GROUP ASSIGNMENT

🔥

PROPOSAL

TO CAD

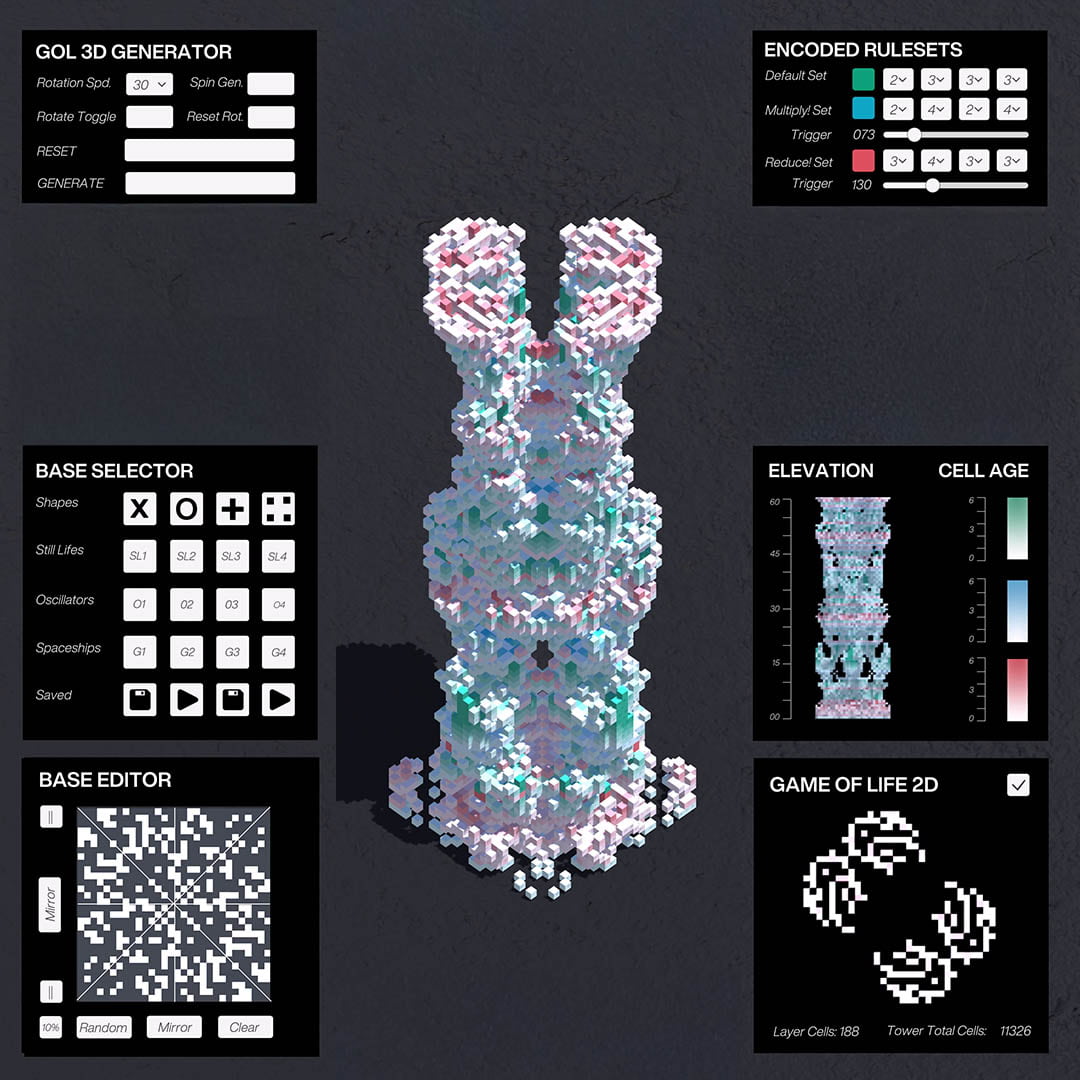

Machine week started by developing ideas. In my case, I had 2 pieces of inspiration that informed my proposal. First, I recently taught a workshop in which we developed an app that generated 3d assemblies based on cellular automata simulations.

