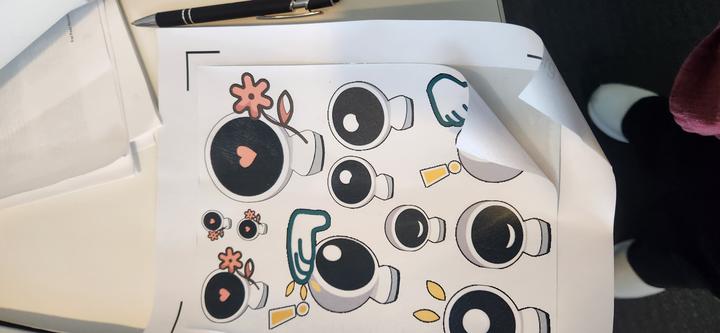

It was a bad start from the first try; several trials later, I had full stickers with good output. More will come in the coming days as I take special requests and gift people some of the ideas.

Printing on the wrong side of the sticker paper! What a start!

Wrong software print.

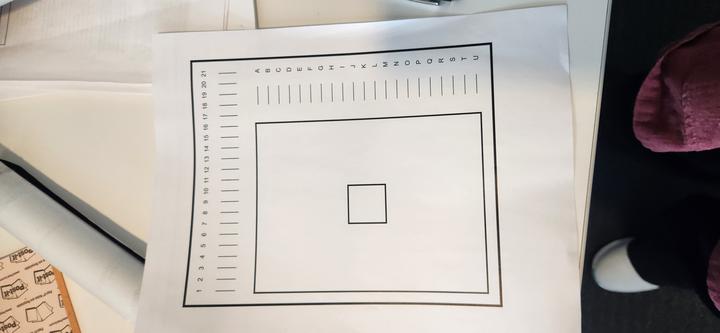

Correct software, but needed calibration.

Wrong individual sticker split.

Wrong cut alignment.

But some of them were saved.

Final product, finally!

What would I do with laser cutting, given only printing was crazy? Let's test that with normal vinyl cutting first! Oh, well!

Wrong transfer material!

What is happening? What is this?

Let's call it a day!

