Assignment Overview

This week covers:

• Introduction to computer-controlled cutting machines

• Laser cutting principles and safety

• Vinyl cutting techniques and applications

• Vector graphics and file preparation

• Kerf compensation and material considerations

• Introduction to computer-controlled cutting machines

• Laser cutting principles and safety

• Vinyl cutting techniques and applications

• Vector graphics and file preparation

• Kerf compensation and material considerations

Learning Objectives

• Understand laser cutting machine operation and safety

• Learn vinyl cutting techniques for surface applications

• Learn vector graphics software (e.g., Inkscape, Illustrator)

• Design and cut a parametric press-fit construction kit

• Apply vinyl cutting for ceramic surface treatment and collaboration

• Document the design process and cutting parameters

• Learn vinyl cutting techniques for surface applications

• Learn vector graphics software (e.g., Inkscape, Illustrator)

• Design and cut a parametric press-fit construction kit

• Apply vinyl cutting for ceramic surface treatment and collaboration

• Document the design process and cutting parameters

Work Completed

Laser Cutting Introduction

• Attended laser cutting safety training• Reviewed machine operation procedures

• Explored available materials and thicknesses

Design Process

• Created parametric design in vector software• Calculated kerf compensation for material

• Prepared files for laser cutting

Fabrication

• Cut test pieces to verify fit• Fabricated final press-fit construction kit

• Documented cutting parameters and results

Detailed Documentation

Project Overview

This week's assignment focused on computer-controlled cutting, specifically laser cutting and vinyl cutting techniques. The main project built on top of the Week 1 assignment and converted the 3D model into a 2D vector format suitable for laser cutting, creating a press-fit construction kit. Additionally, a collaborative vinyl cutting project was undertaken to create touch-sensitive ceramic sake cups through a partnership with Sam Chin.Design Files

• geniji-mon.dxf - 2D vector cutting pattern for laser cuttingDXF format with kerf compensation for press-fit construction kit

Design Process:

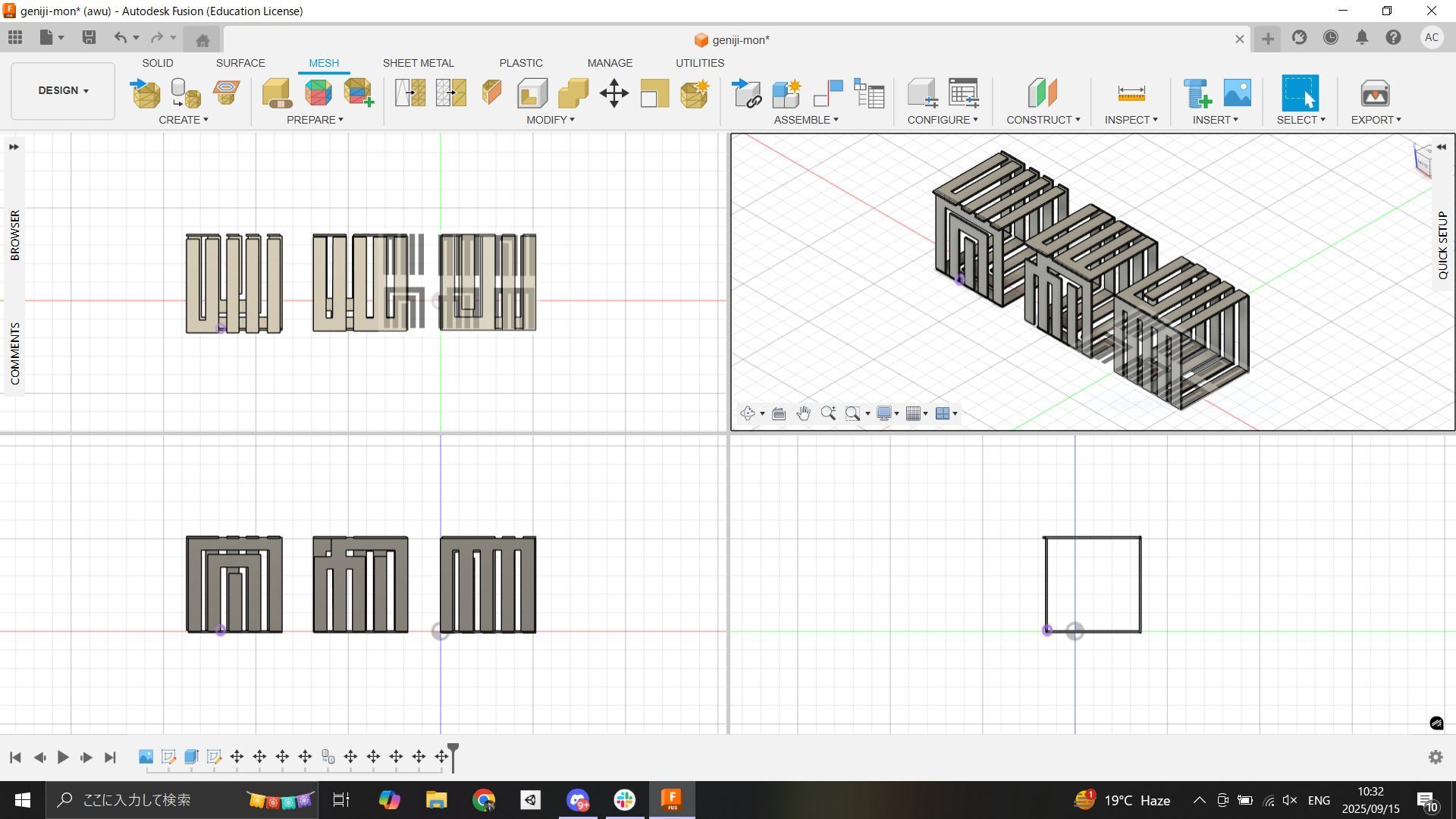

1. 3D to 2D Conversion: Extracted 2D profiles from the Week 1 3D model

2. Vector Creation: Redrew the design in vector graphics software

3. Kerf Calculation: Determined appropriate kerf compensation for material thickness

4. Joint Design: Created press-fit joints for assembly

5. Optimization: Arranged parts for efficient material usage

Technical Specifications:2. Vector Creation: Redrew the design in vector graphics software

3. Kerf Calculation: Determined appropriate kerf compensation for material thickness

4. Joint Design: Created press-fit joints for assembly

5. Optimization: Arranged parts for efficient material usage

• Kerf Compensation: 0.1mm (varies by material and laser settings)

• Material Thickness: 3mm (cardboard)

• Cutting Parameters: Optimized for laser cutting speed and power (88% power, 190 mm/s Speed)

• Material Thickness: 3mm (cardboard)

• Cutting Parameters: Optimized for laser cutting speed and power (88% power, 190 mm/s Speed)