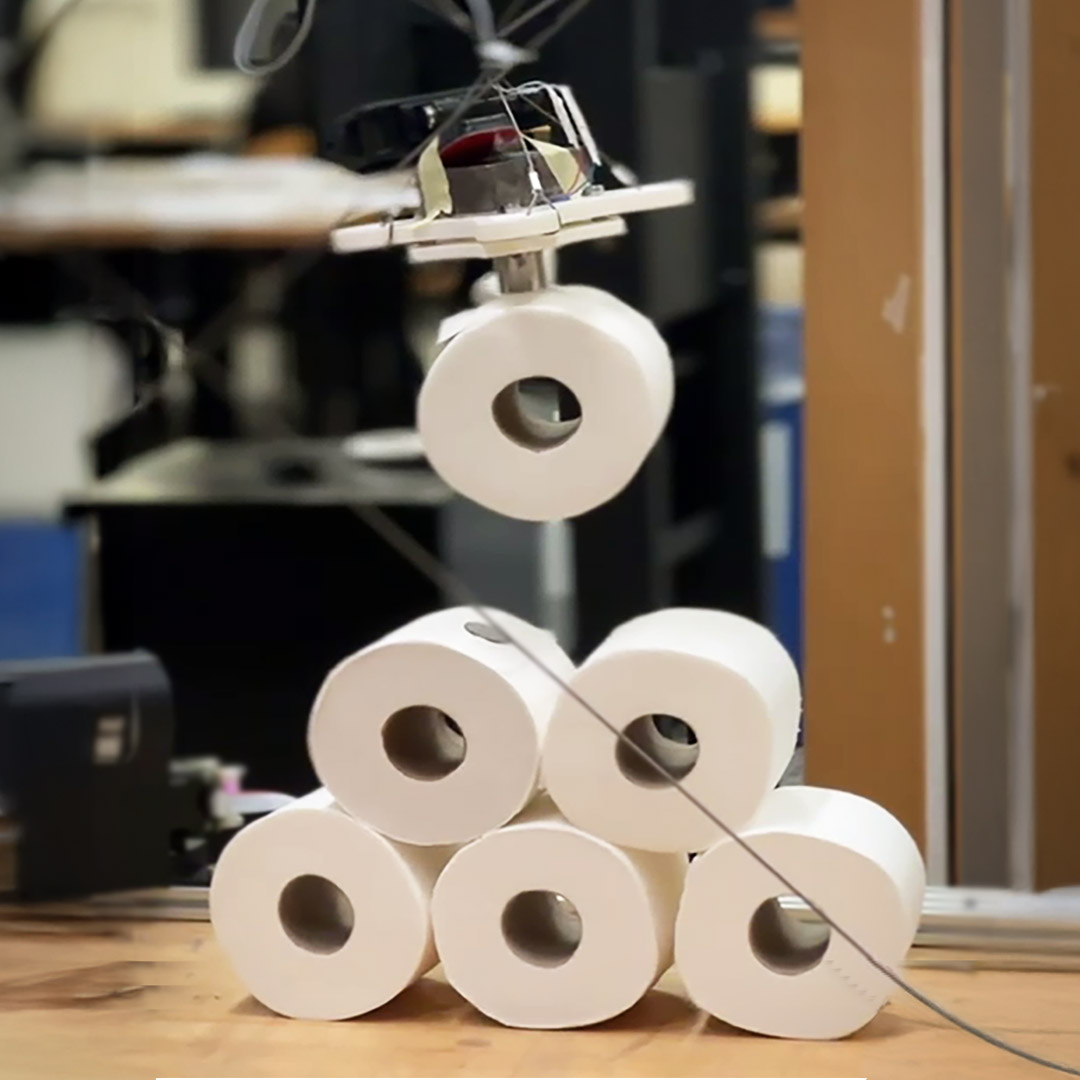

And so, I decided propose a cable-assebmly machine that could assemble the towers generated by the cellular automata app. After some deliveration with the architecture section, and revision by Diana, Quentin, and Jake, we decided to move forward with the idea.

