I had a a lot of fun this week.

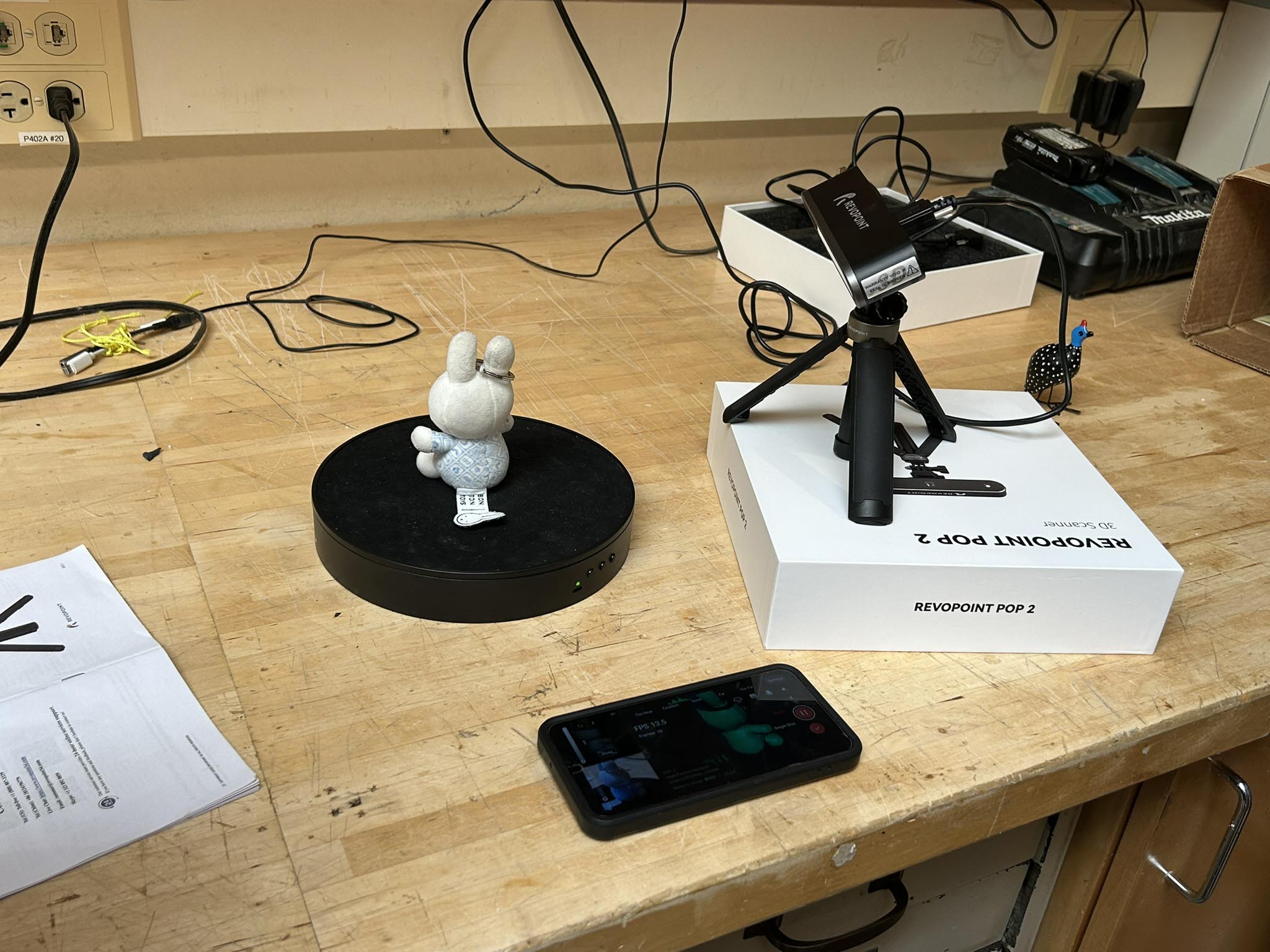

Since I also know how to 3D print, I used it as an excuse to refine my skills in PolyScan (app) and Blender (mesh, and point clouds).

