For Wildcard Week, I worked with the sewing and embroidery machine. This week was about learning a process quickly and translating digital files into physical output, rather than developing a complex electronic system.

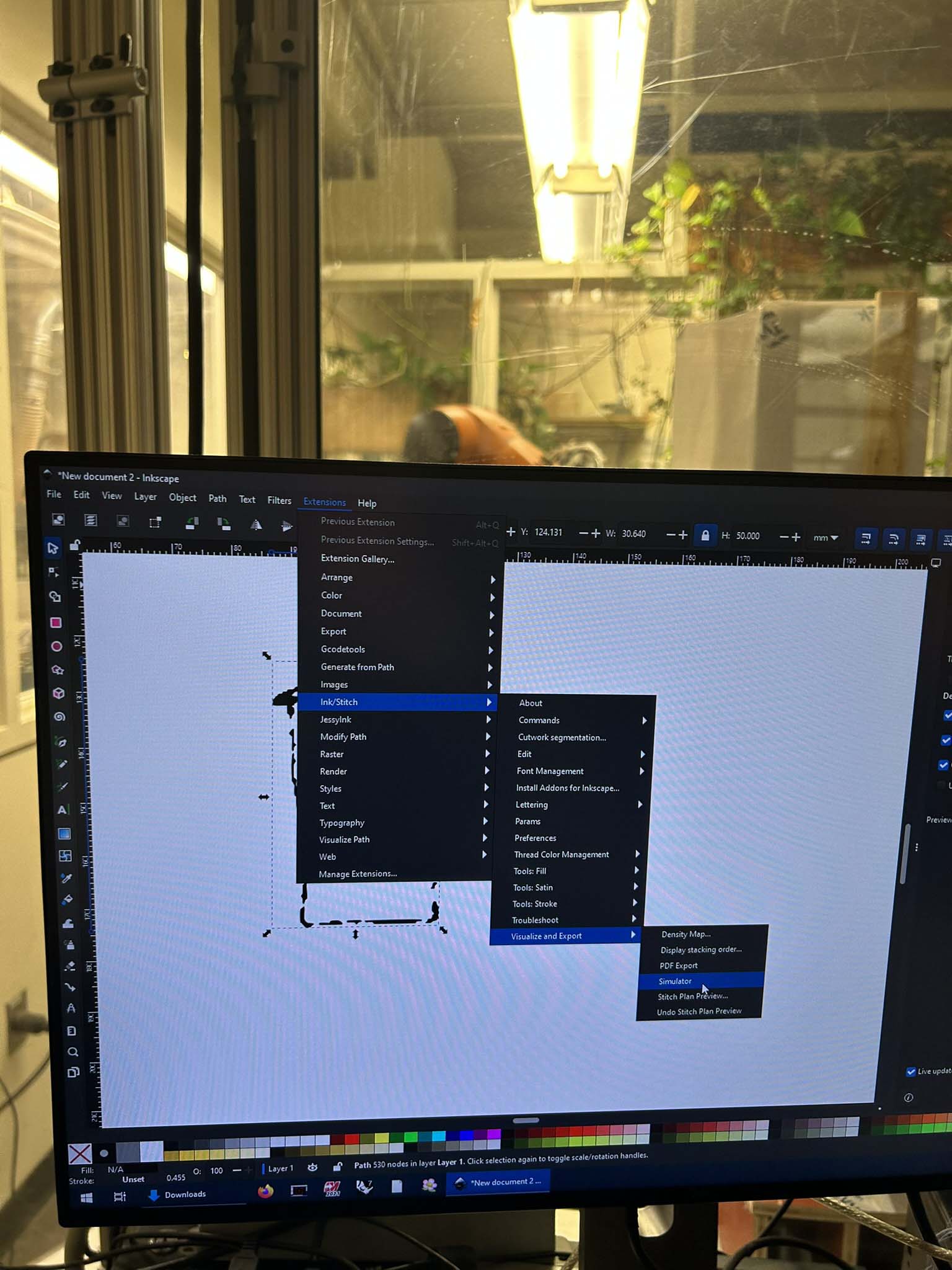

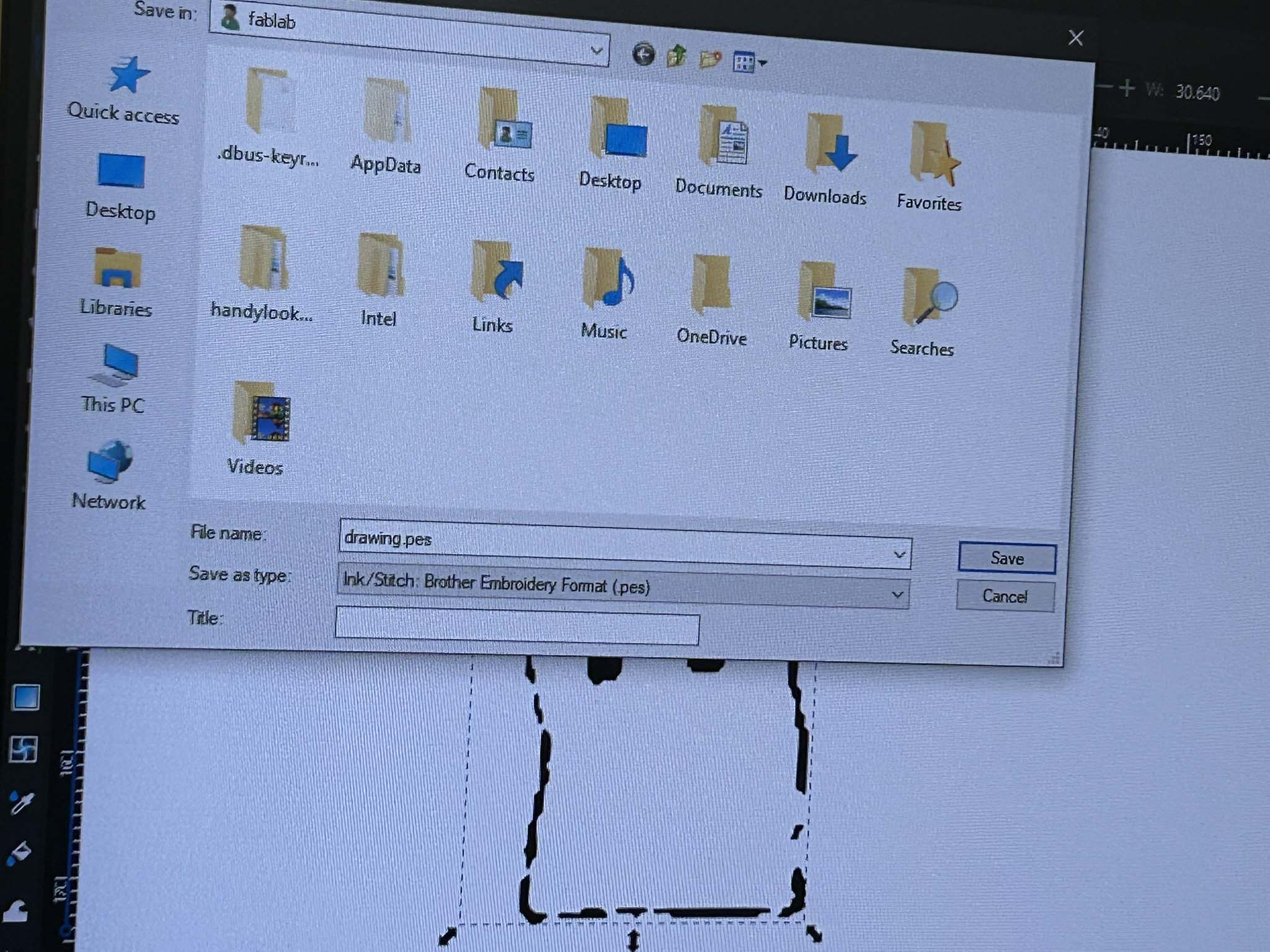

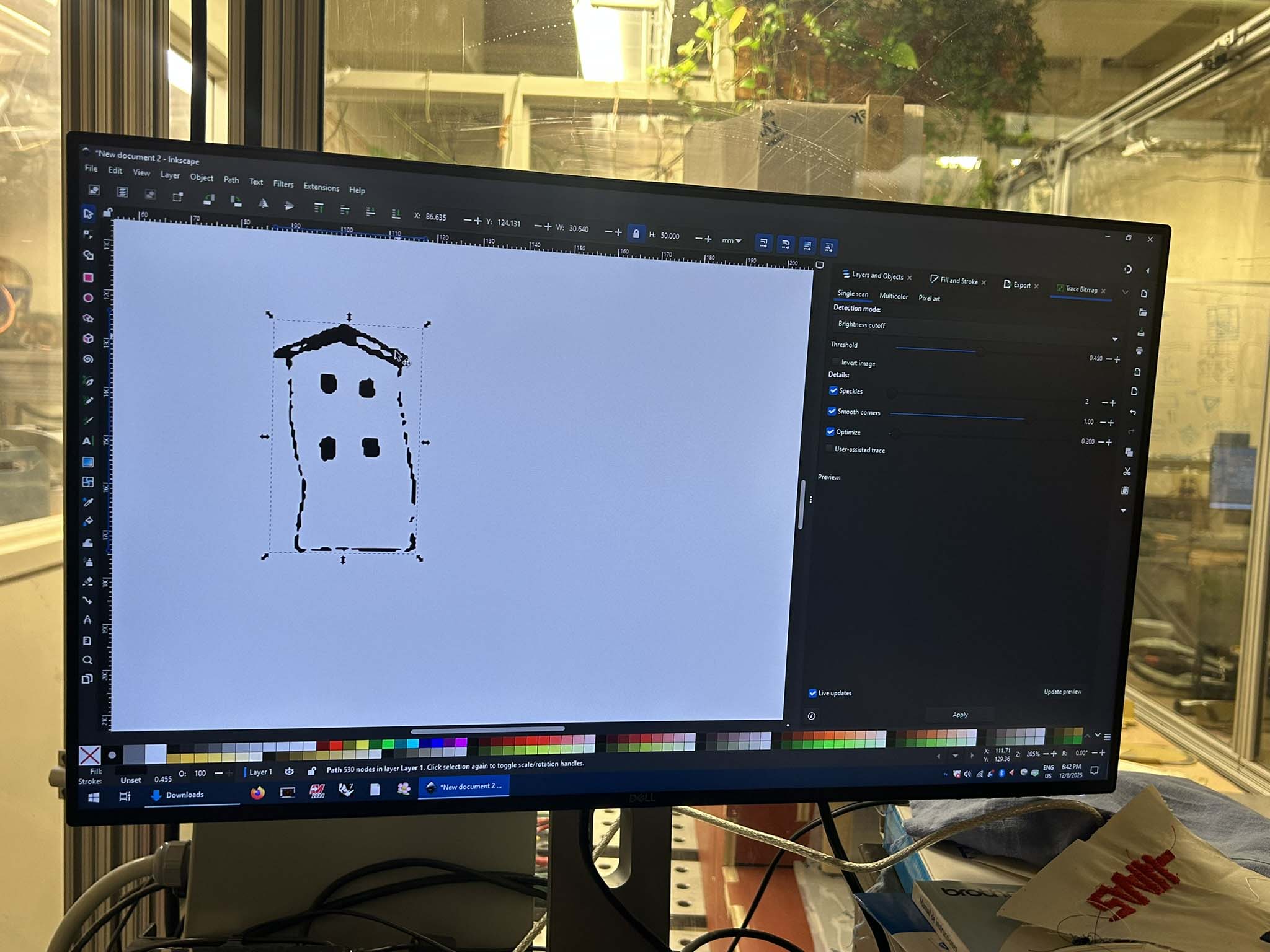

The workflow began with creating a vector drawing. The vector was then loaded into Inkscape, where it was converted into a path that the embroidery machine could interpret.

