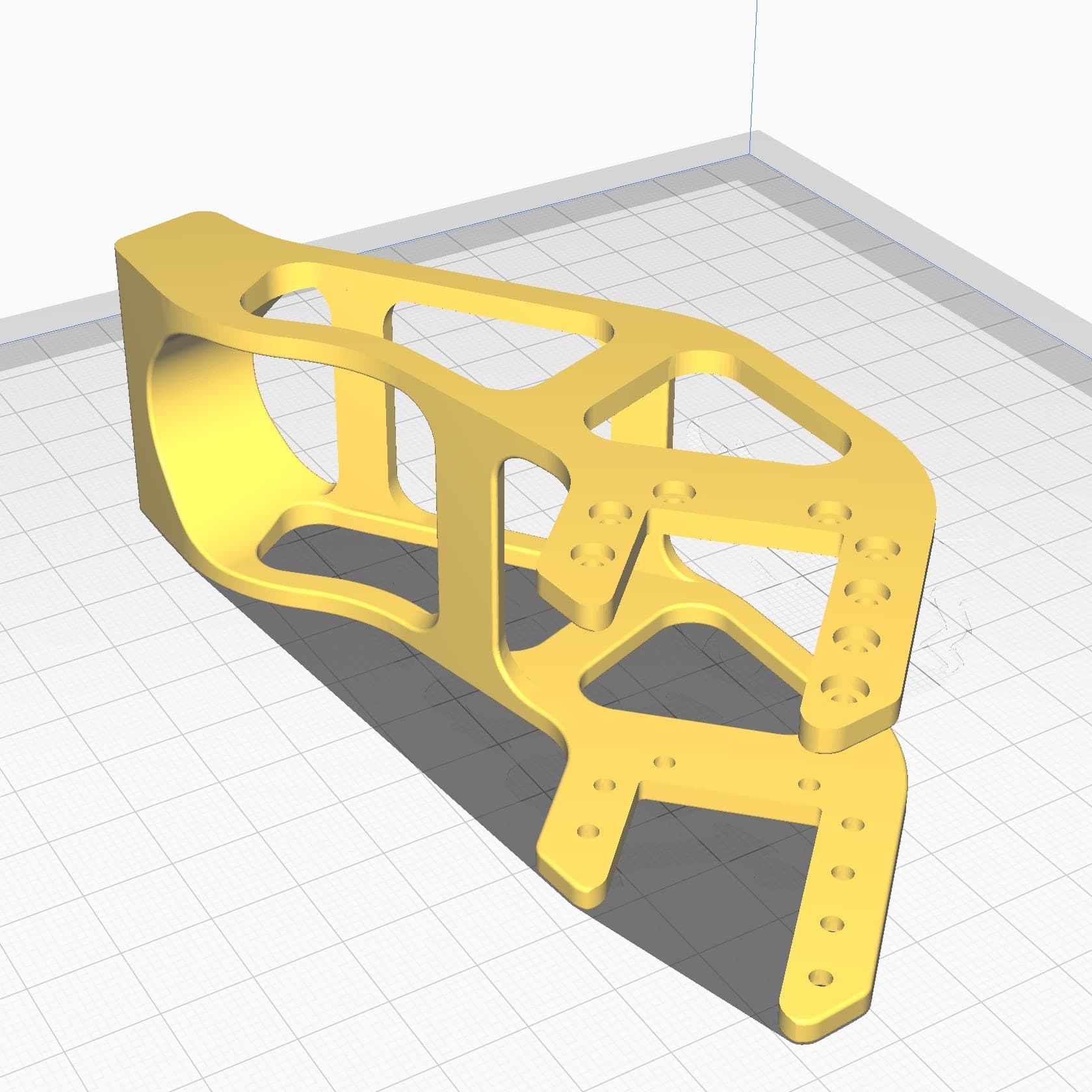

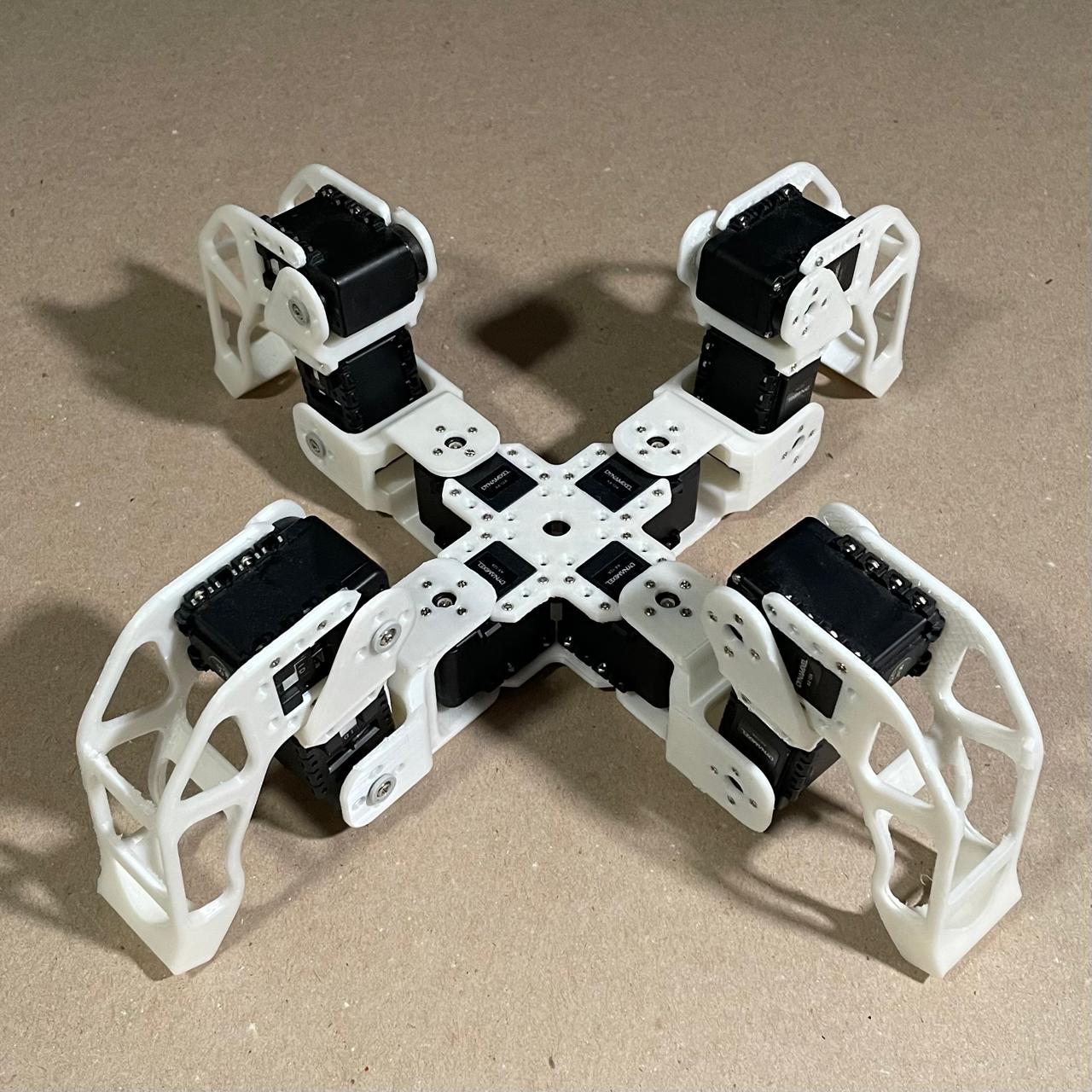

Quadrapod Bot

Step 1: CAD

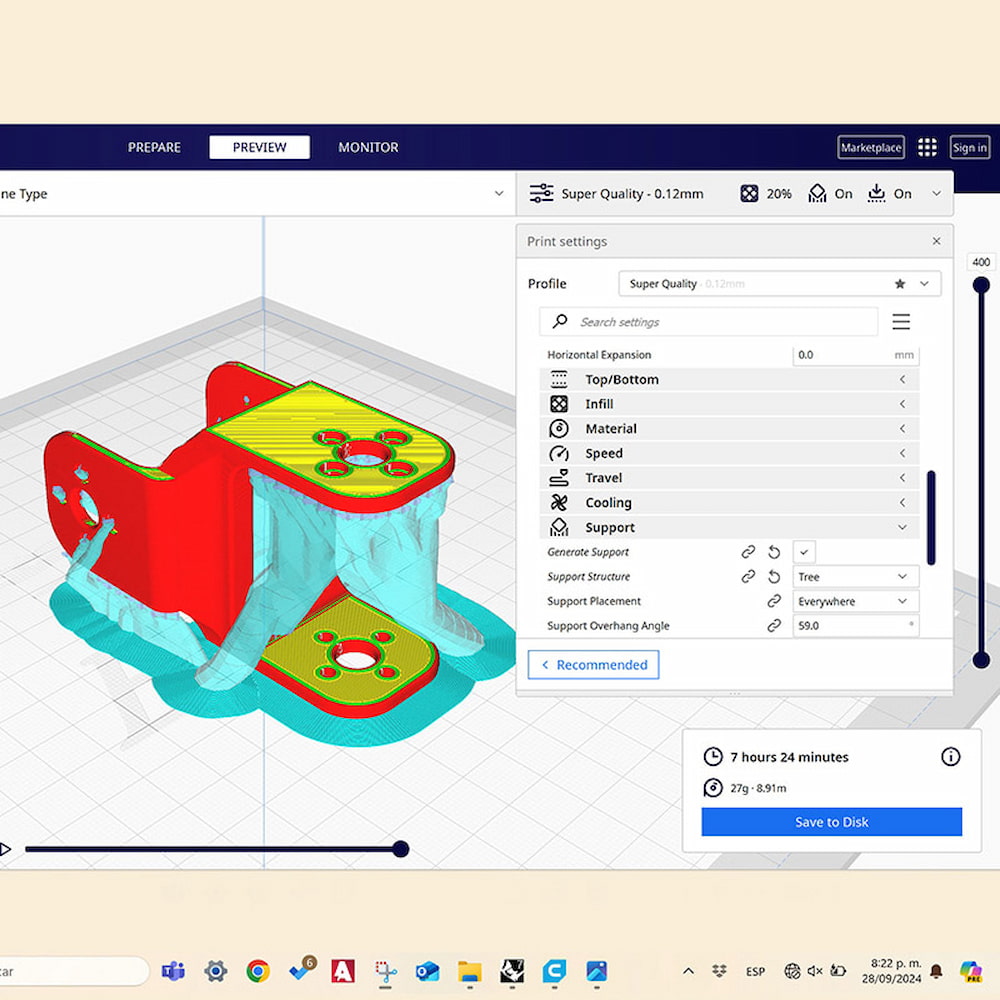