Images

Fusion360 sketching process documentation

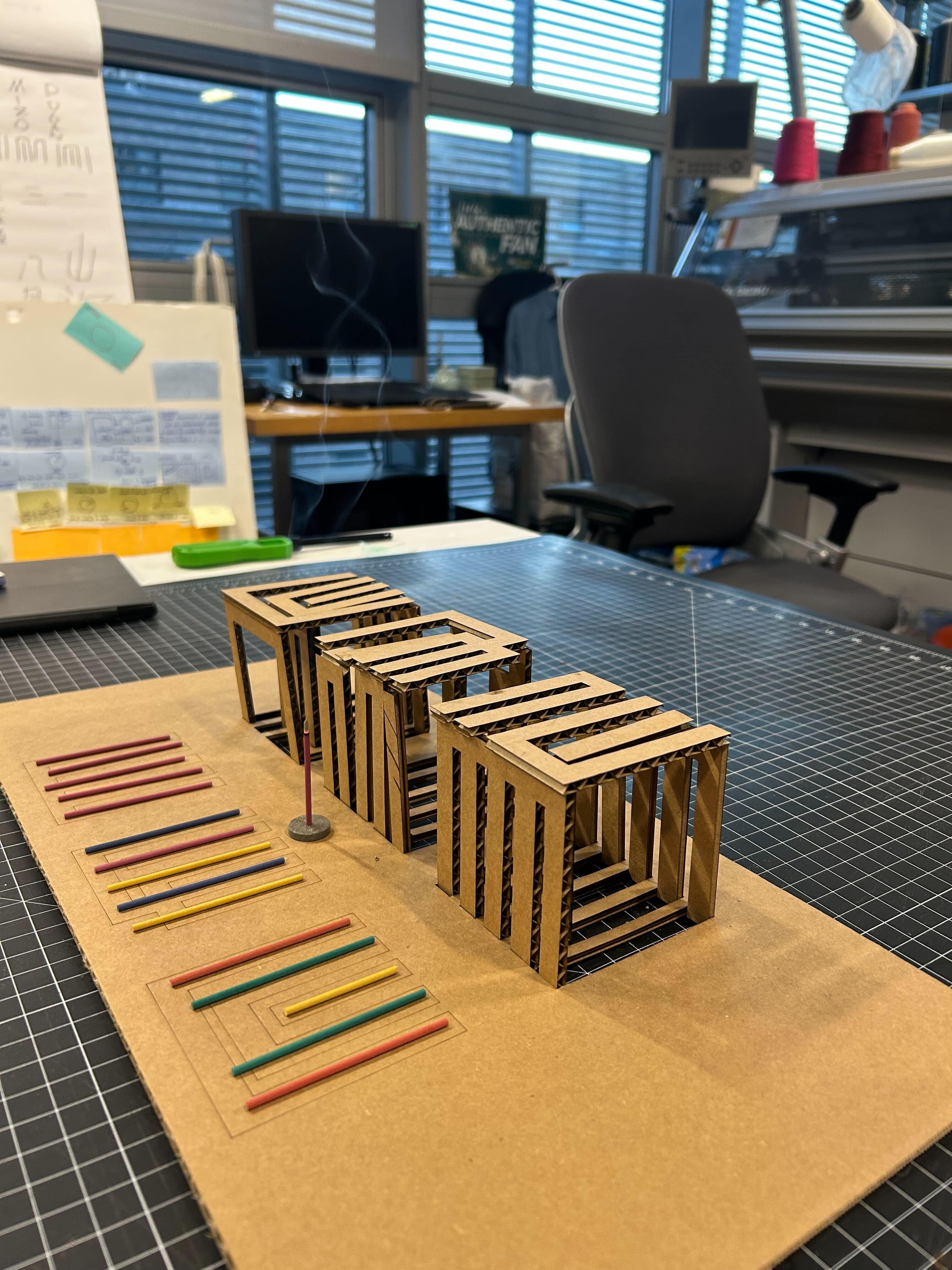

Fusion360 3D mockupn

Final assembled model with incense

1. Removed the parts from the laser cutter

2. Tested press-fit joints for proper fit

3. Assembled the construction kit

4. Lit an incense to test the final design

2. Tested press-fit joints for proper fit

3. Assembled the construction kit

4. Lit an incense to test the final design

Learning Outcomes

Laser Cutting Skills:

• Machine Operation: Learned to safely operate laser cutting equipment

• Parameter Tuning: Understood relationship between power, speed, and material

• Kerf Compensation: Applied material-specific compensation values

• File Preparation: Mastered DXF file creation and optimization

Design Skills:• Parameter Tuning: Understood relationship between power, speed, and material

• Kerf Compensation: Applied material-specific compensation values

• File Preparation: Mastered DXF file creation and optimization

• 2D Vector Design: Converted 3D designs to 2D cutting patterns

• Press-Fit Design: Created functional joints without fasteners

Challenges and Solutions:• Press-Fit Design: Created functional joints without fasteners

