week 4

3d scanning and printing

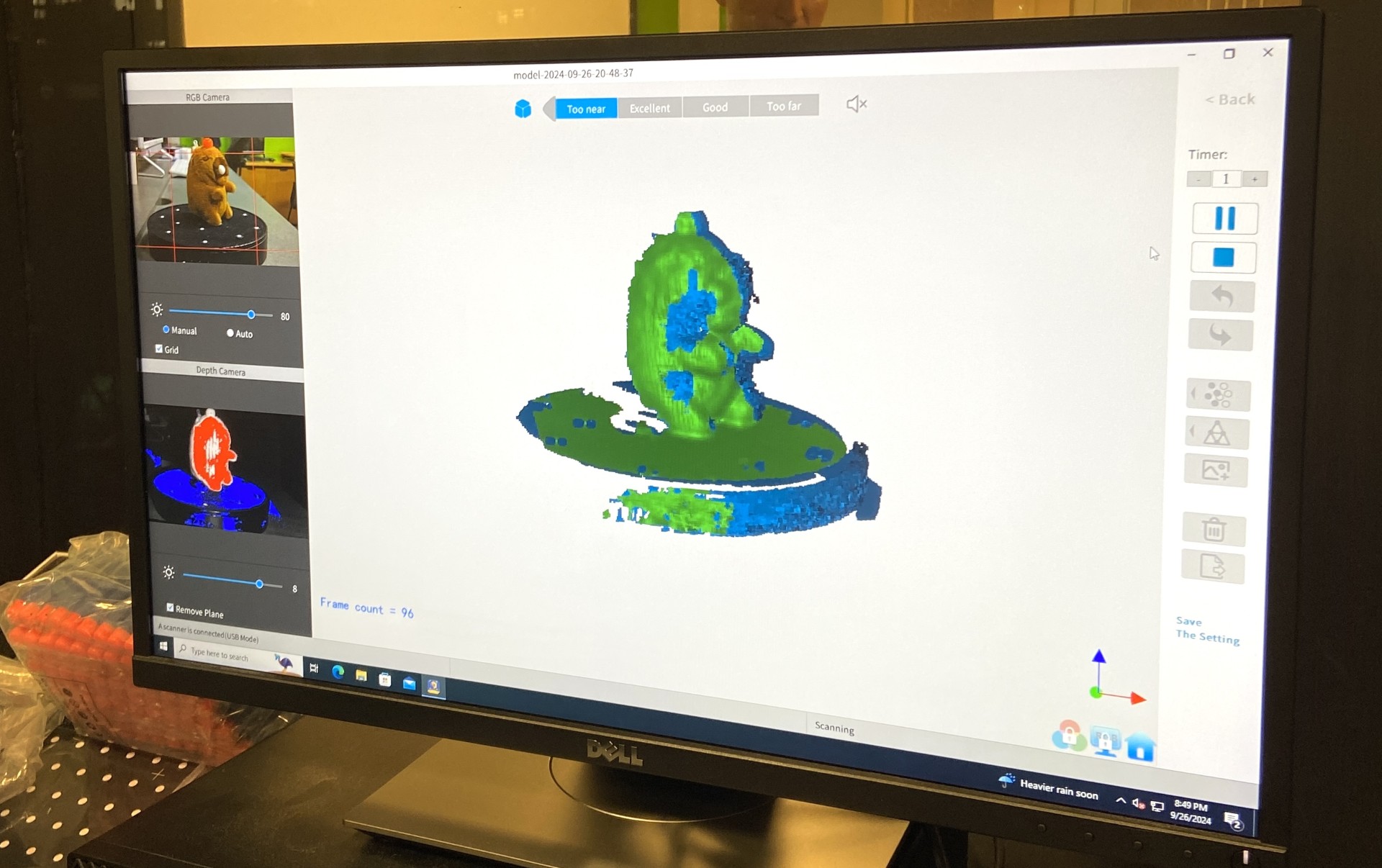

3d scanning

The assignment for this week was twofold: first, we were to 3d scan an object of our choosing, and second, we were to design and 3d print a small object that could not be made subtractively. I decided to first try scanning something I had with me in lab, since it seemed pretty straightforward.

Anthony, our TA, mentioned that the scanner doesn't like shiny or reflective things and works better on things that are lighter in color.

I first tried to scan my capybara keychain. It didn't work particularly well, which maybe isn't surprising given that there's no real distinguishing marker from the capybara's head to its body to its back. I tried to address this by adding stickers to its back so that it could better differentiate front from back, but it didn't work as well as I'd hoped it to.

