week 7:computer-controlled machining

woodshop training

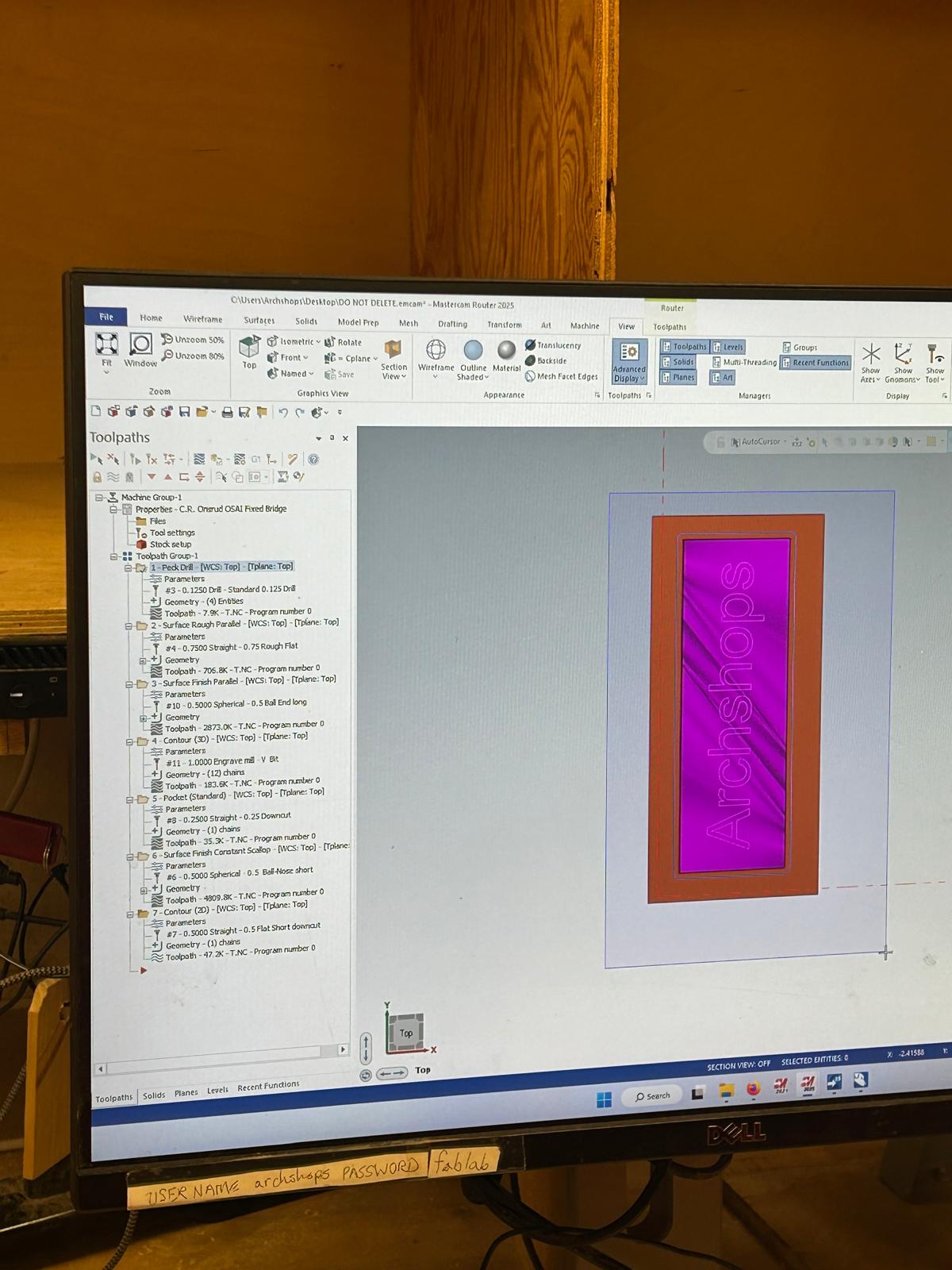

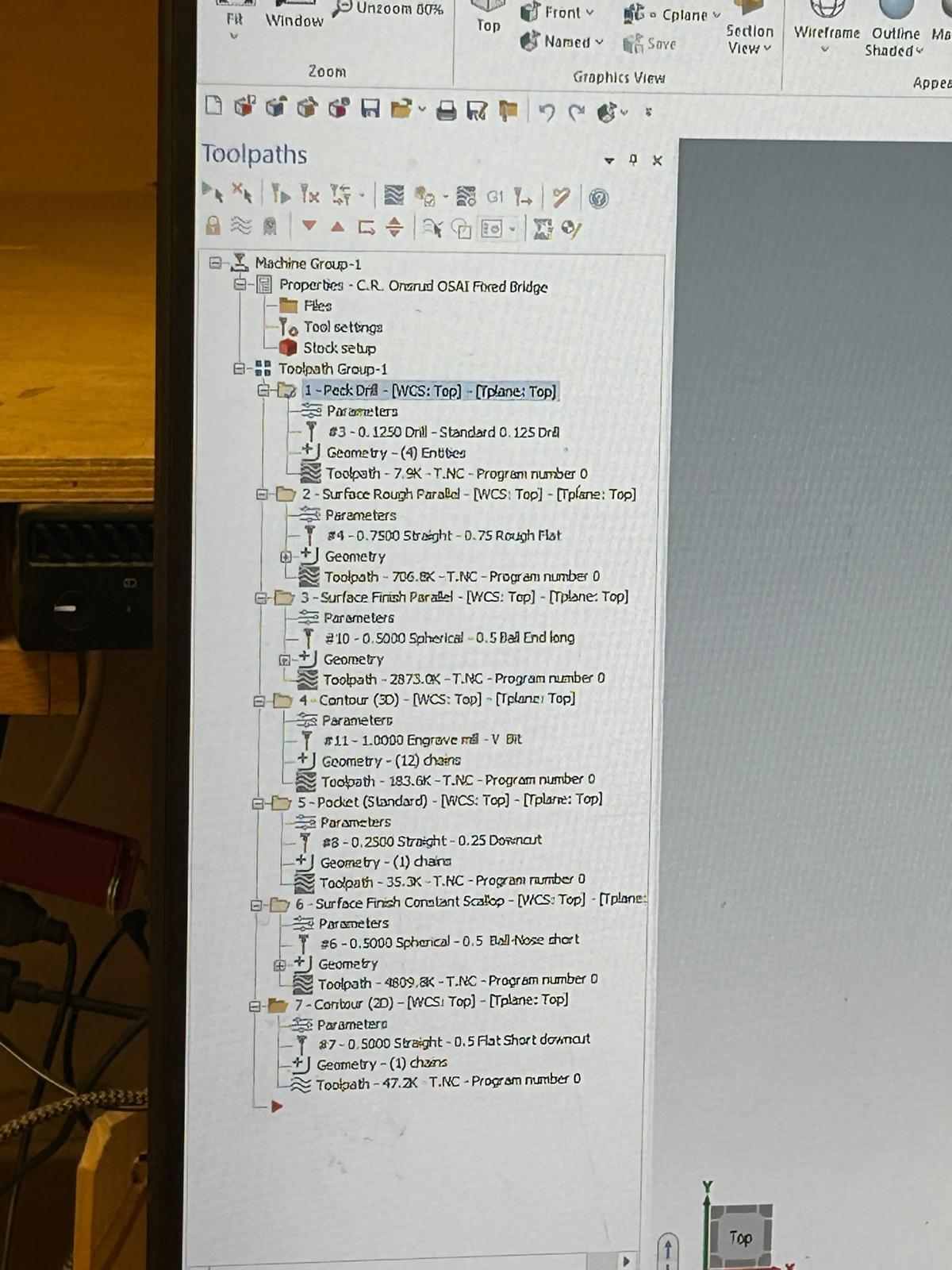

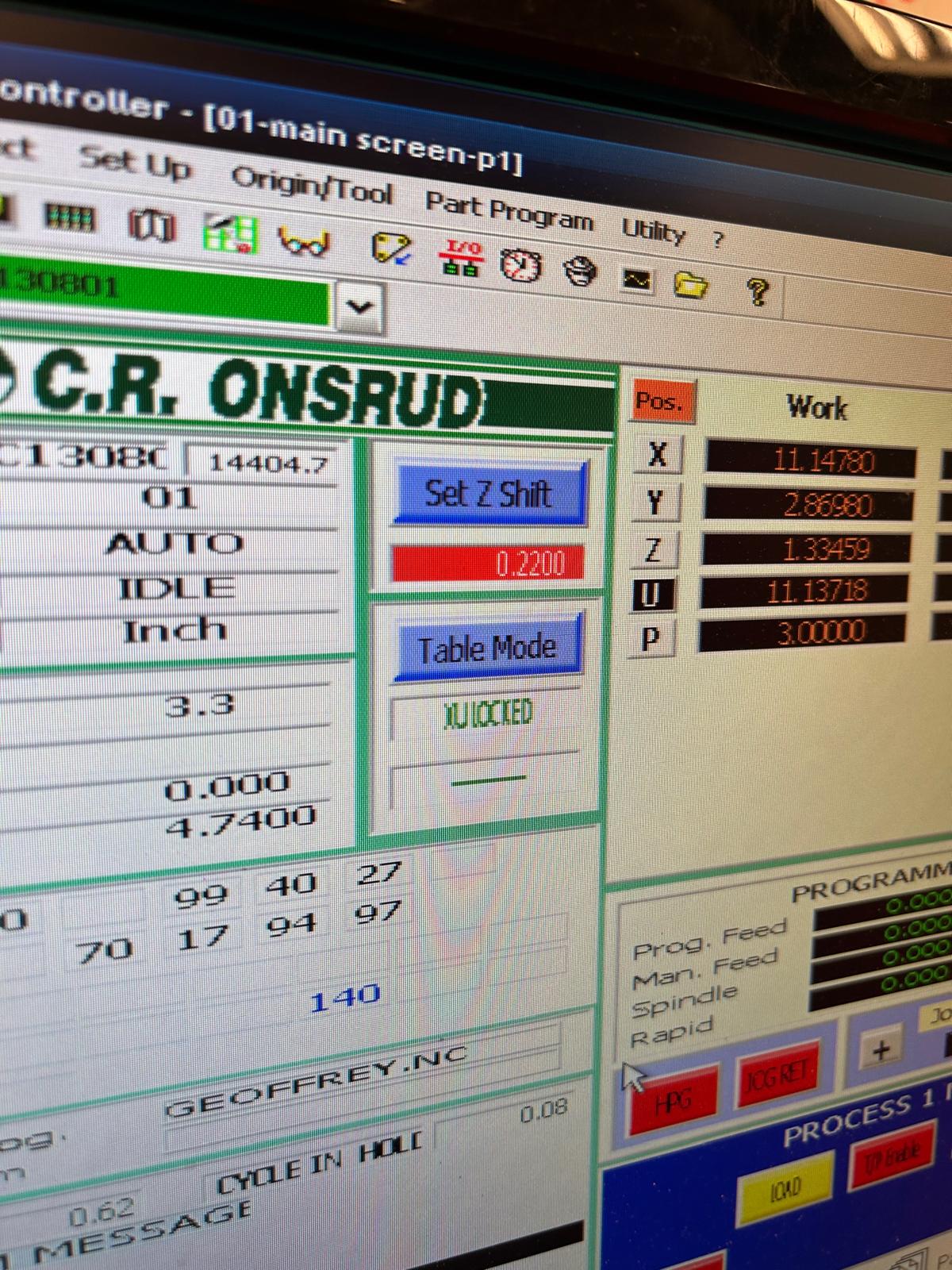

This week started with Chris’s training session at the woodshop. When I arrived, Carlos was already there, working on his project using plywood. Chris explained the main differences between OSB (Oriented Strand Board) and plywood, and in which cases each material is more appropriate. After that, he gave us a short introduction to preparing toolpaths in Mastercam, and once our files were ready, we were set to import the G-code into the Onsrud CNC router. We ran a test cuts using both materials and found that a 0.46-inch toolpath width worked best for the 0.433-inch OSB board.

