OCTOABBY makes something big (ish)! For this week, I wanted to make something practical and... an octopus. I am OCTOABBY, of course. It is in my nature.

So let us begin with the former.

book shelf

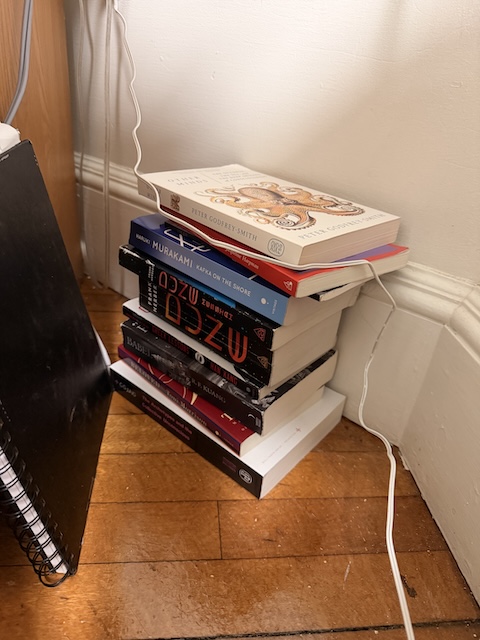

In dorm room at Wellesley, there is nowhere to put my precious books! They sit sadly in a pile in the corner... collecting dust... never to be seen again...

But aha! There is a nice little space under my absurdly lofted bed! Perfect for a little bed for my books.

Sooooo... taking inspiration from this book stand I found on pinterest:

