Project Overview

This week I worked with input devices, focusing on laser-induced graphene (LIG) sensors as an advanced input device for my final project: a "digital nose" capable of sensing and differentiating incense aromas. The LIG sensor array functions as a next-generation AI electronic nose, converting scent molecules into electrical signals that can be read and processed by microcontrollers. This assignment demonstrates how advanced sensing technologies can be fabricated using laser processing techniques and integrated into interactive sensing systems, building on the Genji-Mon incense holder design from previous weeks.

The Input Device: Laser-Induced Graphene (LIG) Sensor

Laser-induced graphene (LIG) is a porous graphene structure created by laser irradiation of polyimide (Kapton) sheets. The LIG sensor functions as an analog input device that detects volatile organic compounds (VOCs) including aromatic compounds found in incense smoke. The sensor operates by changing its electrical resistance when exposed to target gas molecules, producing an analog voltage signal that can be read by a microcontroller's ADC (Analog-to-Digital Converter). The porous structure of LIG provides a high surface area that enhances sensitivity to gas molecules, making it an ideal material for creating sensor arrays capable of identifying different scent types by their unique chemical signatures.

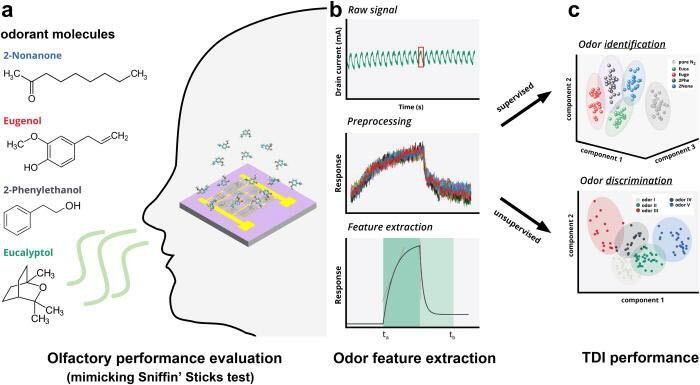

The LIG sensor technology is inspired by research from Korea's Daegu Gyeongbuk Institute of Science and Technology (DGIST), which developed a porous laser-induced graphene sensor array that functions as a "next-generation AI electronic nose." This technology enables the system to distinguish scents like the human olfactory system does and analyze them using artificial intelligence.

Biological Inspiration: Combinatorial Coding

The LIG sensor array is inspired by the biological mechanism known as combinatorial coding, in which a single odorant molecule activates multiple olfactory receptors to create a unique pattern of neural signals. By mimicking this principle, the LIG sensors respond to scent molecules by generating distinct combinations of electrical signals. The AI system learns these complex signal patterns to accurately recognize and classify a wide variety of scents, resulting in a high-performance artificial olfaction platform that surpasses existing technologies.

Input Device Integration

The LIG sensor array can be integrated with microcontrollers to read and process the analog sensor signals. Each sensor in the array produces a unique electrical response when exposed to different volatile compounds, creating a pattern of signals that can be analyzed by AI algorithms. The sensor's analog output connects to microcontroller ADC pins, allowing real-time reading of gas concentrations and pattern recognition. Data from the sensor array can be transmitted via USB for logging, analysis, and visualization, enabling the creation of a complete input-to-output system for smell detection and classification.

The multi-sensor array approach allows each sensor to respond differently to the same scent molecule, creating a unique "fingerprint" pattern that enables accurate scent identification even among similar aromas.

Fabrication Process

The LIG sensor fabrication process builds upon laser-induced graphene research and documentation by Wedyan Babatain from the HTMAA 2022 class. Her comprehensive work on LIG fabrication using CO2 lasers at MIT CBA provides the foundational methodology for creating the porous graphene sensor arrays used in this project.

