week 7

molding and casting

making a mold and casting parts

The assignment for this week was to design a mold around the process that I'll be using, produce it with a smooth surface finish that does not show the production process toolpath, and use it to cast parts.

Another week, another new concept: I've never created my own mold before, and I was excited about all of the different possibilities for this week. I decided to make something very practical: a miniature Snoopy.

We usually get a lot of creative control when it comes to the type of software we can use in this class, but Anthony mentioned that this week is perhaps the one week where we don't get to exercise that control. We all had to use Fusion for this week.

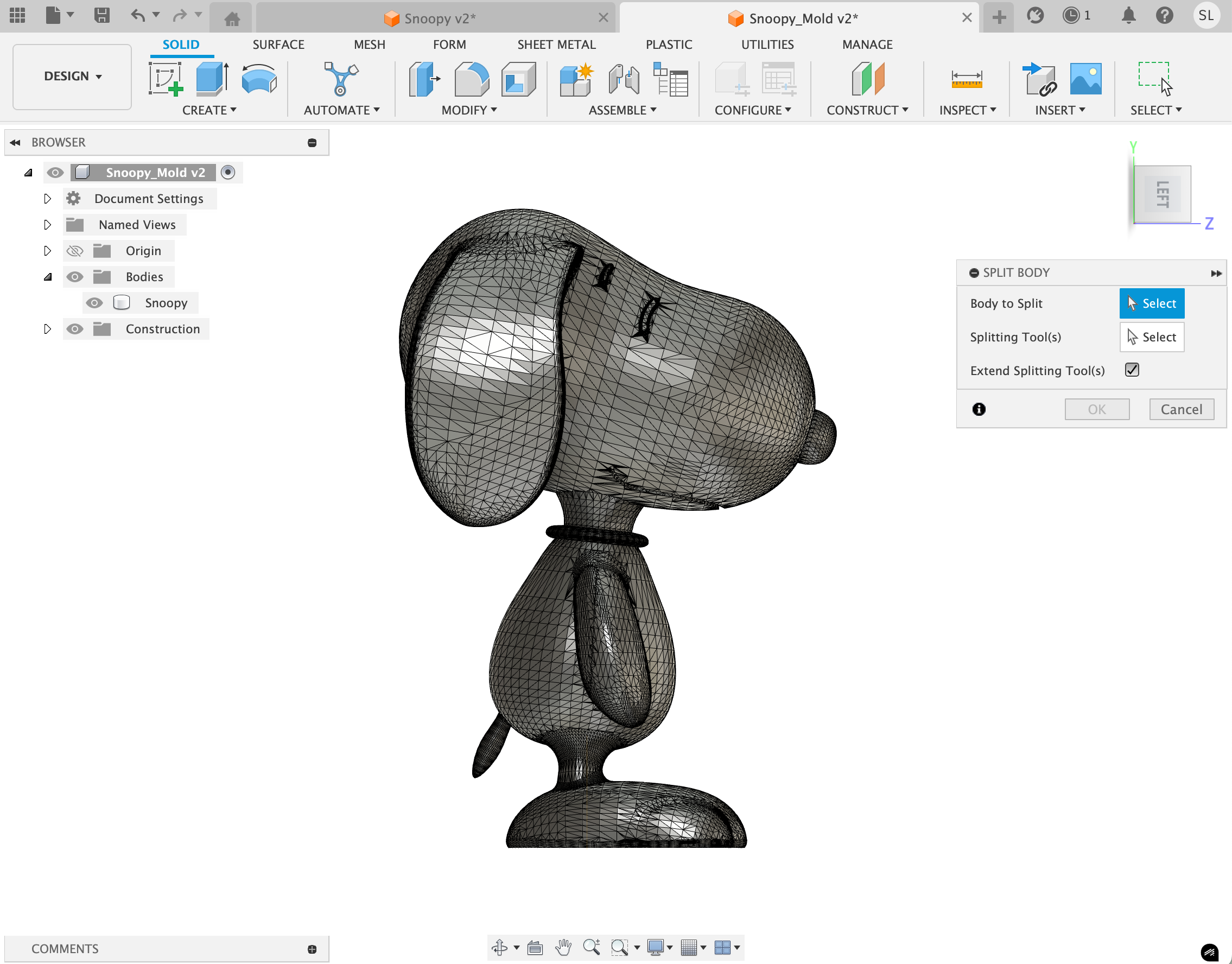

First, I found an STL file of Snoopy that I could work off of and imported it into Fusion:

I then designed the wax mold in Fusion by splitting Snoopy down the middle and encasing him. The wax that we have in the EECS shop is exactly 7" x 3" x 1.5" so I set the dimensions accordingly.