Project Development

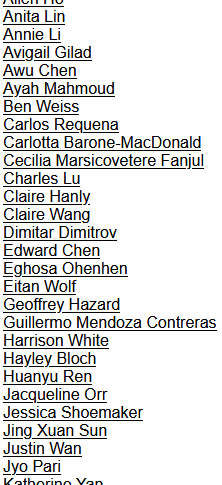

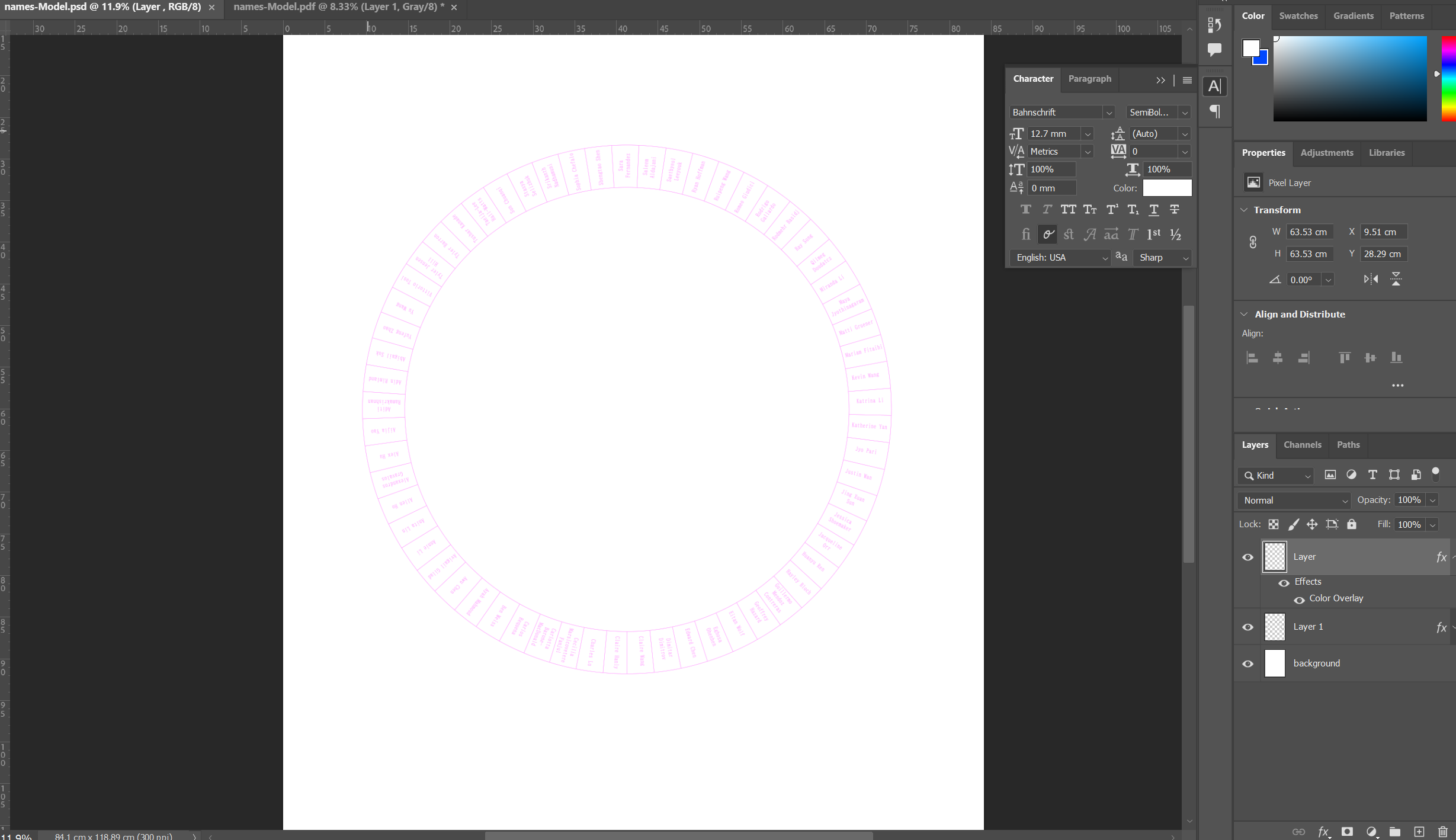

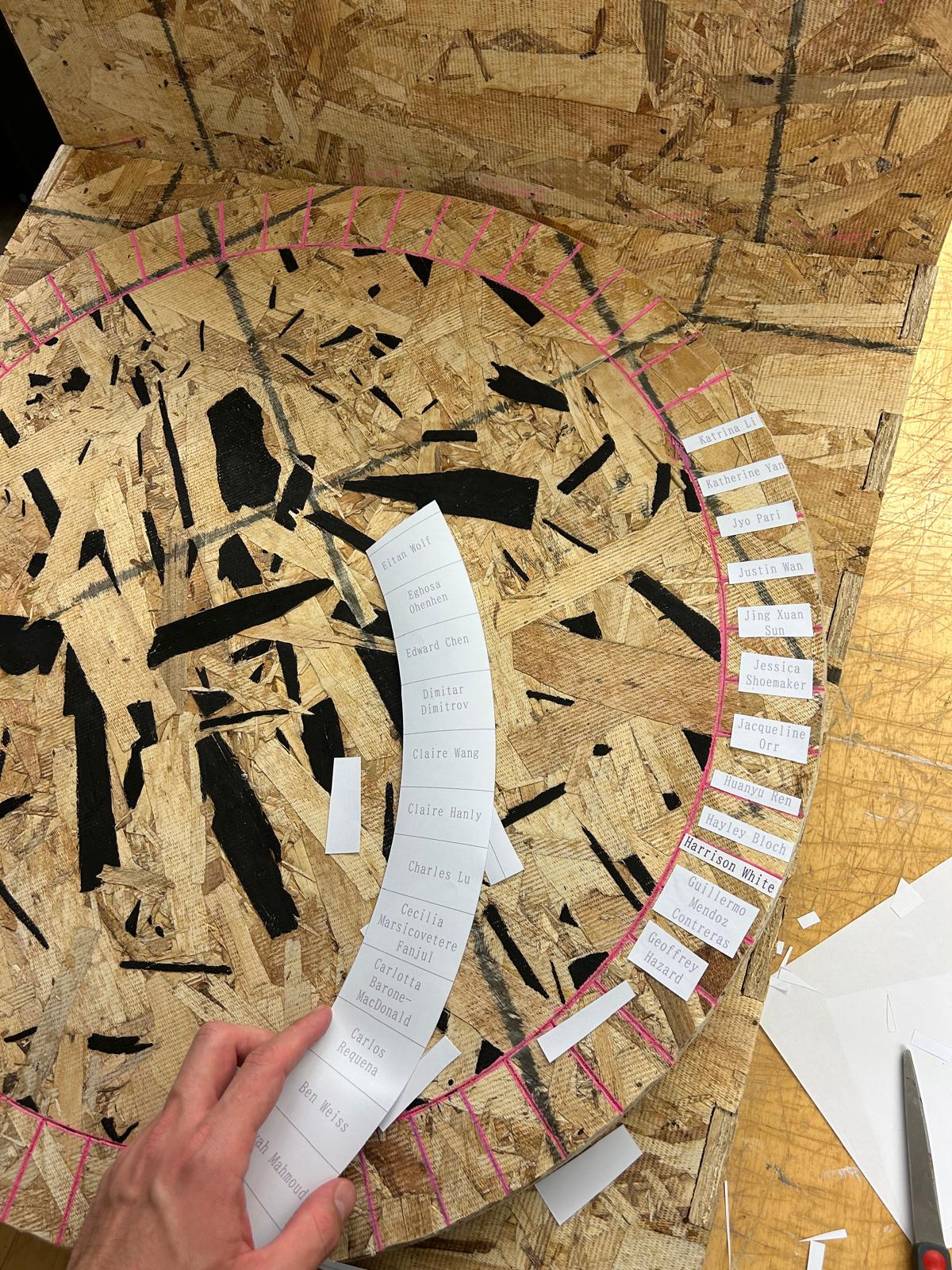

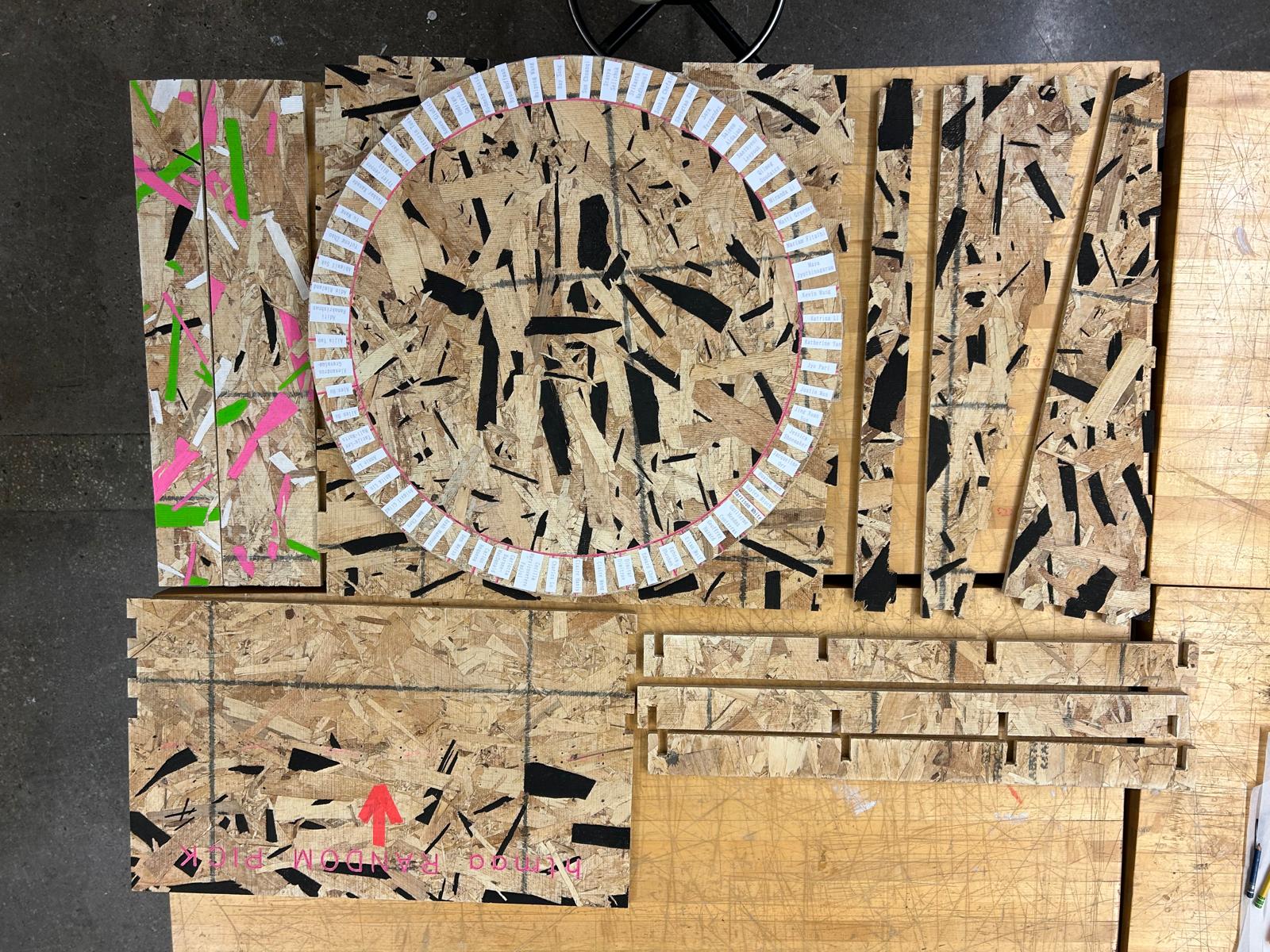

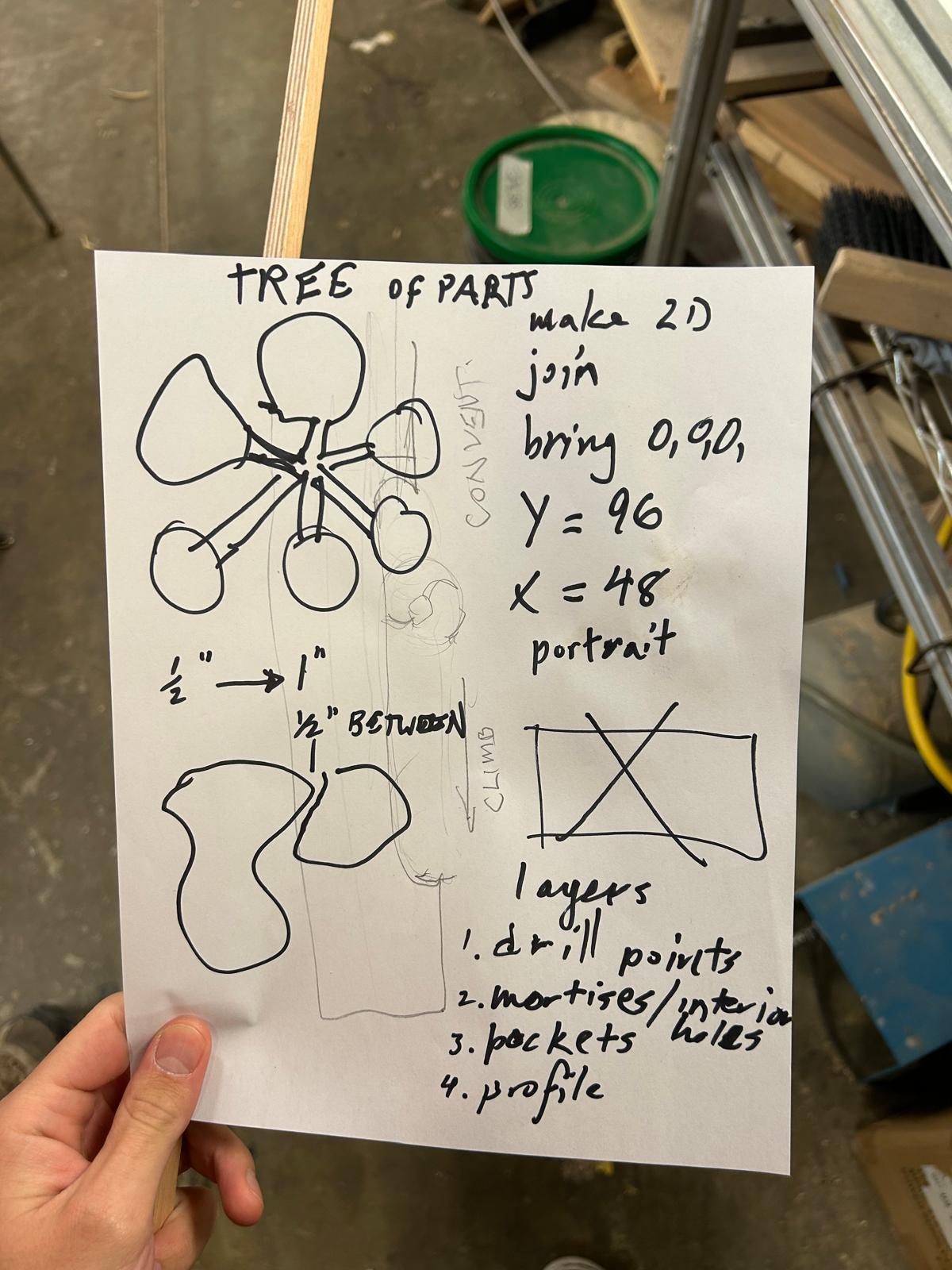

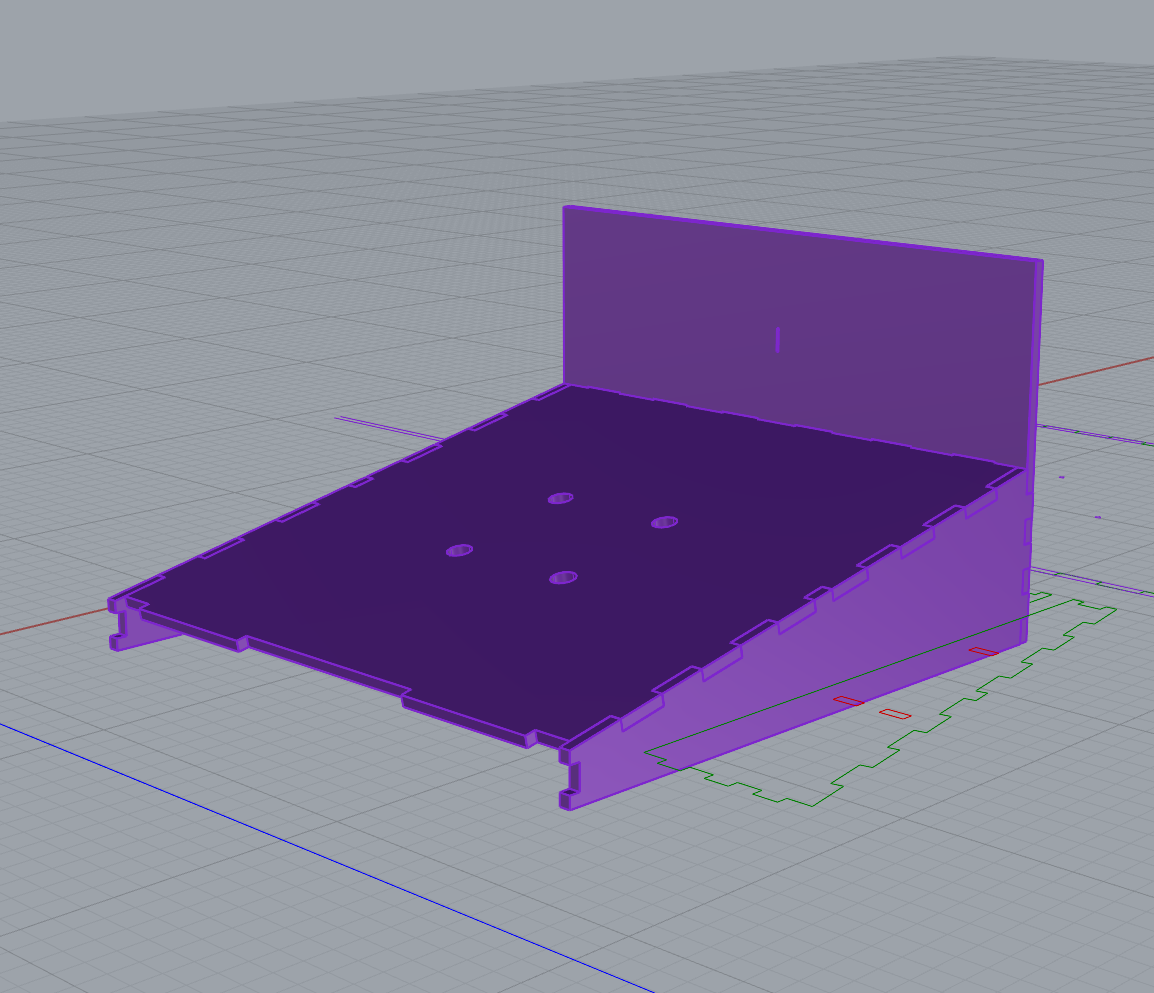