The fabrication process involves:

1. Material Preparation: Starting with polyimide (Kapton) sheets as the substrate material

2. Laser Processing: Using a CO2 laser to irradiate the polyimide surface, converting it into porous graphene structures

3. Pattern Design: Creating sensor patterns optimized for gas sensing applications

4. Electrical Characterization: Testing the resistance and electrical properties of the created graphene structures

5. Sensor Array Formation: Arranging multiple LIG sensors into an array for pattern recognition

The single-step laser fabrication method eliminates the need for complex manufacturing equipment and enables high-efficiency production of integrated sensor arrays. The laser parameters (power, speed, focus) are critical for creating the optimal porous graphene structure that provides both conductivity and high surface area for gas sensing.

LIG Sensor Development

I developed LIG sensors by testing different laser parameters and patterns to create functional gas sensing structures. The initial tests involved creating simple resistive patterns to verify that the laser process was successfully converting polyimide into conductive graphene. Subsequent tests focused on optimizing the sensor geometry and laser parameters to enhance sensitivity to volatile organic compounds.

The sensor patterns were designed to create resistive elements that change resistance when exposed to different gas molecules. By testing multiple patterns and measuring their electrical responses, I was able to develop sensors suitable for integration into an array for scent detection and classification.

Input Device Testing and Validation

The LIG sensors were tested for their electrical response characteristics, measuring resistance changes when exposed to different aromatic sources. Each sensor in the array produces a unique response pattern, allowing the system to distinguish between different types of volatile compounds. The sensor responses showed distinct patterns for different sources, demonstrating that the input device array could successfully differentiate between different types of scents.

The multi-sensor array approach creates a combinatorial response pattern - similar to biological olfaction - where each scent produces a unique combination of signals across the sensor array. This enables accurate classification even when dealing with similar aromas, such as different incense varieties or floral perfumes with similar notes.

Images

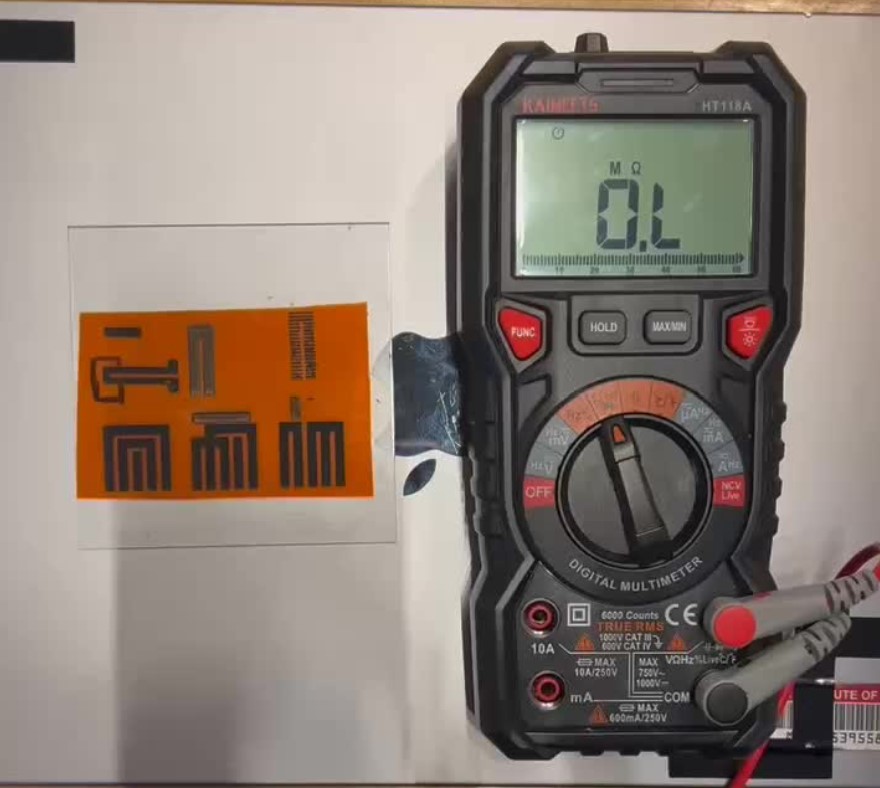

LIG Sensor Pattern Development

Initial sketch and design for LIG sensor pattern showing the basic geometry for resistive gas sensing elements

