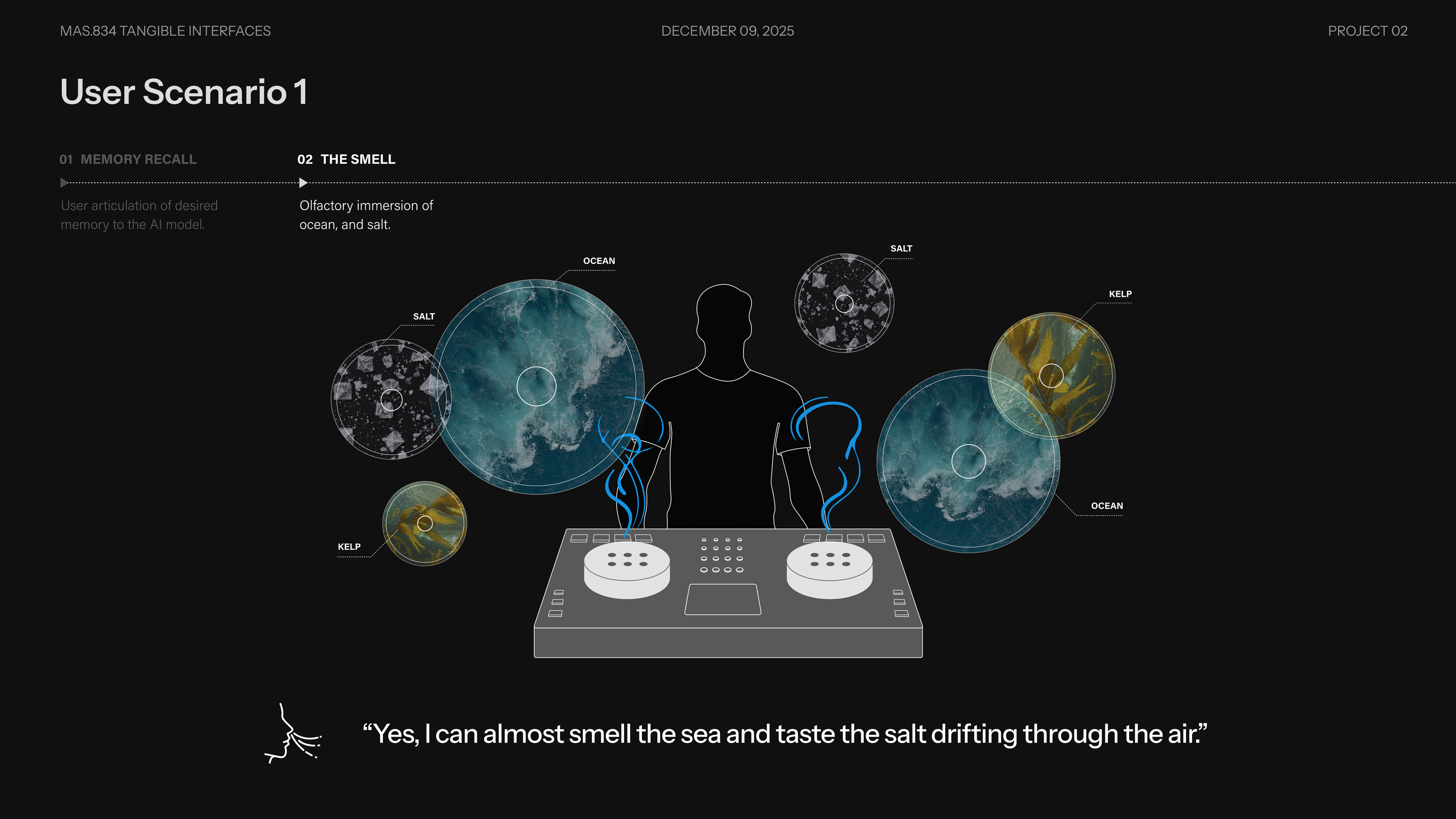

The scent DJ device featuring the laser-engraved rotational tracking PCB integrated with the modular scent rack system

Scent DJ mixer sketch (by Yichen Wang)