Second, I revisited "With | Without" (2021), a project from the Bartlett School of Architecture at UCL, developed by Santiago Del Aguila, Argyrios Delithanasis, Ghanem Younes, and Andrea Terceros Baroron, that utilized a cable crane for architectural assembly.

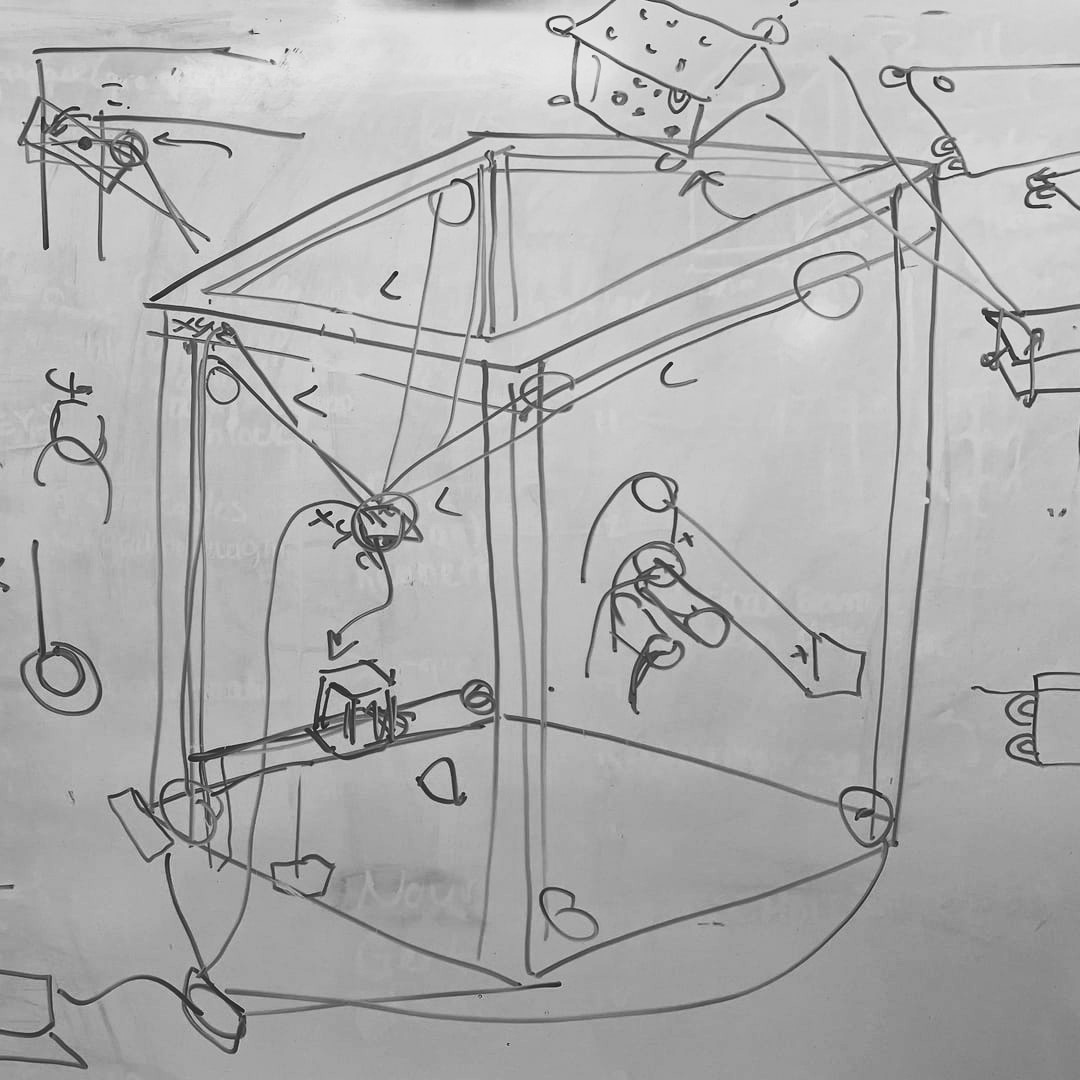