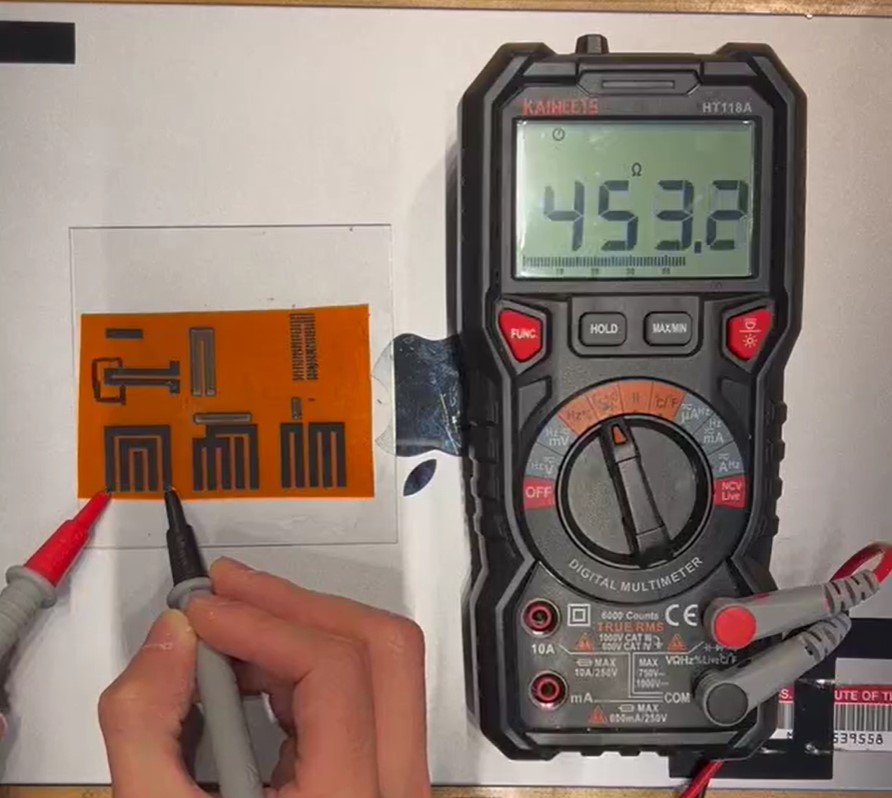

LIG Fabrication Process

Laser-induced graphene sensor pattern test showing the porous graphene structure created by CO2 laser processing. This pattern forms the foundation of the sensor array that will detect scent molecules through electrical resistance changes.