Step 2: Slicing

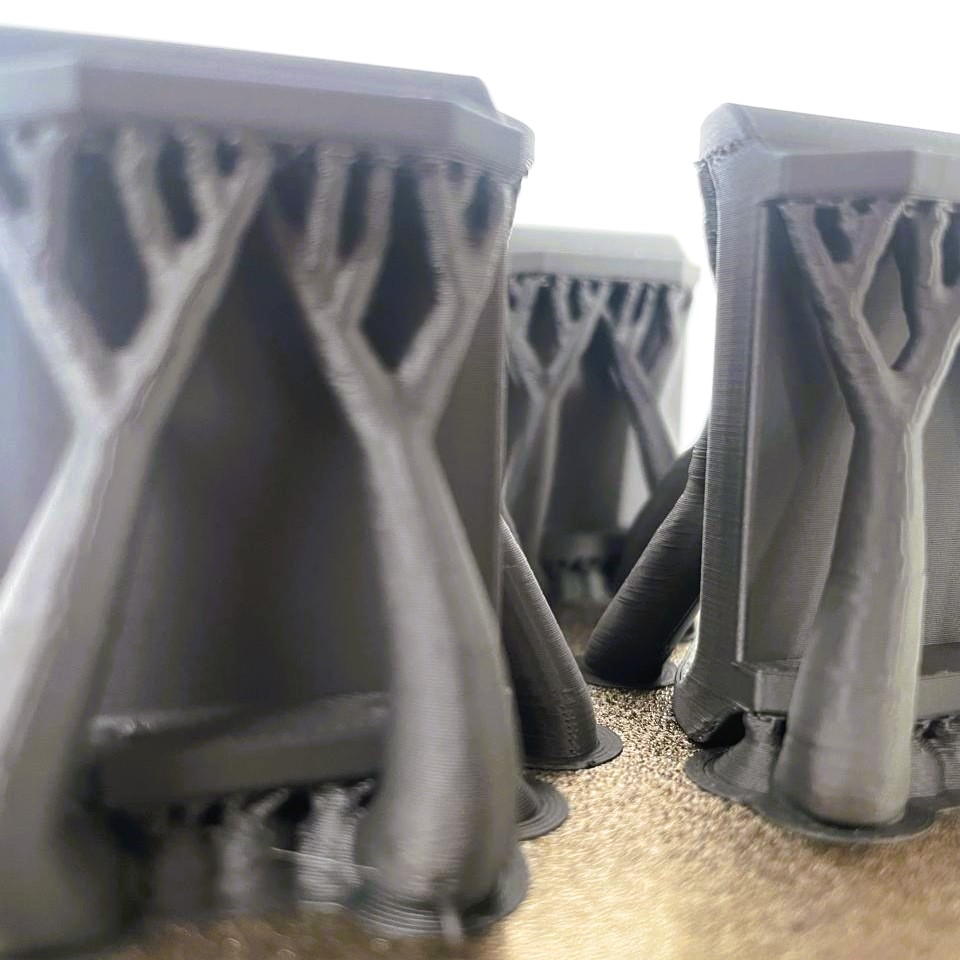

Support Material

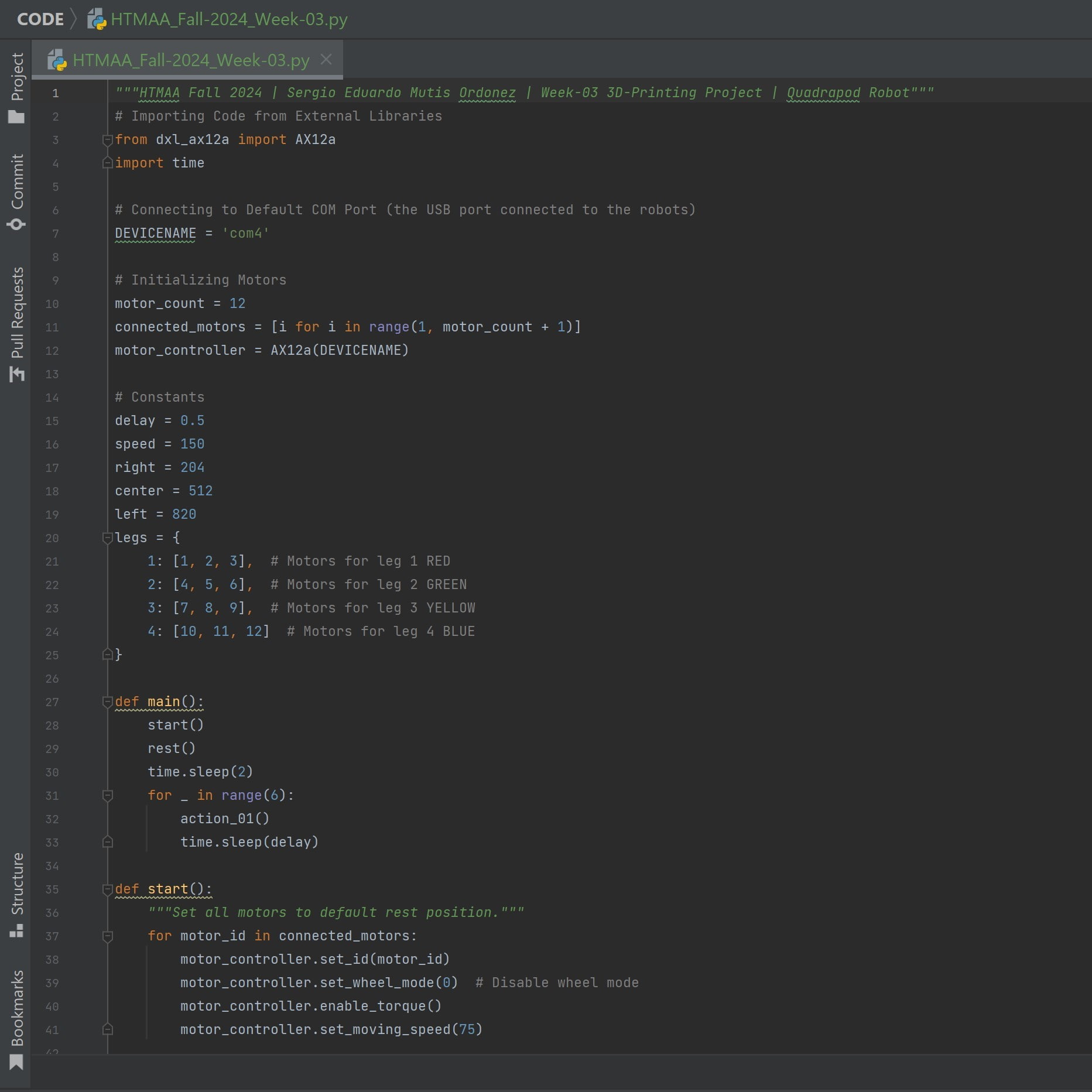

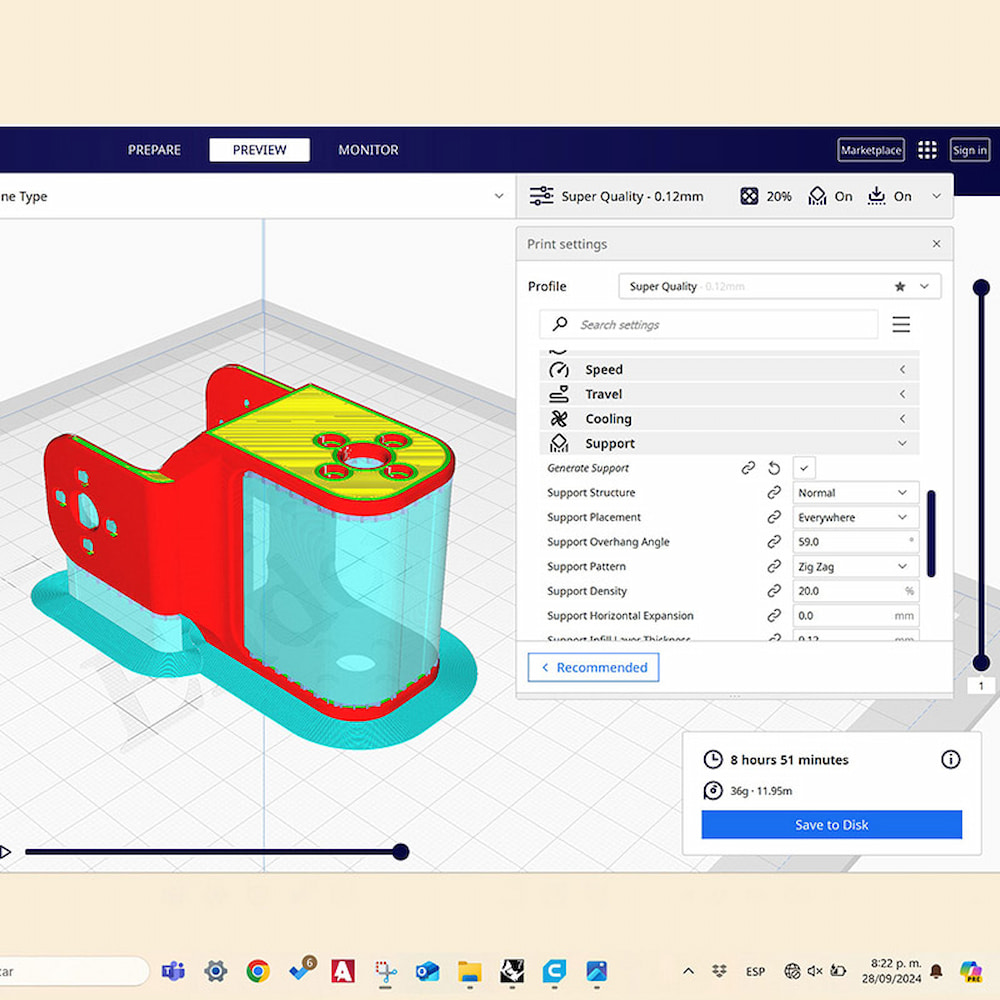