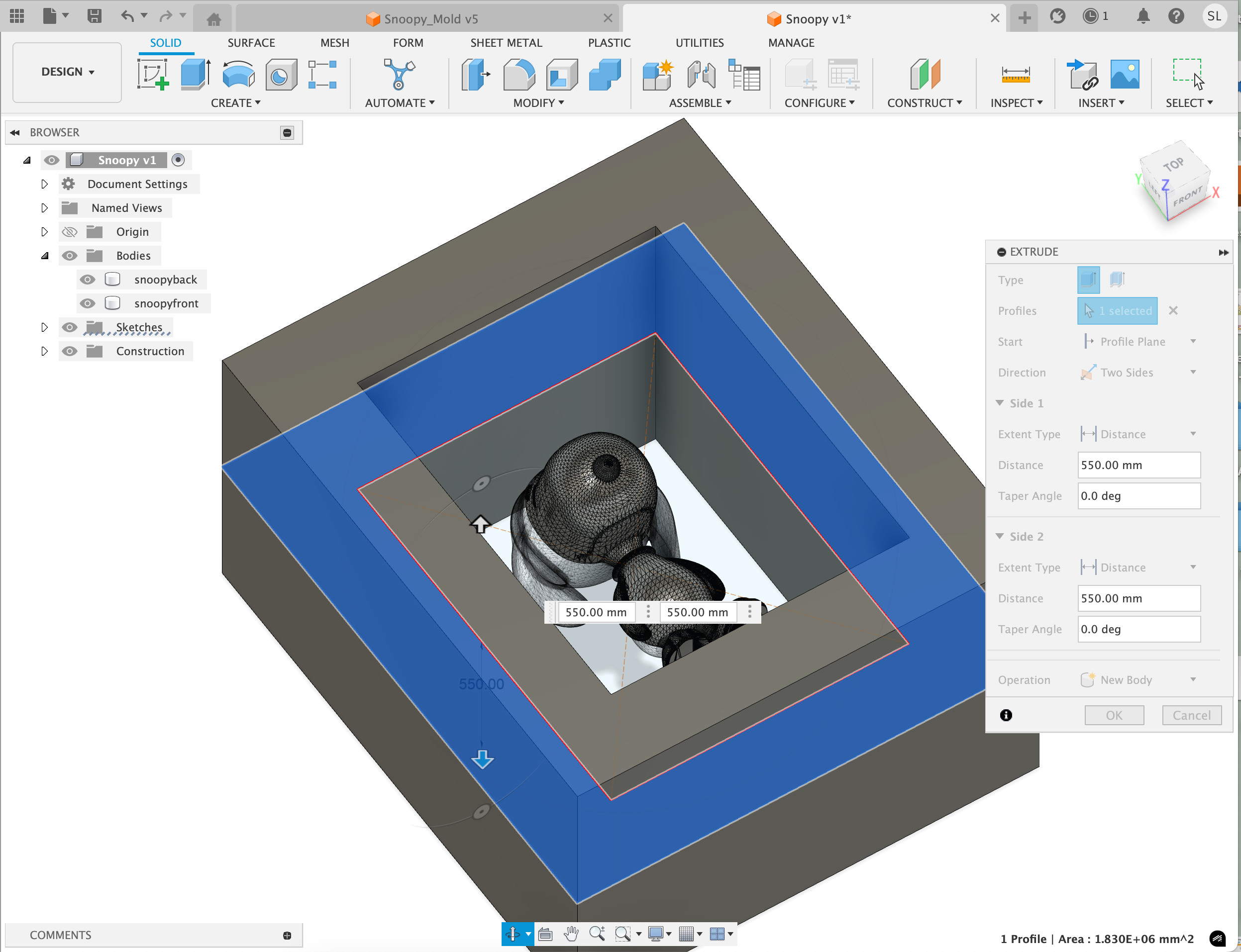

Here lies Snoopy:

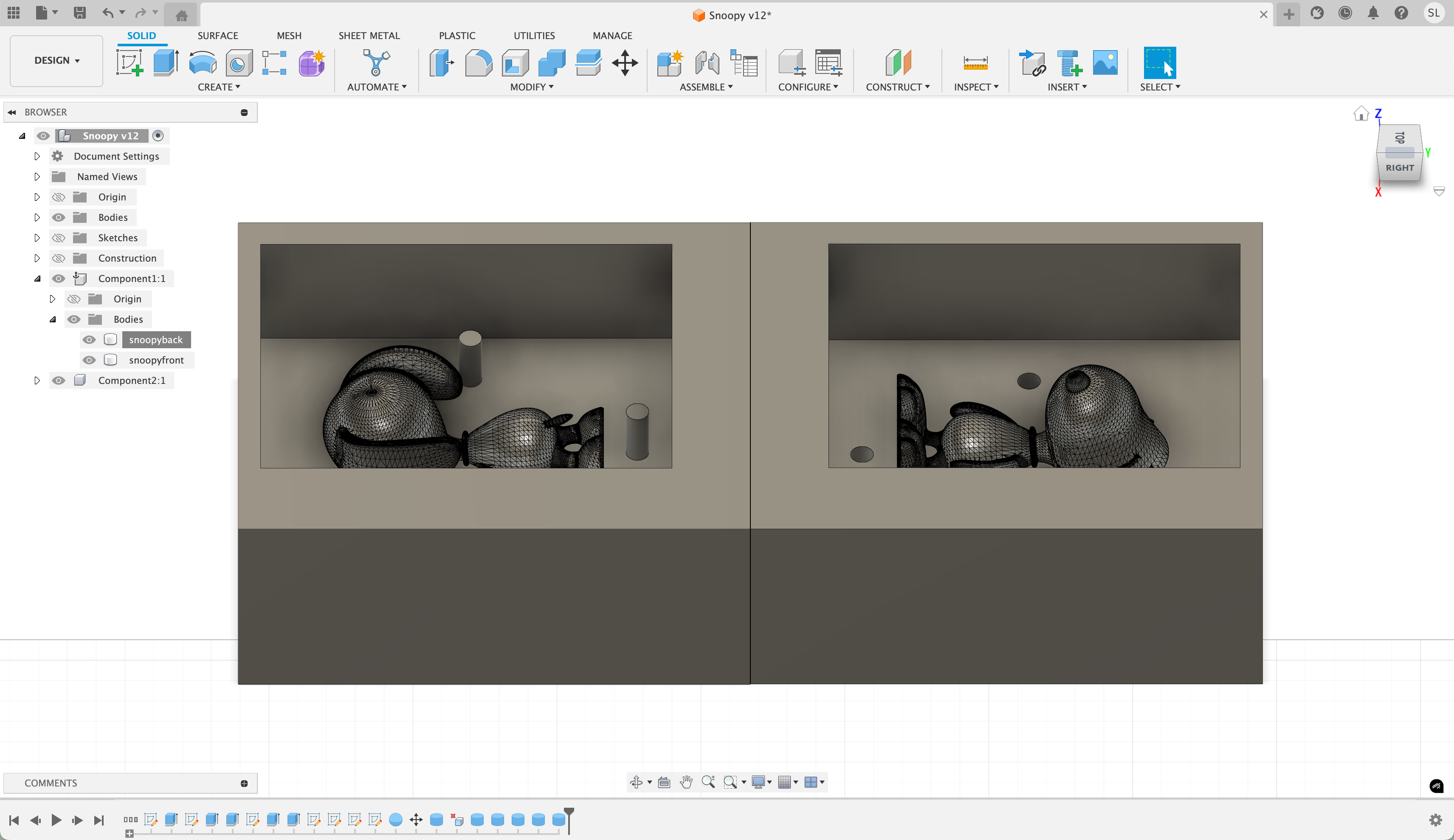

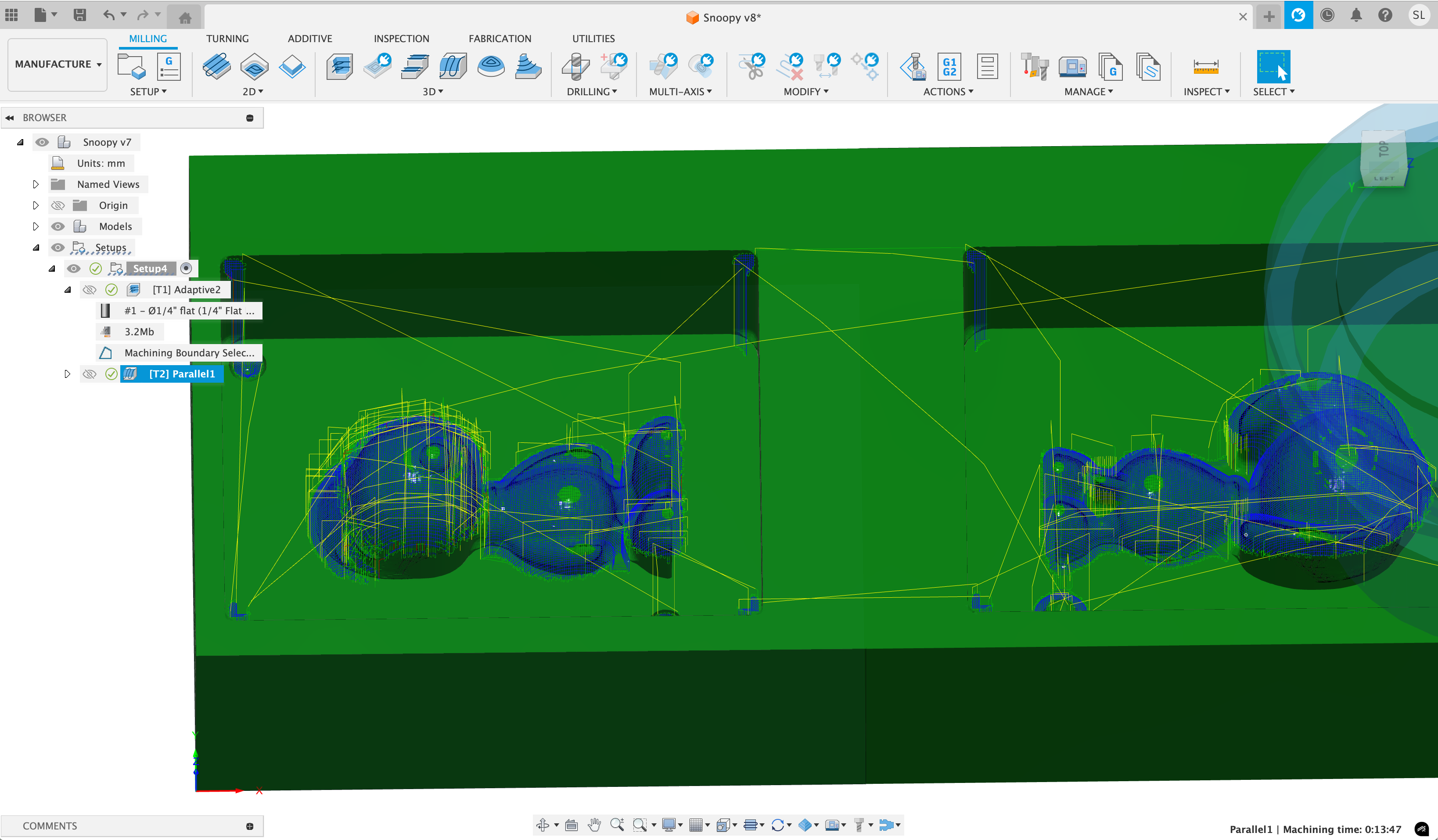

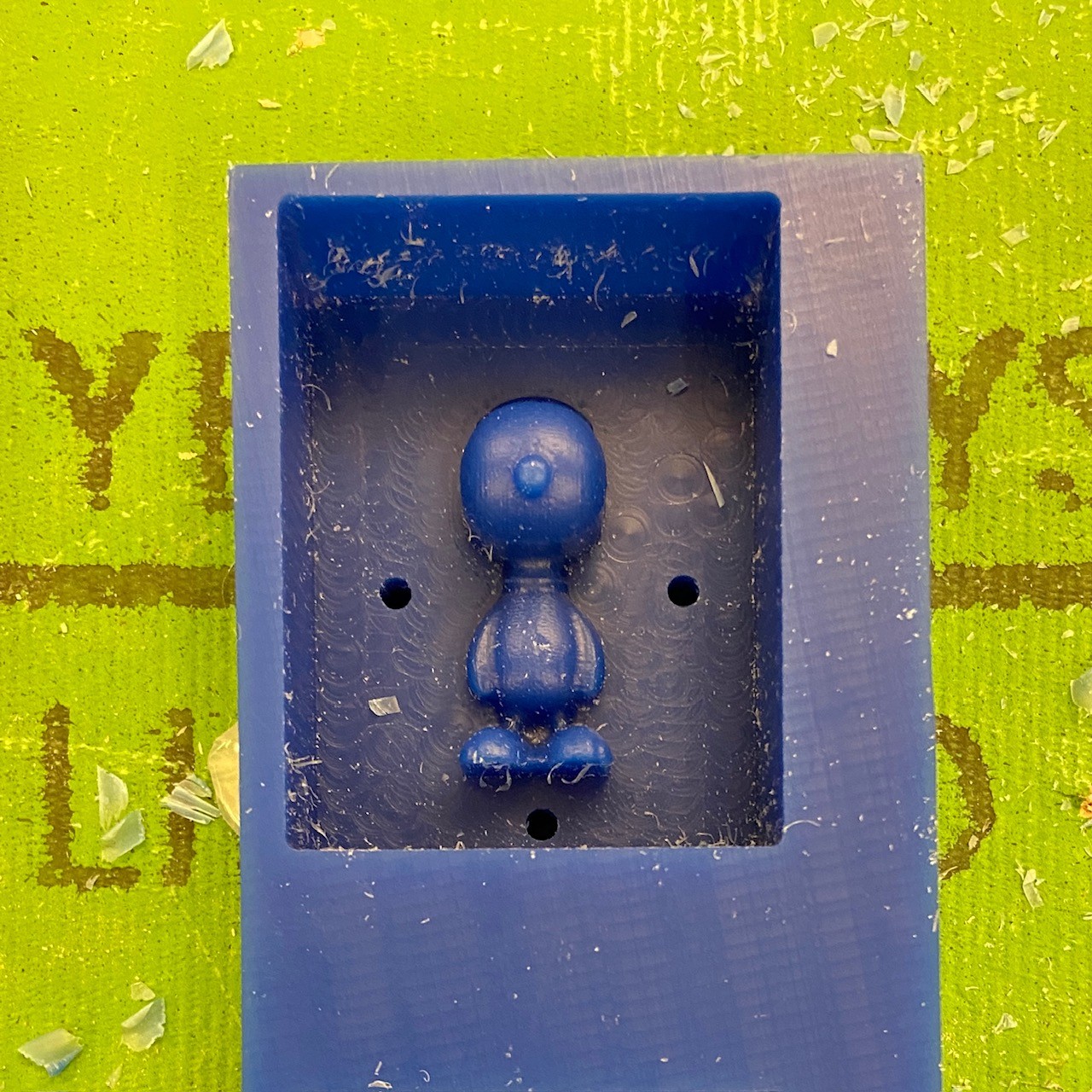

Splitting Snoopy to design the wax mold, which will be used to make the Oomoo mold later on. I set the registrations so that I would be able to align the mold when I cast Snoopy later on, then I prepared the CAM design