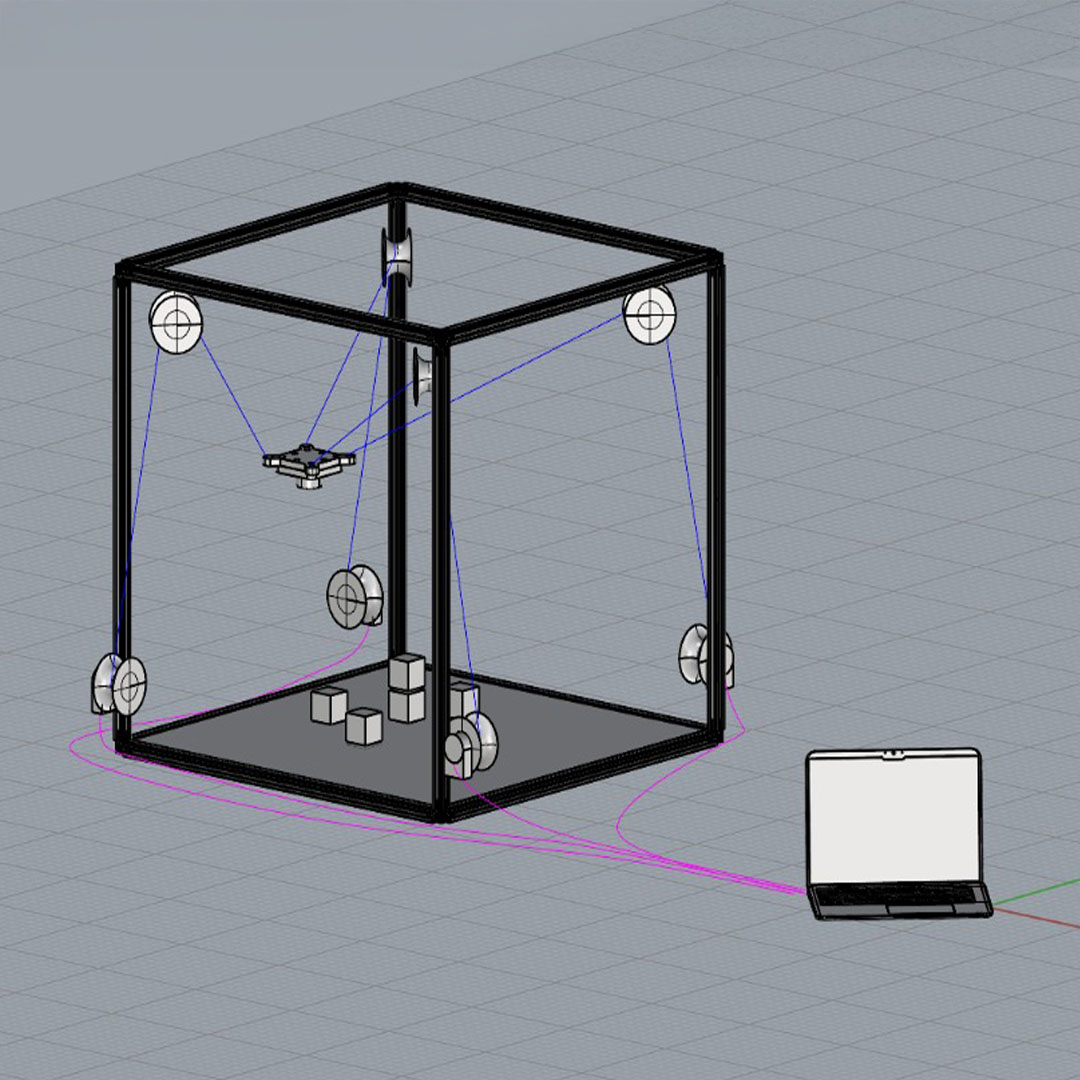

After task division, I ended up in the integration team. And my first task was to create a reference concept model of our machine, and to coordinate the kickoff of a coordinaton model, a drive, and a documentation system.