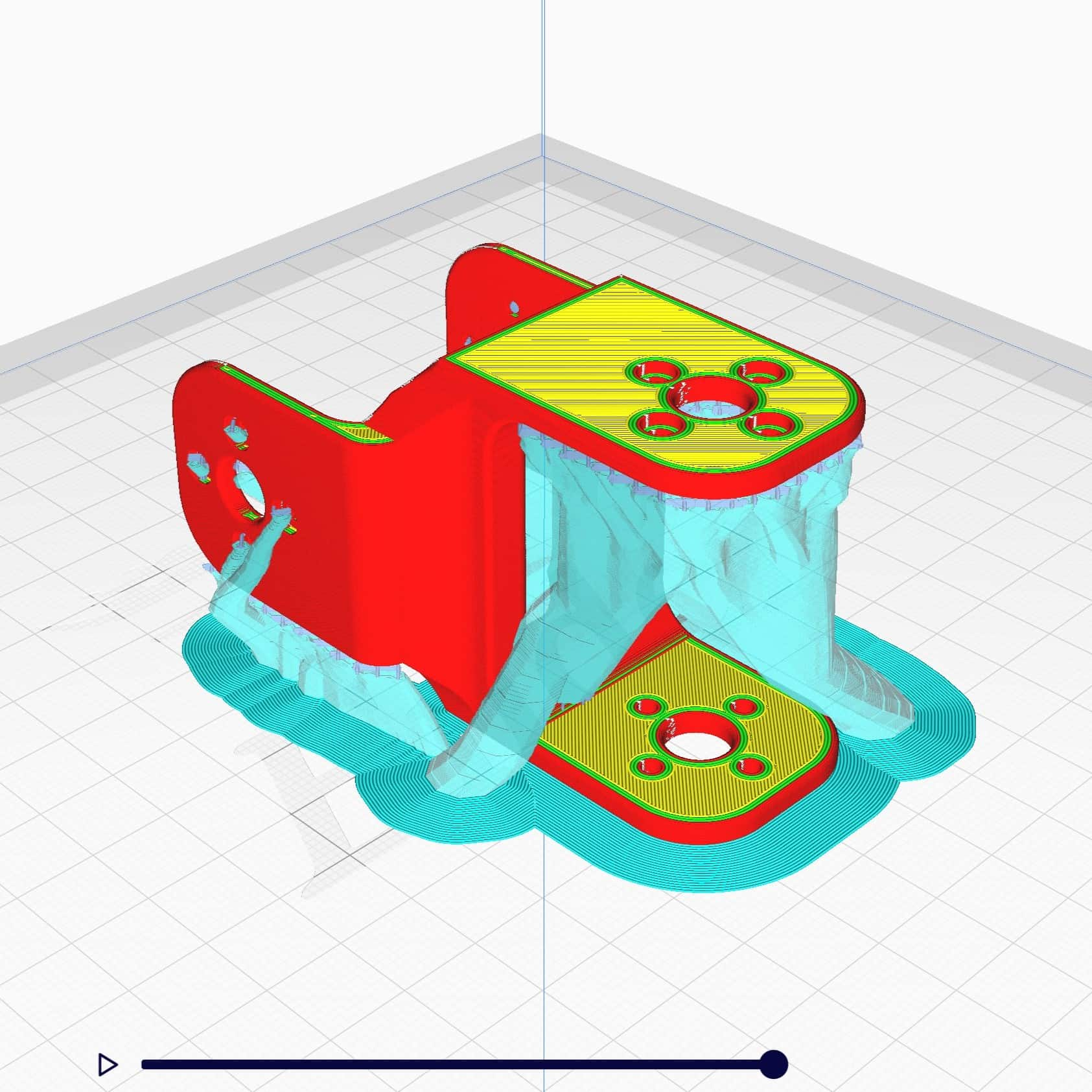

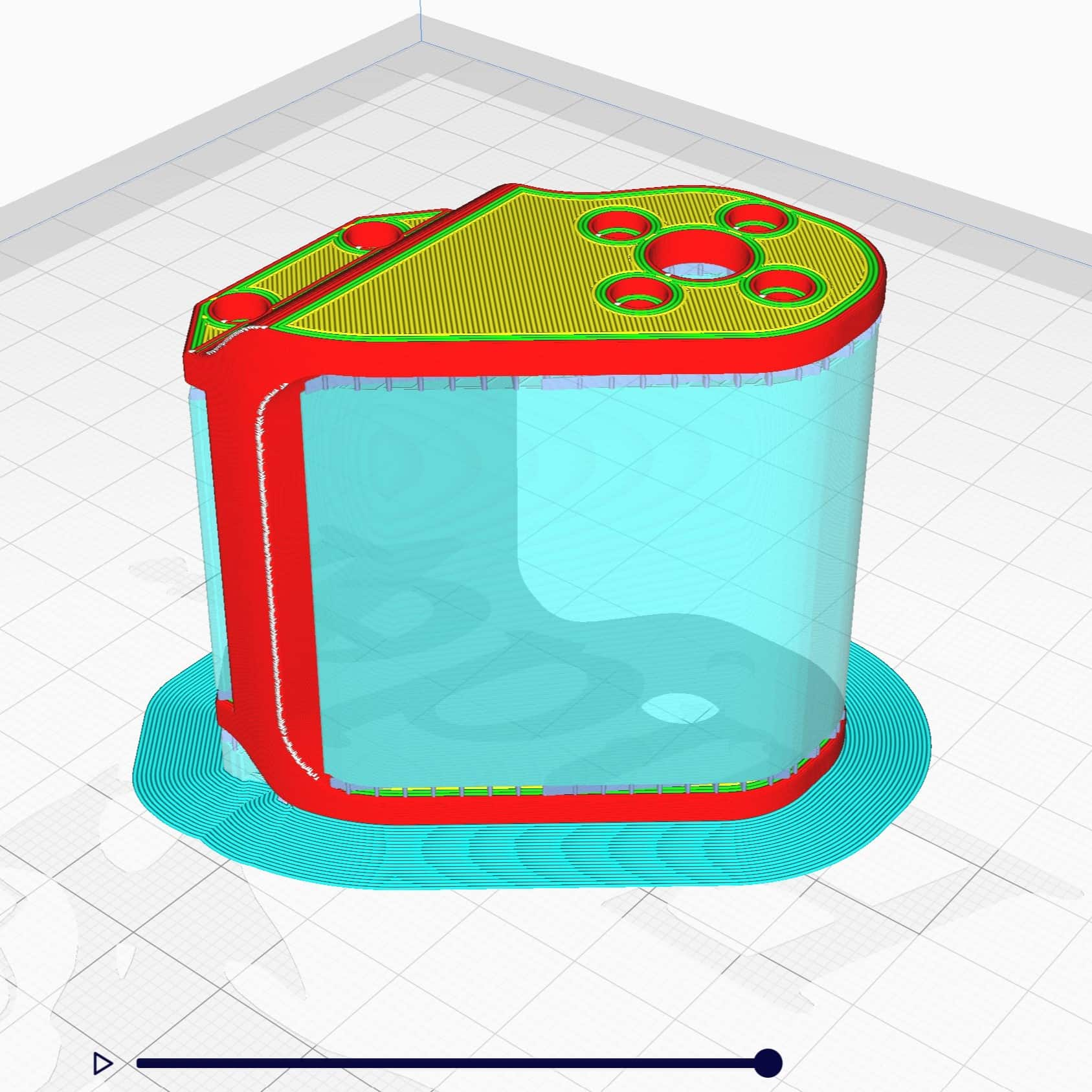

I used Ultimaker Cura's slicing software.