It sort of worked, except it scanned with 3 arms and 3 legs

I later scanned my running shoe via Polycam, which worked a lot better

3d printing

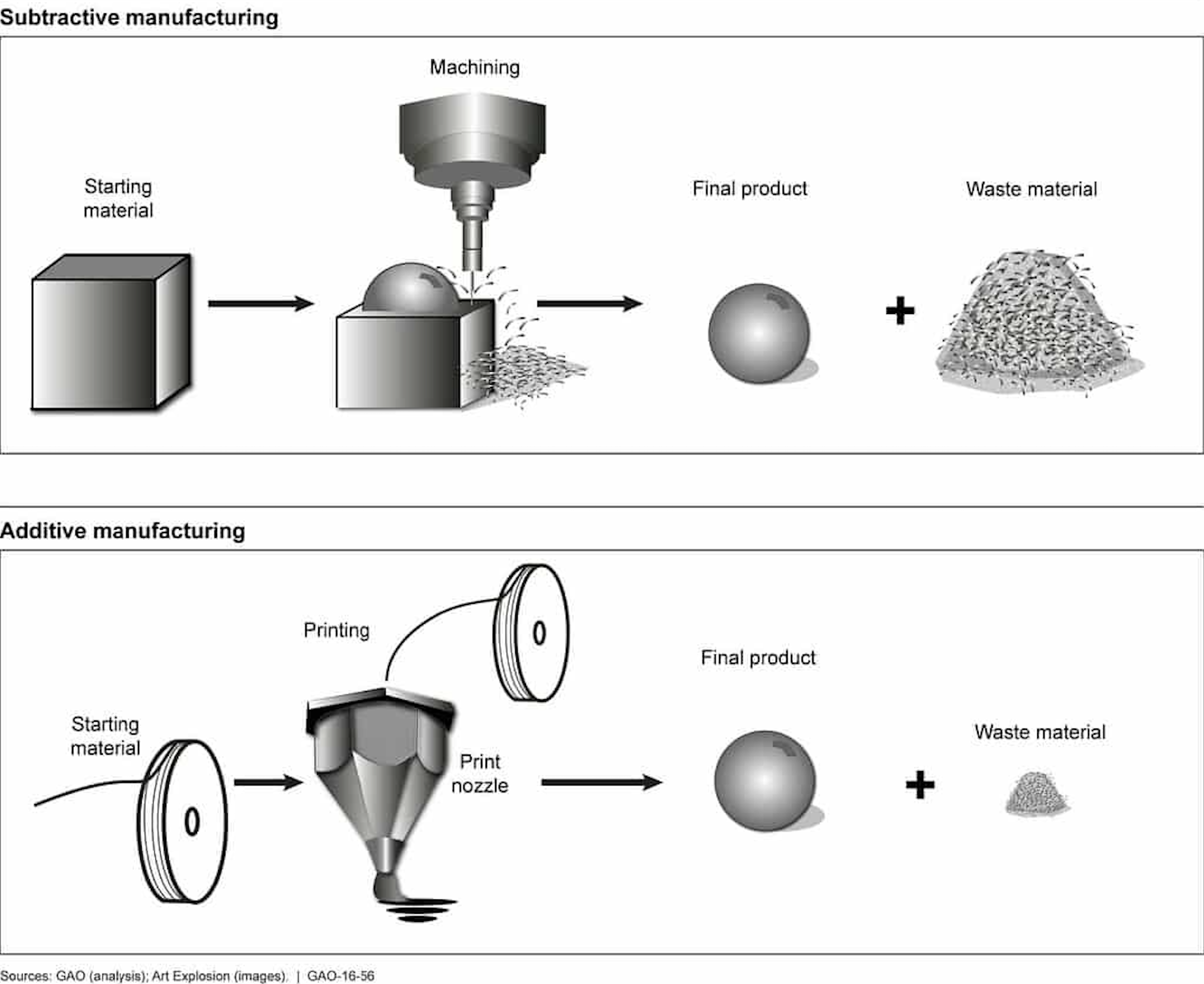

The next part was to design and 3d print something.

The key was that whatever we decided to design and print, it could not be made subtractively.