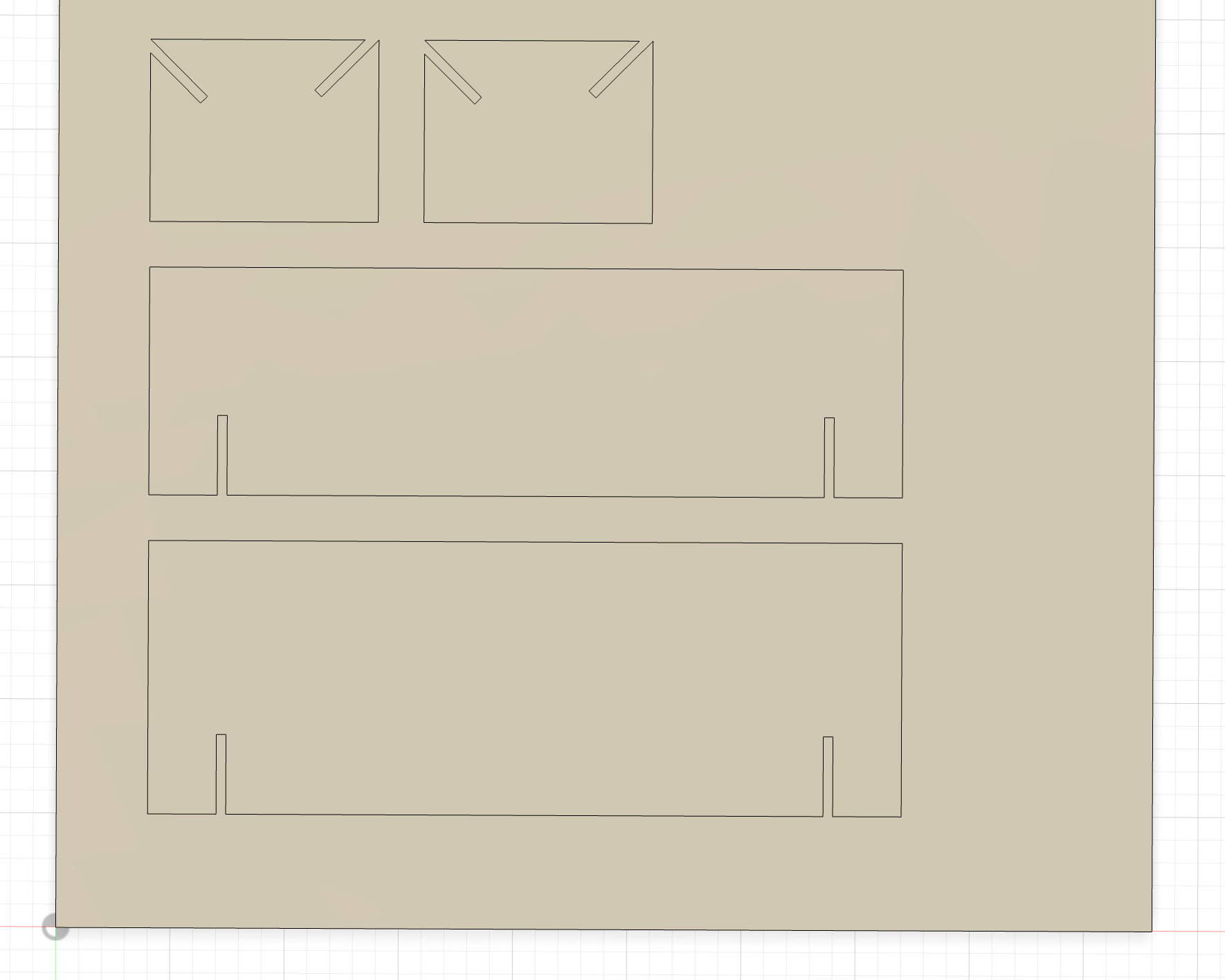

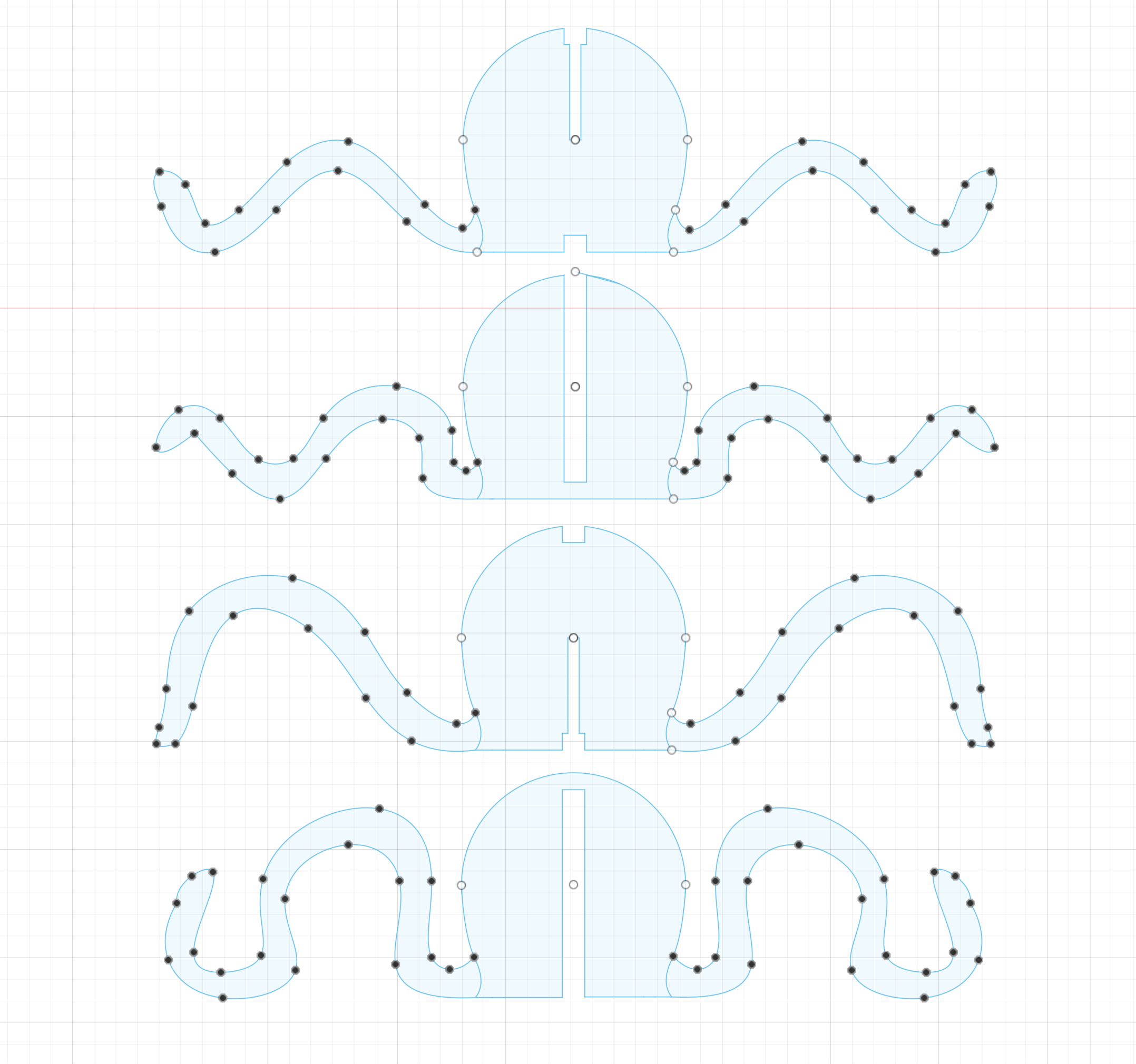

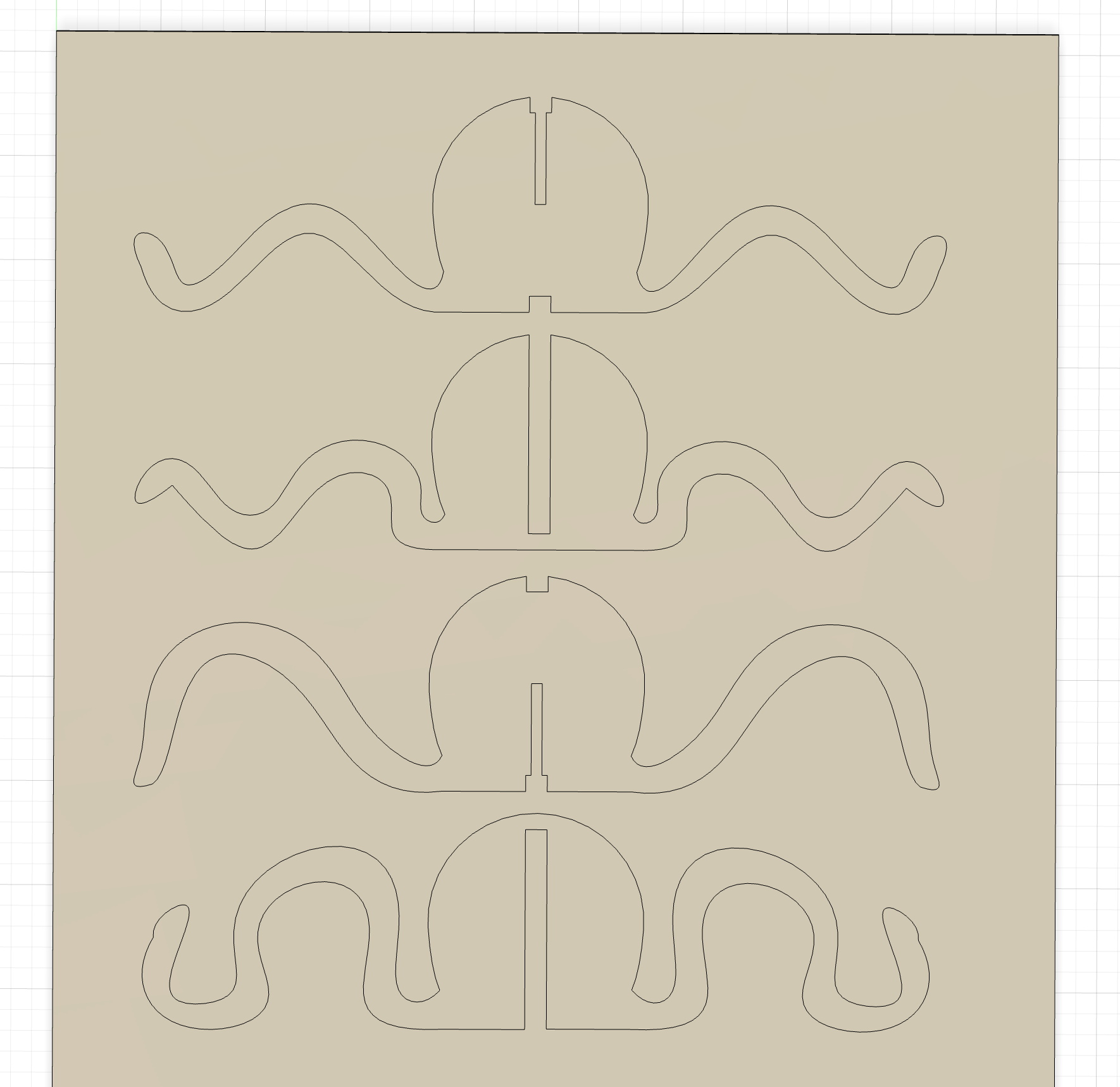

I designed my own! I measured an optimal length of around 33 inches to fit between the posts. Using some sketches and then fusion, I created my stock and the four pieces I'd need to make the book stand.