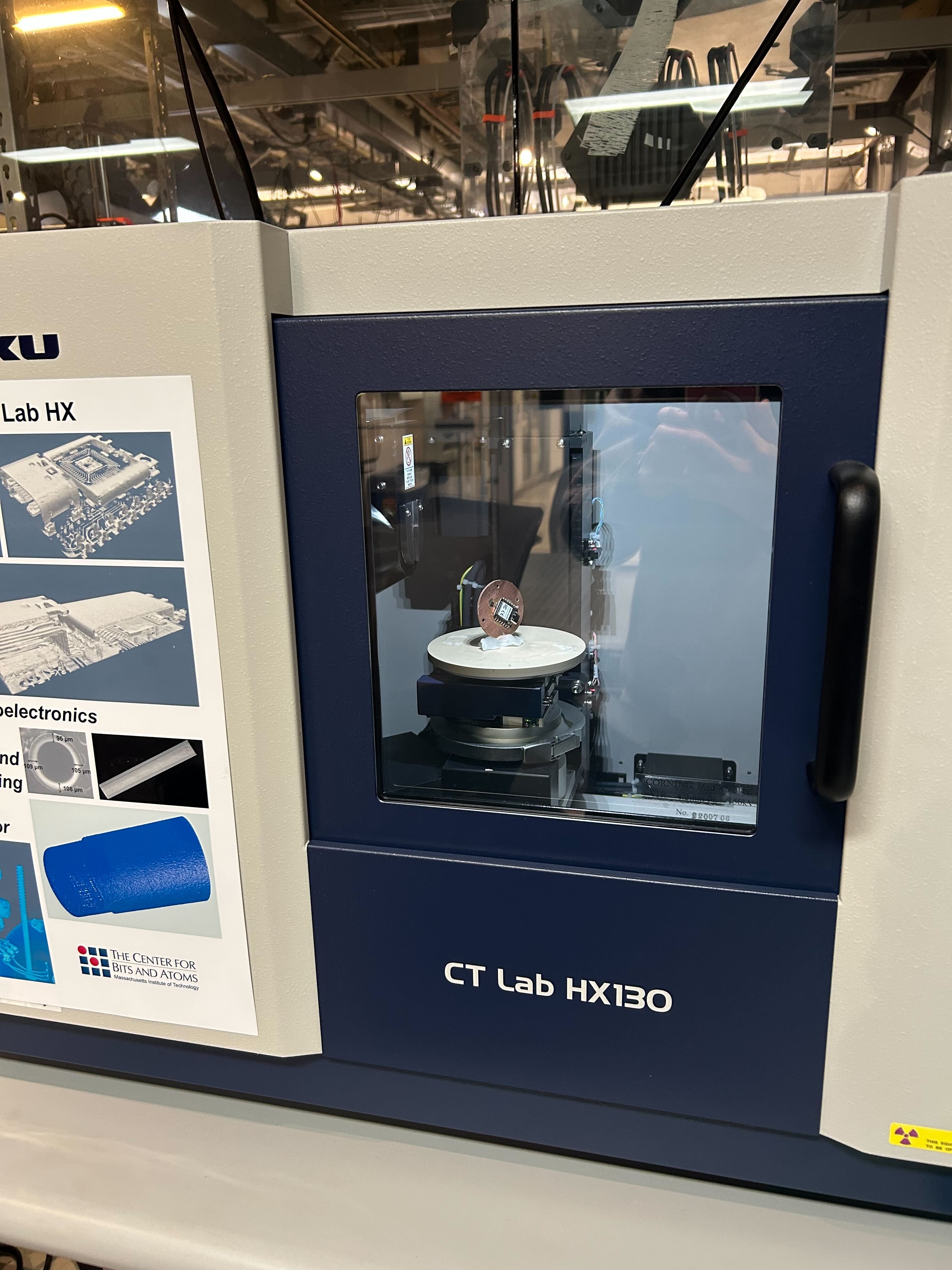

This week I worked on laser engraving a PCB designed by Quentin to track rotational movement for my scent DJ device. The PCB detects rotation and activates different scents within a modular rack, creating a DJ-like interface for controlling multiple scent emitters.