There, "Normal Support" proved to generate

1.5h more printing time than "Organic Support"

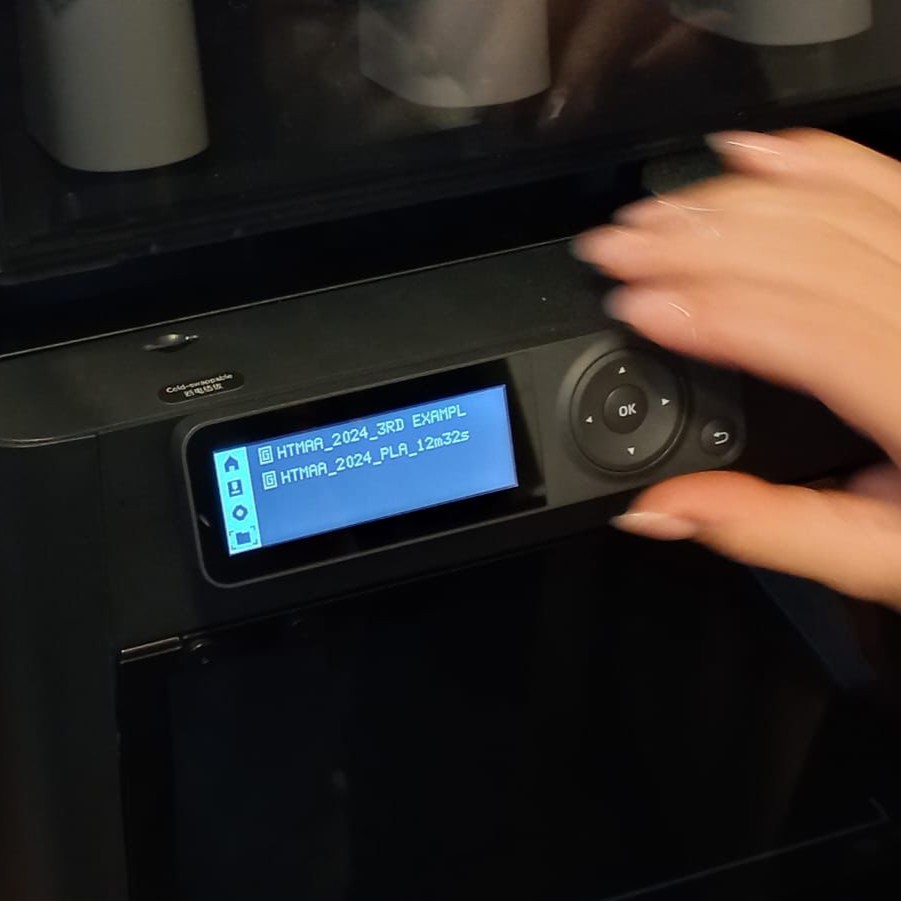

Step 3: 3D-Printing

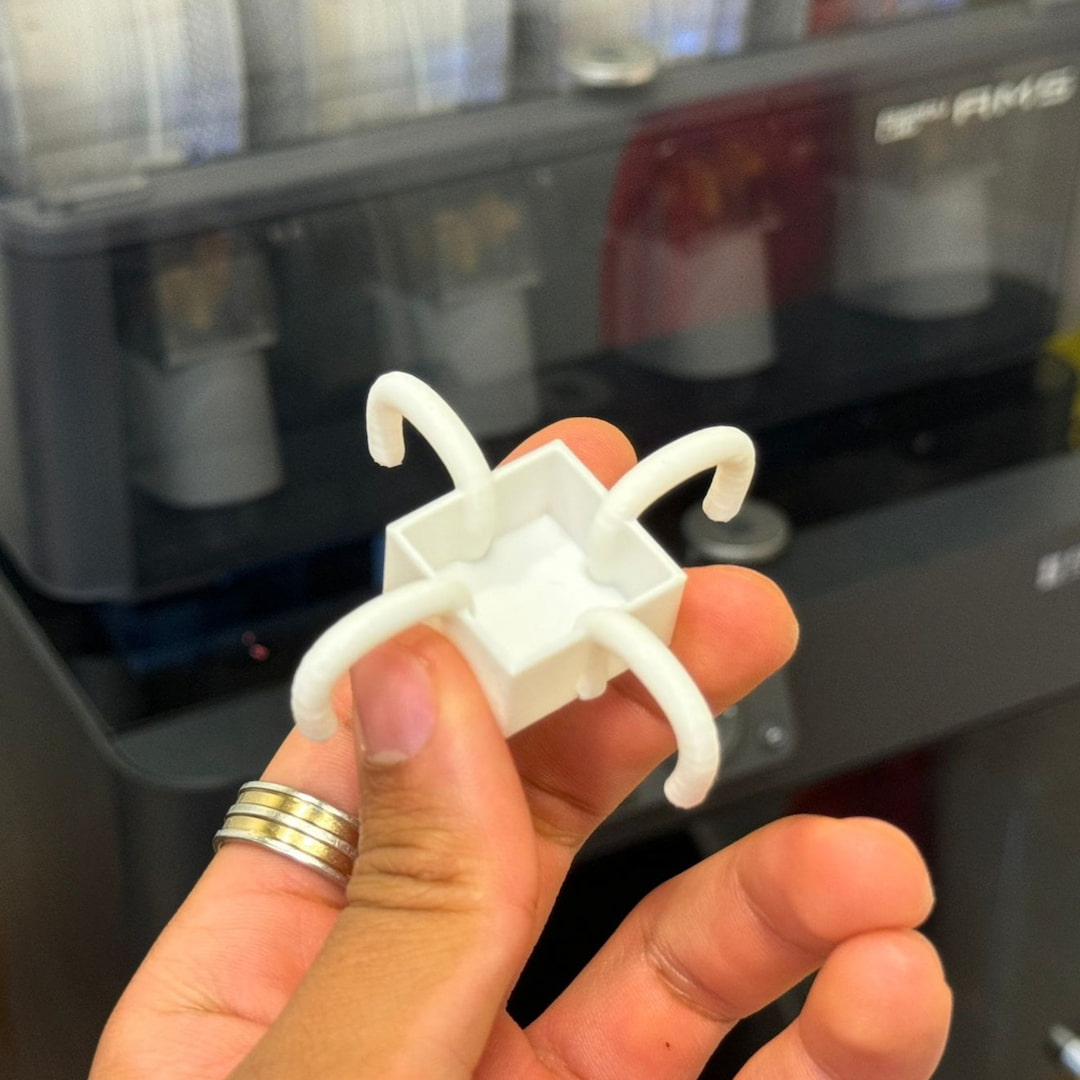