I'm far from mastering the skill, but it got me excited to deep-dive into more tutorials.

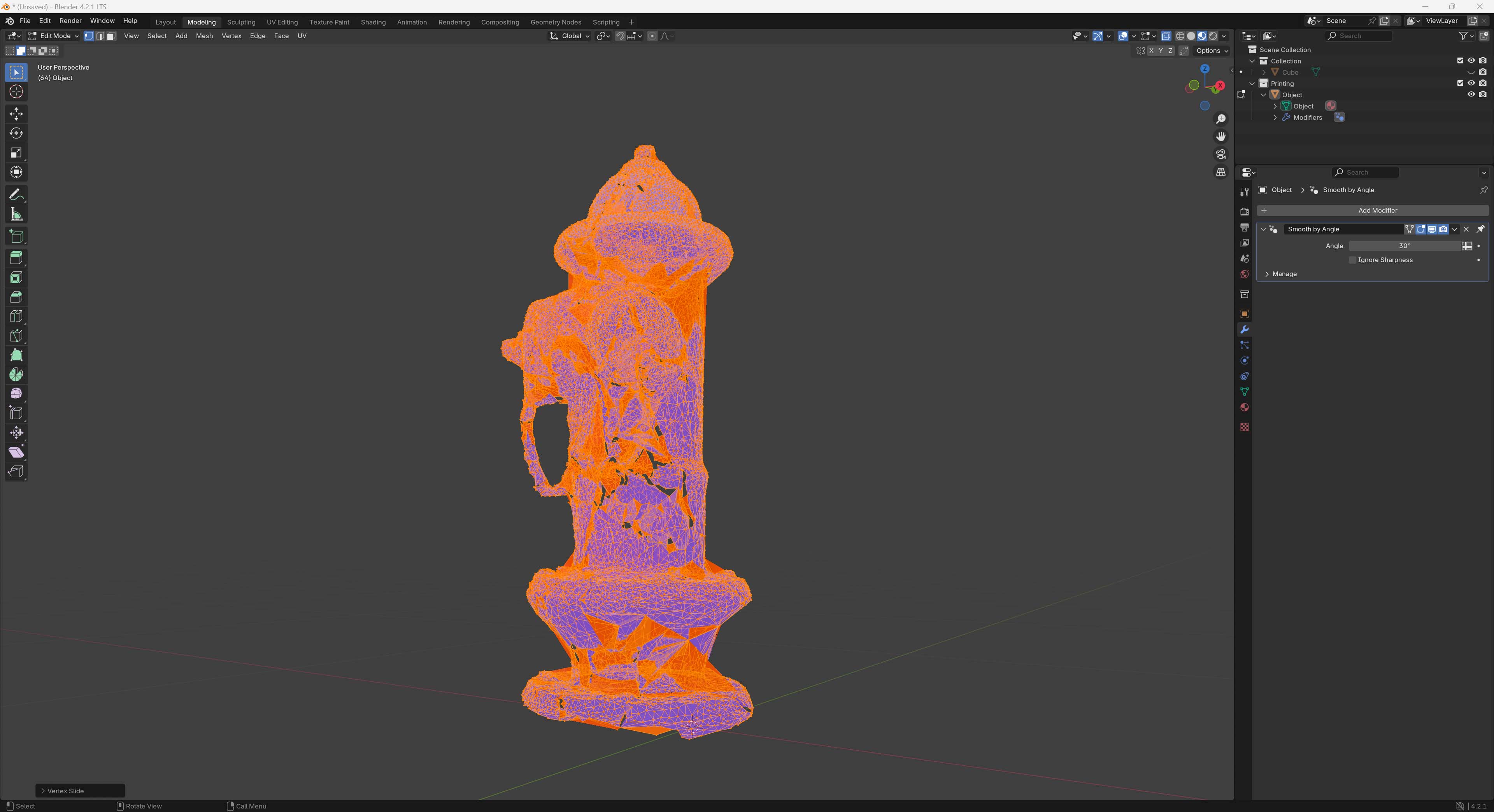

I scanned a firehydrant outside building 10, and tried to play with the mesh:

Again - fun to scan and have an object on your computer, however these scans are not conducive to immediately printing, as I originally thought.