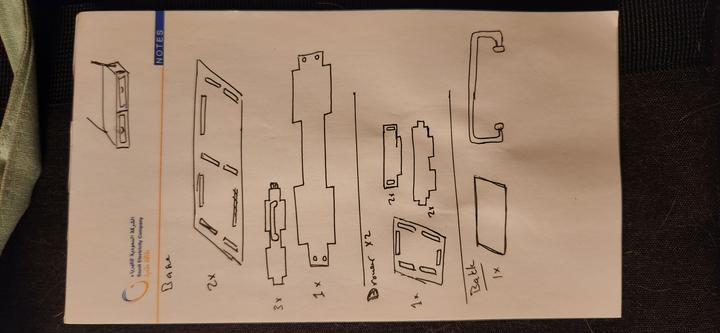

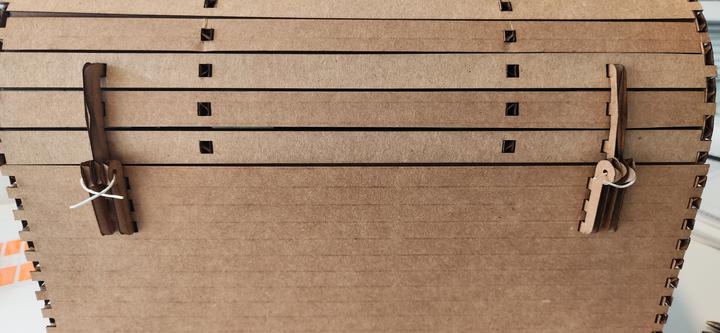

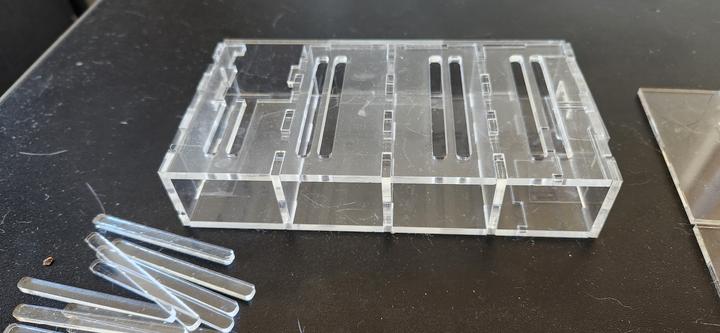

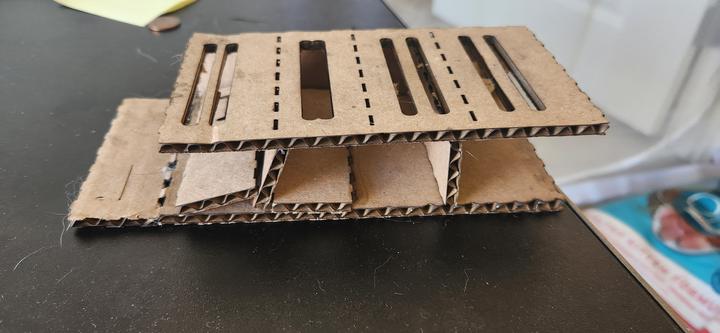

Also, a very desperate start with AutoCAD. The amount of time I spent trying to make my design and not being able to move beyond creating a rectangle was disappointing. To save my sanity, I took a design from the web, for a treasure box, and printed it. Fun assembly, with extra screws (am I missing something?), when will it break? Normal IKEA assembly feeling.

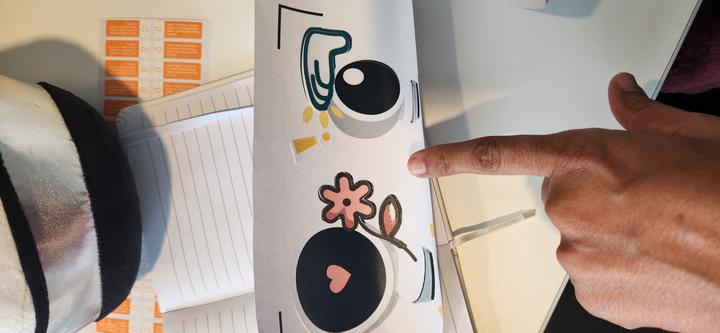

Original planned design.

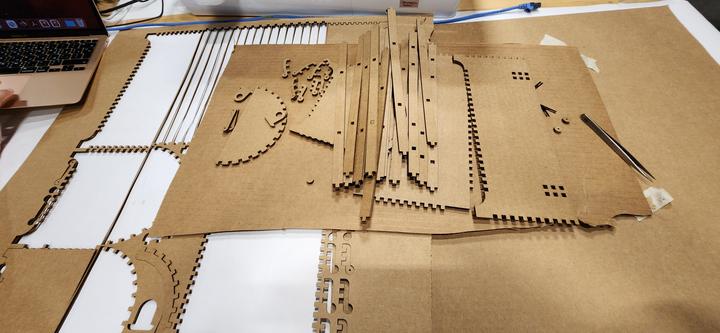

Printing in progress; smells funny!

Success?

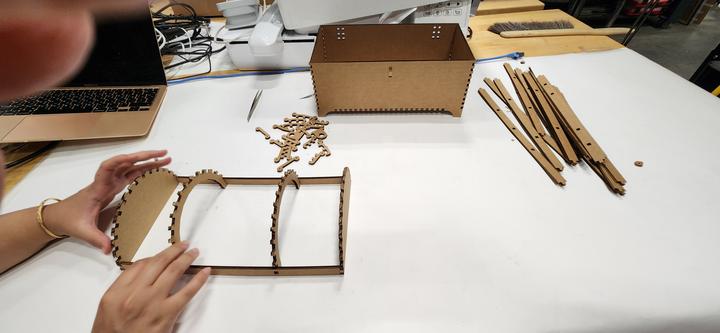

Let's assemble.

Looks like they should be here.

Extra screws?

Let's keep you together!

I should find a better material.

Better transfer material is what you already know! Avoid fancy.

Final product, but not yet satisfied. More time for the actual project(s) I planned.

I managed to learn Fusion (just basics to get by -- but it really helped a lot). Resources include:

Made a few more stickers for our group.

A few more for my husband's website logo. Printer's color quality differs from one printer to another!

