Welcome to Week 7

Molding and Casting

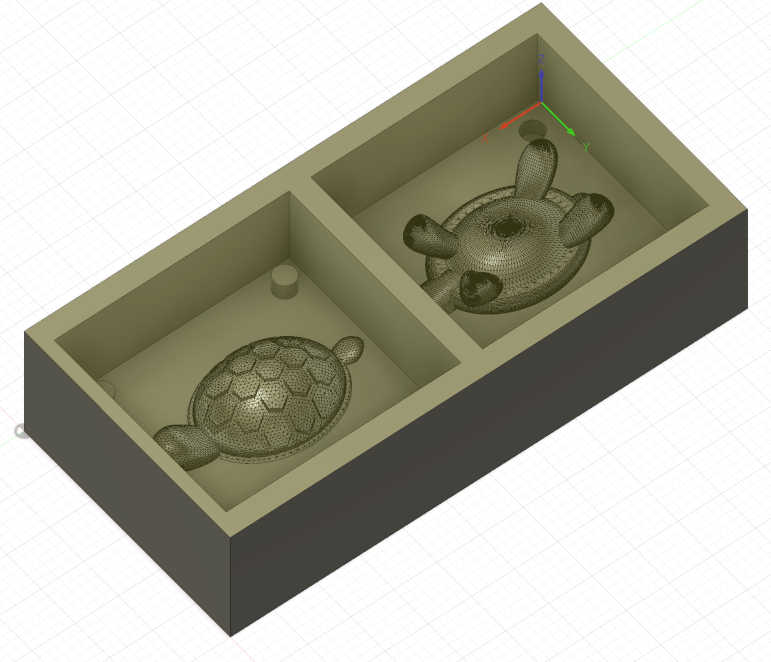

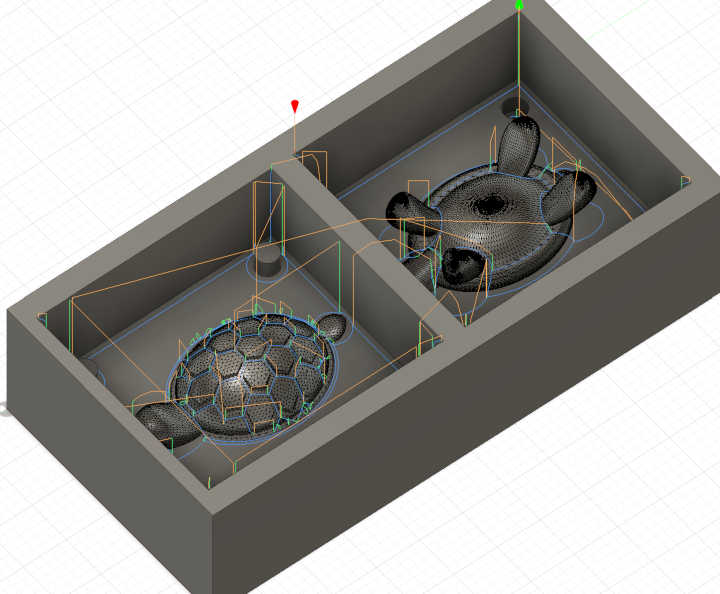

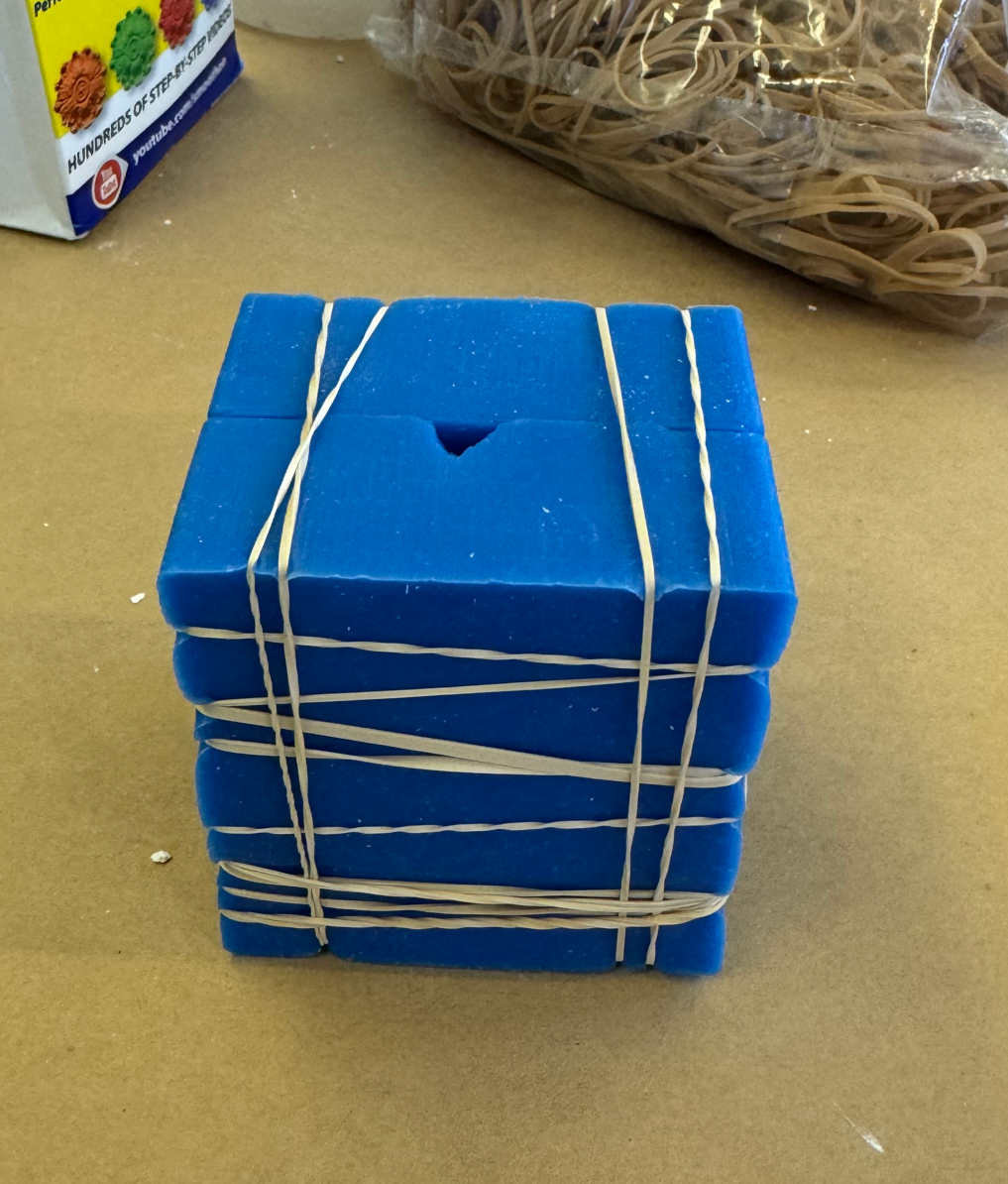

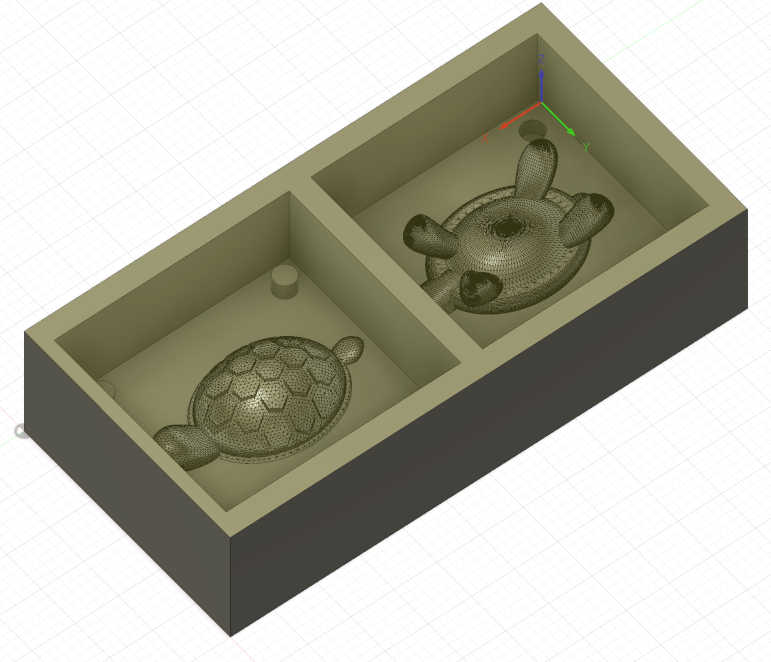

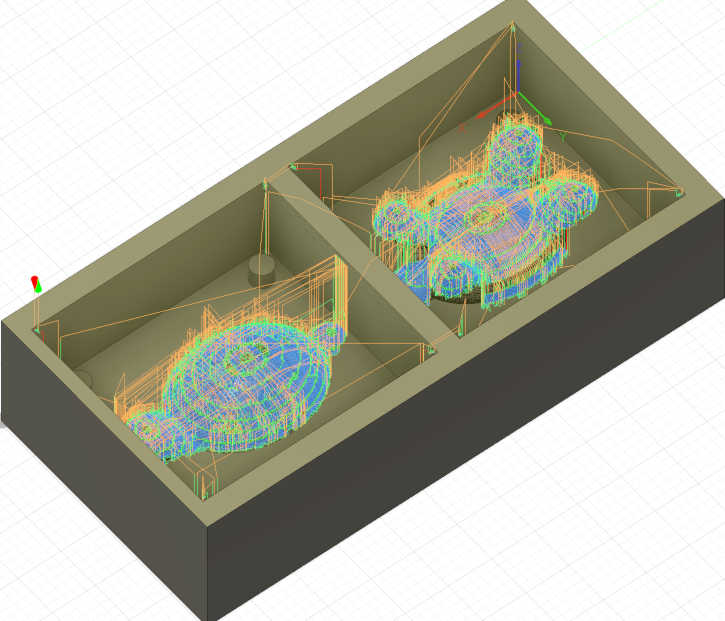

This week was all about designing a mold and I decided to make a little turtle. After receiving all the necessary trainings for the week I got started on designing my CAD in Fusion. I made a block to resemble the wax block we are using and then imported an STL file of a turtle. I had to cut it in half so that I could make two halves of a mold.