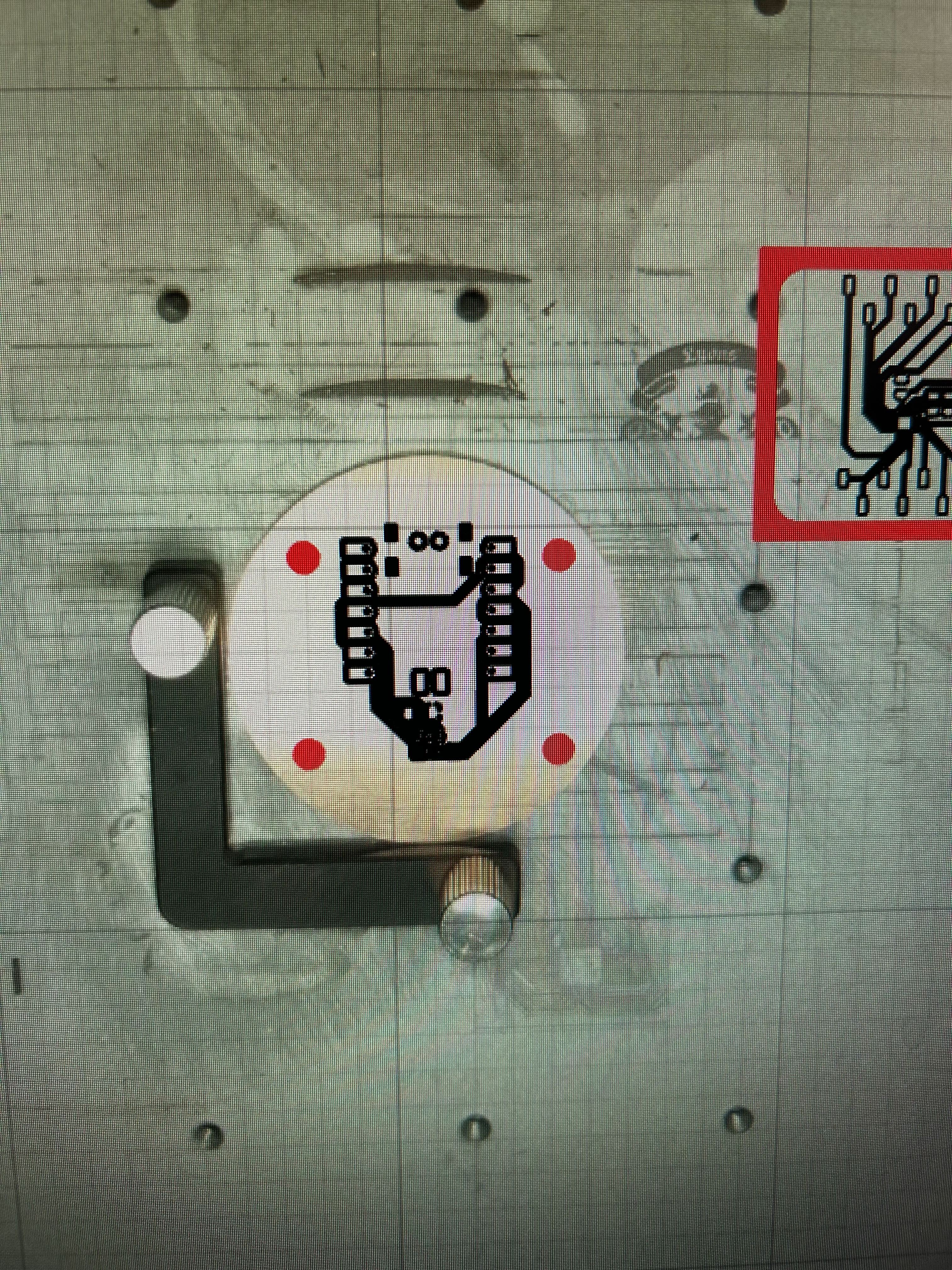

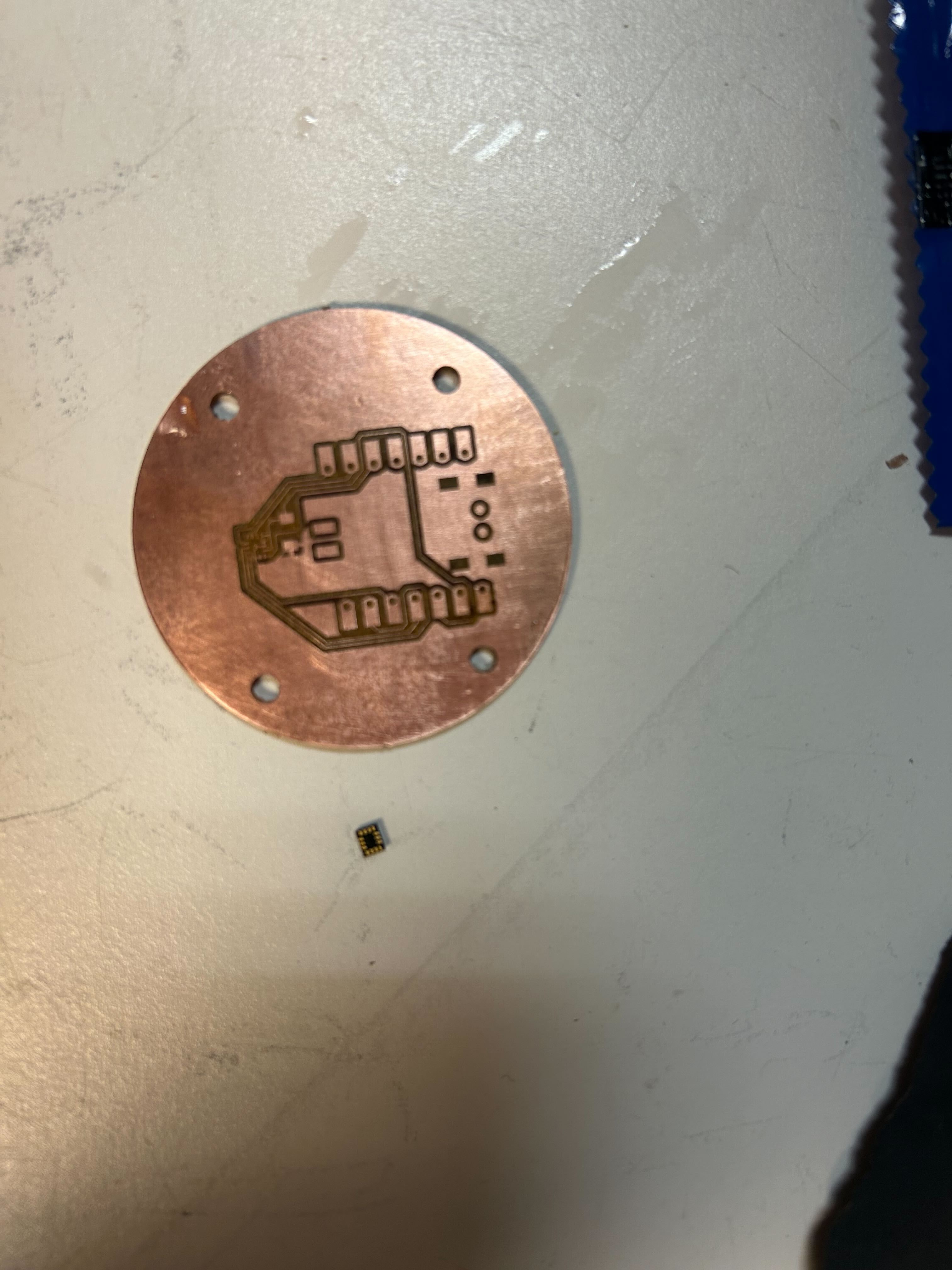

Due to the space constraints of the DJ device, we needed a very small PCB to fit within the compact form factor. The IMU sensor itself is already very small, requiring a compact PCB design. This is why we chose laser engraving as the fabrication technique—it allows for precise, fine-pitch traces on a small board that would be challenging to achieve with other methods like milling. The laser engraving process uses a focused laser beam to selectively remove copper from a copper-clad board, creating precise circuit traces. For this rotational tracking PCB, precision was essential for accurate sensor performance and to accommodate the small form factor required by the device.