The mesh has holes and isn't watertight -- two conditions for a successful 3D print. Anthony revealed that even the biggest companies prep a successful "scan" for weeks with perfect lighting, the perfect rotating wheel to get a high-resolution scan.

Again - fun to scan and have an object on your computer, however these scans are not conducive to immediately printing, as I originally thought.

The mesh has holes and isn't watertight -- two conditions for a successful 3D print. Anthony revealed that even the biggest companies prep a successful "scan" for weeks with perfect lighting, the perfect rotating wheel to get a high-resolution scan.

I followed this tutorial to attempt to understanding how to mesh repair, however got lost at the point of UV mapping and swore to return to the matter.

***

This might be a good time to link my entire HTMAA YouTube Public playlist.

Meme of the day:

Courtesy of Conversations with Anthony.

3D Printing

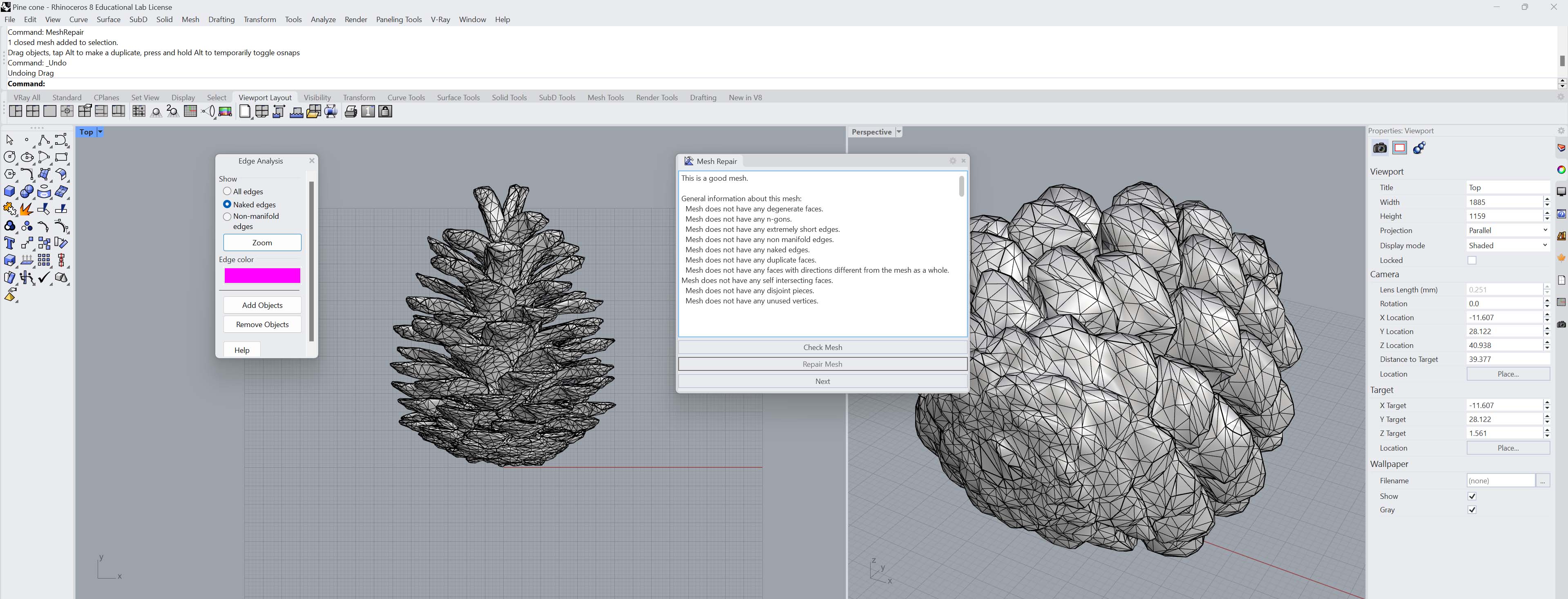

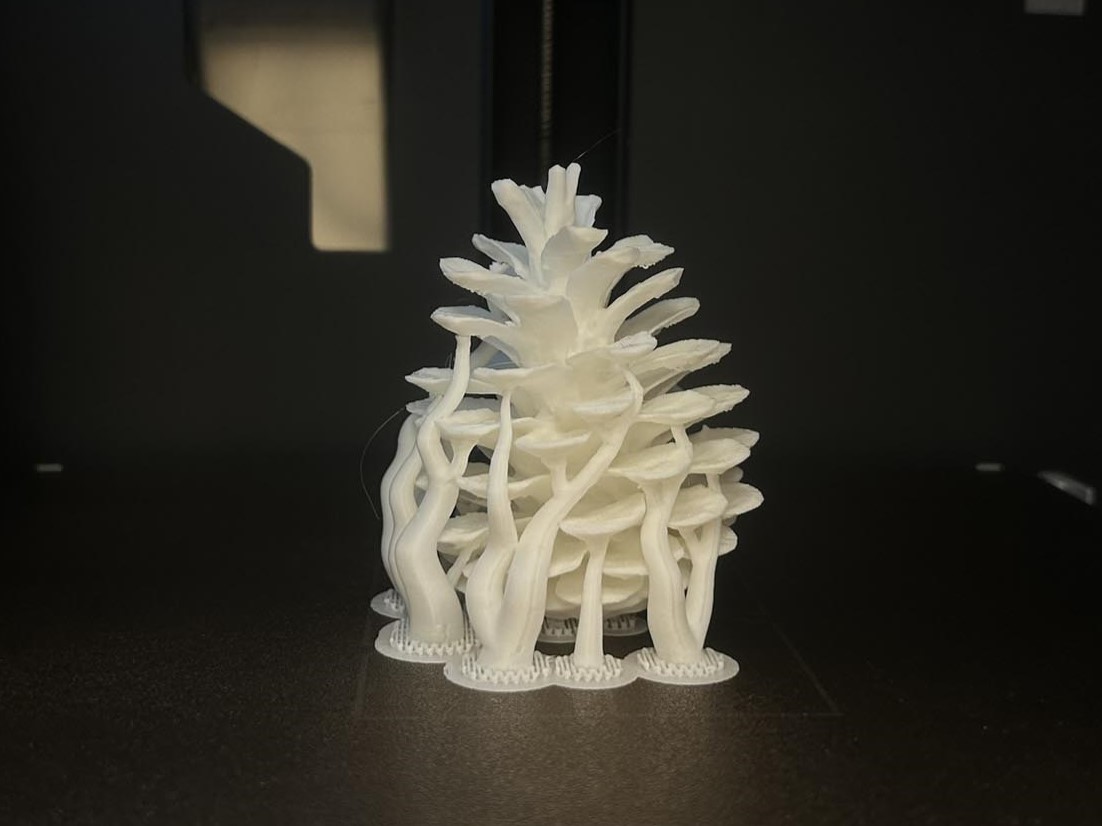

I chose to 3D print a pine cone .stl file I downloaded from 3D Warehouse. It's amazing once you realized everything is already modeled on the internet.

I wanted to print a natural object (after abandoning the idea to scan one), and check the overhang capacity on the architecture shop Bambu printers.

I was highly impressed.

For the model, I opened it in rhino and 'Scale'-ed the size for the required ~3" size.

My favorite trick and command to fix downloaded meshes is 'MeshRepair' which will do a local repair to the mesh without further programs.