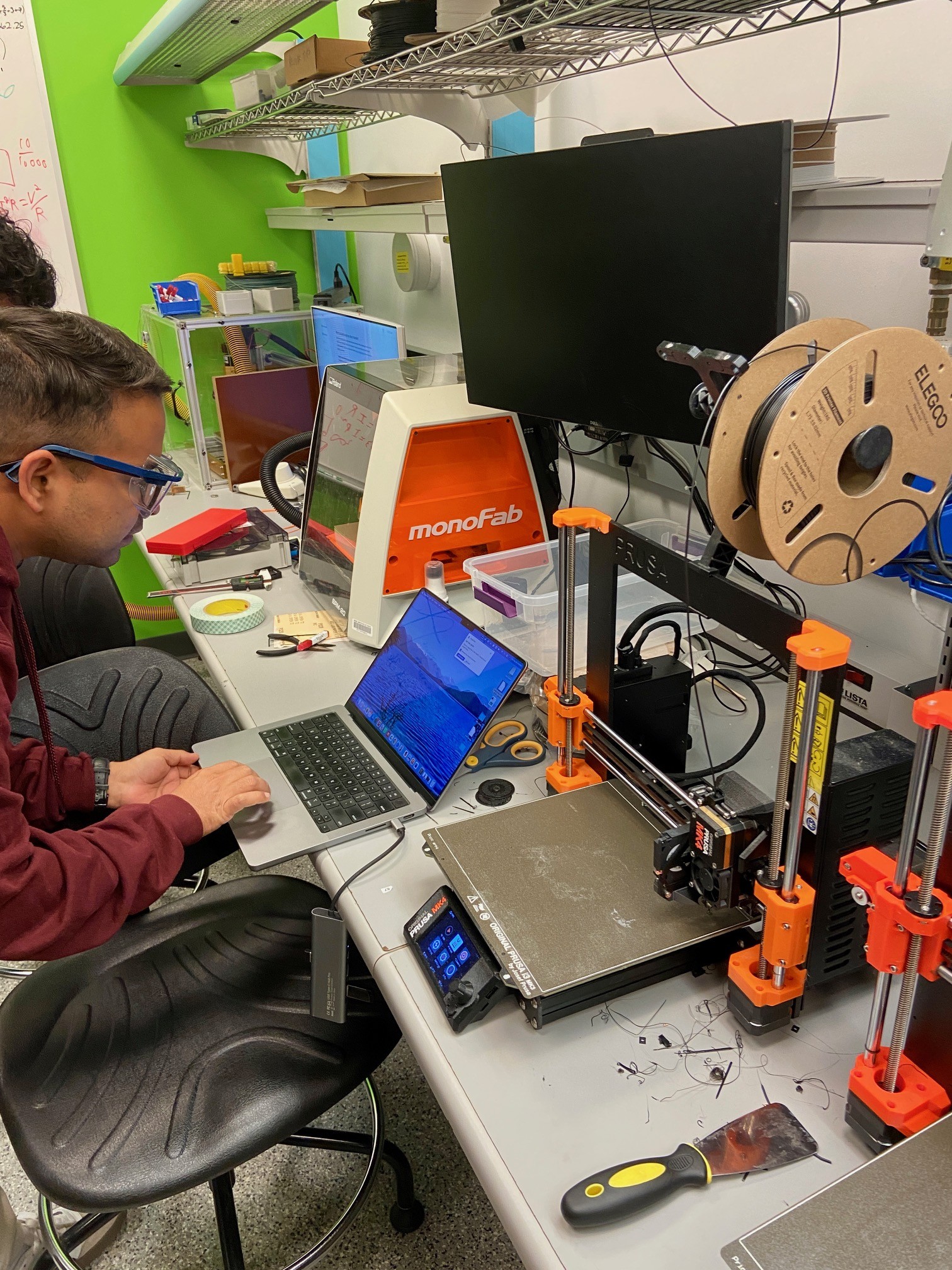

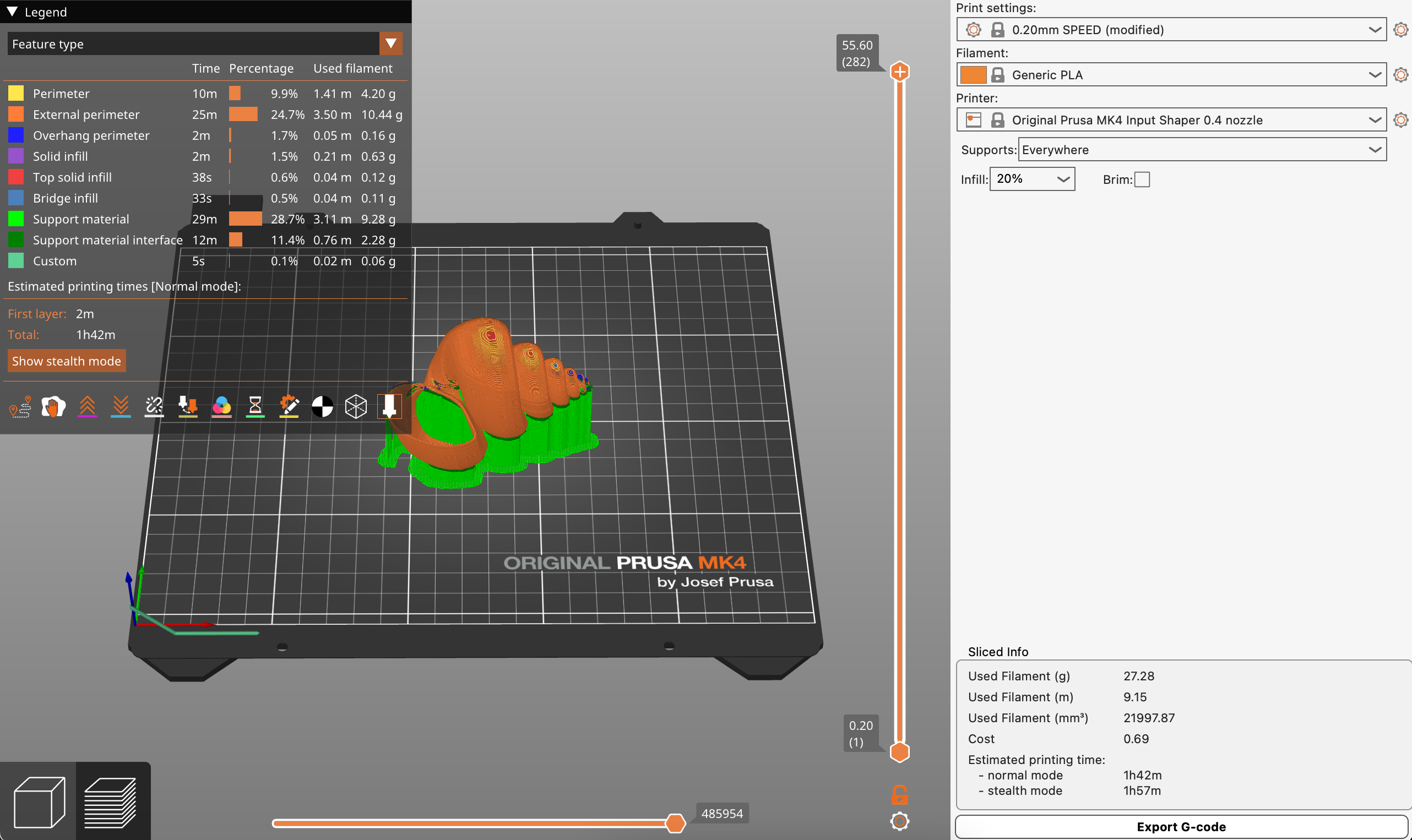

My labmates and I first tested the design rules for the