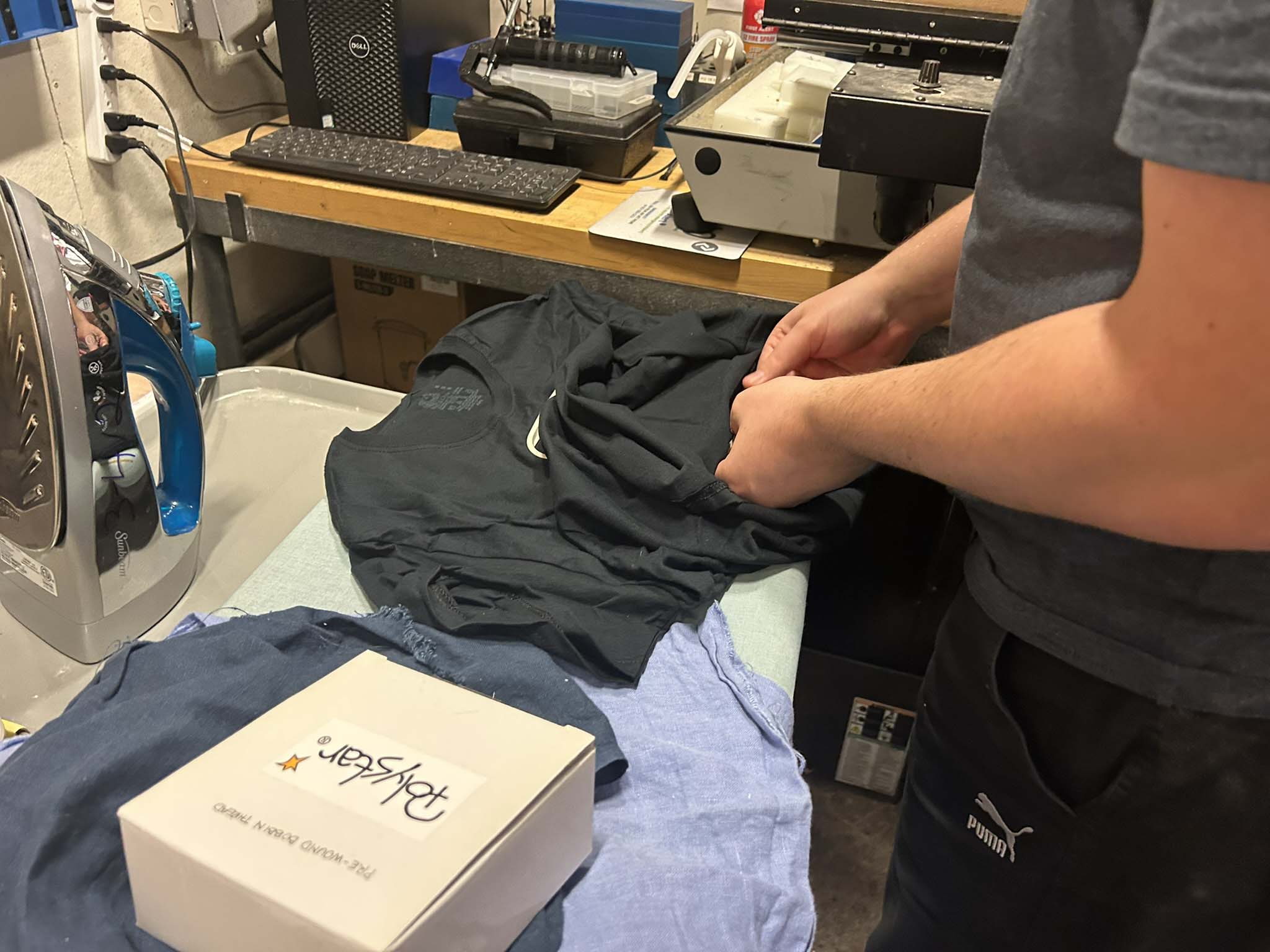

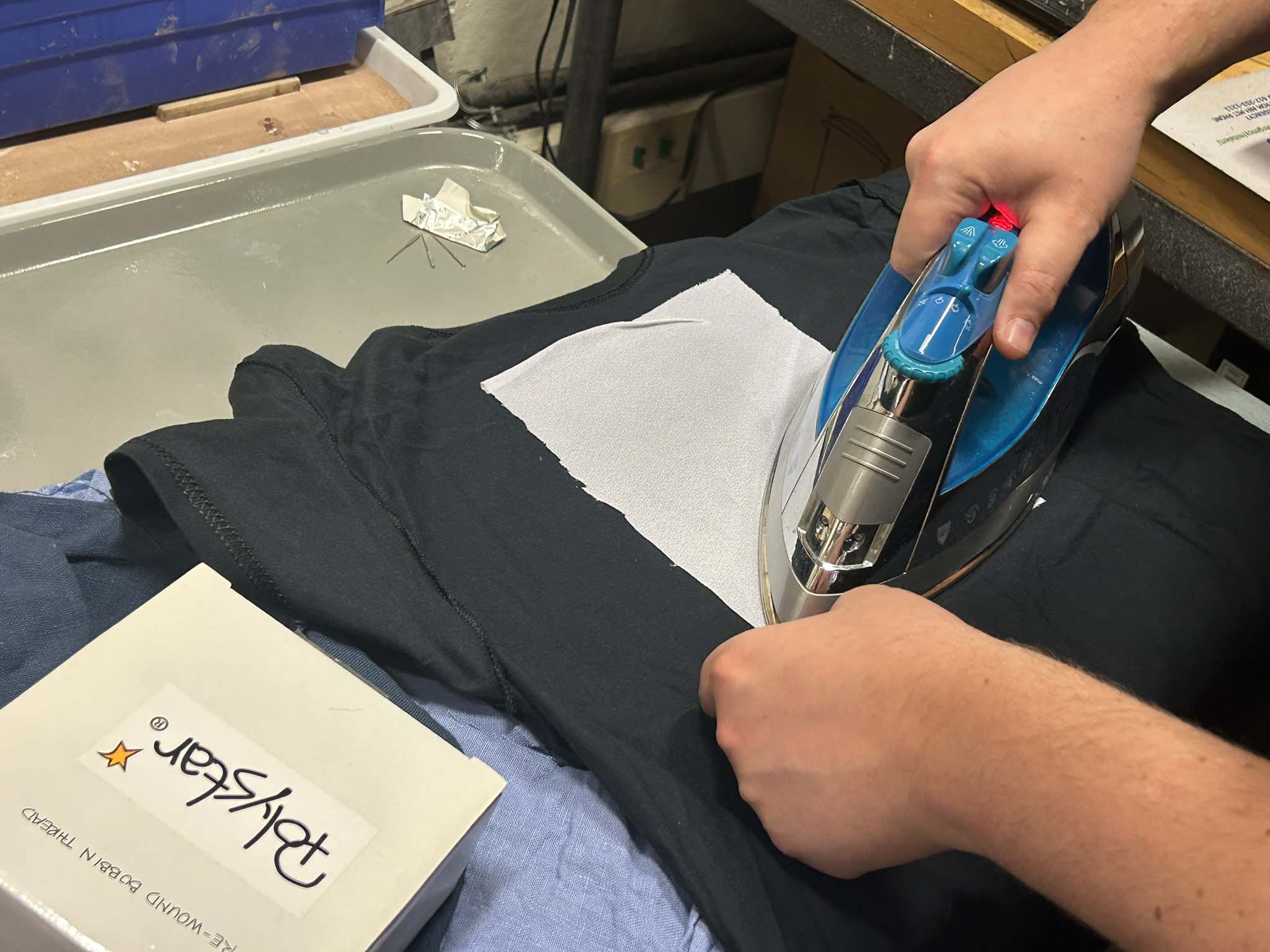

Because the base material was a t-shirt, the fabric needed additional structure. I added a stronger backing layer by ironing a fusible stabilizer onto the shirt. The rough, glue-coated side was placed against the fabric and heat was applied until it bonded securely.