Turtle CAD:

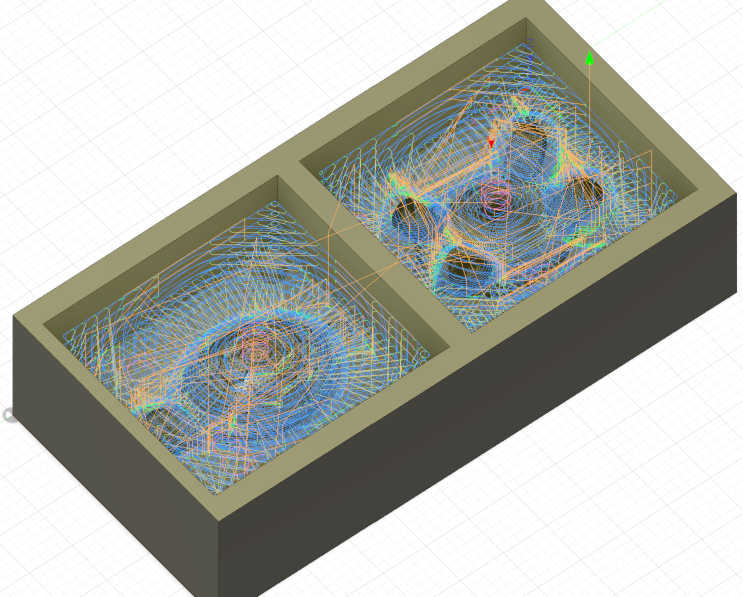

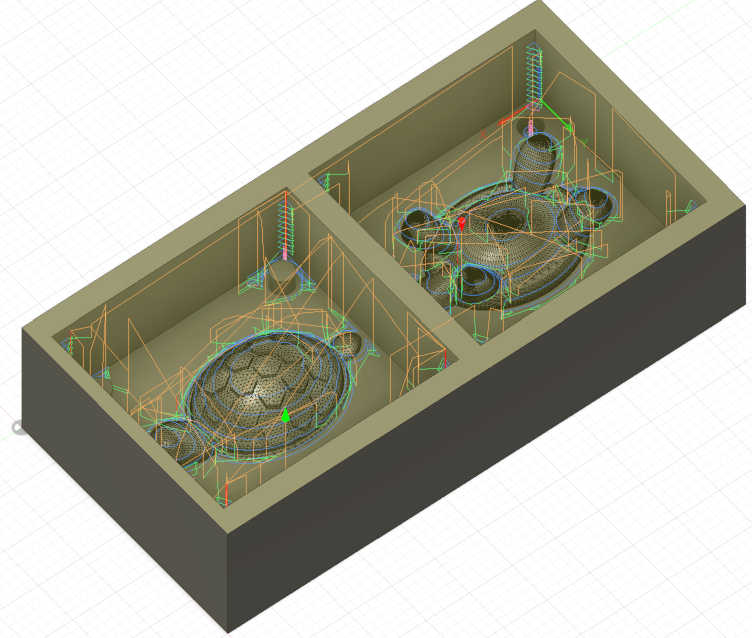

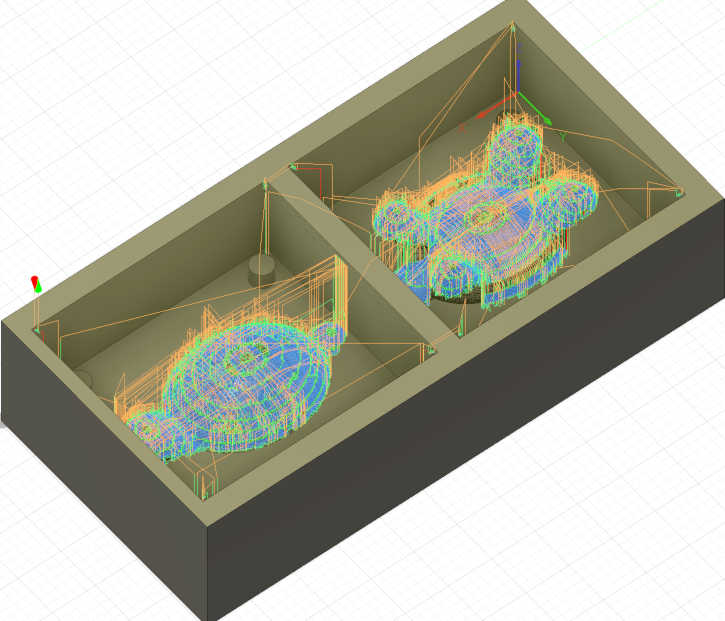

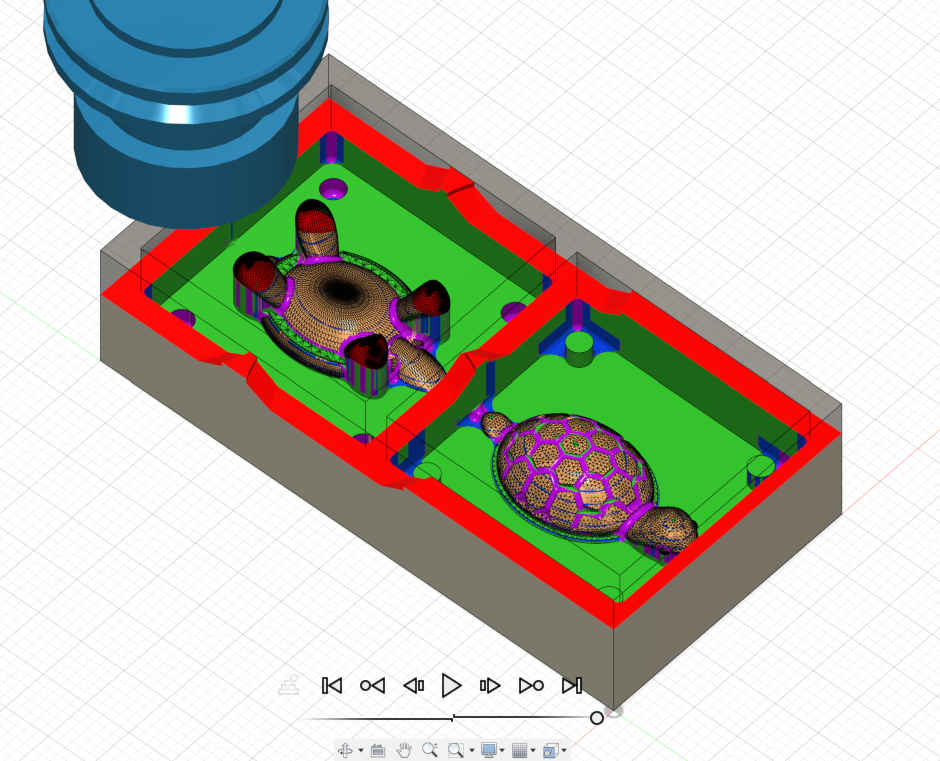

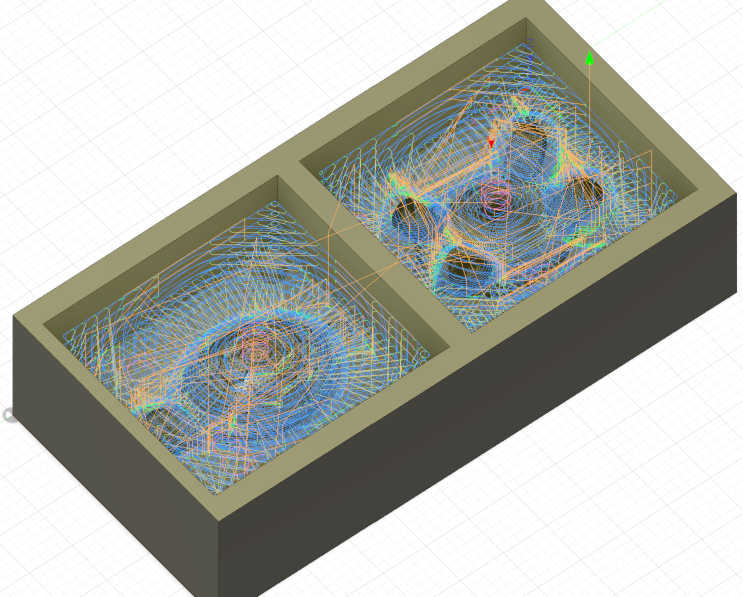