1. Challenge: Achieving proper kerf compensation

Solution: Test cuts with different compensation values

2. Challenge: Converting complex 3D geometry to 2D

Solution: Extracted key profiles and simplified design

3. Challenge: Ensuring press-fit joint functionality

Solution: Iterative testing and adjustment of joint dimensions

Solution: Test cuts with different compensation values

2. Challenge: Converting complex 3D geometry to 2D

Solution: Extracted key profiles and simplified design

3. Challenge: Ensuring press-fit joint functionality

Solution: Iterative testing and adjustment of joint dimensions

Vinyl Cut Exploration: Touch-Sensitive Ceramic Sake Cups

Collaboration with Sam Chin

This project involved creating touch-sensitive ceramic sake cups through a collaborative process combining vinyl cutting, sandblasting, and metallic glazing techniques.

Project Goals:

• Create sake cups that respond to touch through metallic glaze application

• Explore surface treatment techniques using vinyl as a resist material

• Develop collaborative fabrication processes between different disciplines

Technical Process:• Explore surface treatment techniques using vinyl as a resist material

• Develop collaborative fabrication processes between different disciplines

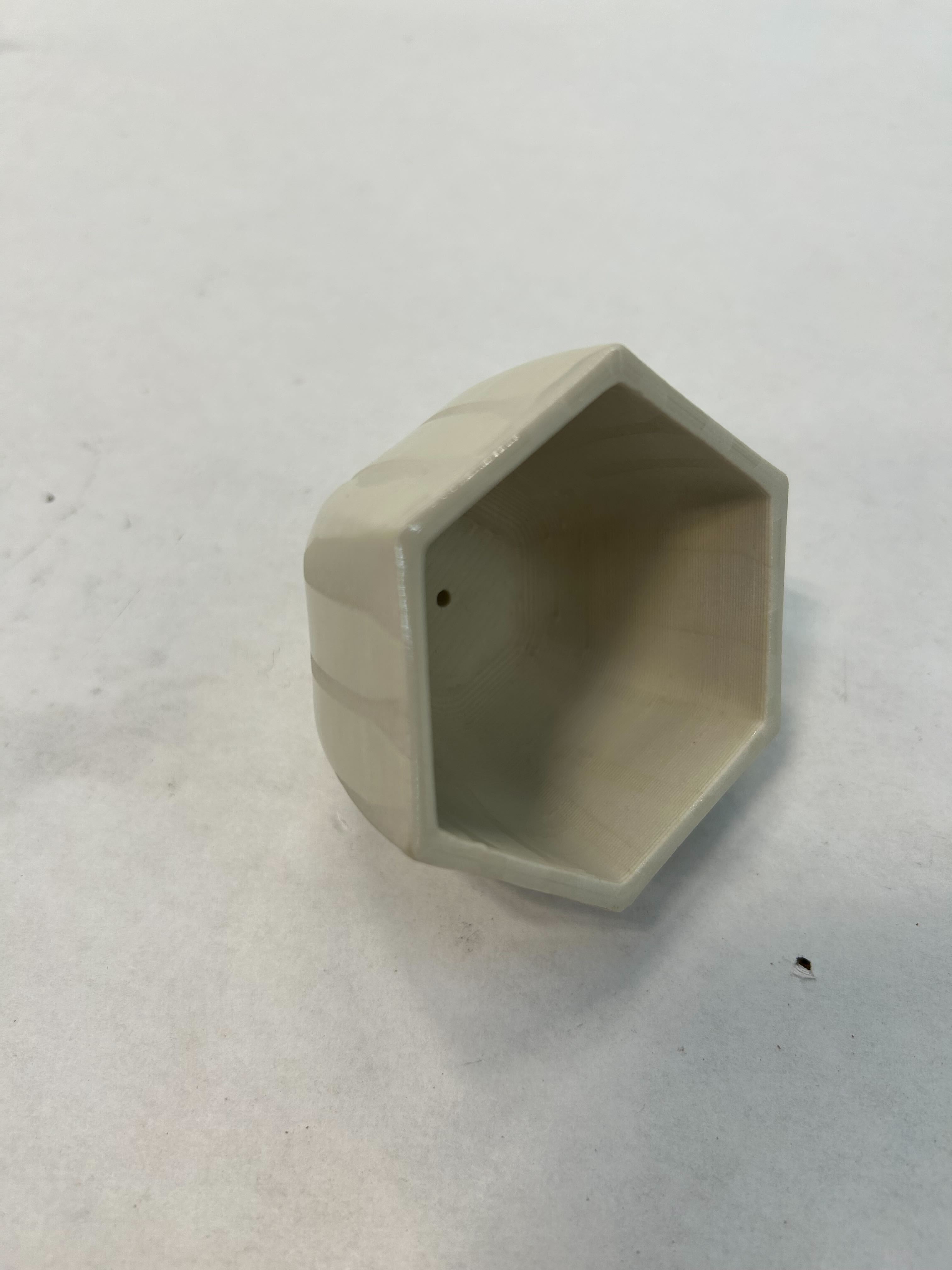

1. Design Phase: Created vinyl cutting patterns for both interior and exterior surfaces of ceramic sake cups

2. Vinyl Application: Applied cut vinyl pieces to ceramic surfaces as resist material

3. Sandblasting: Used sandblasting to texture the exposed ceramic areas

4. Collaboration: Partnered with Sam Chin to apply metallic glaze to create touch-sensitive properties

Materials and Tools:2. Vinyl Application: Applied cut vinyl pieces to ceramic surfaces as resist material

3. Sandblasting: Used sandblasting to texture the exposed ceramic areas

4. Collaboration: Partnered with Sam Chin to apply metallic glaze to create touch-sensitive properties

• Ceramic Substrate: Hand-thrown sake cups

• Vinyl Material: Cutting vinyl for resist application

• Surface Treatment: Sandblasting equipment

• Finishing: Metallic glaze (applied by Sam Chin)