After task division, I ended up in the integration team. And my first task was to create a reference concept model of our machine, and to coordinate the kickoff of a coordinaton model, a drive, and a documentation system.

PULLEY DEV

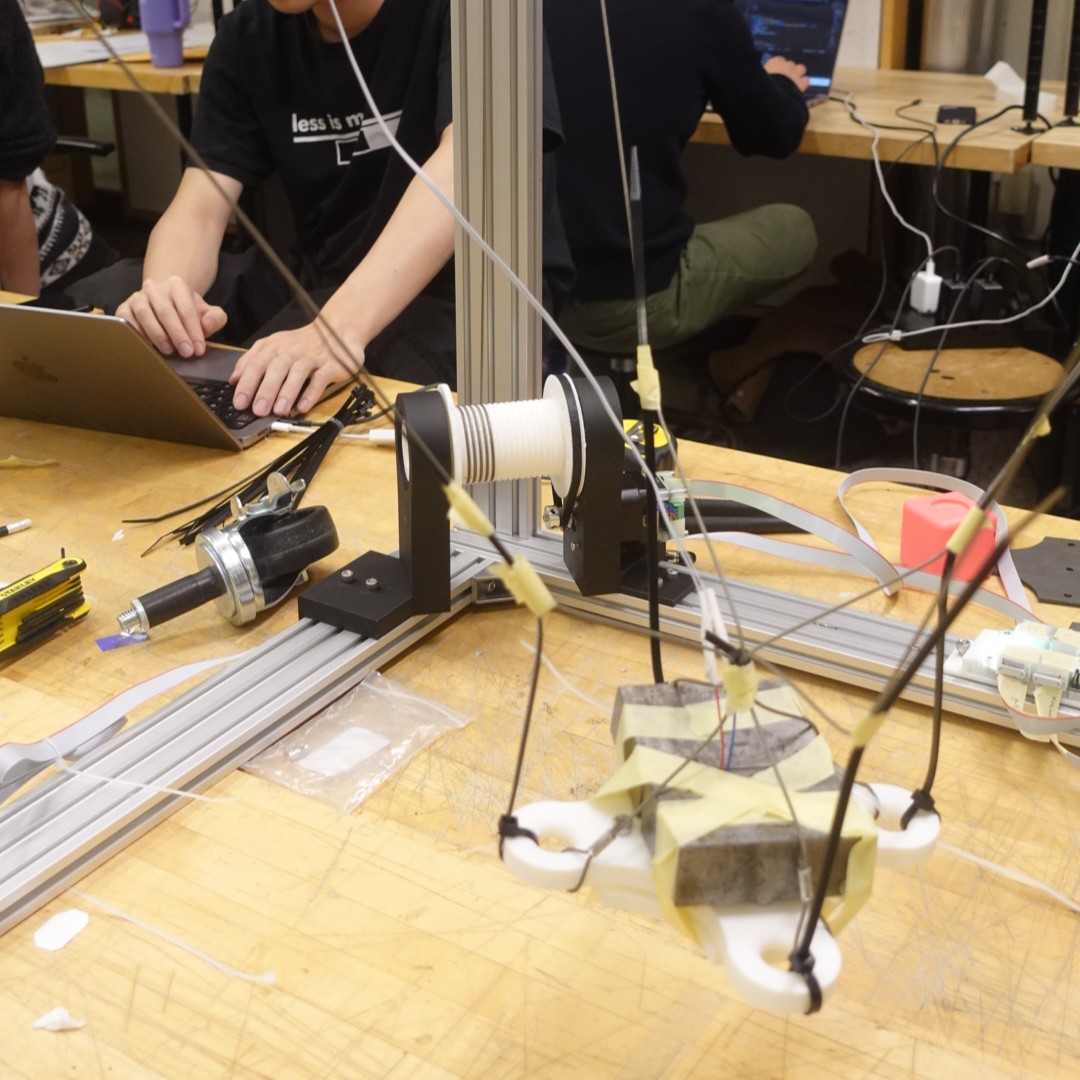

As the project developed, the pulleys proved trickier than originally predicted, and so I joined Yutian in parallel pulley development.