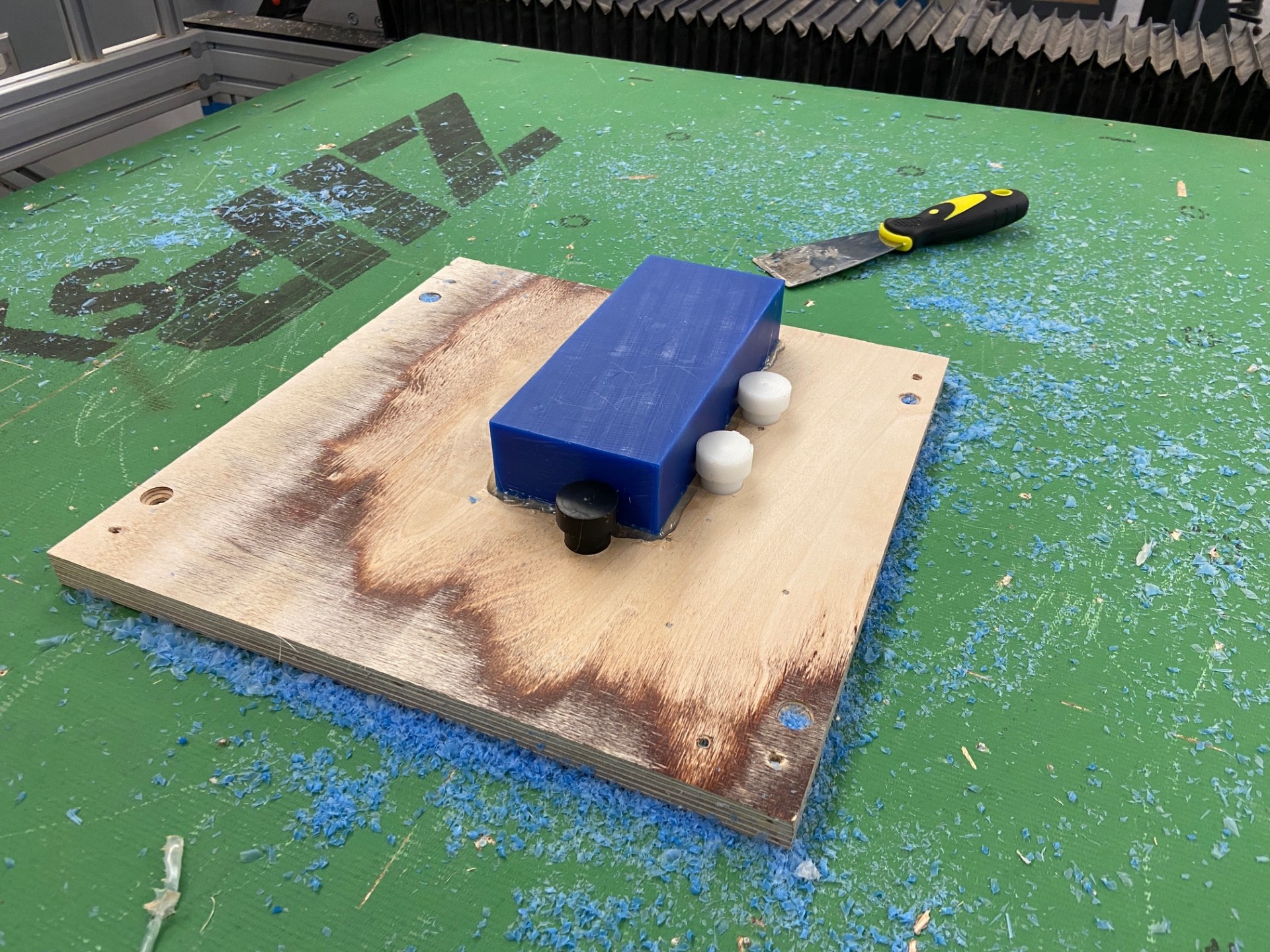

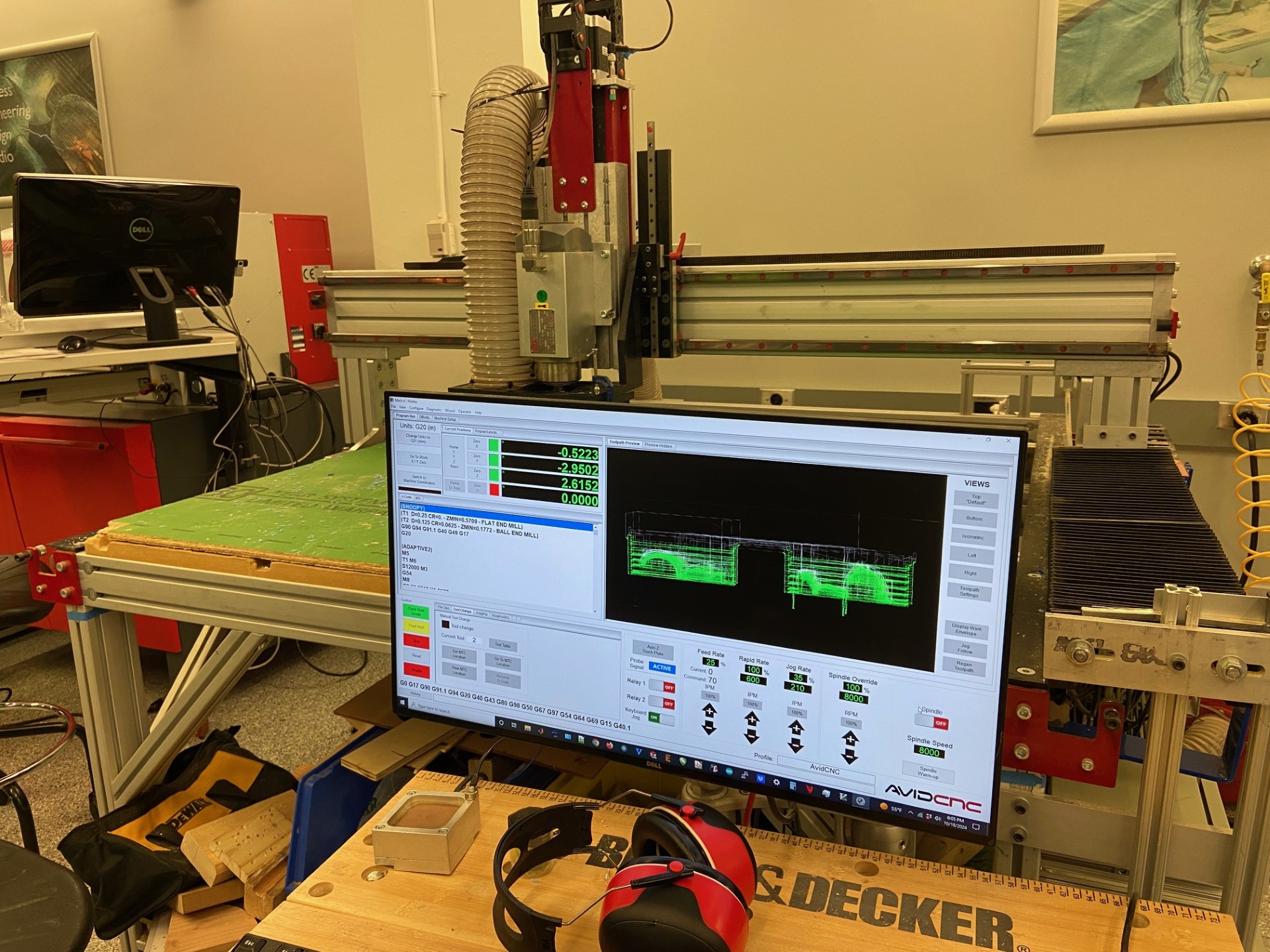

After finishing the mold, I got ready to make the actual mold via milling. Anthony help me set up the machine -- because my Snoopy wasn't very big, it was a fairly quick job (we also bumped up the milling speed to 150 percent). I first hot glued the wax block onto the wooden board; we then started with a rough mill to remove more chips faster, then switched the tool to a ball end tool so that it could mill granular details (Snoopy's nose, eyes, ears)