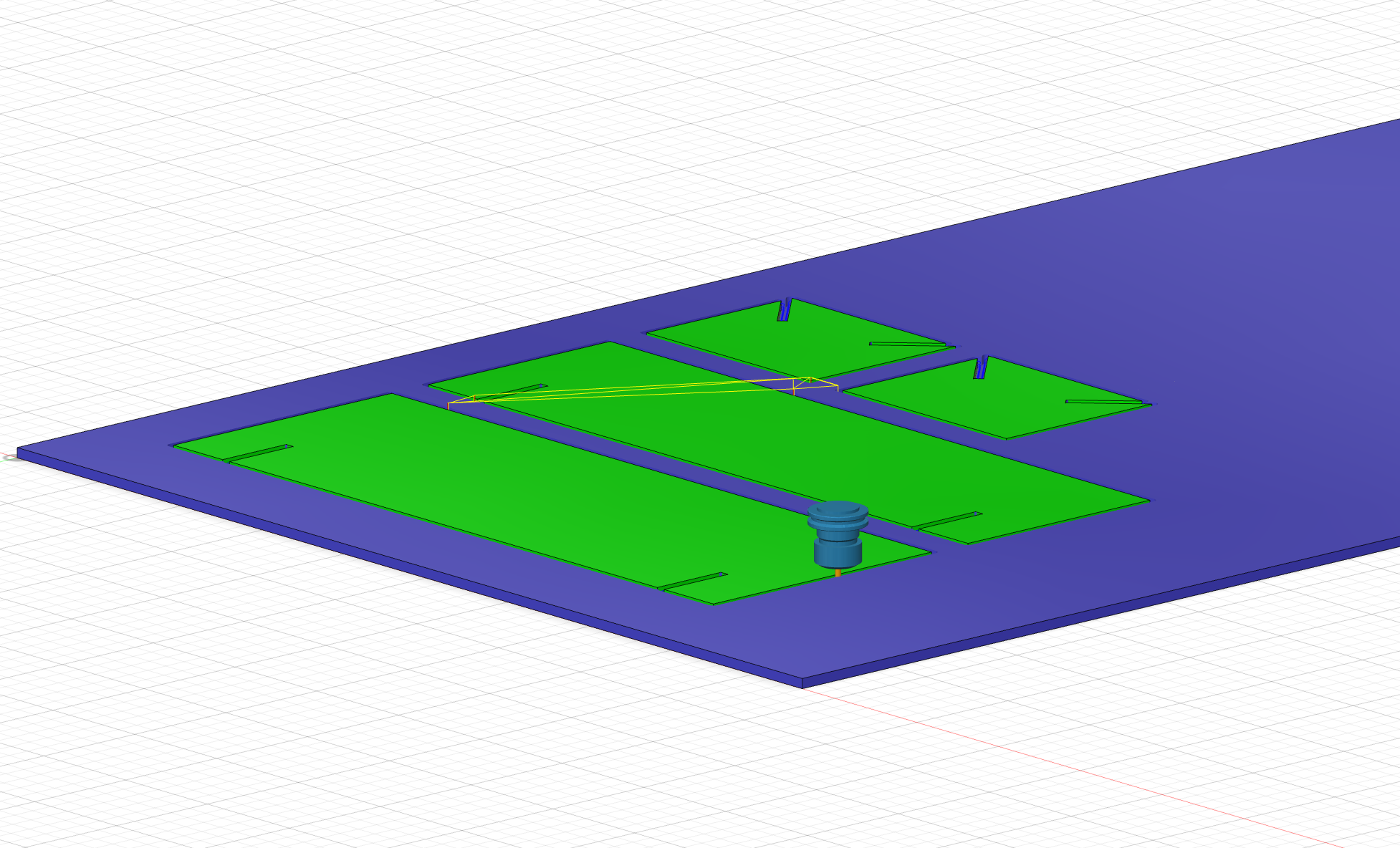

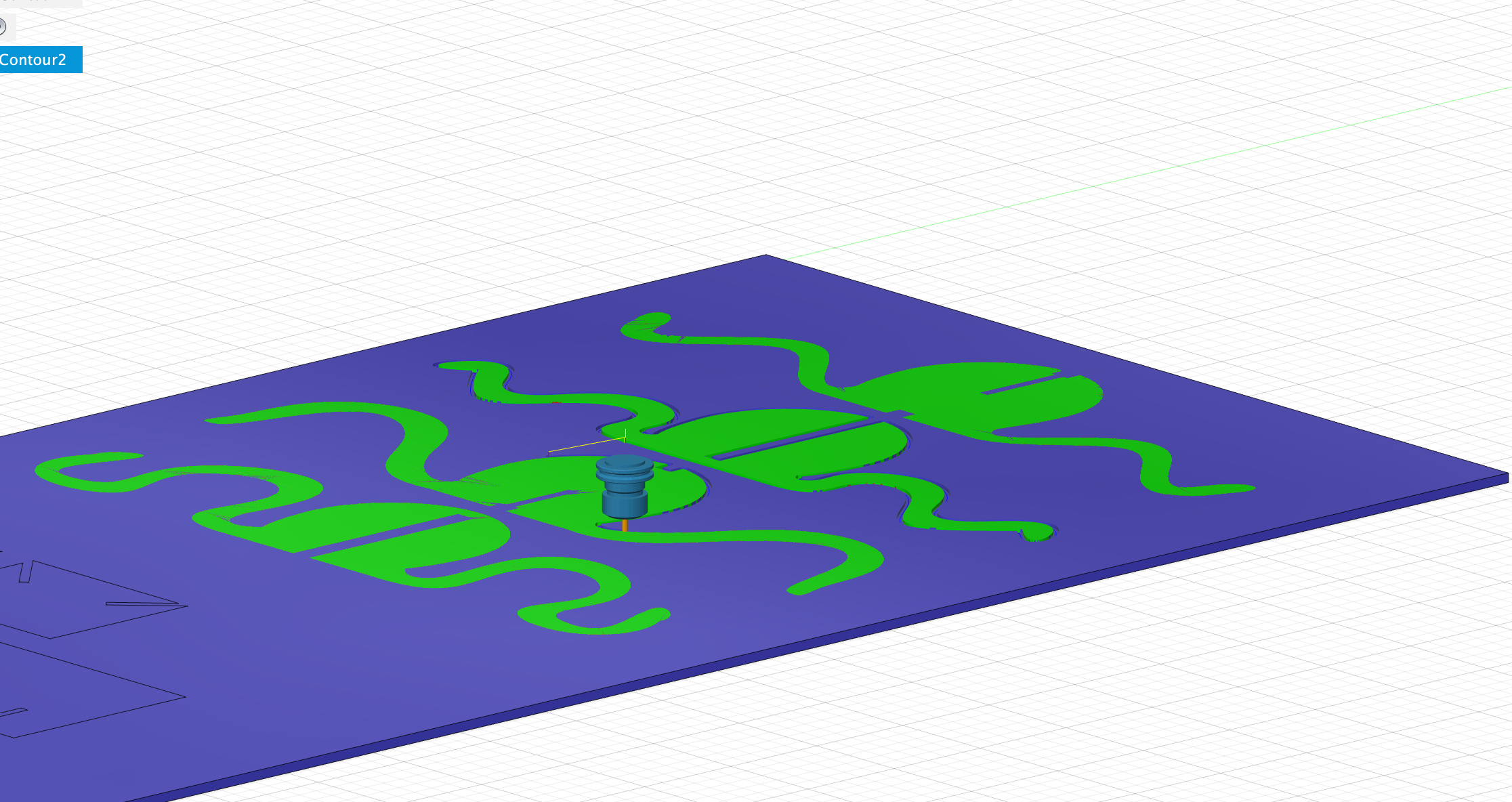

Before I came in, I completed the Setup and 2D contour sections of manufacturing in Fusion. I simulated, and everything looked good!