Version A:

Metal, 1 DOF Pulley.

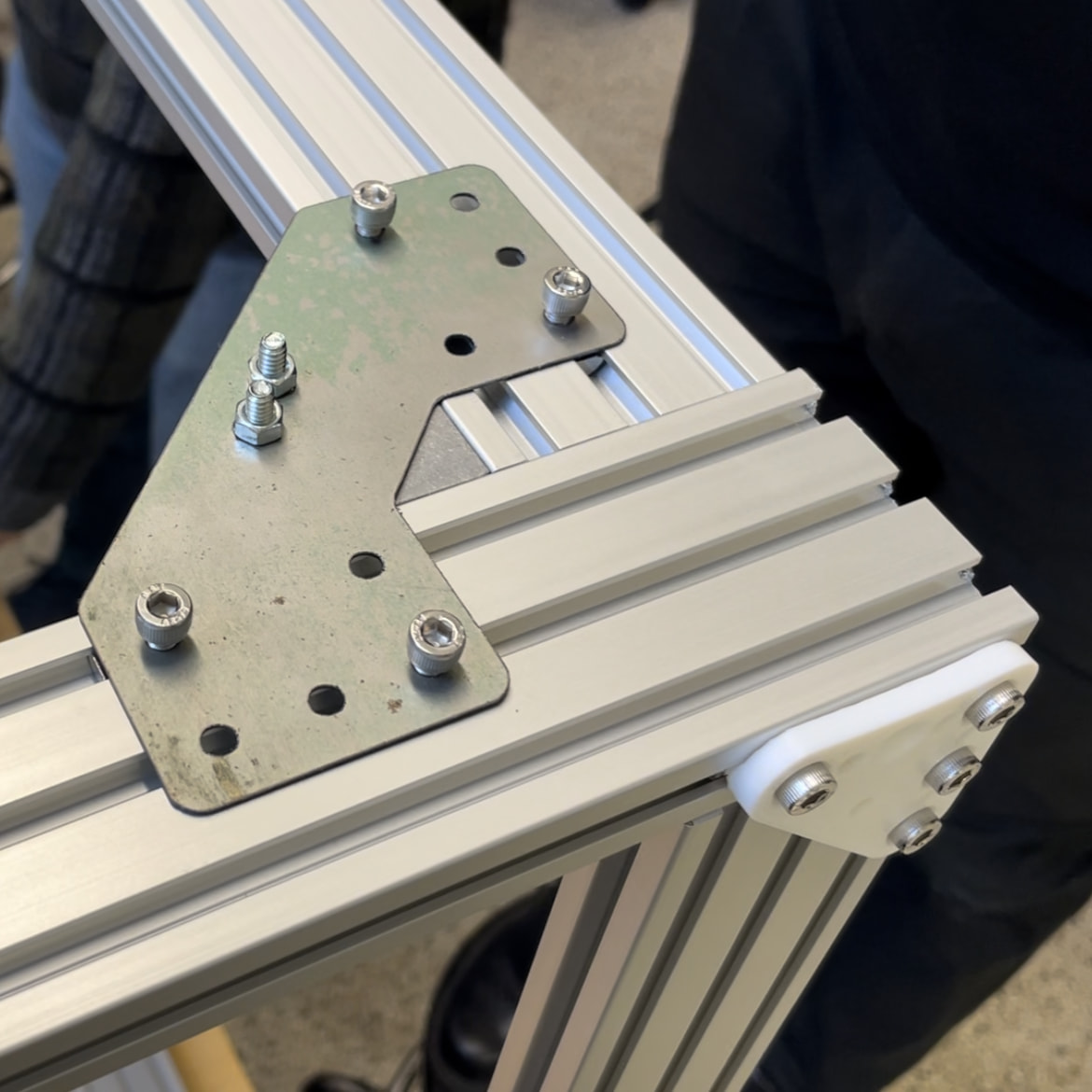

First, with Nour and Kareem, we laser-cut scrap steel pieces into 4 frames, to which we embedded small pulleys with 1 degree of angular freedom. The first integration test was run with this setup without major issues.