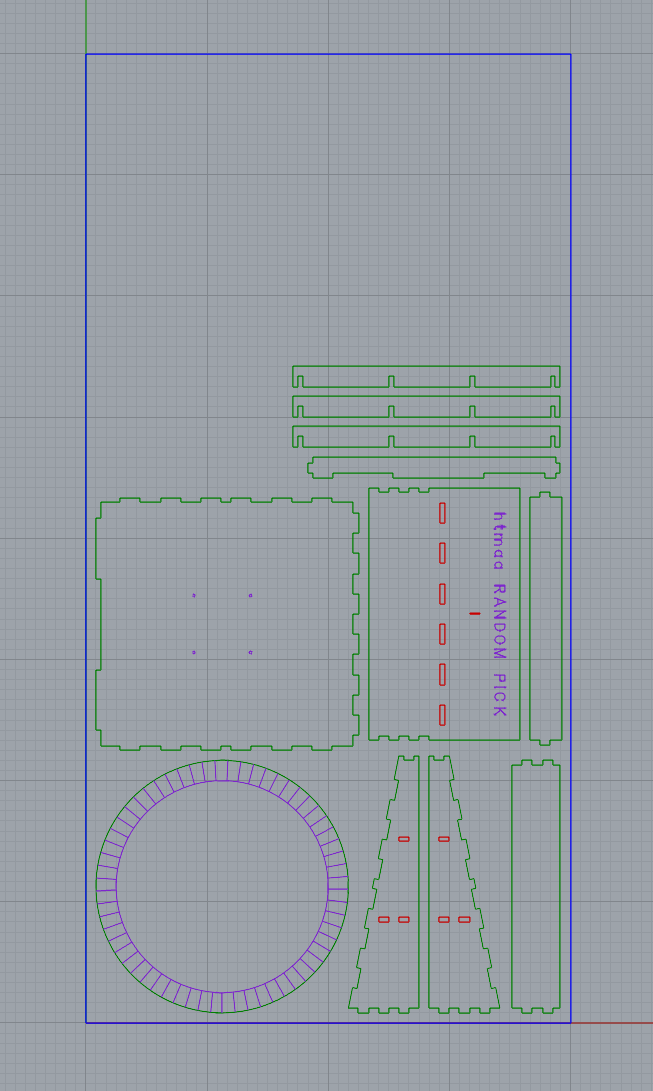

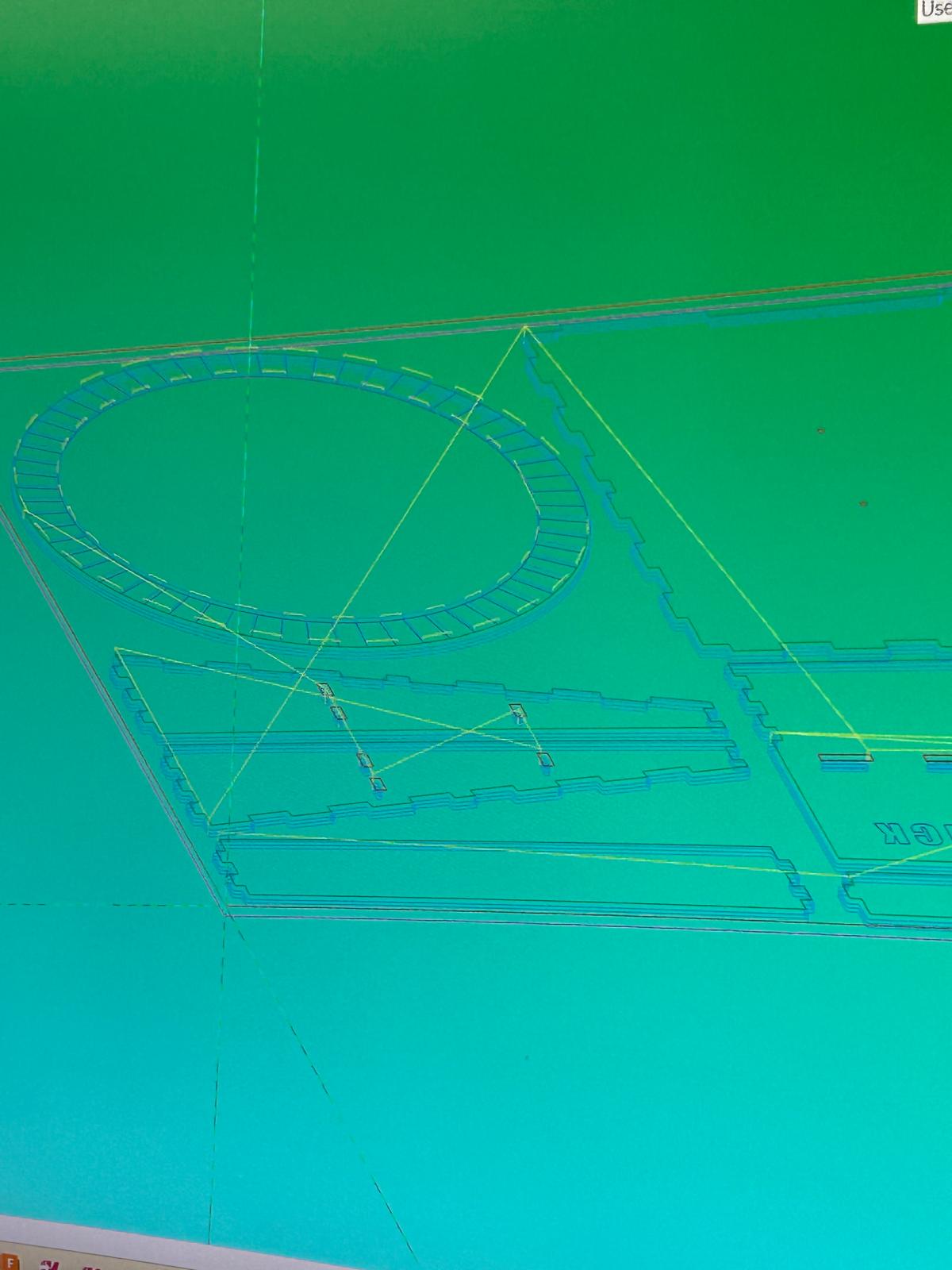

For this week’s assignment, I had several ideas on a larger scale, but they were too big to fit within a standard 48" × 96" OSB sheet. So, I started thinking ahead to my final project, which will probably require bearings to allow a surface to rotate. My idea evolved through class discussions, and I decided to create an HTMAA Random Pick Generator, inspired by the spinning “lucky wheel” games used in gambling. I modeled the design in Rhino, and once the file was ready, Dan kindly helped me prepare it for G-code generation. Unfortunately, the first file didn’t have the correct parameters, so I had to rebuild it from scratch with Chris’s help. The CNC process involved four operations: Drilling the holes Engraving the text and patterns Profile cutting the parts Chamfering (shaping) the edges It was really interesting to observe how the machine automatically switched between bits and how each bit type corresponded to a specific operation.