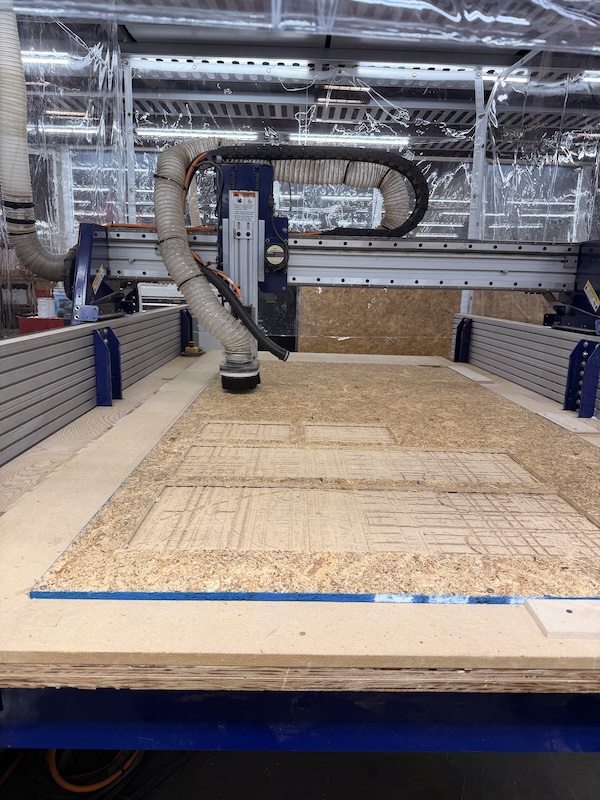

I came in for my session with the ShopBot and set everything up. I zeroed my axes, uploaded my gcode file, and sent it off. I just used a 1/4 up cut end mill for the whole cut. Everything honestly went super smoothly. It only took maybe 20 minutes to cut.

Then, I removed the pieces from the board by cutting my tabs and pulling them off.

I discovered that I did not make any dogbones... but there were these square chisels, so I used them to clean up my corners in the joints. I also sanded down the faces with an orbital sander.