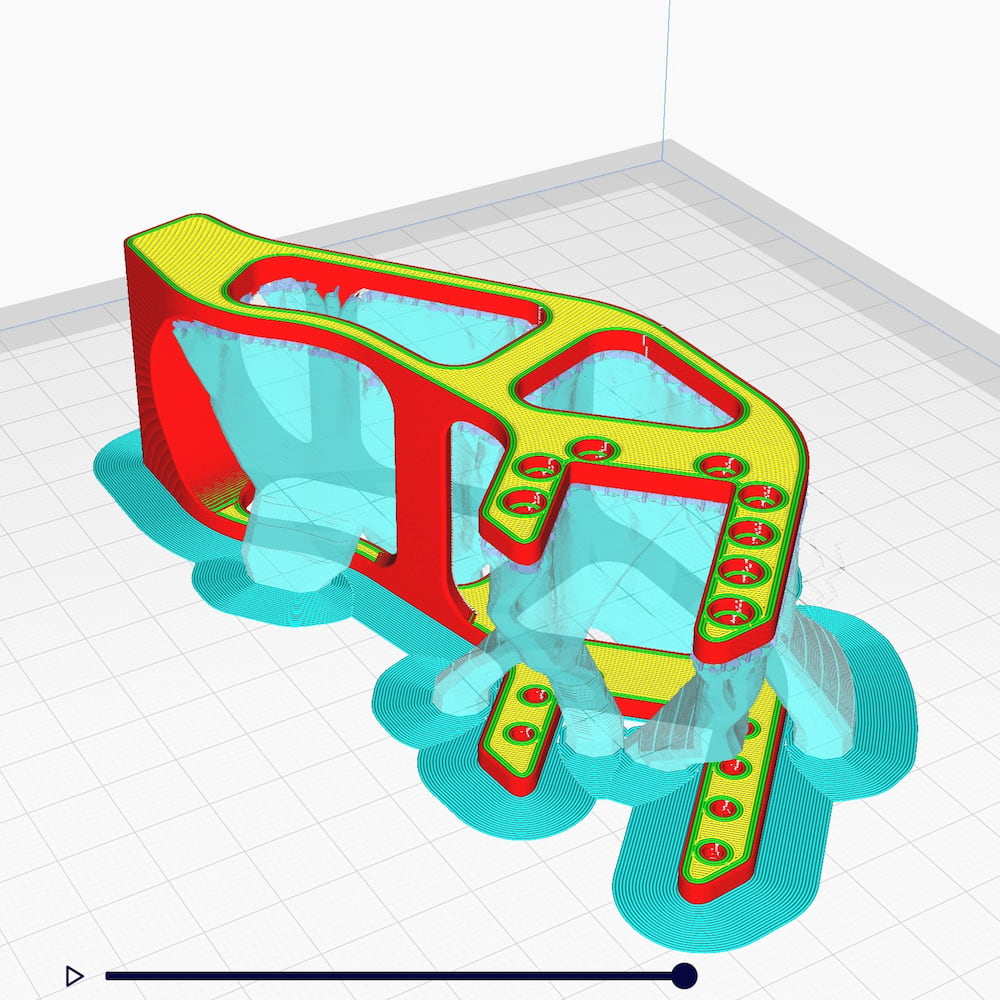

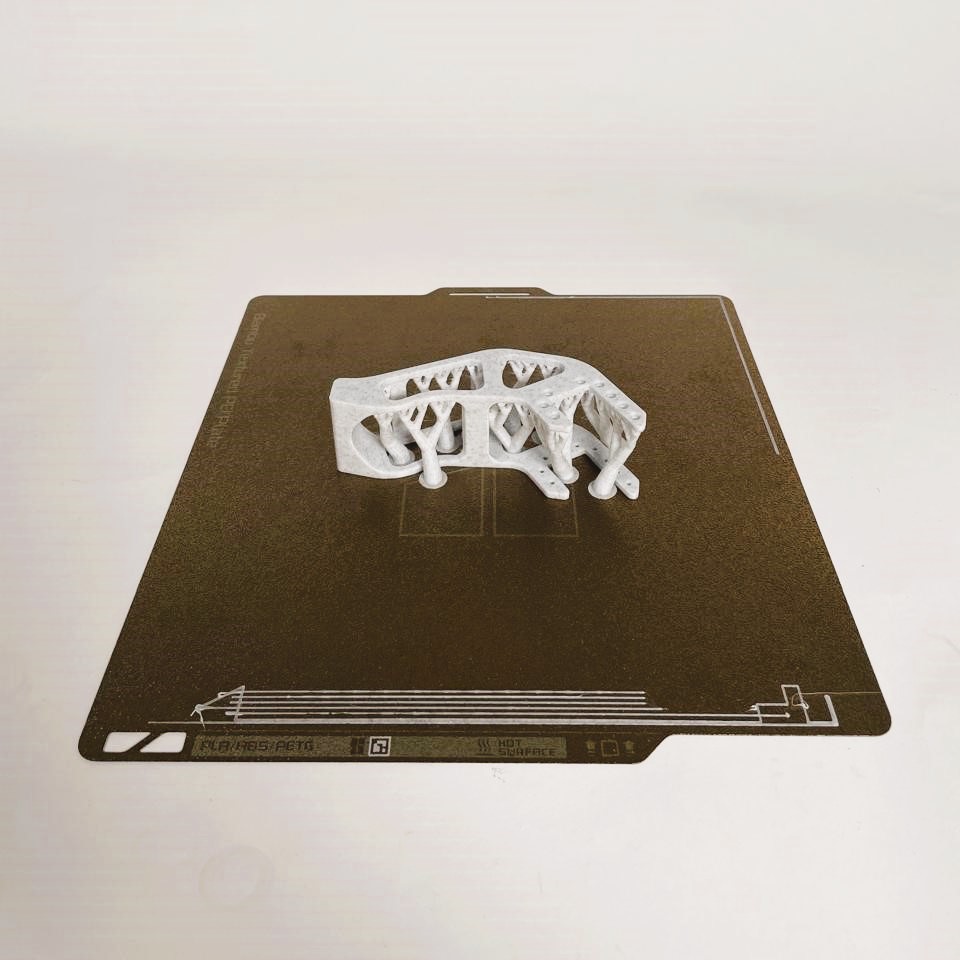

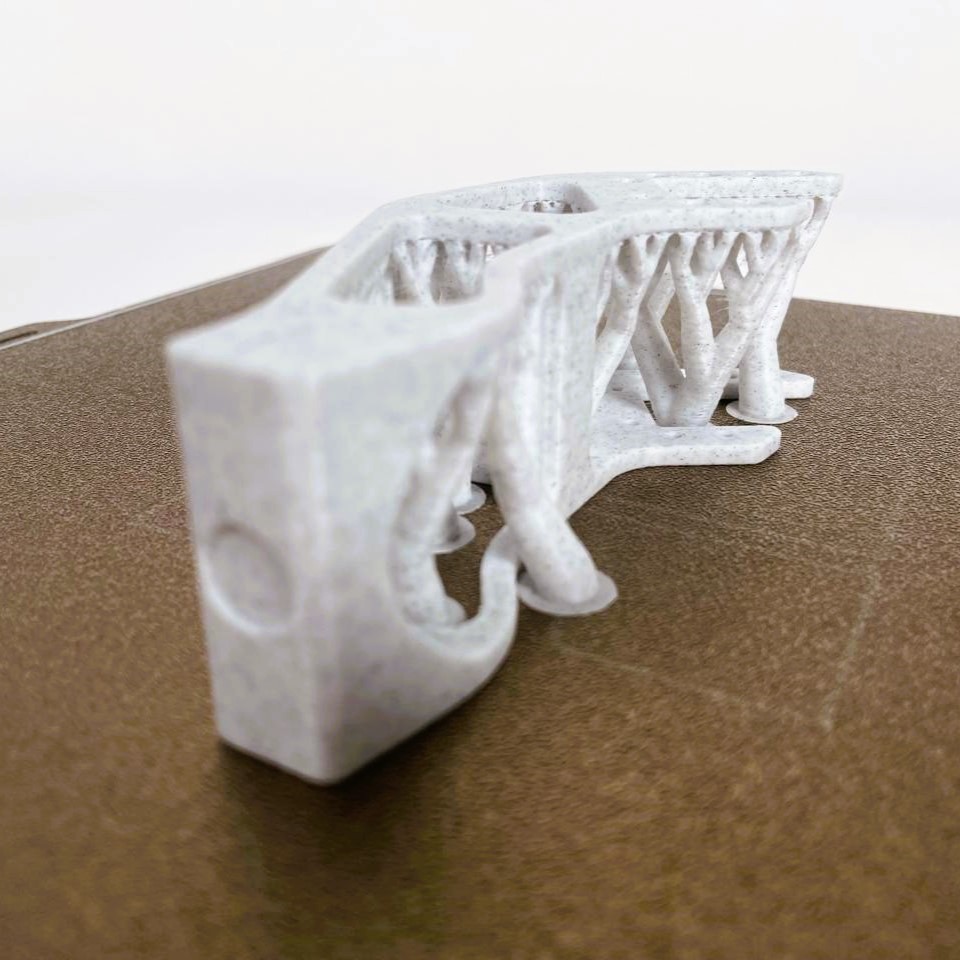

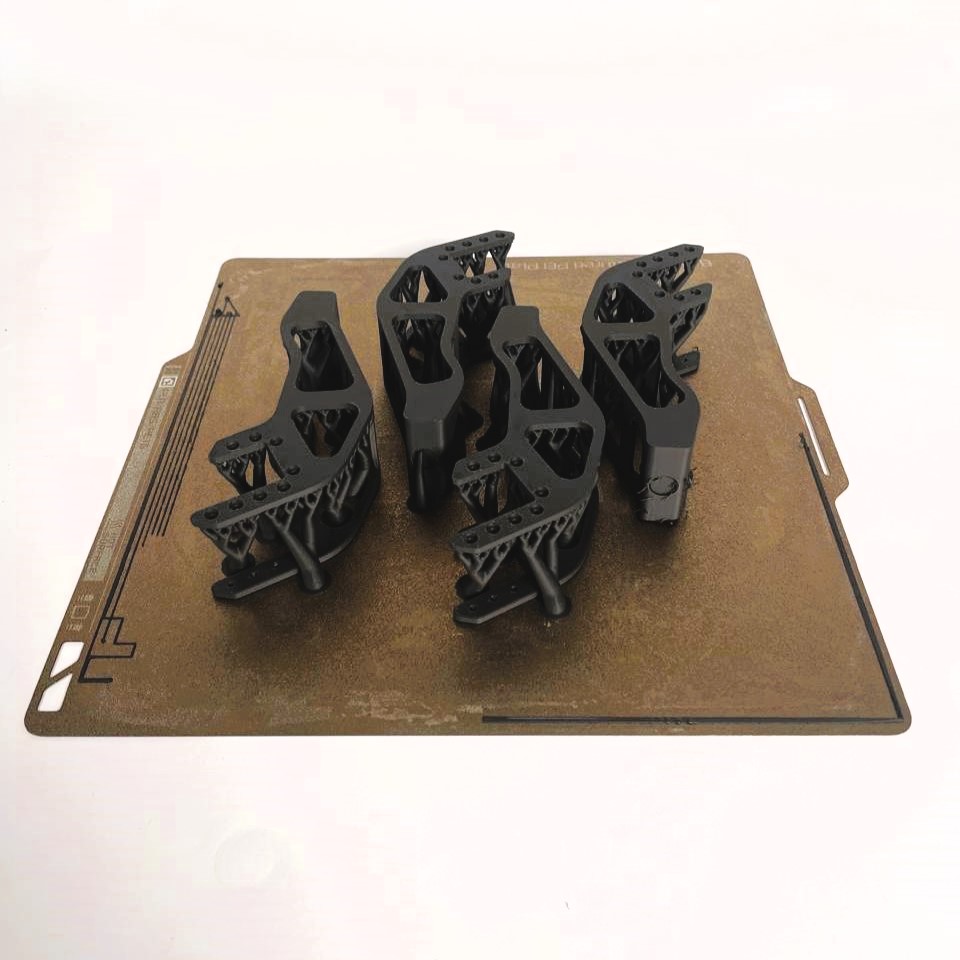

Test Print

I ran an initial print to make sure