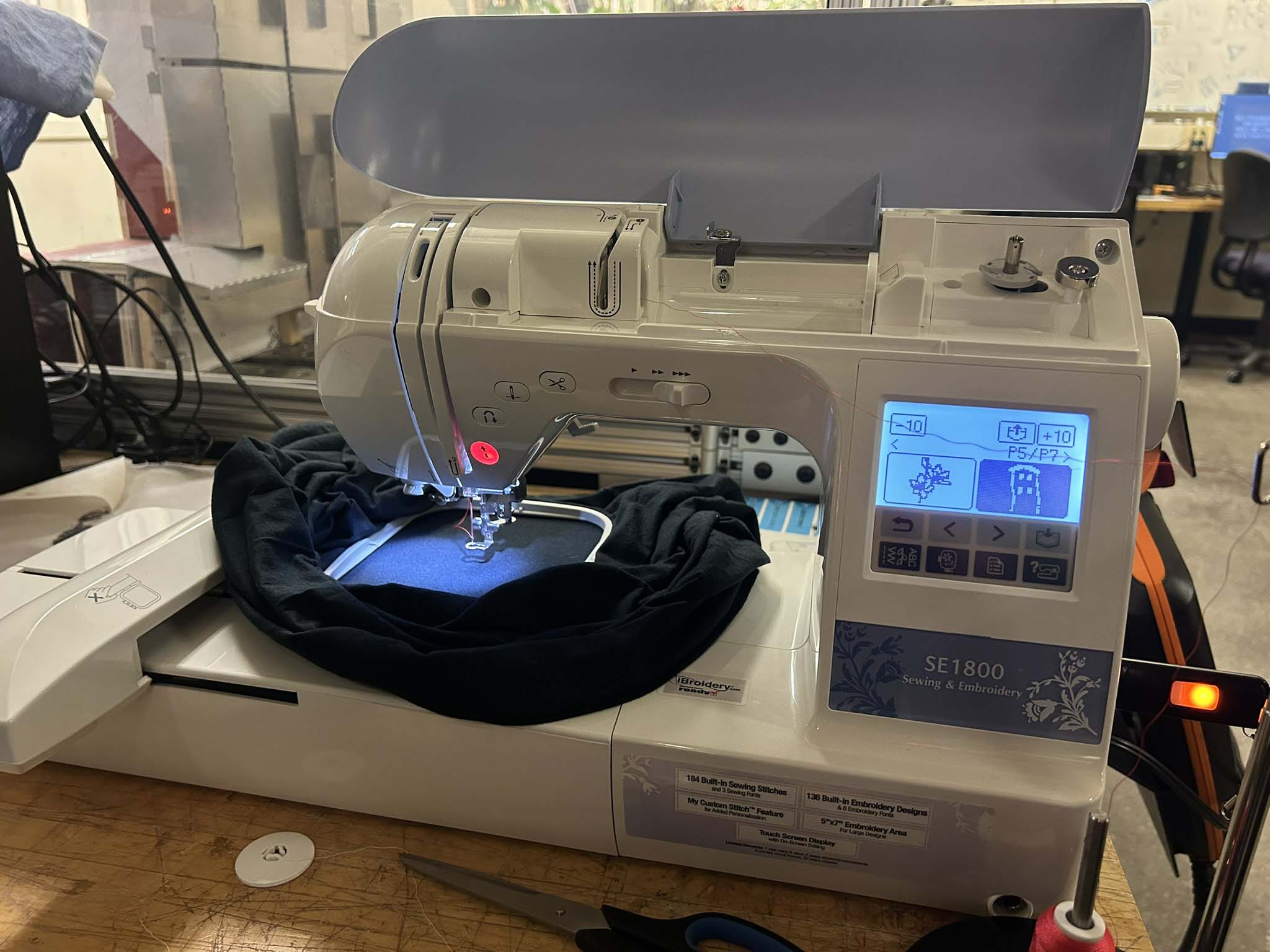

Once the fabric was prepared, it was mounted in an embroidery hoop. The orientation mattered: the flat side of the hoop needed to face upward to ensure even tension across the fabric surface.