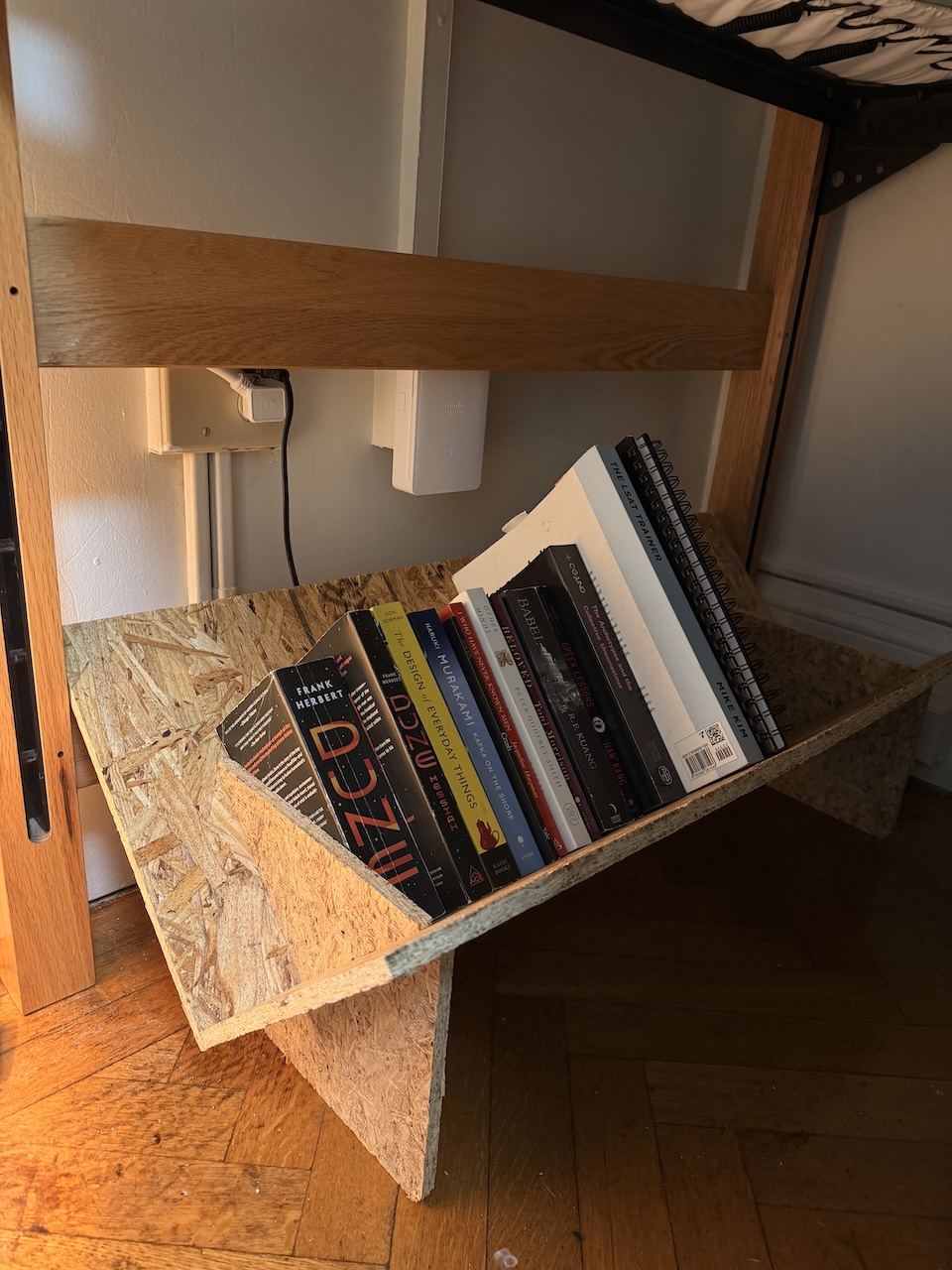

Then I assembled! Beautiful. I did make my slots just slightly too small, so I was hammering at this for a little while and making all sorts of noise. But it is super snug in there now!

And now it sits perfectly under my bed holding my books :D

It does kind of smell like hamster enclosure, so I think I will bring it back in and seal it. But otherwise a great success!!

octopus

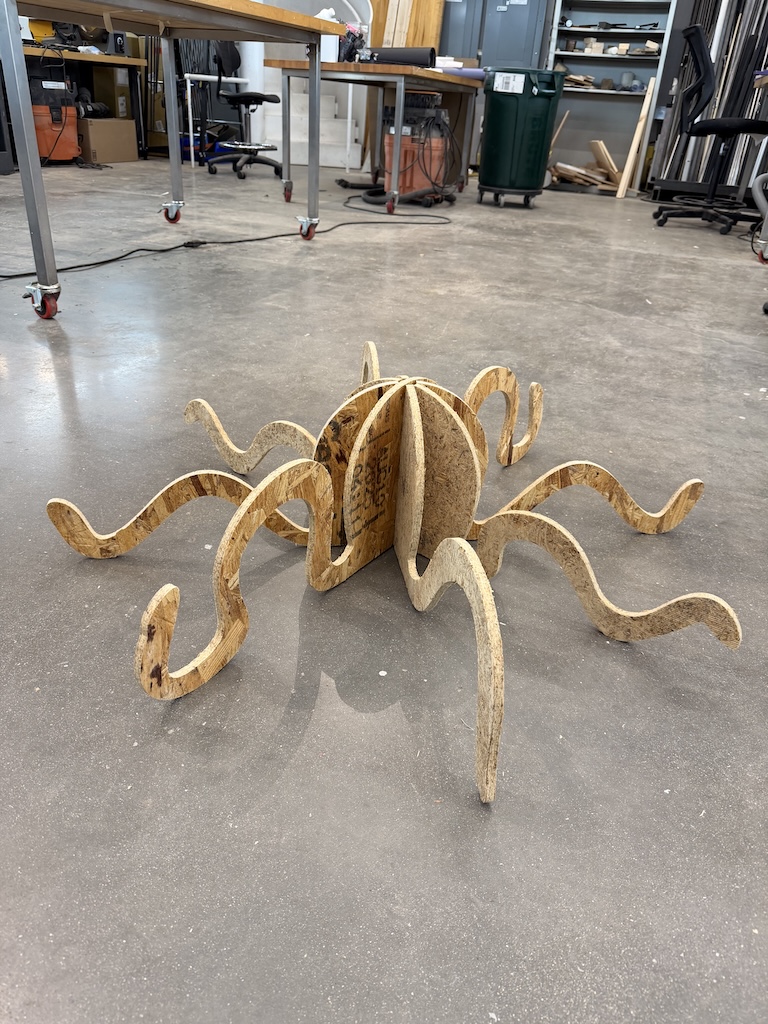

During lasercutting week, I obviously made an octopus. But it was somewhat of a feat, as I created my own 4-way cross joint. I wanted to take this and see if it would work scaled up, so I exported my octopus head file to Fusion.

I then drew in different waving tentacles for some variety. The head part works by intersecting the two smaller slots perpendicularly, and then the larger slotted ones intersect those.

I set it up again in Fusion and simulated with the same settings as before.

I milled it soon after the book shelf and used the same 1/4 up cut end mill, and the job took around 15 minutes.