Version B:

PLA, 0 DOF Pulley.

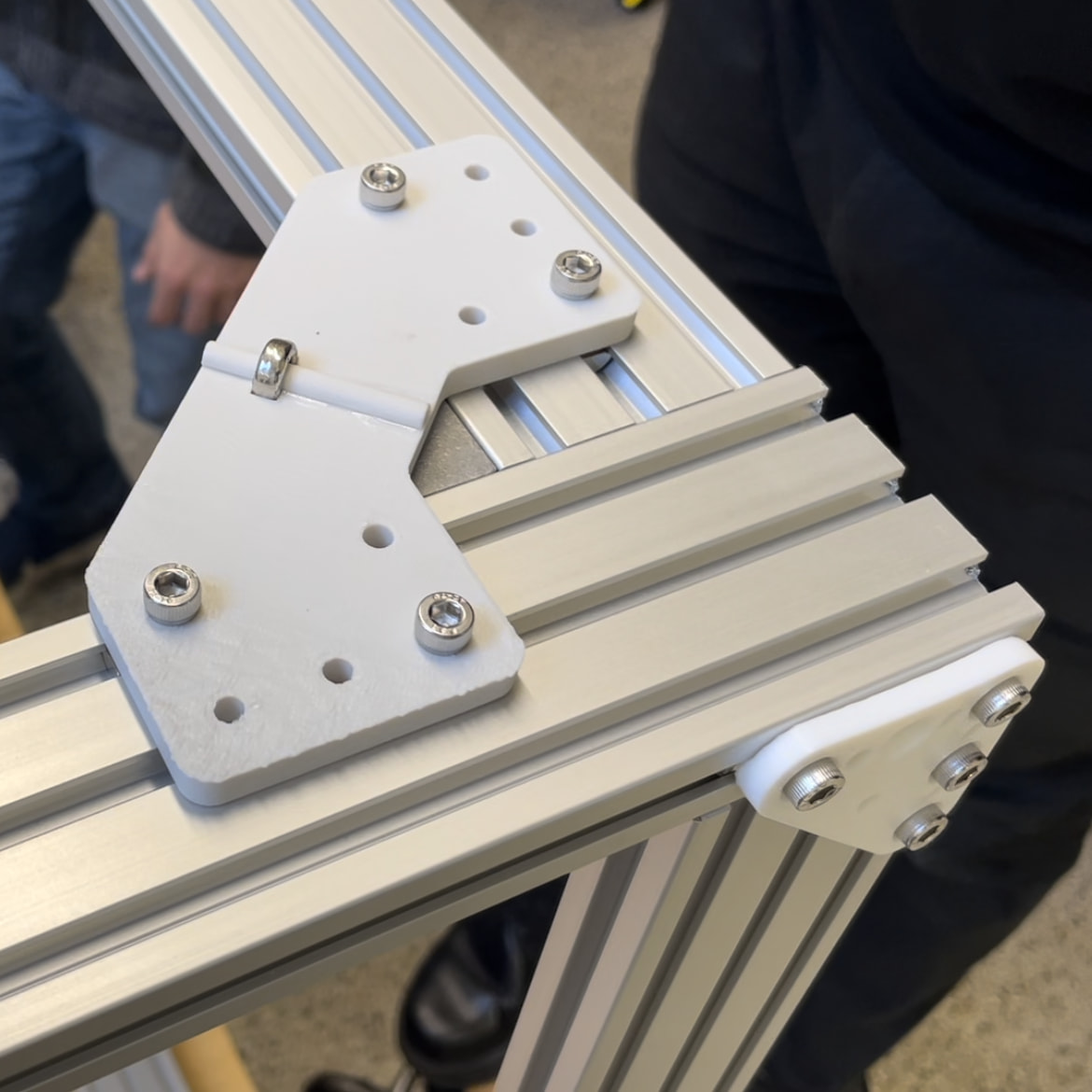

Then, we tried a slightly more constrained approach, embbeding and gluing a fixed pulley to a 3d-printed PLA plate. We tested both version and, following Quentin's advice, decided for the 3d-printed more controlled version.