the standard settings,plus the "organix support",

would work properly

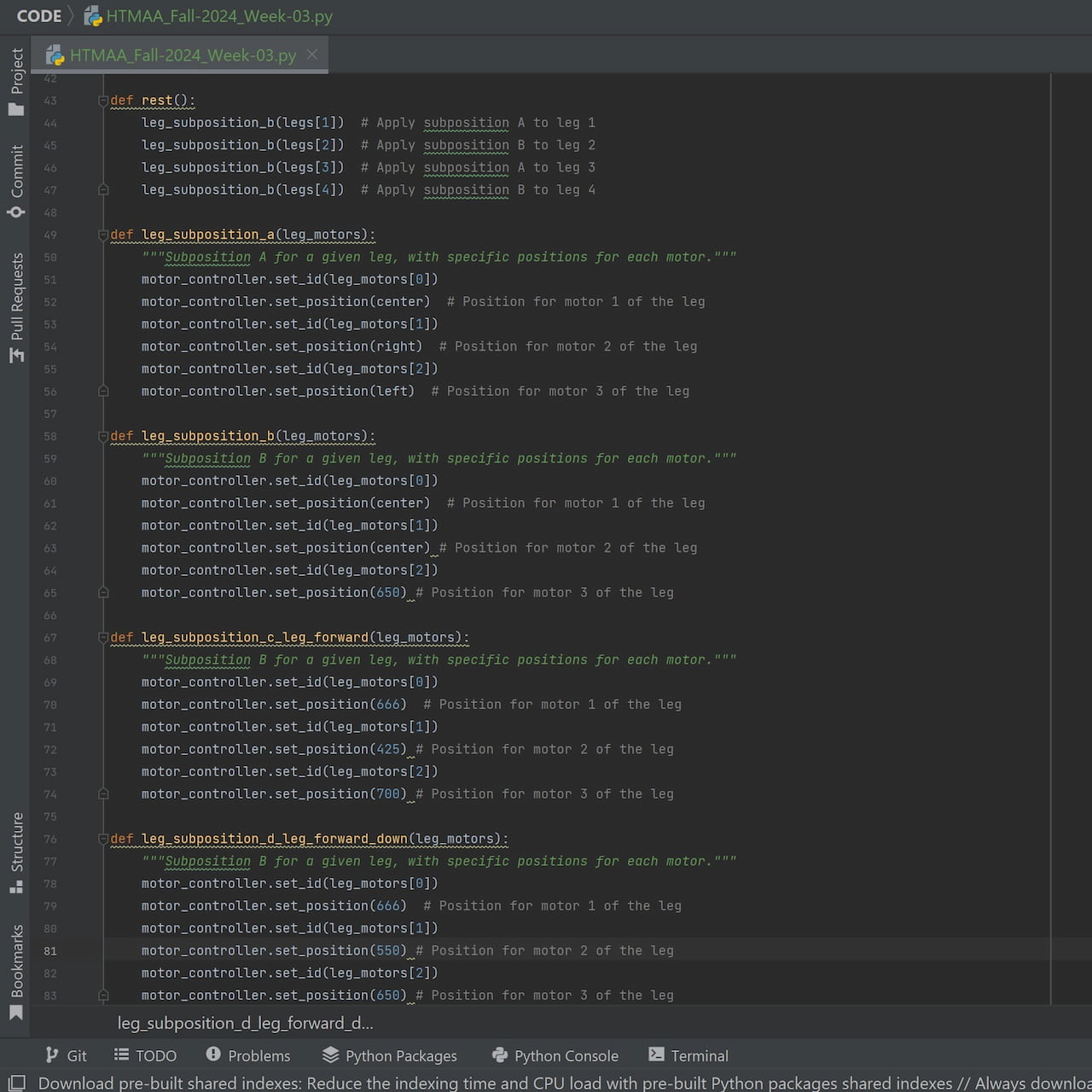

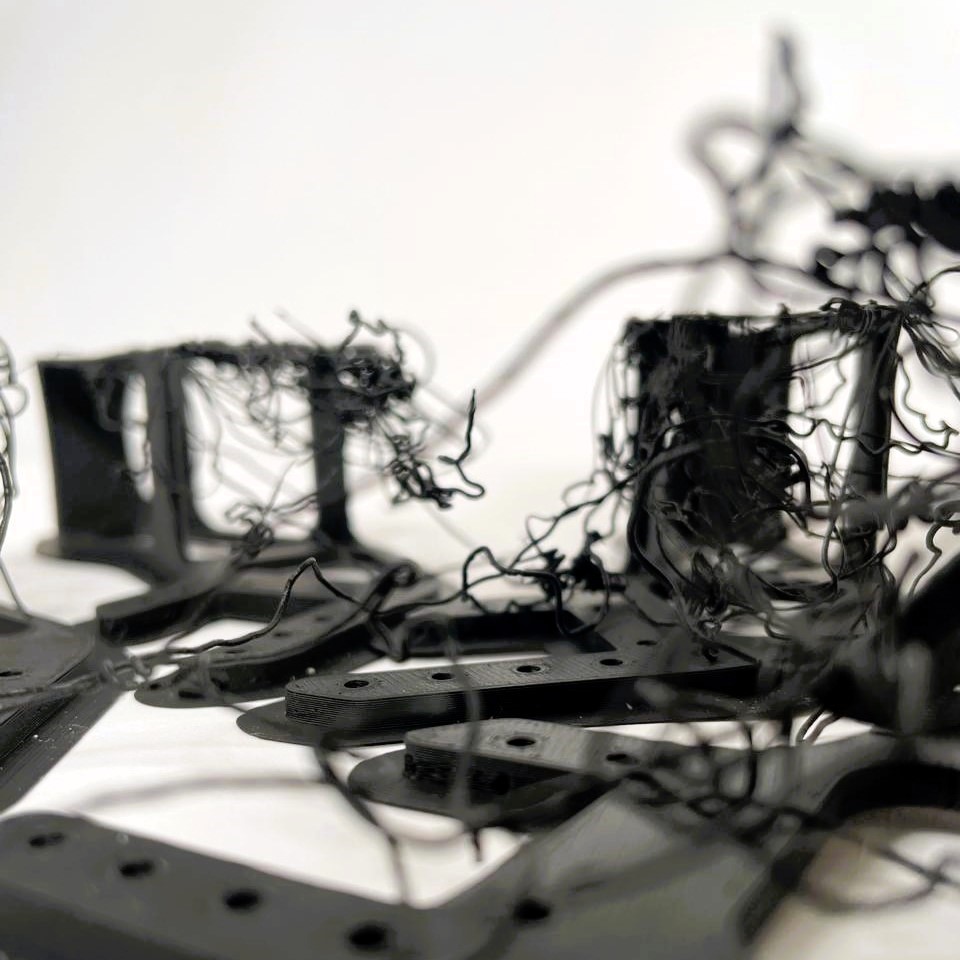

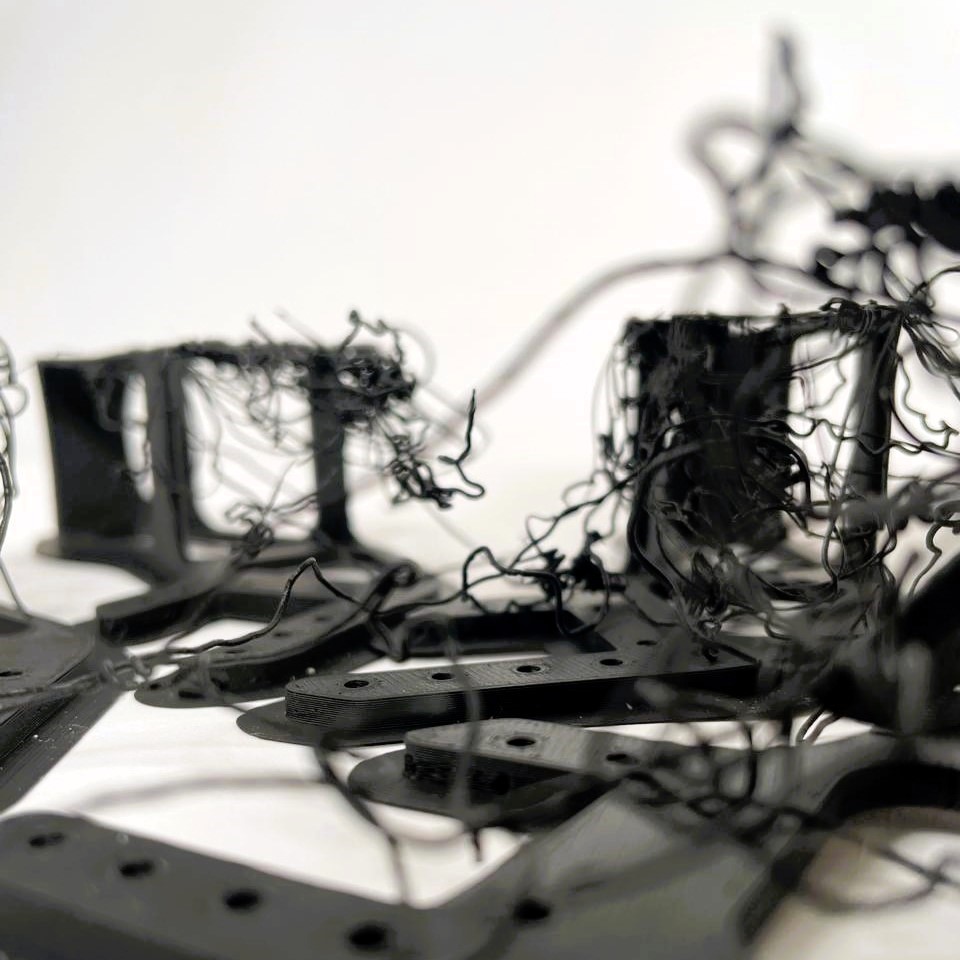