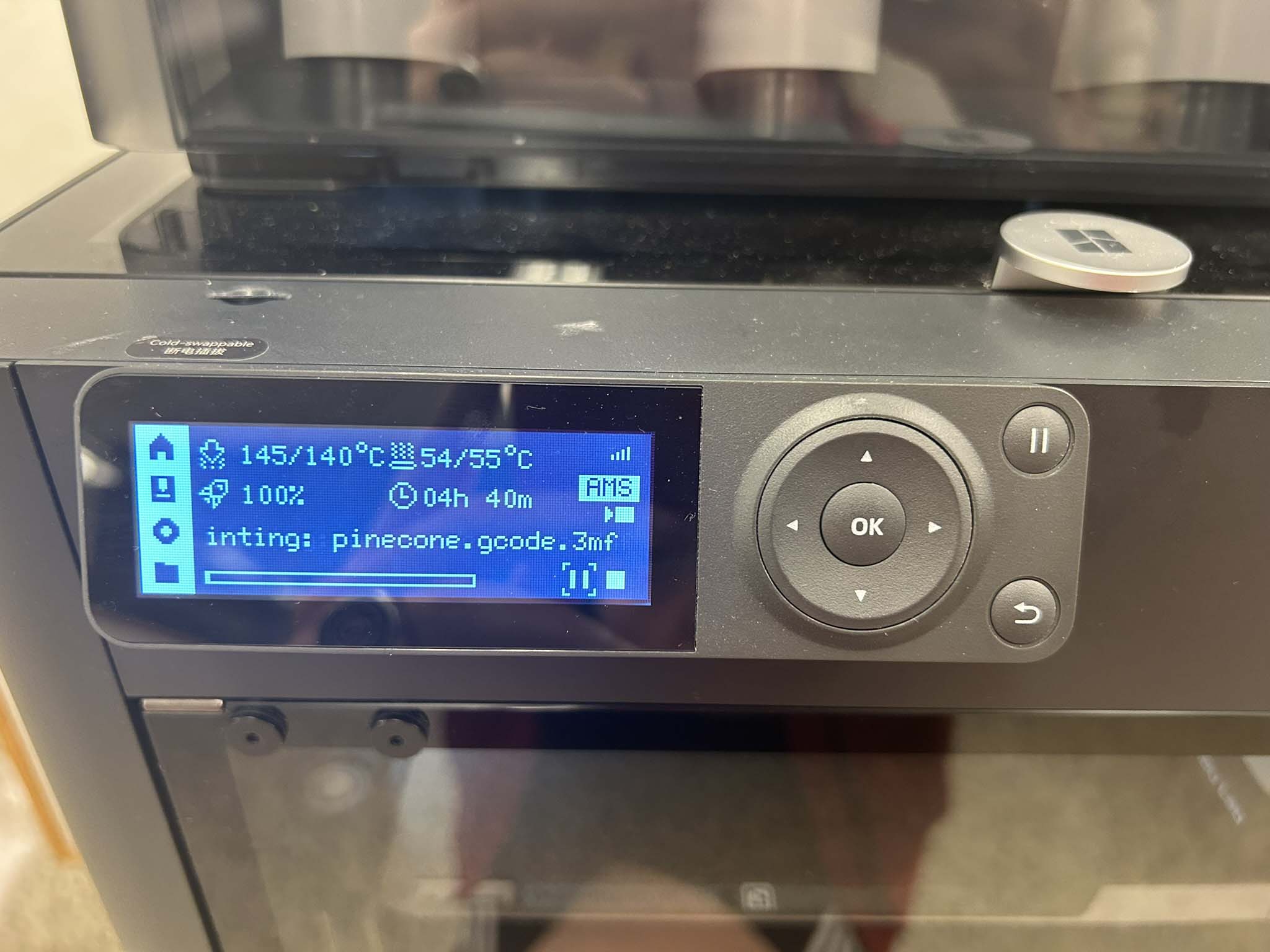

I downloaded my rhino as an .stl and opened it on the Bambu software installed in the architecture lab.