Design Considerations:• Vinyl Material: Cutting vinyl for resist application

• Surface Treatment: Sandblasting equipment

• Finishing: Metallic glaze (applied by Sam Chin)

• Pattern Placement: Strategic positioning of vinyl patterns on both interior and exterior surfaces

• Resist Function: Vinyl served as protective mask during sandblasting process

• Surface Texture: Sandblasted areas created texture contrast with protected areas

• Touch Sensitivity: Metallic glaze application created interactive surface properties

Collaborative Process:• Resist Function: Vinyl served as protective mask during sandblasting process

• Surface Texture: Sandblasted areas created texture contrast with protected areas

• Touch Sensitivity: Metallic glaze application created interactive surface properties

The project demonstrated interdisciplinary collaboration, with the vinyl cutting and sandblasting preparation done by the student, and the final metallic glaze application completed by collaborator Sam Chin. This process highlighted the importance of understanding material properties and surface treatments in creating functional ceramic objects.

Vinyl cut pattern applied to exterior of ceramic sake cup

Vinyl cut pattern applied to interior of ceramic sake cup

Ceramic sake cup after sandblasting treatment with vinyl resist removed

Software and Tools Used

• Laser Cutting Software: xTool control software

• Vinyl Cutting Software: Vinyl cutting machine software

• CAD Software: Fusion360

• Surface Treatment: Sandblasting equipment

• Vinyl Cutting Software: Vinyl cutting machine software

• CAD Software: Fusion360

• Surface Treatment: Sandblasting equipment

Reflection

This week introduced me to computer-controlled cutting and the importance of precision in digital fabrication. Learning about kerf compensation and parametric design was crucial for creating accurate press-fit joints. The vinyl cutting project provided valuable experience in surface treatment techniques and interdisciplinary collaboration, demonstrating how digital fabrication tools can be applied to traditional craft materials like ceramics.

Links