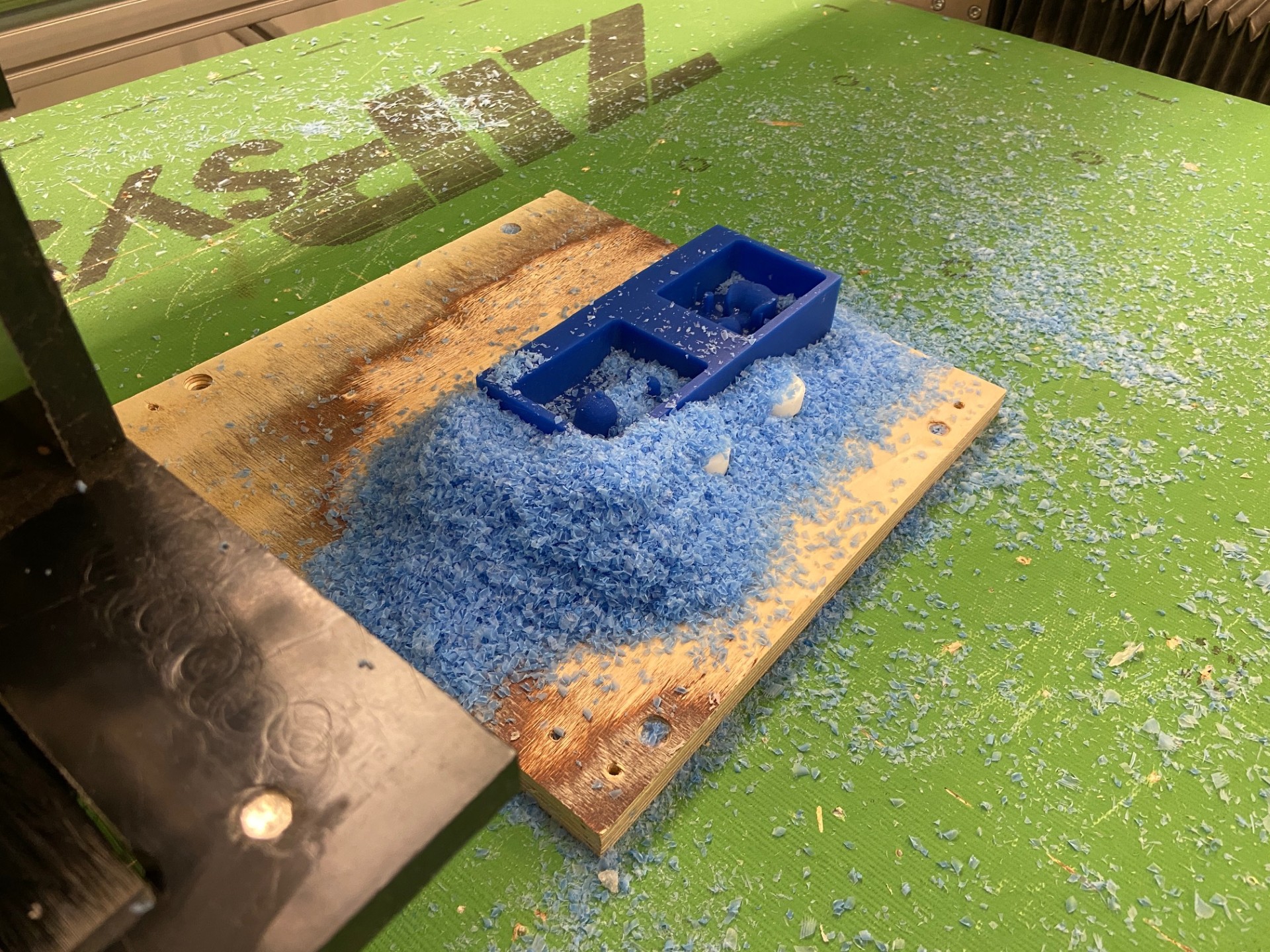

The milling took a total of 45 minutes to complete! Afterwards, I was left with a pile of shaved wax

The wax mold after blowing away the wax shavings:

Snoopy post-shower:

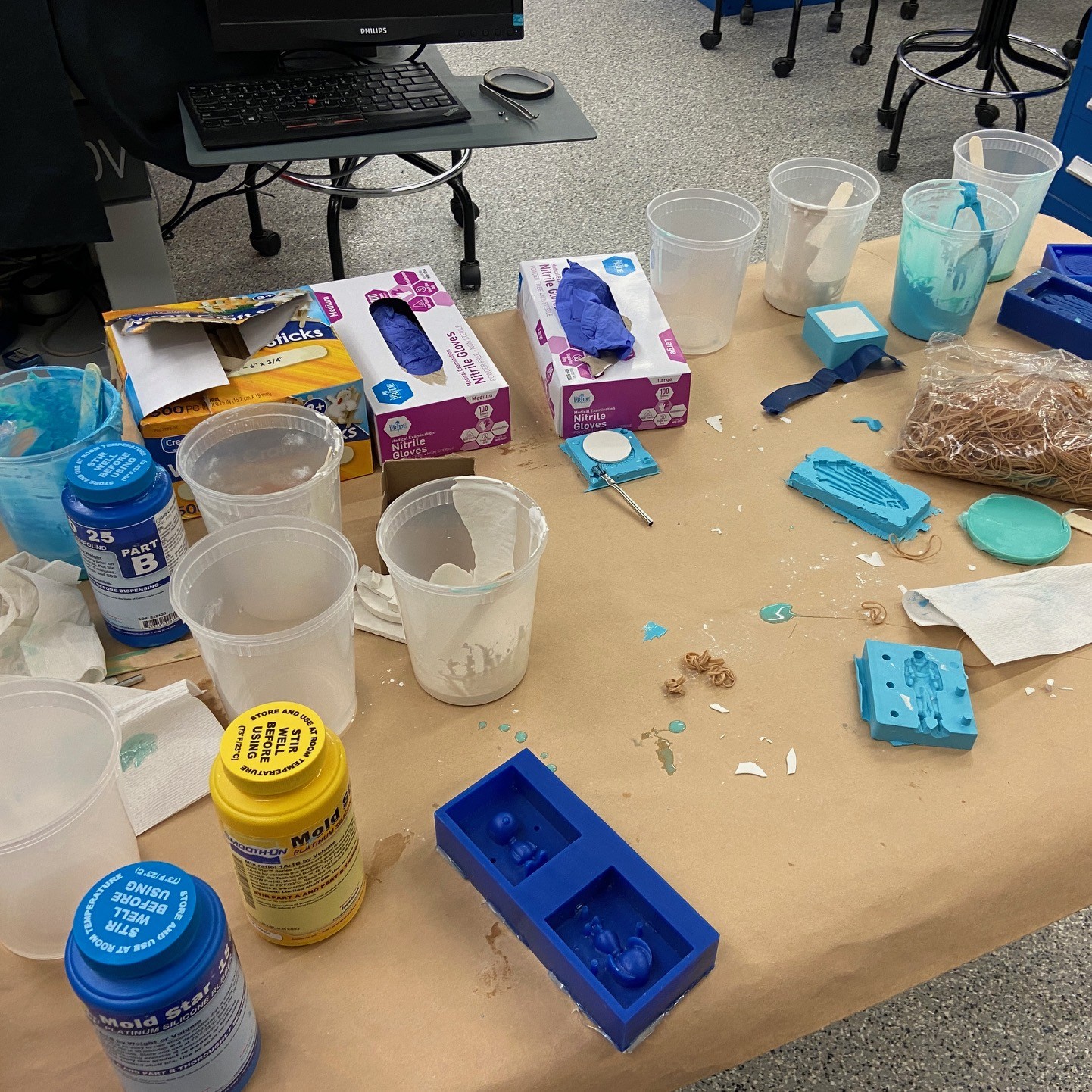

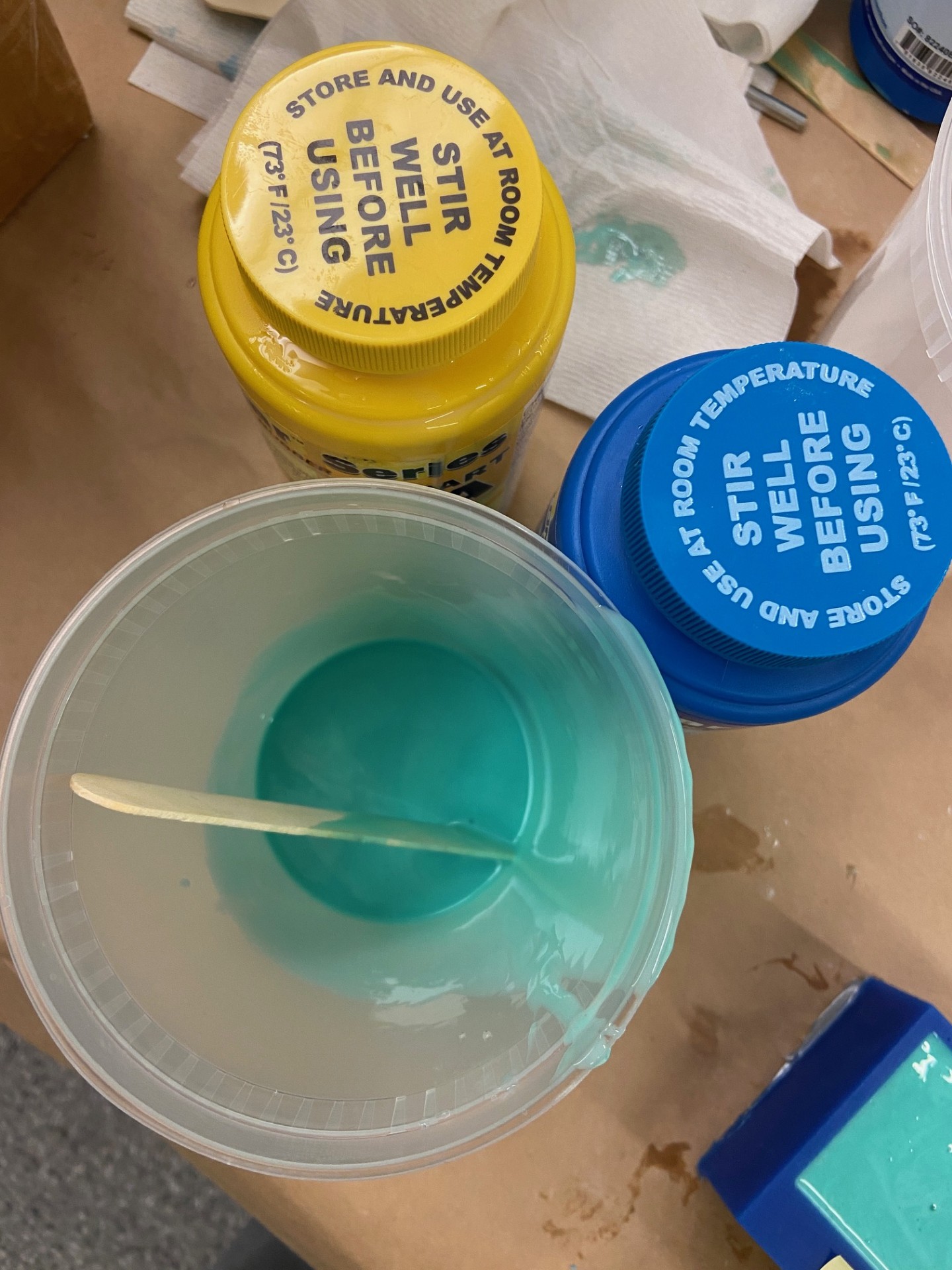

After checking that the wax turned out OK, I started to get the Oomoo ready to make the actual mold that I'll be using to cast Snoopy. The Oomoo ratio was 1:1 parts A:B. I let the mold cast overnight.