Then I did the same thing, chiselling out the slots with the square chisel.

And there she was!! In all of her wiggly glory. She lived like this in the CBA shop for a few days... But I came back and decided I wanted to paint her.

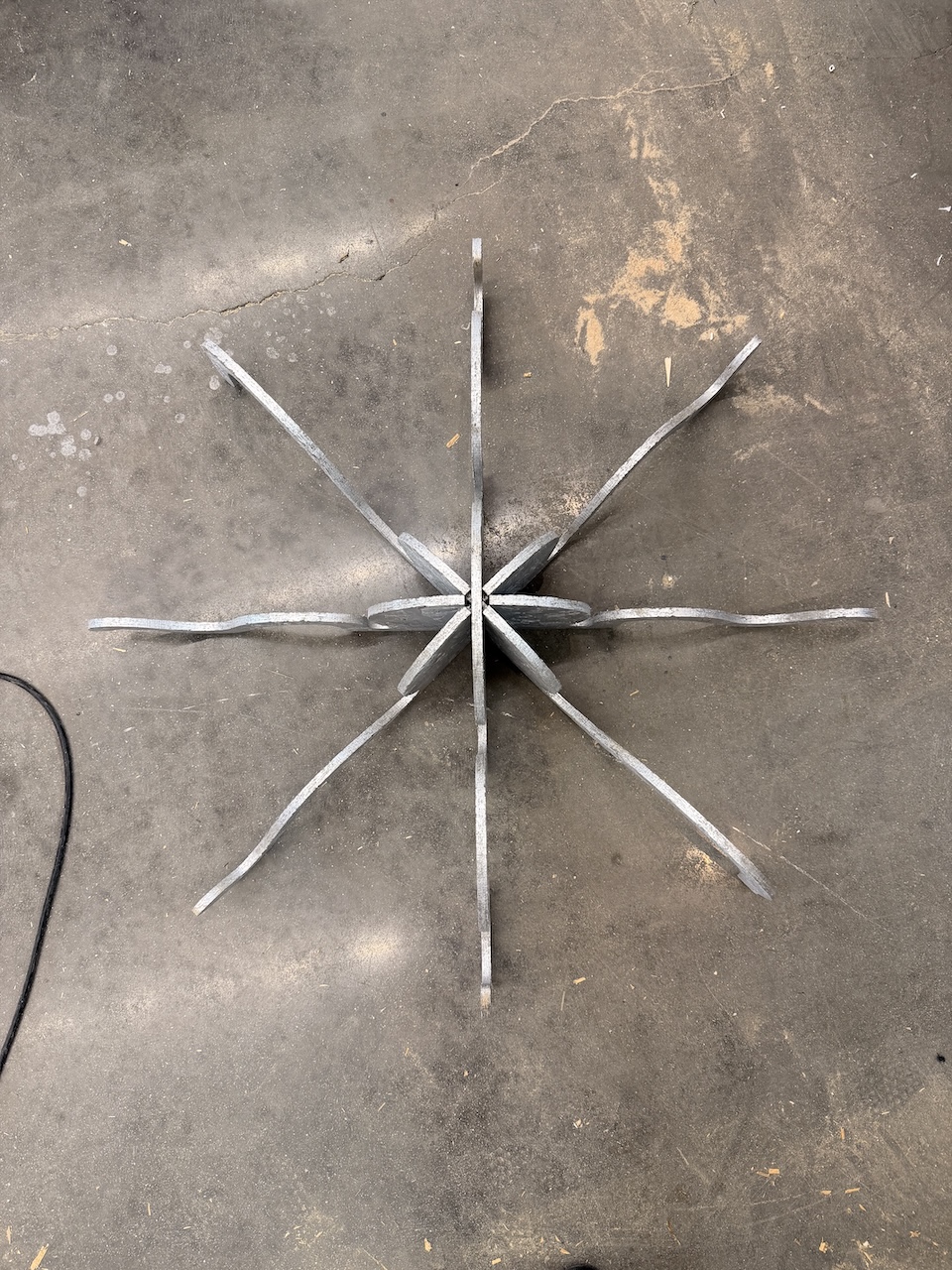

Sooooooo I painted her silver!! Shiny and majestic!

TADAAAAAA my beautiful silver shiny octopus! I've received some suggestions on what she could become next.. maybe a coat rack.. a disco ball.. let me know what you think.

The creature emerges...

Files