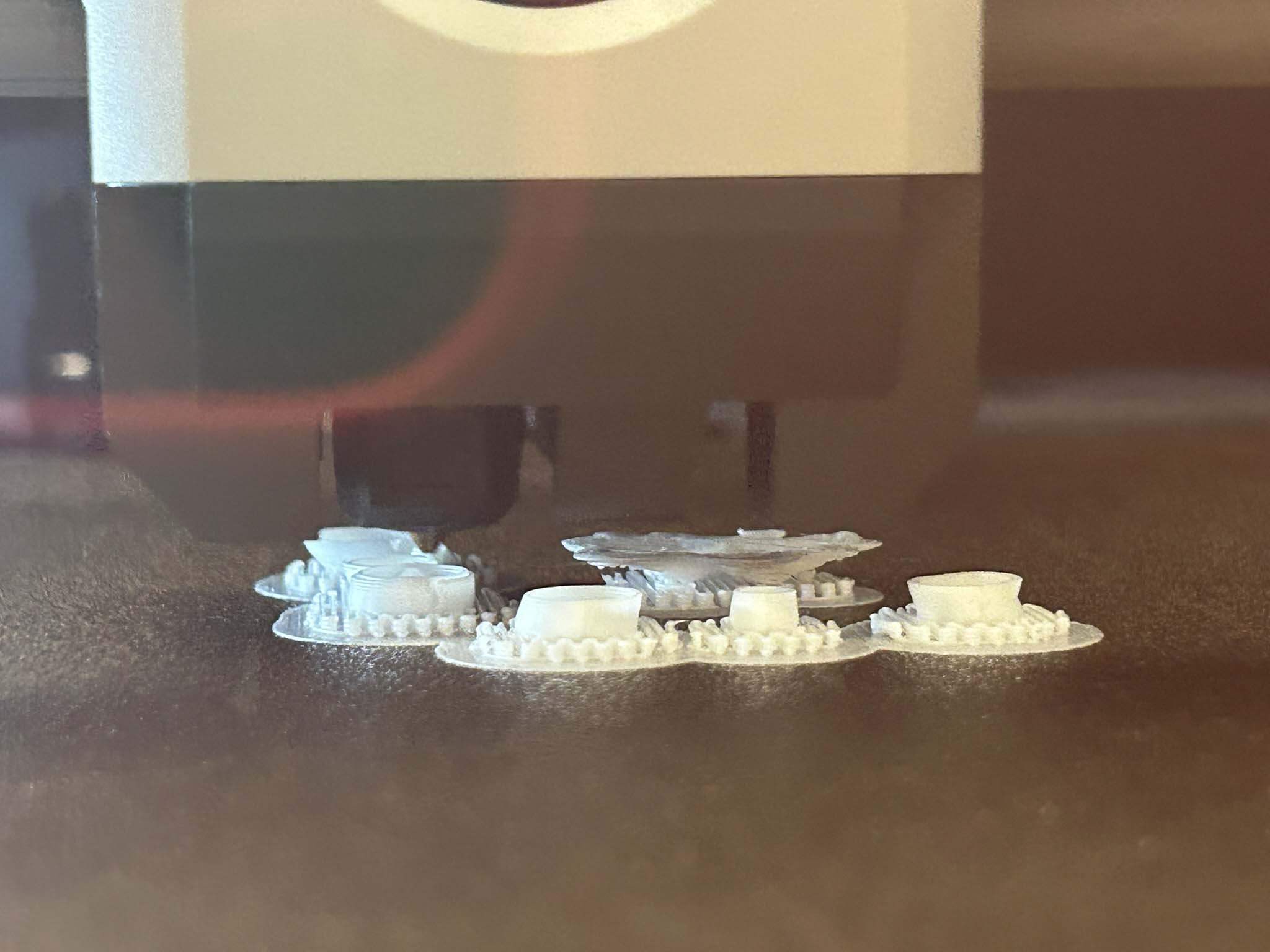

I followed these instructions for the correct settings, and sliced:

***

I love this object, as a plastic PLA representation of a 1:1 pinecone. It's eary, and secondly, I setup 3D "tree" supports to a fake "tree".

***

Assignments for this week:

Group Assignment:

1. test the design rules for your 3D printer(s)

Individual Assignment

2. Design, document, and 3D print an object

that could not be made subtractively

(small, few cm3, limited by printer time)

3. 3D scan an object (and optionally print it)