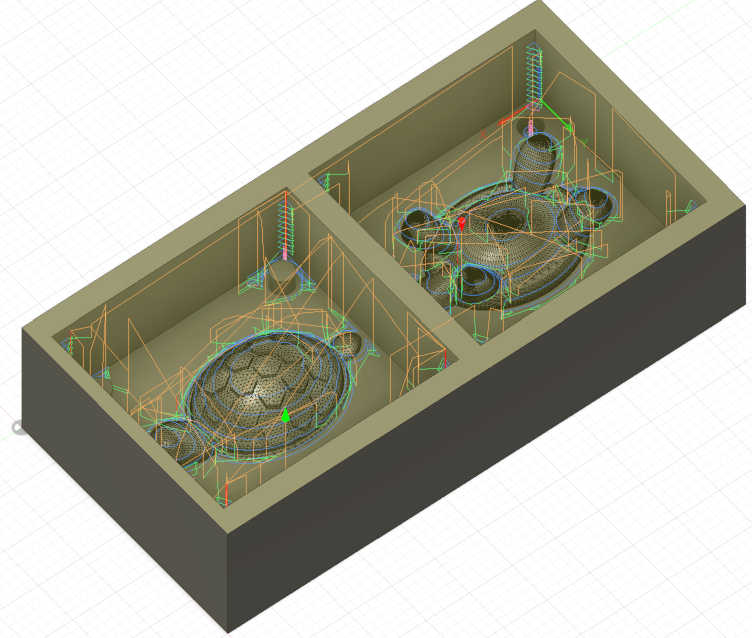

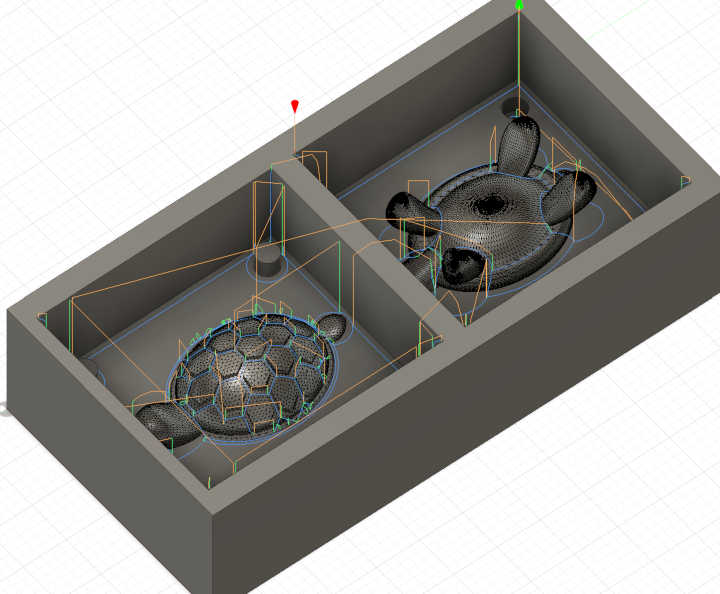

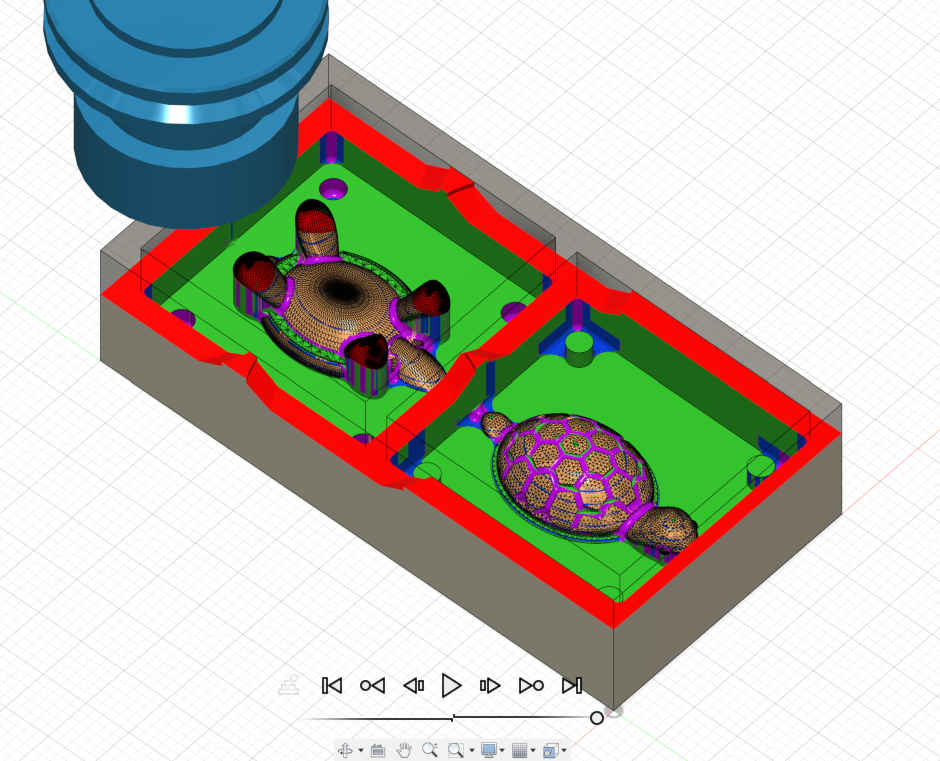

The hard part was now making the toolpaths for the CNC machine to follow. Thanks 100% to Anthony this actually wasn't too difficult. I had to do 4 toolpaths so that I could clear out material, fix some issues, and then do finer detailing.

Adaptive:

Pocket:

Parallel:

Pencil:

Simulation:

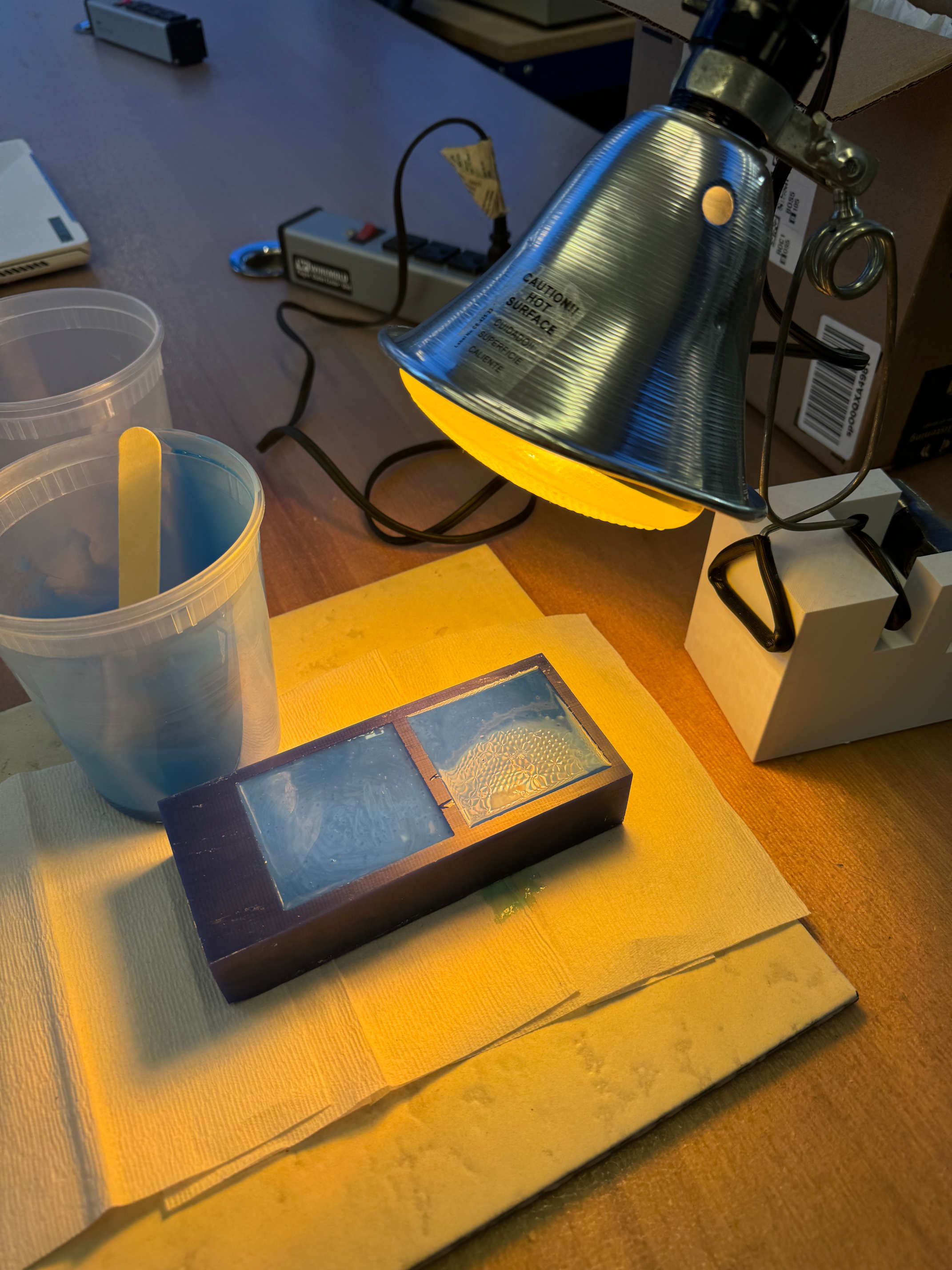

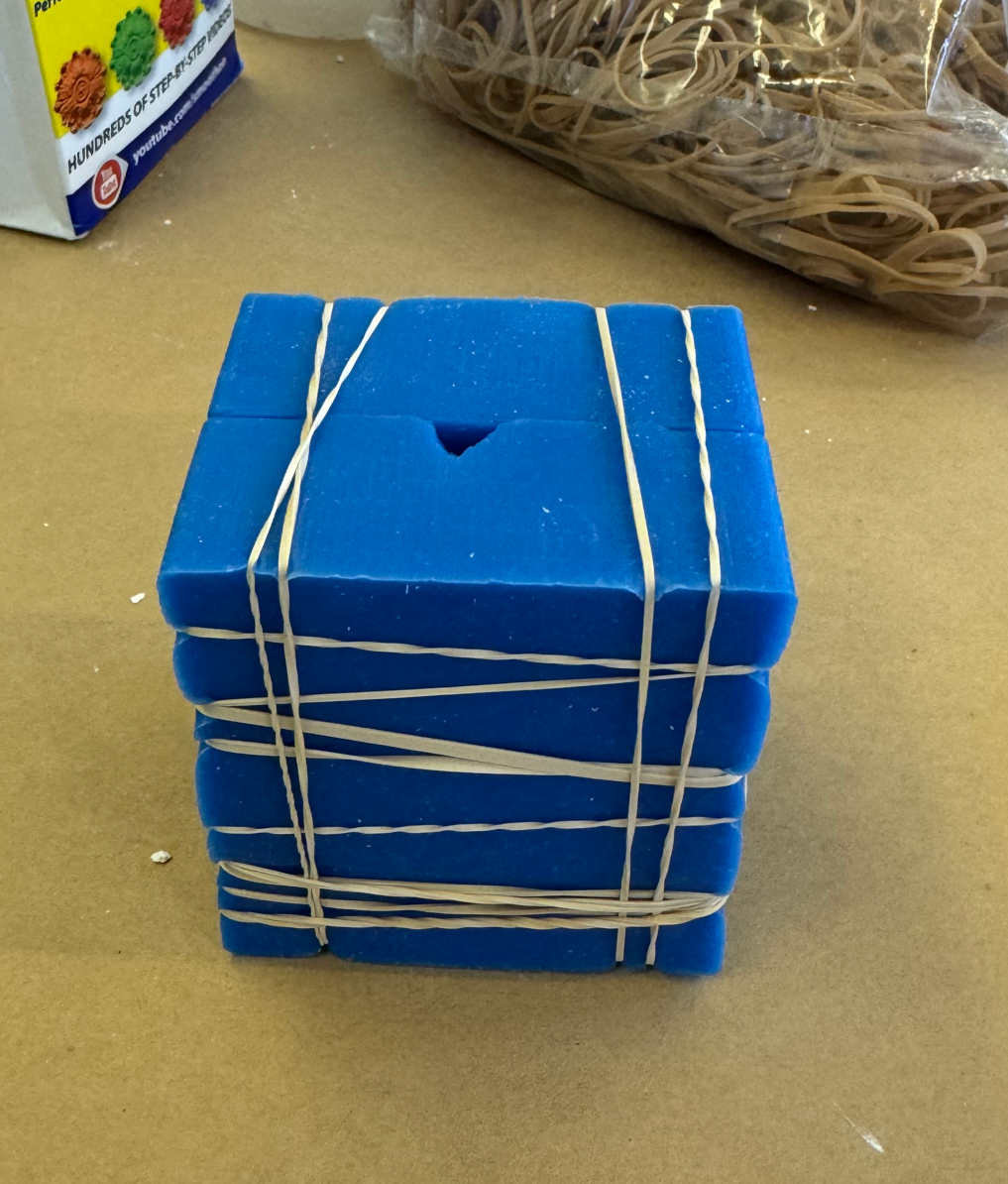

Then I moved onto actually CNCing the part. In about an hour I had my finished part.......

Final block:

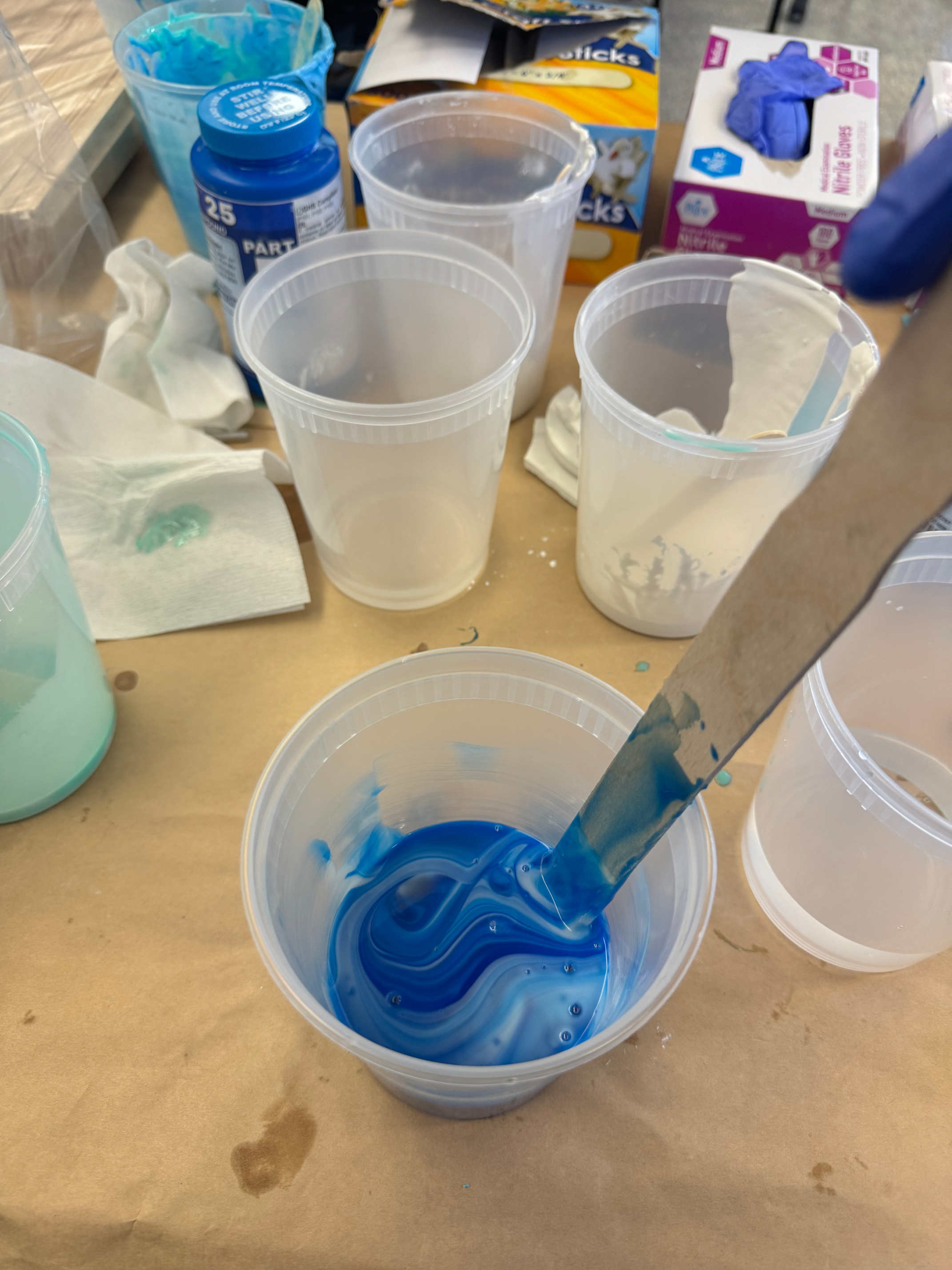

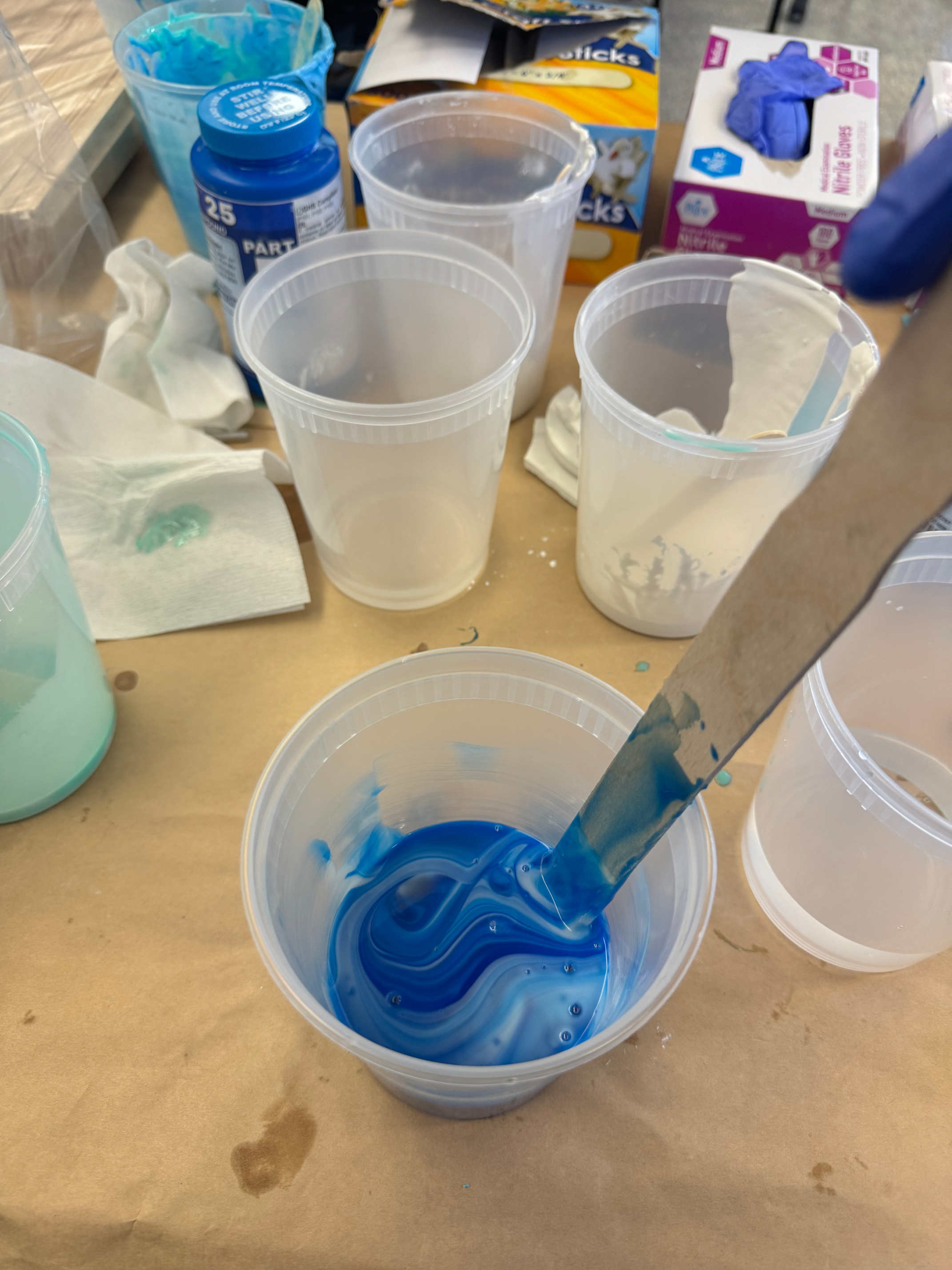

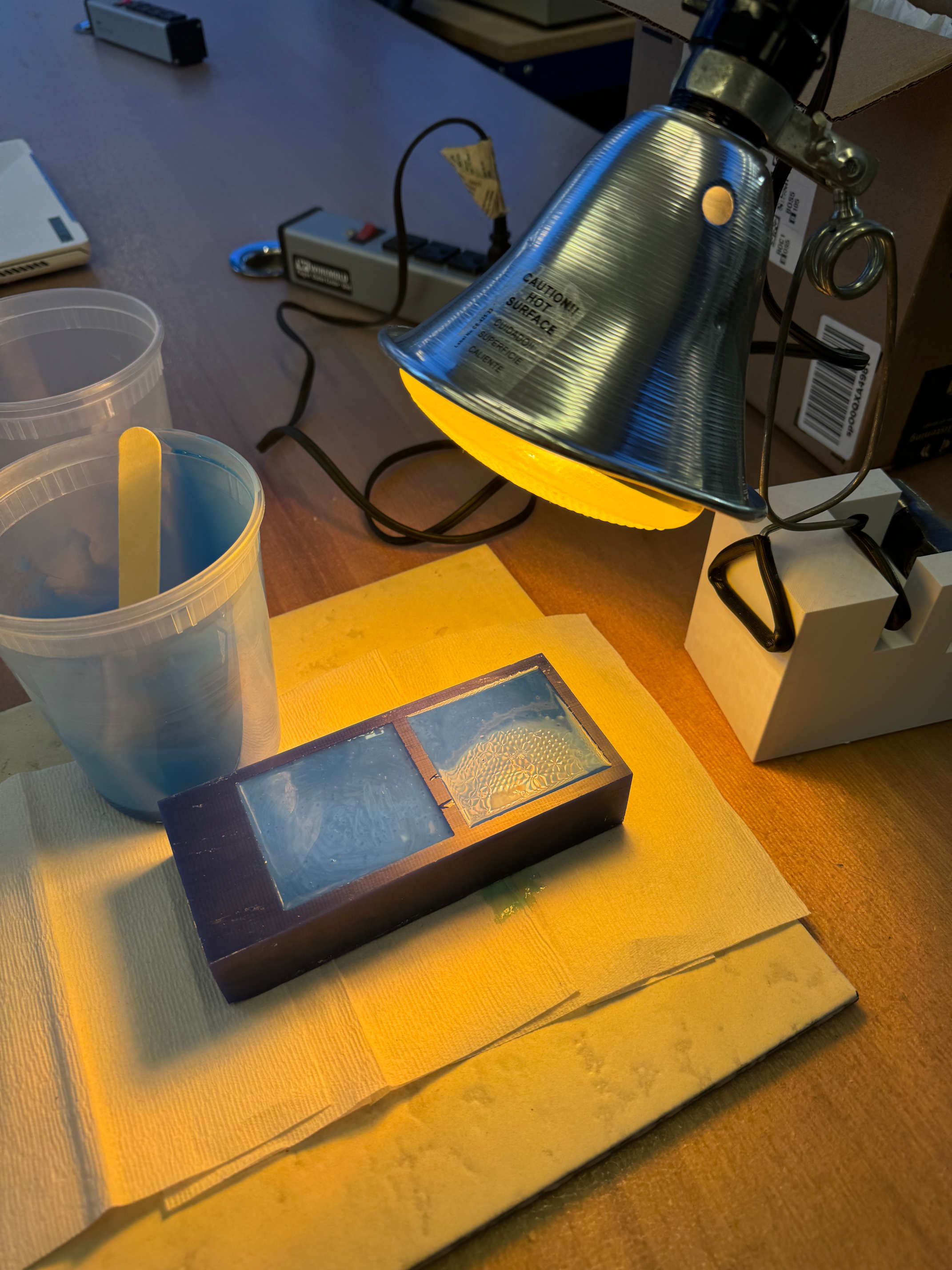

After checking out the SDS for MoldStar, I mixed the solution and poured it into the wax block. The next day I came back to a nice finished mold.

It was now time to cast the mold. I checked out the SDS again for the materials I used and poured it into the mold. The next day again I came back to instead a quite disappointing product. I seemed to have forgotten to really look at my CAD and make sure everything was aligned. So I was quite upset to see that because the two halves weren't aligned, Mr.Turtle's shell isn't exactly on his body.....

Mold:

The final product :(

I plan to re-cast the mold and align it slightly differently to try and make it work. I'll keep you updated