EECS lab 3d printer, a Prusa i3 MK4S.

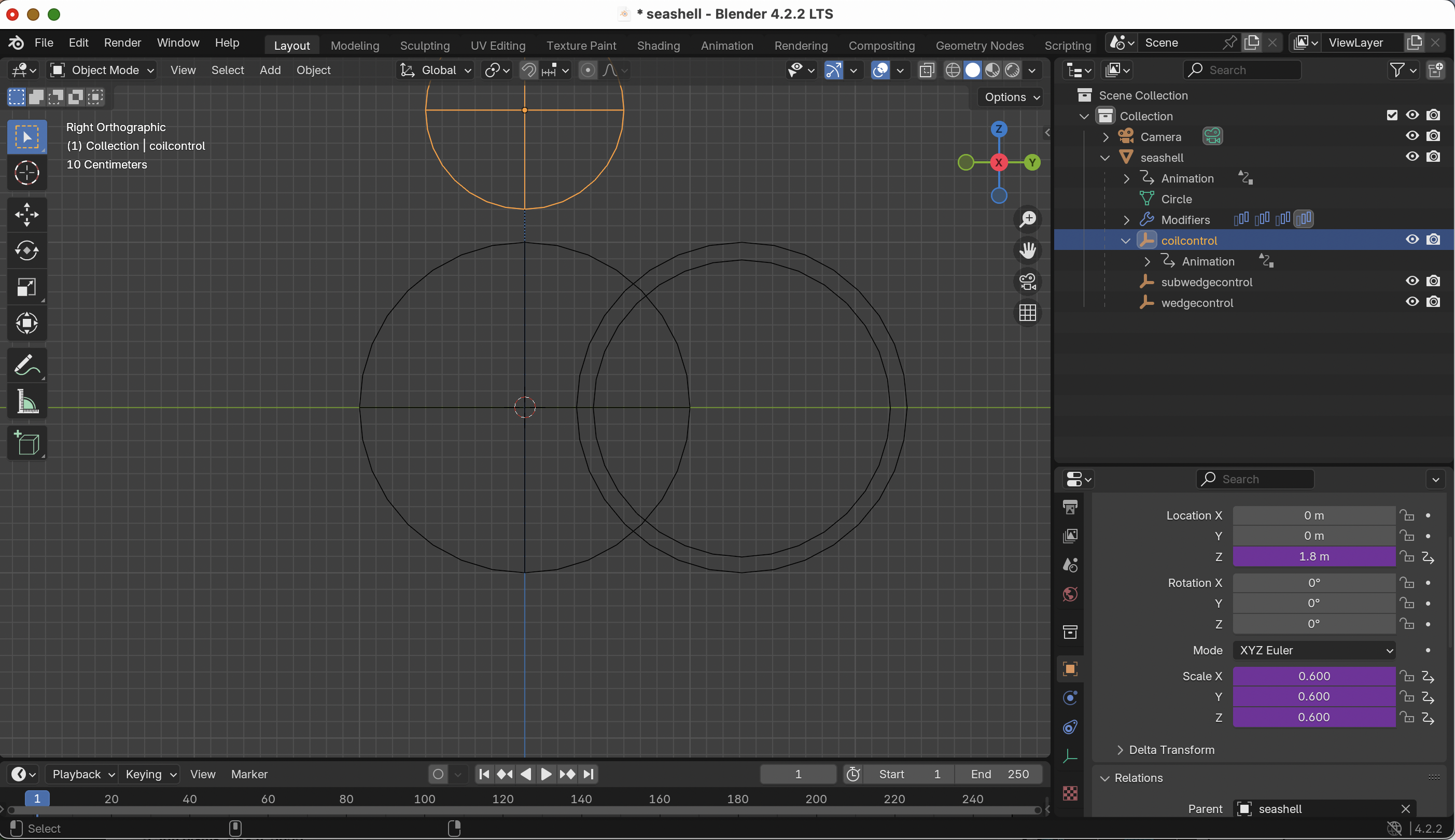

I decided to print a seashell, which I designed on Blender.