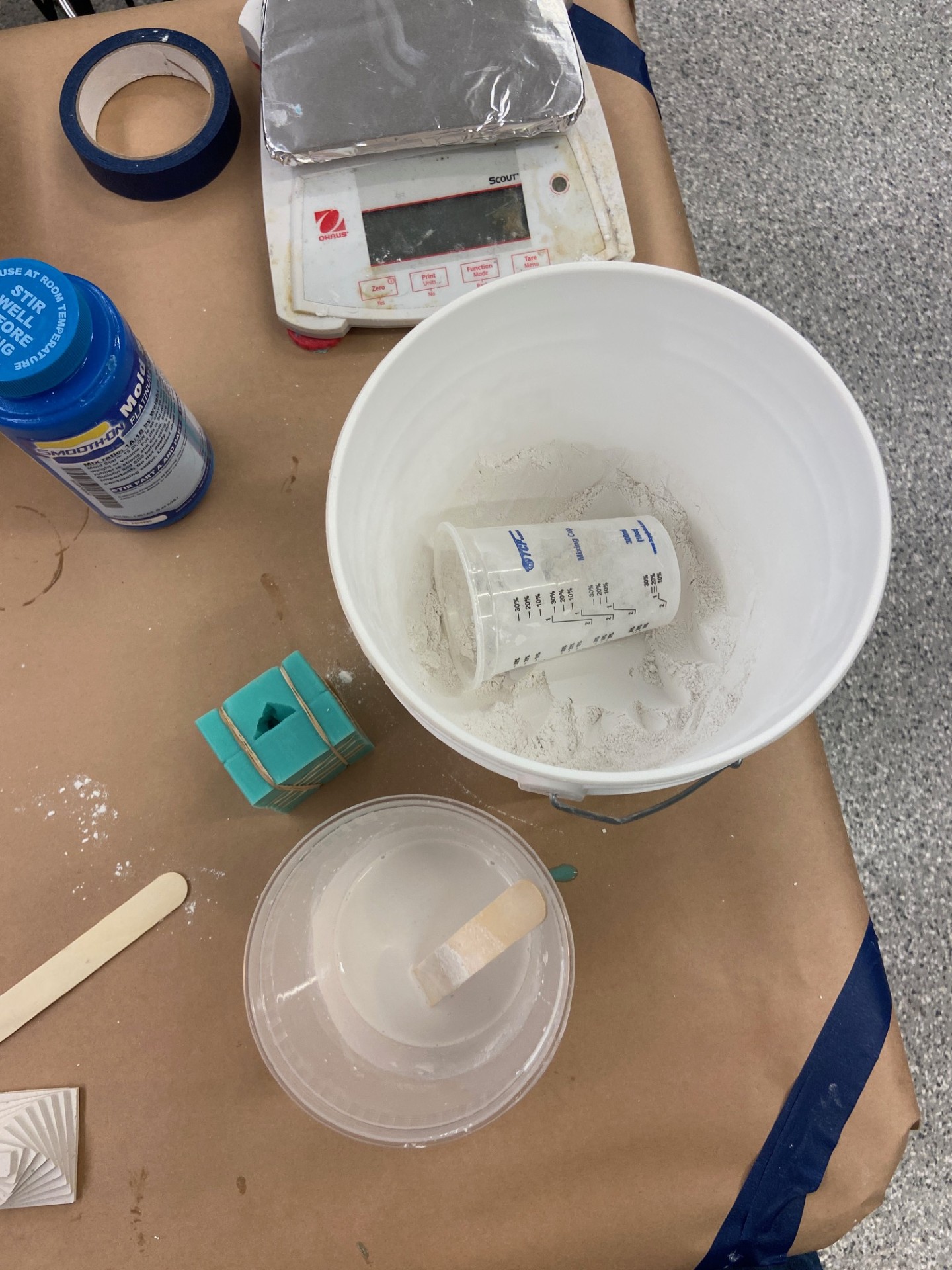

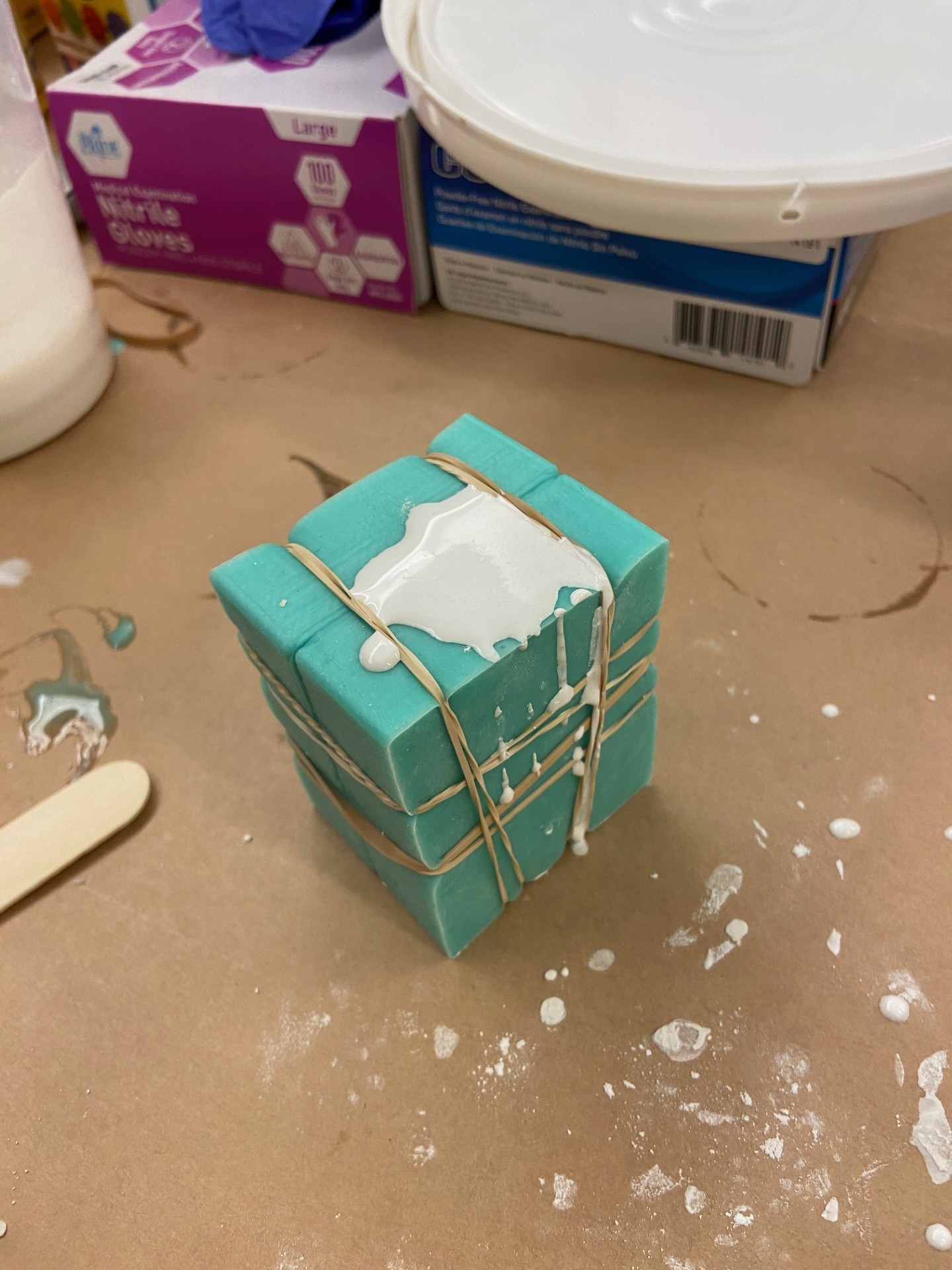

I planned to make a metal Snoopy to use as some kind of paperweight, but I started off with plaster. Using a 1:5 ratio of power to water, I mixed the plaster until it reached a milkshake like consistency, then poured it into my mold.

Snoopy turned out OK, but his legs actually didn't survive the casting -- presumably I didn't leave it in long enough for it to fully harden, or the legs were just too skinny and delicate to begin with. I superglued the legs to his torso which seemed to do the trick, but I decided to make another plaster Snoopy (it's currently in lab, drying) to see if it would work better if I left it overnight. Either way, I'm very happy with how he turned out, though I'll have to file and/or sand the edges, especially his ears.