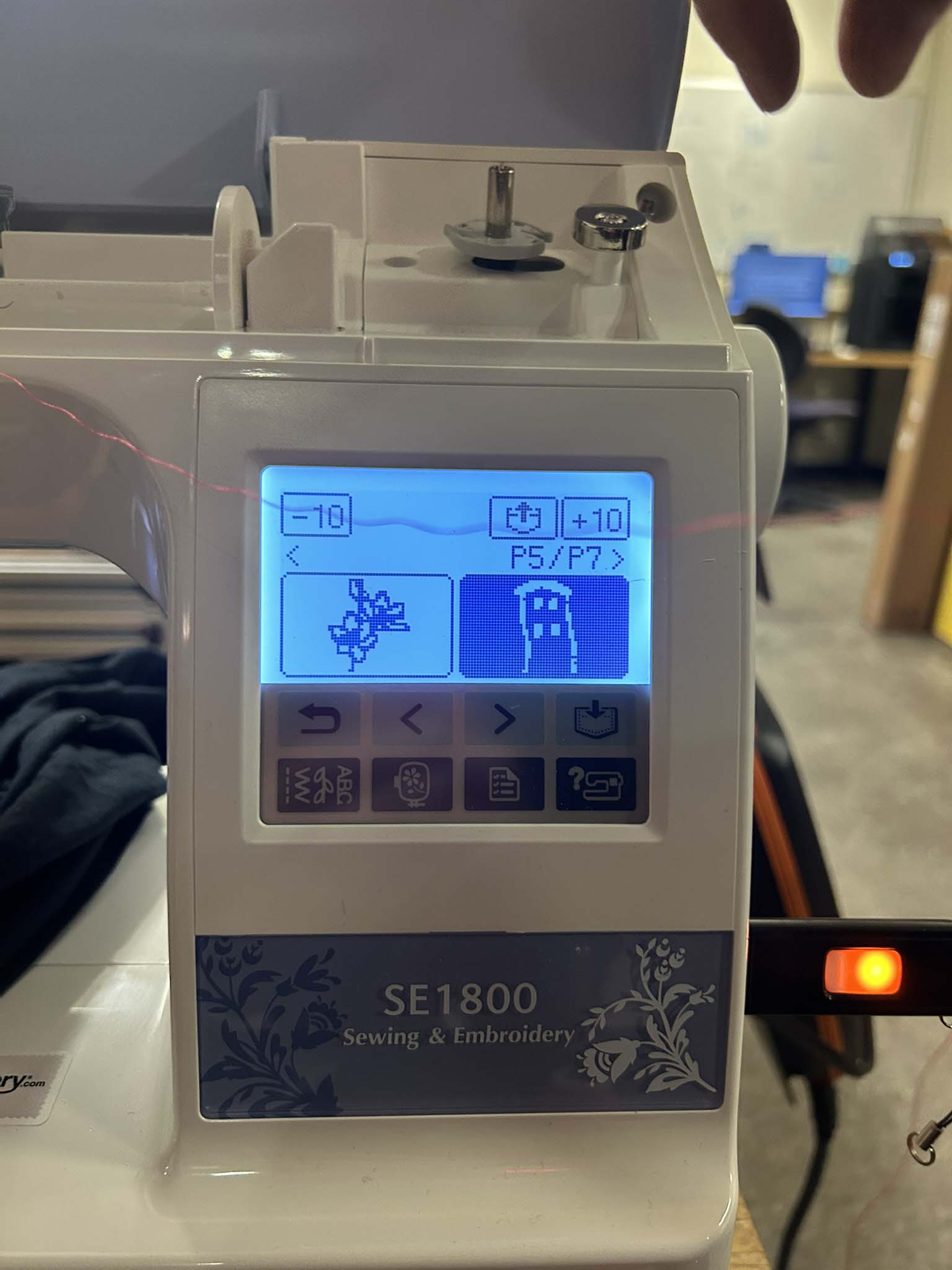

The SVG file was transferred to the sewing machine using a USB drive. After selecting the file on the machine interface, the job could be started and the needle traced the vector path directly onto the fabric.