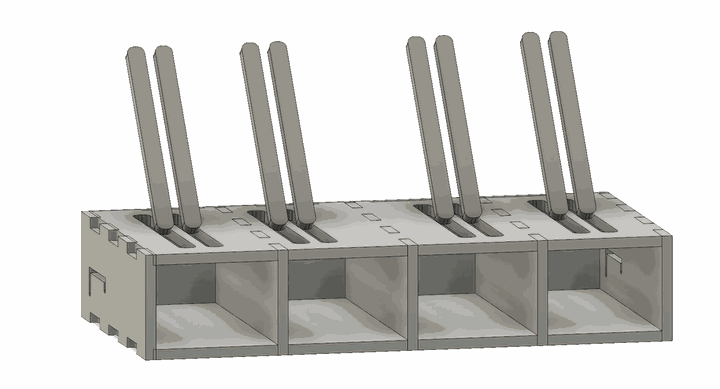

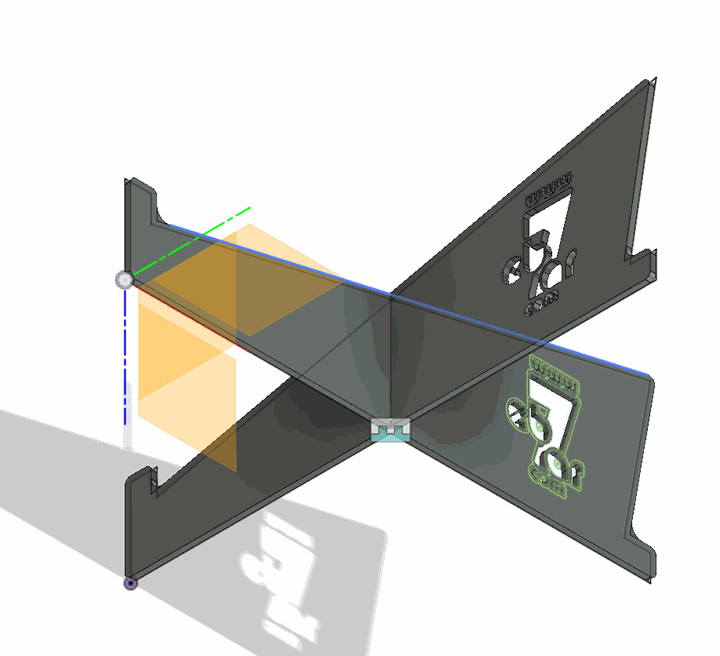

For making something big, I wanted to design a daybed, where the back of the couch is adjustable in two levels. Straight back to provide space for sleeping, and back at an angle to reduce the seating space and give back support. The mechanism should be very simple, where a metal pipe holds the wood strips (and is attached to the side panels).

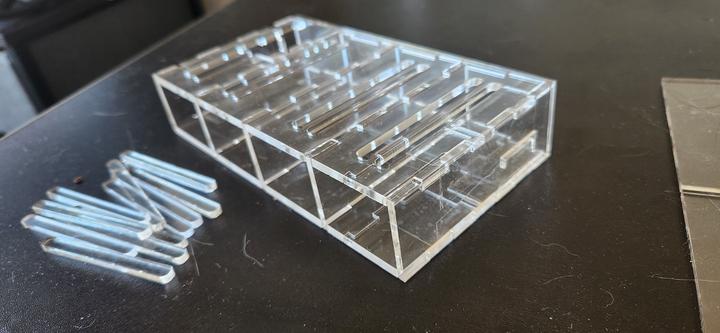

Printed the daybed on a small scale to test the idea, which made me change my mind.

Don't mind the hole; the material was overused :)

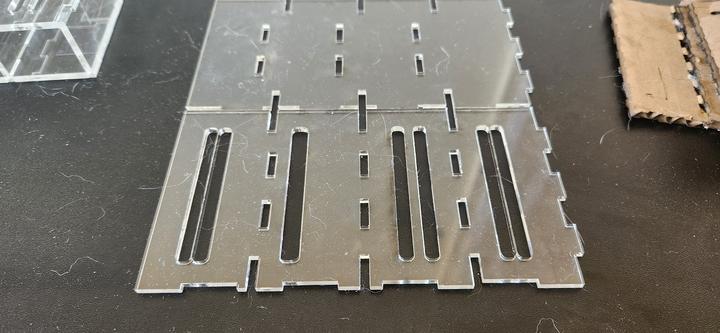

Failed attempts, where I forgot to change the parameter for material thickness.

Another failed attempt, where the machine wasn't aligning the cuts! I had to use the other laser cutter.

Fun project for my friend to personalize wood train parts as a gift for MAC, her little nephew.

I also designed a laptop stand personalized with my husband's website logo.

The laser cutter was out of alignment, but I already lost the material, so I couldn't recut. We have to settle for this for now!