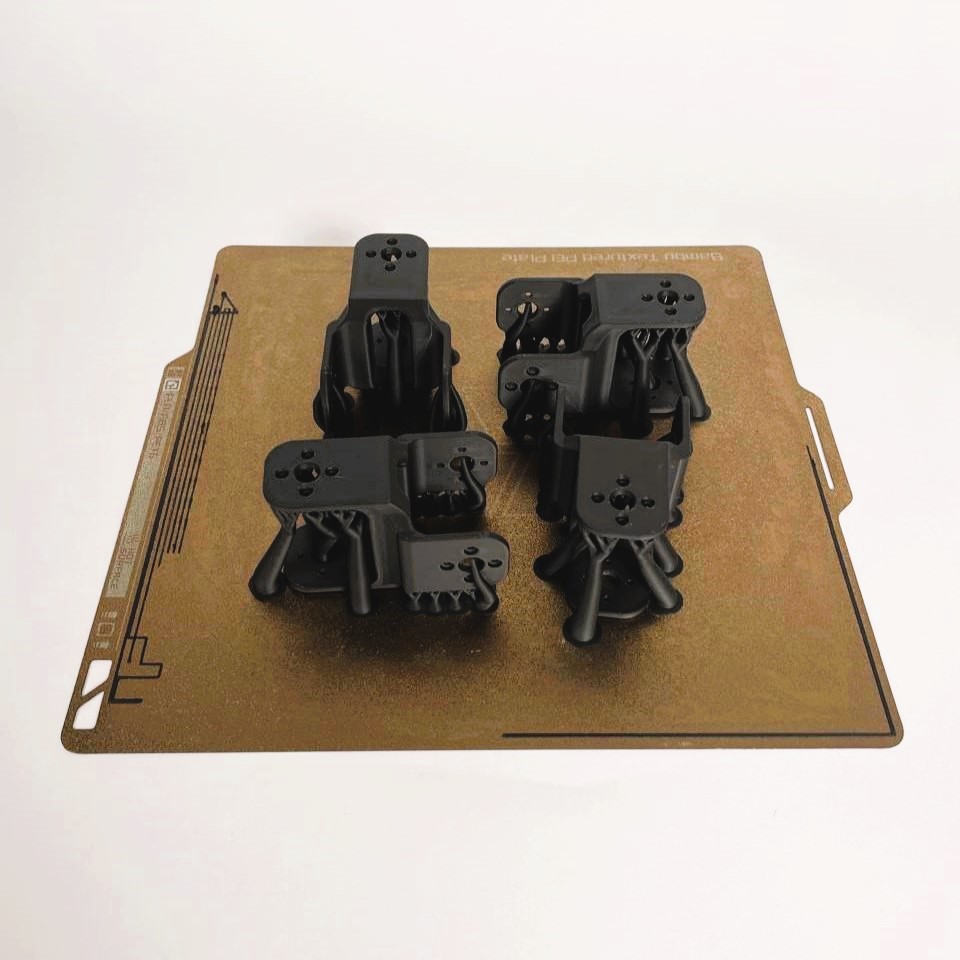

Failed Grouped Print

I tried 3d-printing multiple components

at the same time, yet, I failed to cosider that

it would require 4 times more material (it ran out)