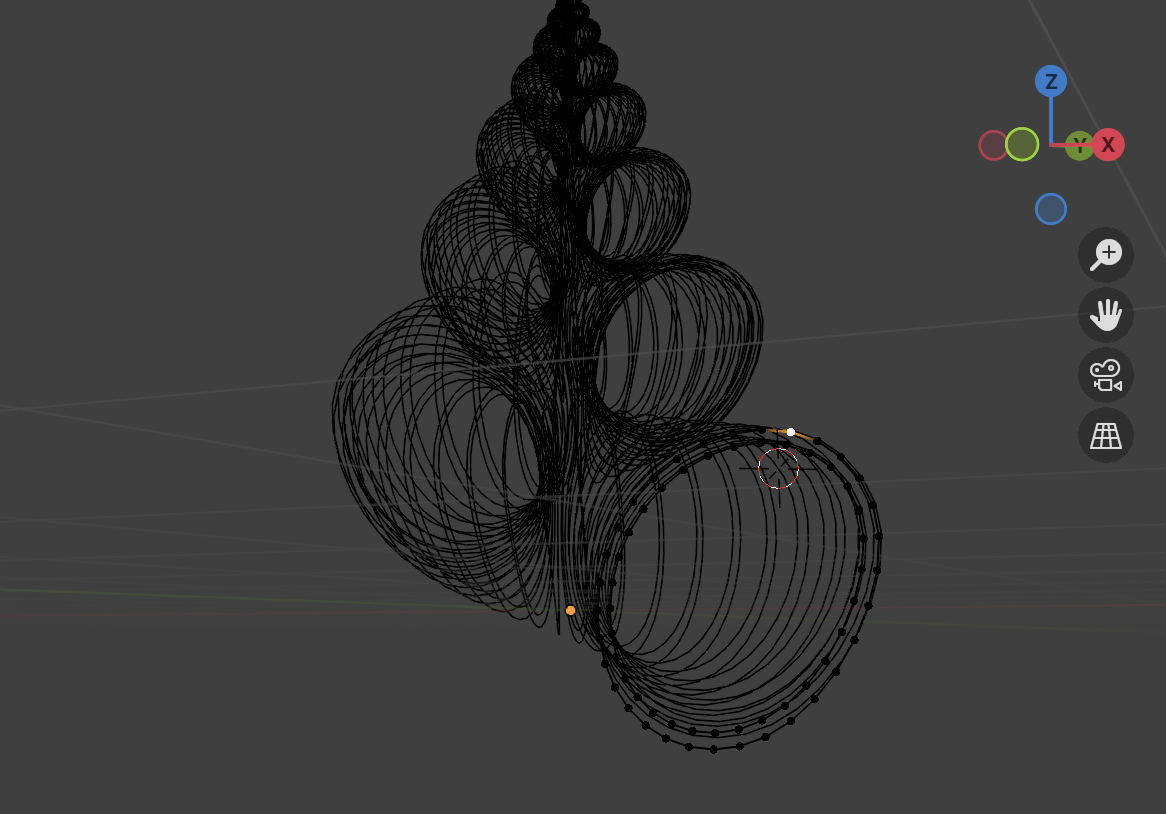

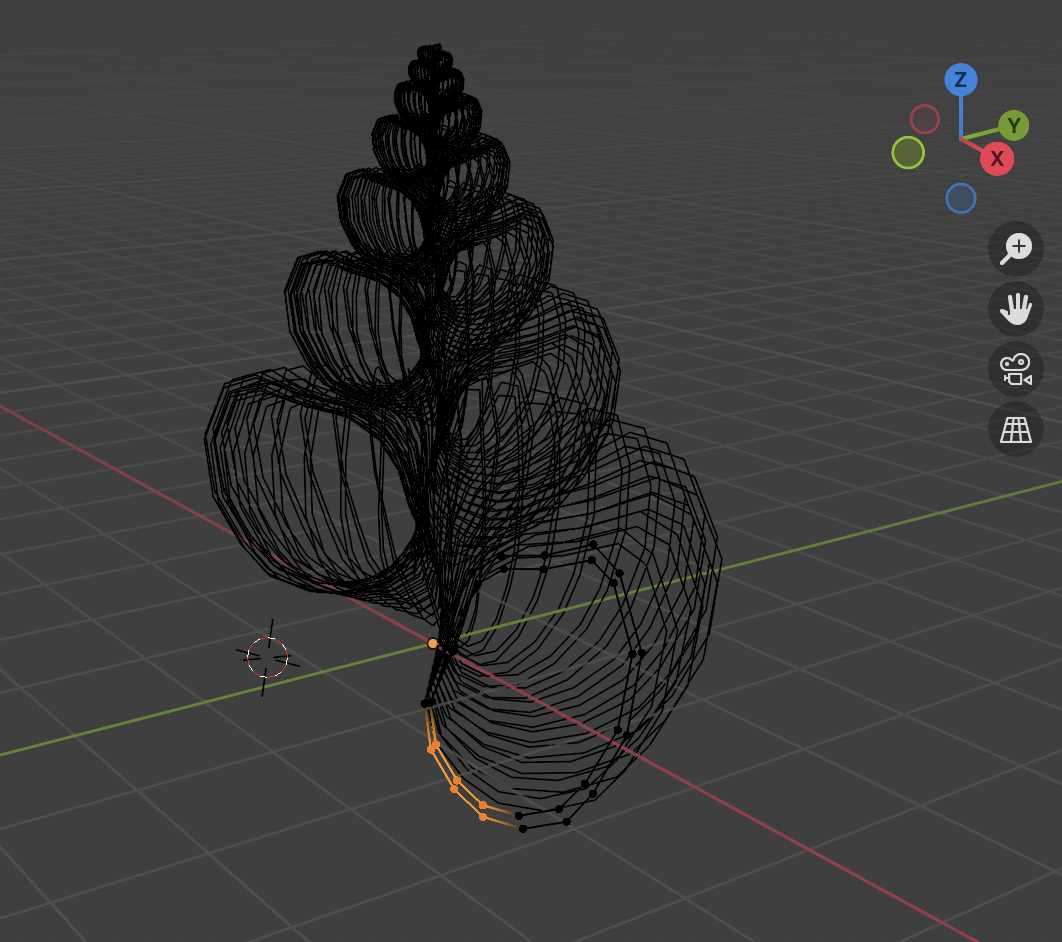

Parametrizing the seashell design

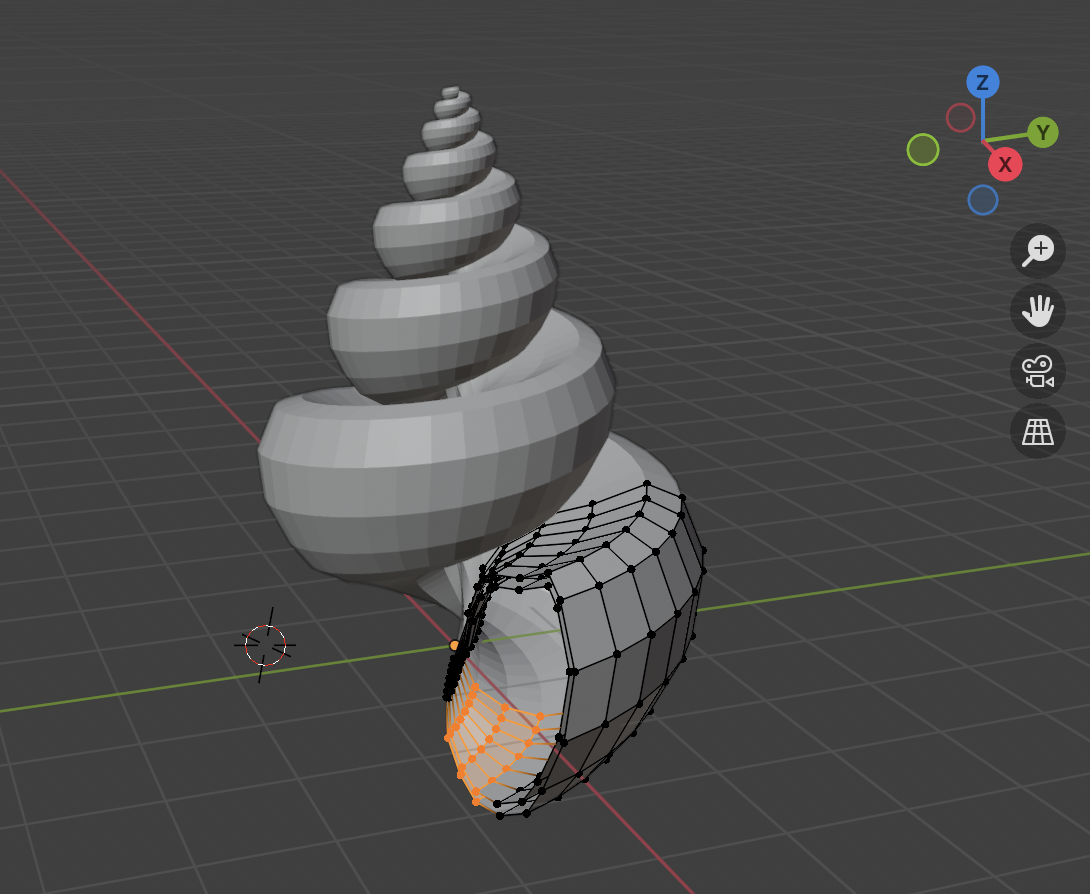

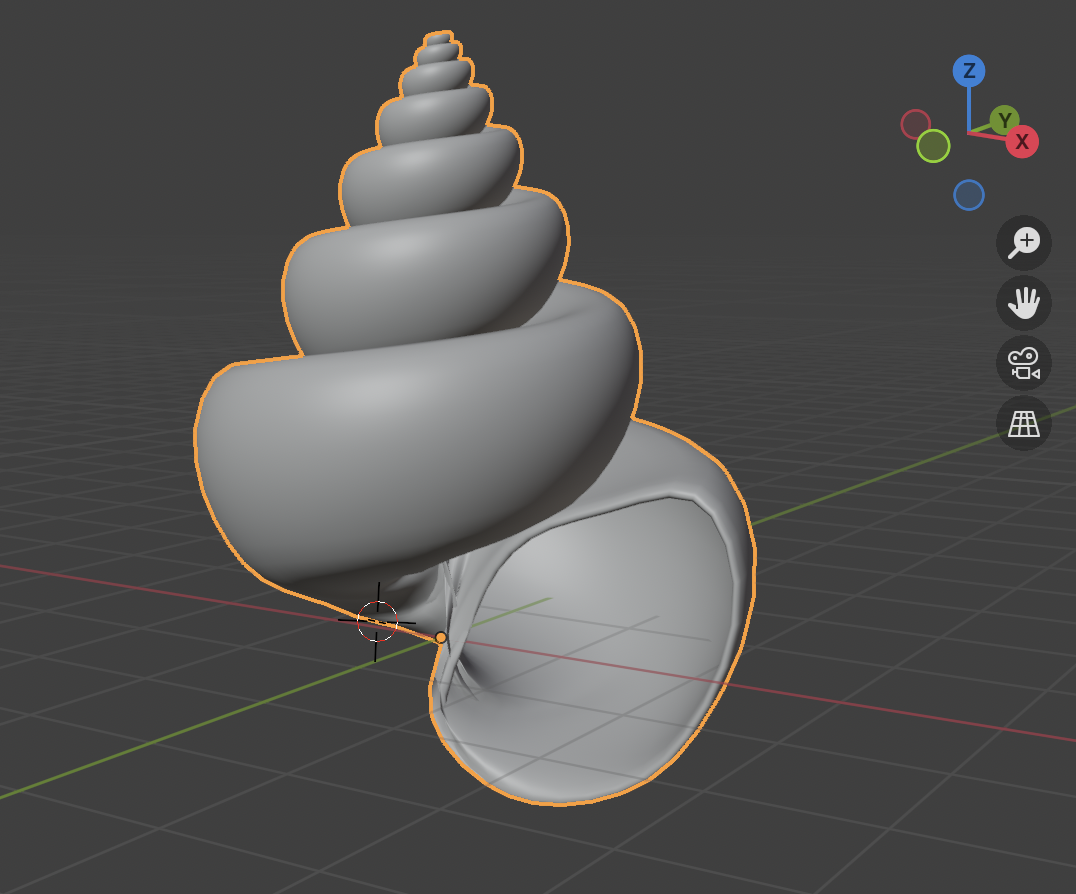

Making the seashell printable and rounding out the edges

Here are the settings before I sent it over to the printer. Interally, I was thinking how I'd get all of the support out from the inside of the seashell... this proved to be a bit challenging later on.