Production

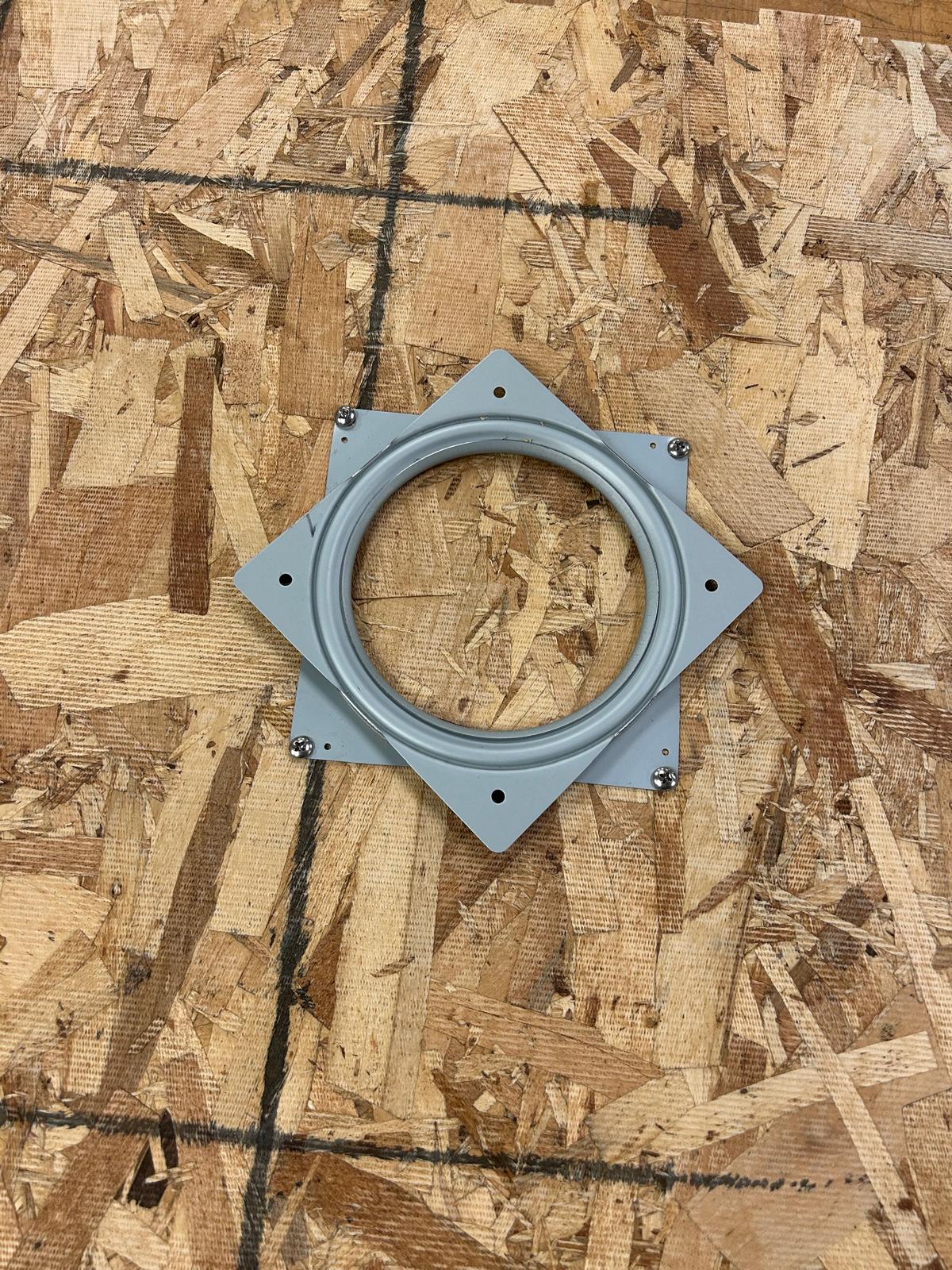

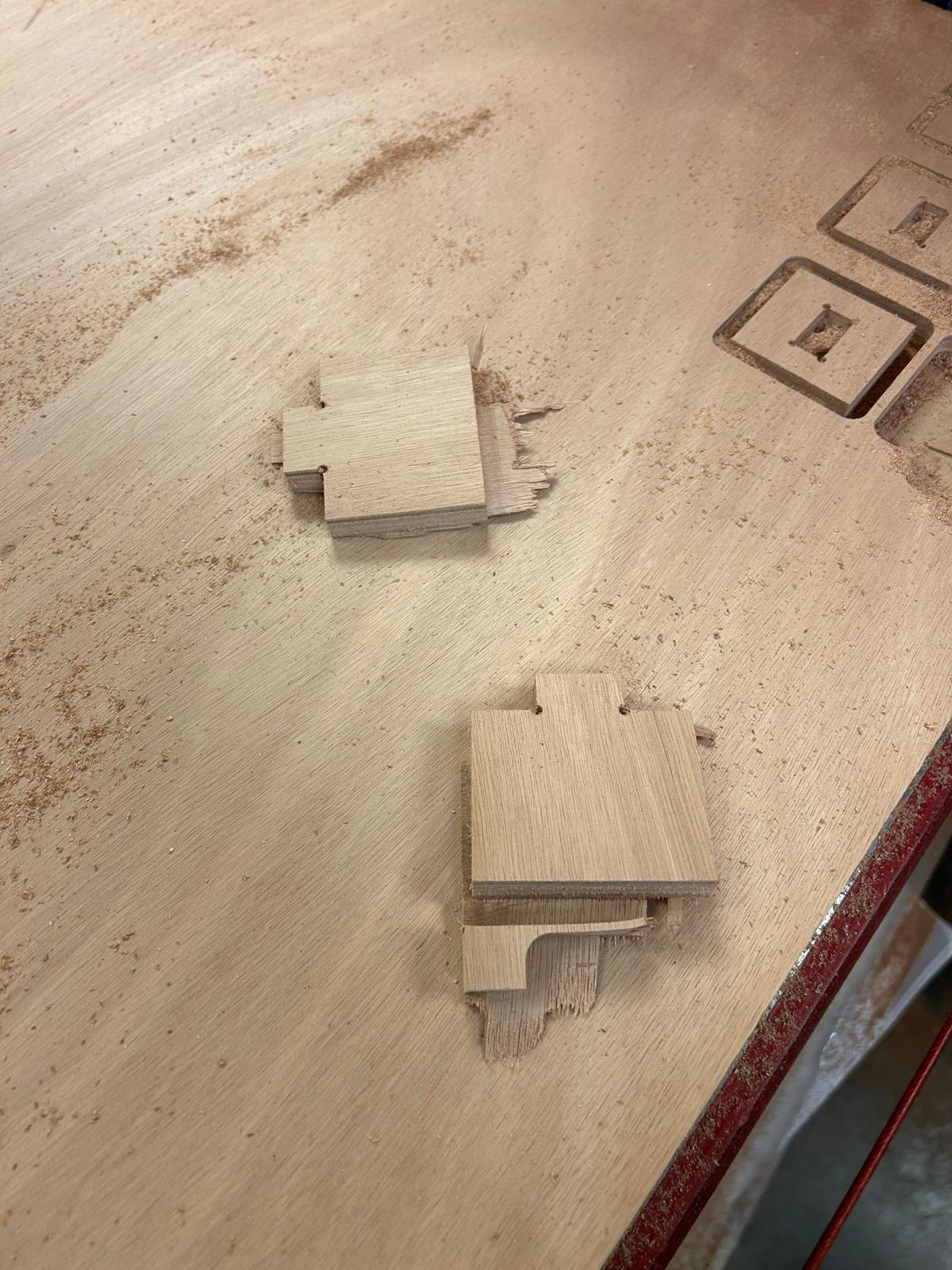

Most of the pieces were cut accurately, except for one that I hadn’t noticed was misaligned from the beginning. I sanded all the parts to smooth the surfaces and remove splinters, then recut the faulty piece. Chris suggested using the table saw for a faster fix. I transferred the measurements onto a new OSB sheet, and Chris helped me make the precise cut. After that, I adjusted the stock edges so the pieces would fit together properly. The most challenging part of the whole process was installing the Lazy Susan bearing. I ordered one from Home Depot for about seven dollars. To attach it, I had to drill offset holes on one side to allow access for the screws from the opposite wooden plate. Once everything was assembled, I moved on to the artistic finishing using Posca markers. I experimented with several color combinations, but mainly used black to emphasize the OSB’s layered composition.