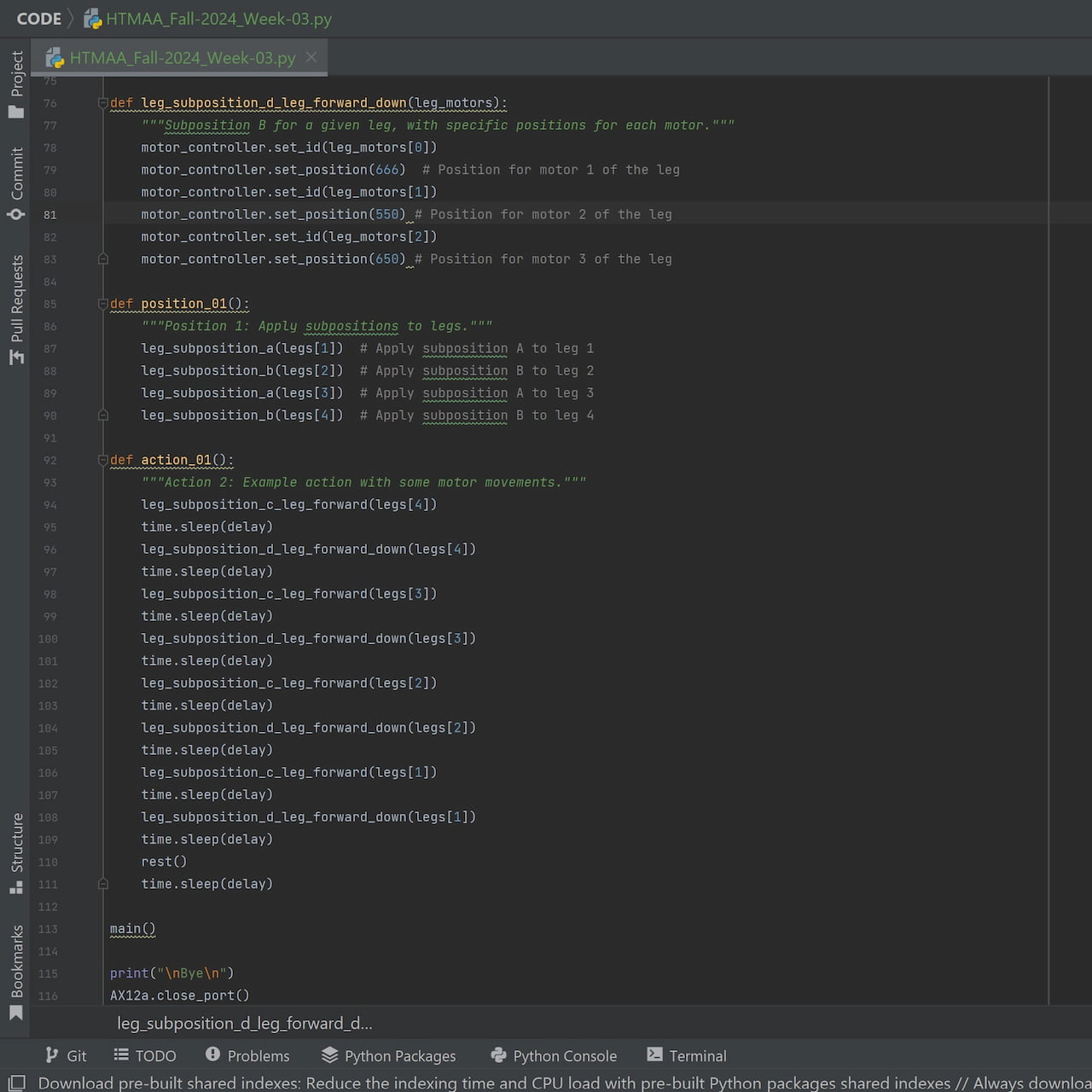

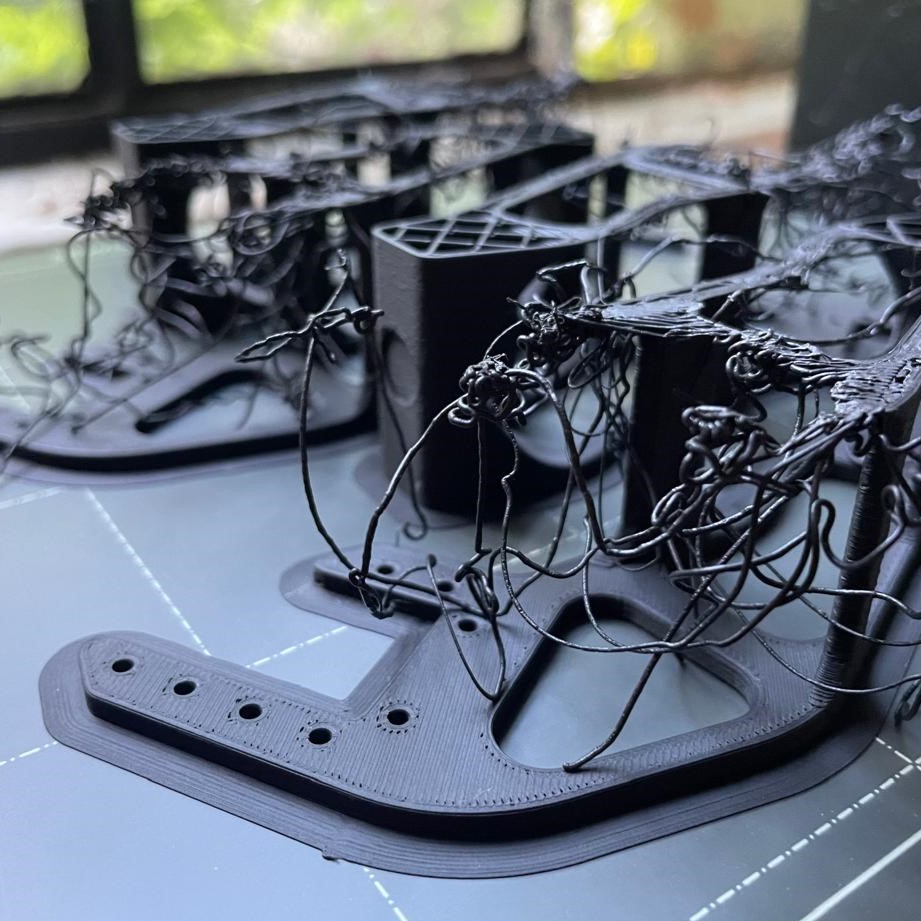

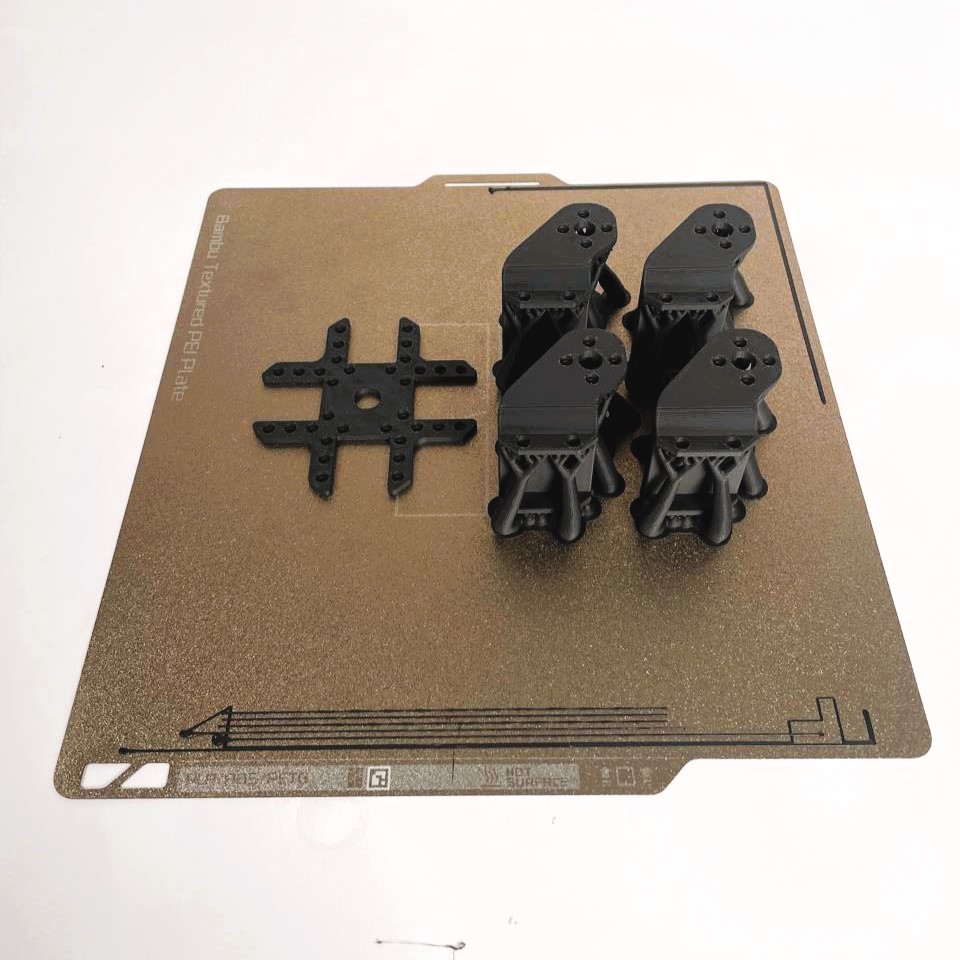

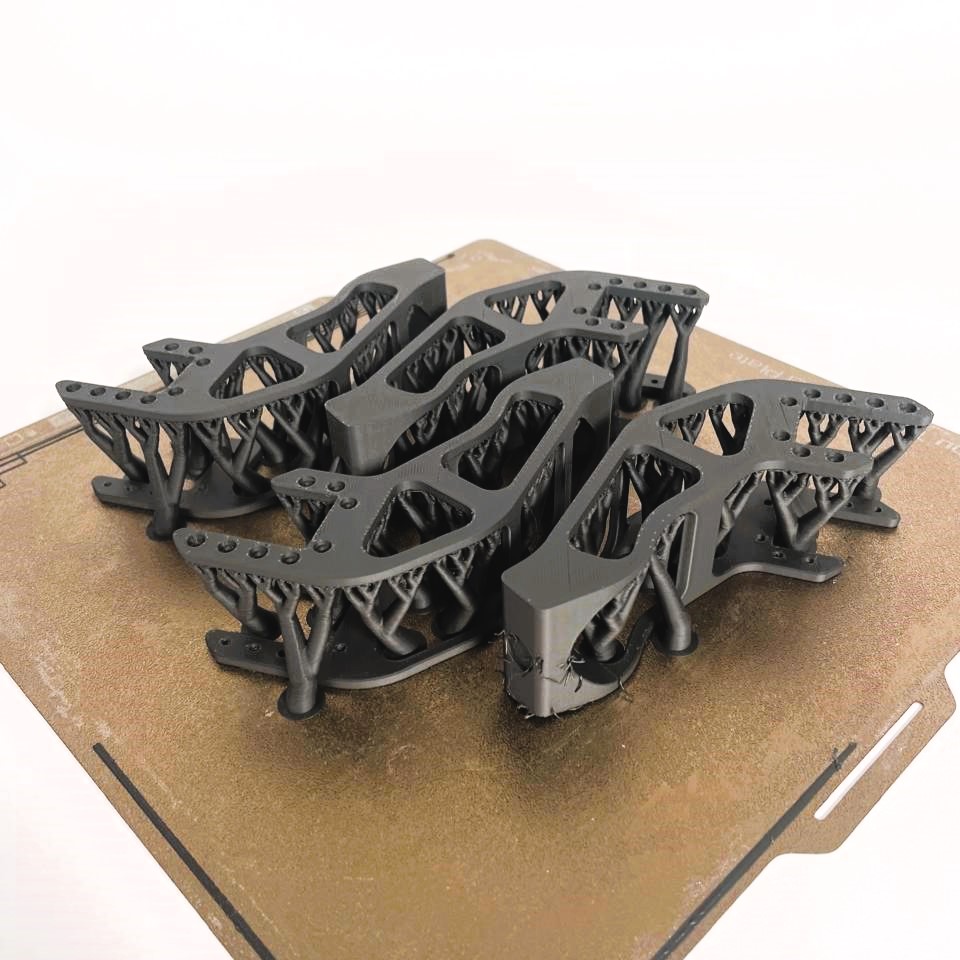

Succesful Grouped Print

After ensuring there would be enough material for each print

I set up multiple group prints to get all the pieces in 3 runs.

Fortunately, all of them were succesful

Step 4: Assembly

Step 5: Deployment