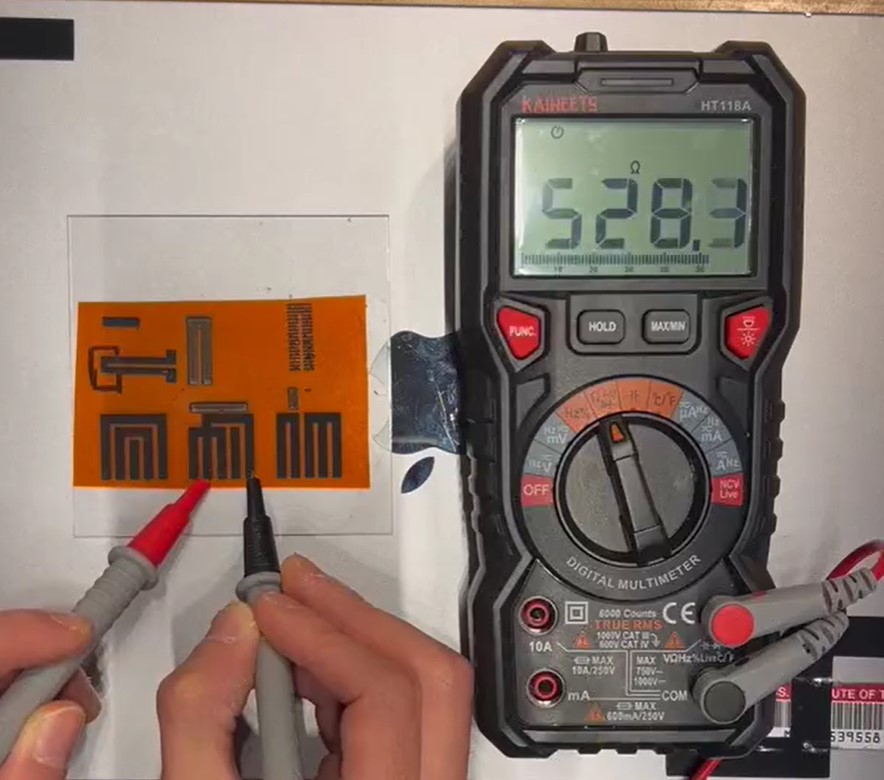

LIG Sensor Electrical Characterization

LIG sensor resistor testing demonstrating the electrical response characteristics of the graphene sensor. The sensor's resistance changes when exposed to different gas molecules, creating unique signal patterns for scent identification.

Additional LIG sensor testing showing multiple resistive patterns and their electrical characteristics. Each sensor in the array produces a unique response pattern when exposed to scent molecules, enabling accurate classification through combinatorial coding.

Reference: Exfoliated Graphene Structure

Exfoliated graphene structure used in machine-learning-enabled electronic nose systems. Image from: Machine-learning-enabled graphene-based electronic nose for microplastic detection

Reflection

This week focused on working with advanced input devices, specifically laser-induced graphene (LIG) sensors as an analog input technology for my digital nose project. The assignment demonstrated how cutting-edge sensing technologies can be fabricated using laser processing techniques and how their analog signals can be read and processed for pattern recognition.

Working with LIG sensors introduced me to an entirely different approach to gas sensing compared to traditional semiconductor sensors like the MQ-3. The laser fabrication process creates porous graphene structures that provide both electrical conductivity and high surface area for gas interaction. This unique combination makes LIG sensors highly sensitive and suitable for creating multi-sensor arrays that can distinguish between similar aromas.

The most significant learning was understanding how the combinatorial coding approach - inspired by biological olfaction - enables accurate scent classification. By creating an array where each sensor responds differently to the same scent molecule, the system generates unique "fingerprints" that can distinguish even similar aromas. This is fundamentally different from single-sensor approaches, which struggle with distinguishing subtle differences.

The laser fabrication process requires careful parameter tuning - power, speed, and focus all affect the resulting graphene structure. Too much power can burn through the material, while too little power may not fully convert the polyimide. Finding the optimal parameters for creating functional sensors was a process of iteration and careful measurement.

This week's work emphasized the importance of understanding both the physical properties of sensing materials and the signal processing approaches needed to extract meaningful information from sensor arrays. The LIG sensors demonstrate how advanced materials science and AI can combine to create input devices that approach biological sensing capabilities. The ability to fabricate custom sensor arrays and process their signals for pattern recognition opens up new possibilities for creating interactive systems that can "sense" and respond to their environment in sophisticated ways.

The LIG sensor array is now ready to become the foundation for the digital nose system, which will be integrated with the Genji-Mon incense holder from earlier weeks. This creates a system that bridges traditional Japanese aesthetics with cutting-edge sensing technology - a device that can actually "smell" and distinguish different incense varieties through advanced input device integration.

Note: This assignment documentation website was created with assistance from Cursor AI.

Note: This assignment documentation website was created with assistance from Cursor AI.

Attachments

Links

Back to Awu's Page

Final Project: 3D Incense Diffuser with Genji Mon Pattern

Course Homepage

Fab Academy Input Devices Reference

Wedyan Babatain's LIG Fabrication Documentation (HTMAA 2022)

Machine-learning-enabled graphene-based electronic nose research

Week 1: Genji-Mon 3D Incense Holder Design

Week 2: Genji-Mon Vinyl Cut Incense Heater

Week 6: Electronics Production - Making my own PCB

Final Project: 3D Incense Diffuser with Genji Mon Pattern

Course Homepage

Fab Academy Input Devices Reference

Wedyan Babatain's LIG Fabrication Documentation (HTMAA 2022)

Machine-learning-enabled graphene-based electronic nose research

Week 1: Genji-Mon 3D Incense Holder Design

Week 2: Genji-Mon Vinyl Cut Incense Heater

Week 6: Electronics Production - Making my own PCB