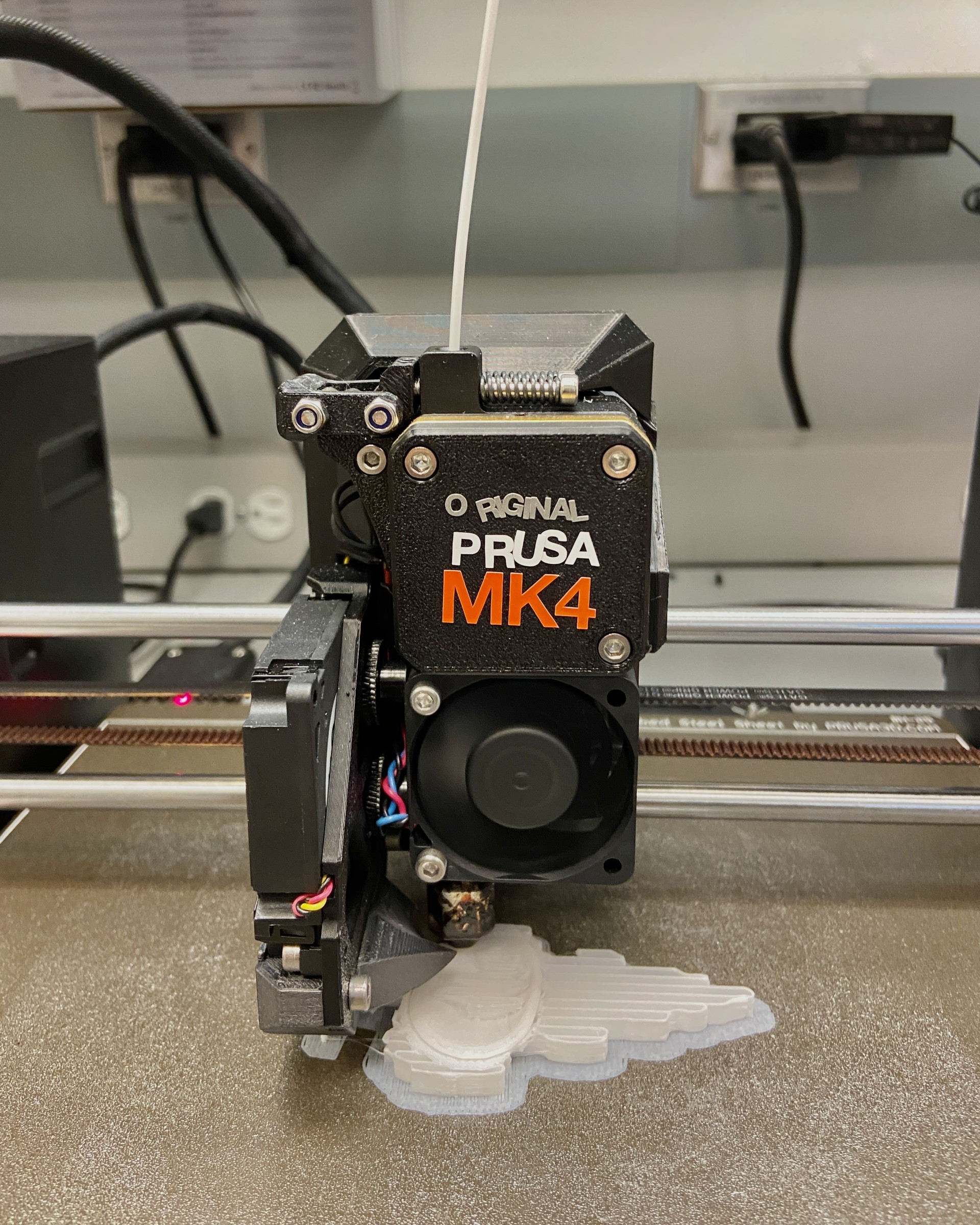

The Prusa hard at work