ASSEMBLY

& TESTING

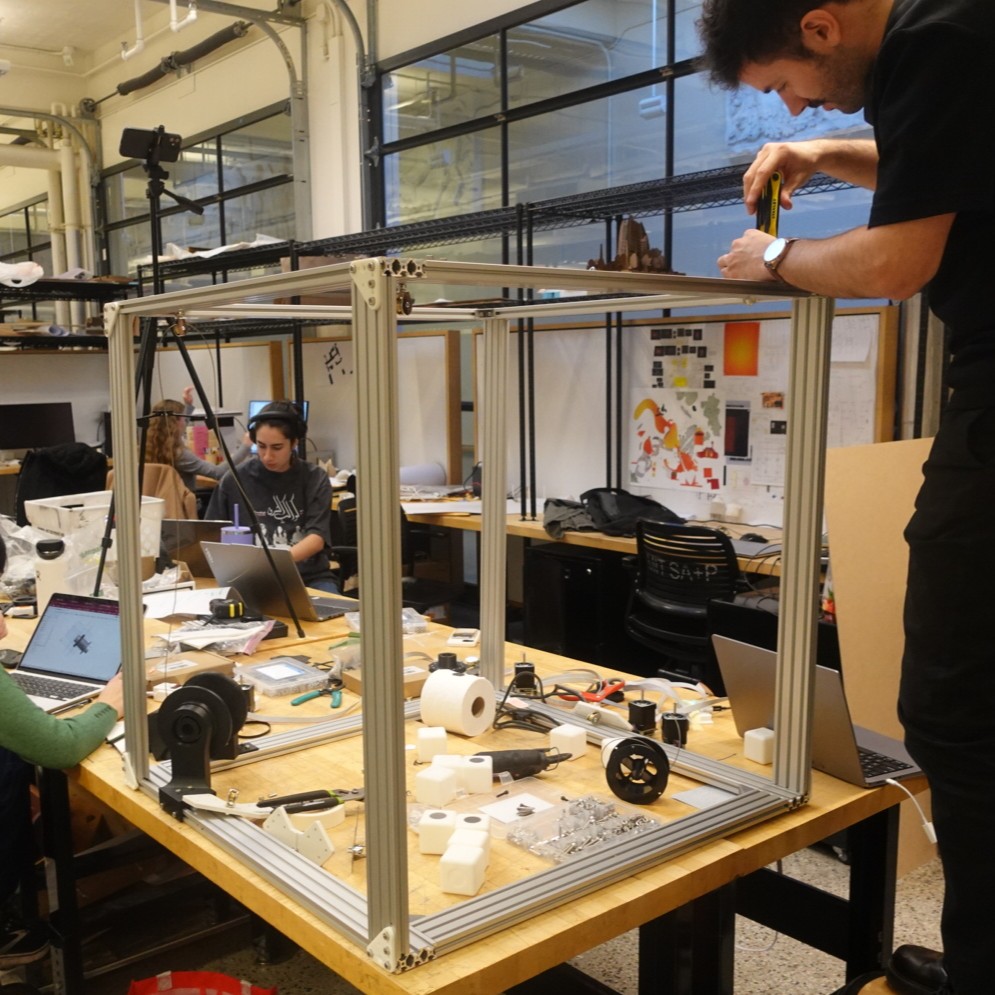

First, once the team had developed most pieces of the system, we collaborated in assemblying them together. Moreover, we were able to run a quick test with 1 motor, aligning the code to the real-life movement of the machine.

Next, once we had all of the main components, we were able to assemble and run a full integration test. Among other details, we worked in stabilizing the grabber plate, adding weight, and calibrating the 3d grid with the code environment.

Finally, we had a working machine. Yet, this process revealed a number of new tasks and issues to resolve, ranging from frame reinforcement to cable management.

DEMOS

One the machine was running, and with the arcade theme preffered by the team, it was evident that we had t migrate from hardcoded assembly sequences into real-time game-like control. In the end, multiple users were able to play with it succesfully!.