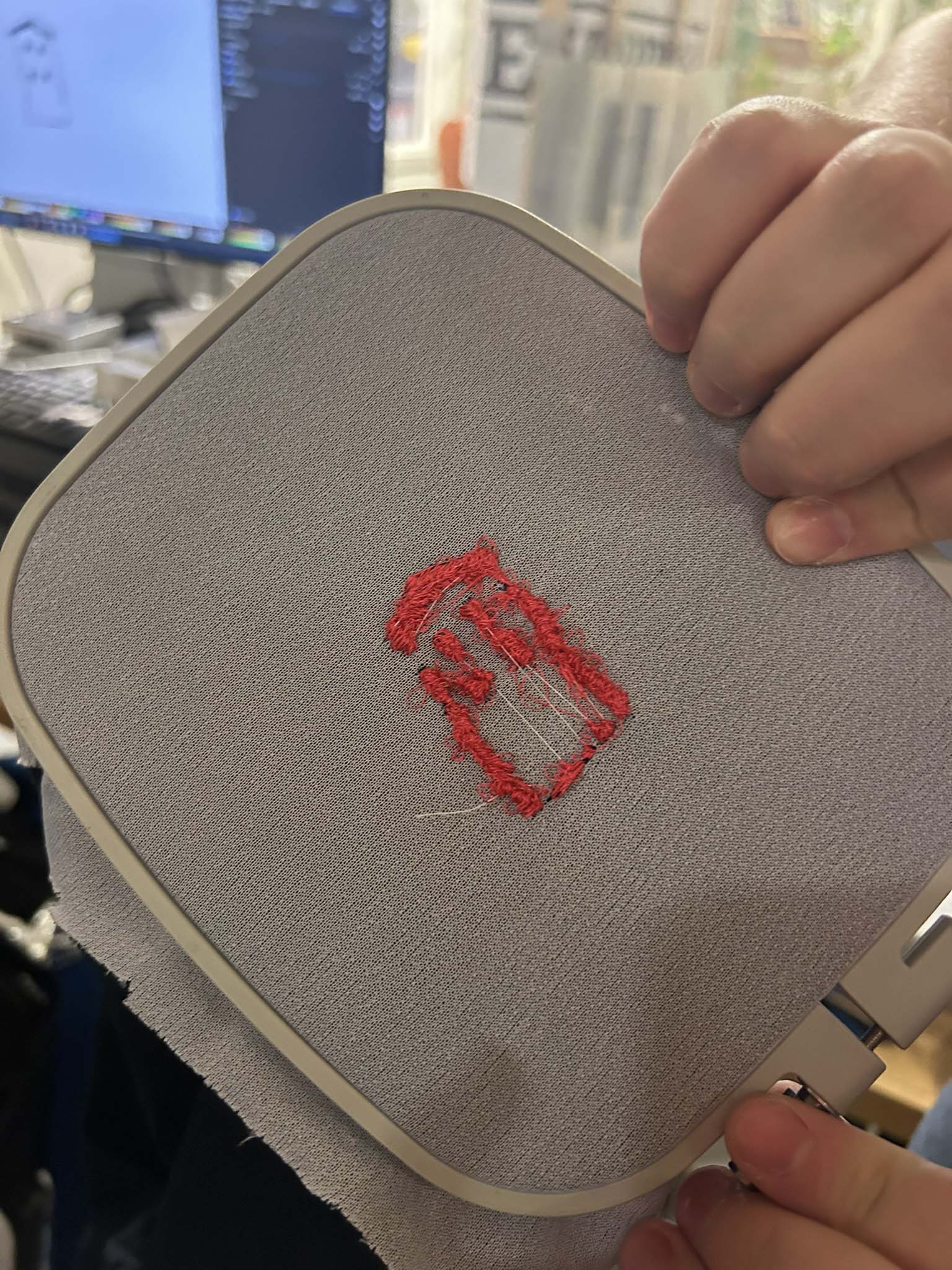

One of the main challenges was maintaining correct needle and thread tension. Small adjustments had a large effect, and the process involved a lot of trial and error. With help from Gert and Jen, the machine was tuned until the stitching became consistent.

This week emphasized how sensitive physical machines are to setup and material conditions. Even with a correct digital file, the outcome depends heavily on calibration, tension, and how the material is supported during the operation.

Images from the process and final embroidery are shown below.