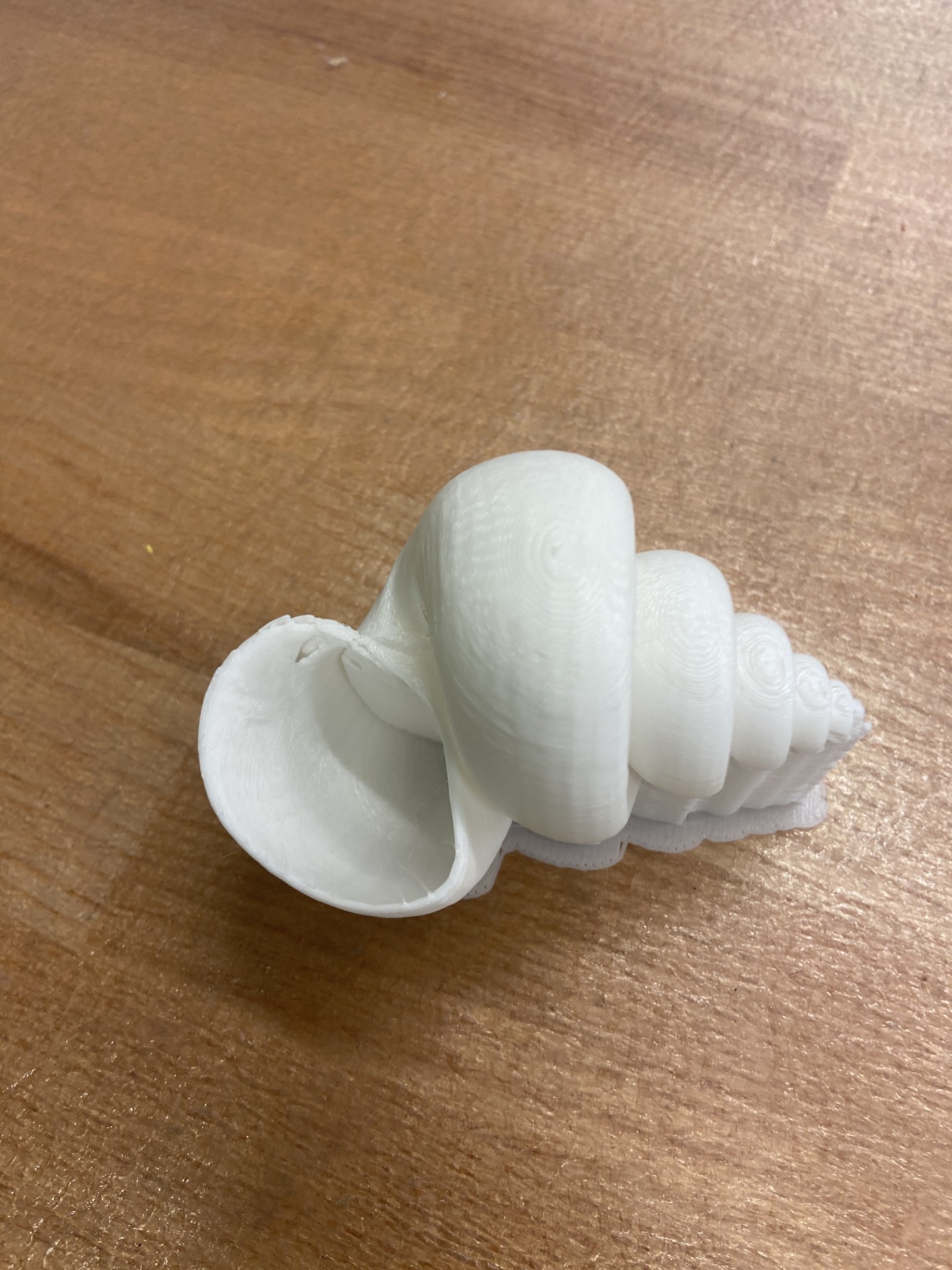

Seashell with support still attached

Final 3d printed seashell