Laser engraving process in action, creating the rotational tracking PCB

PCB after wash along with tiny IMU sensor

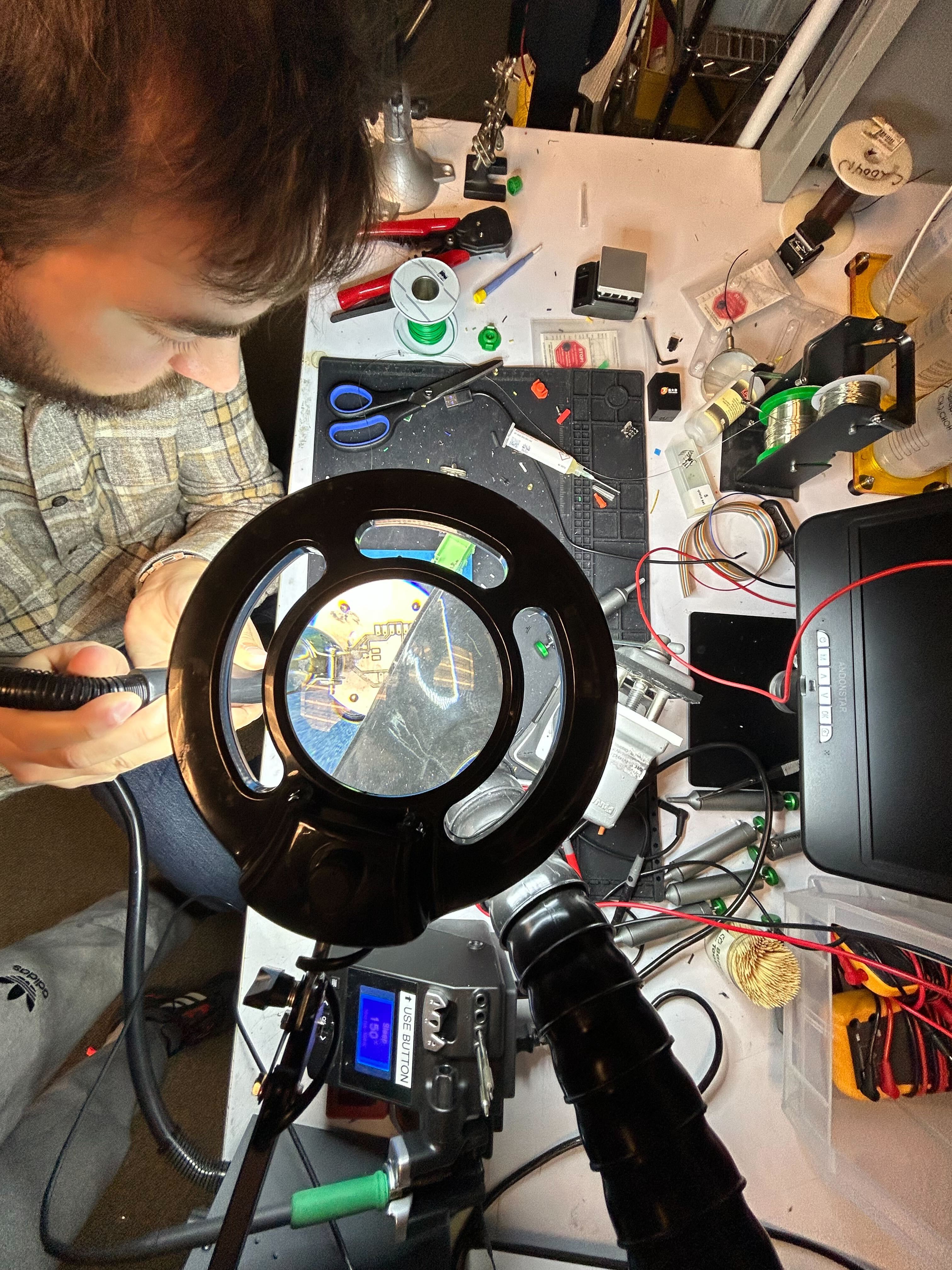

Quentin's support in soldering components onto the laser-engraved PCB

Testing the laser-engraved PCB and identifying issues that required troubleshooting

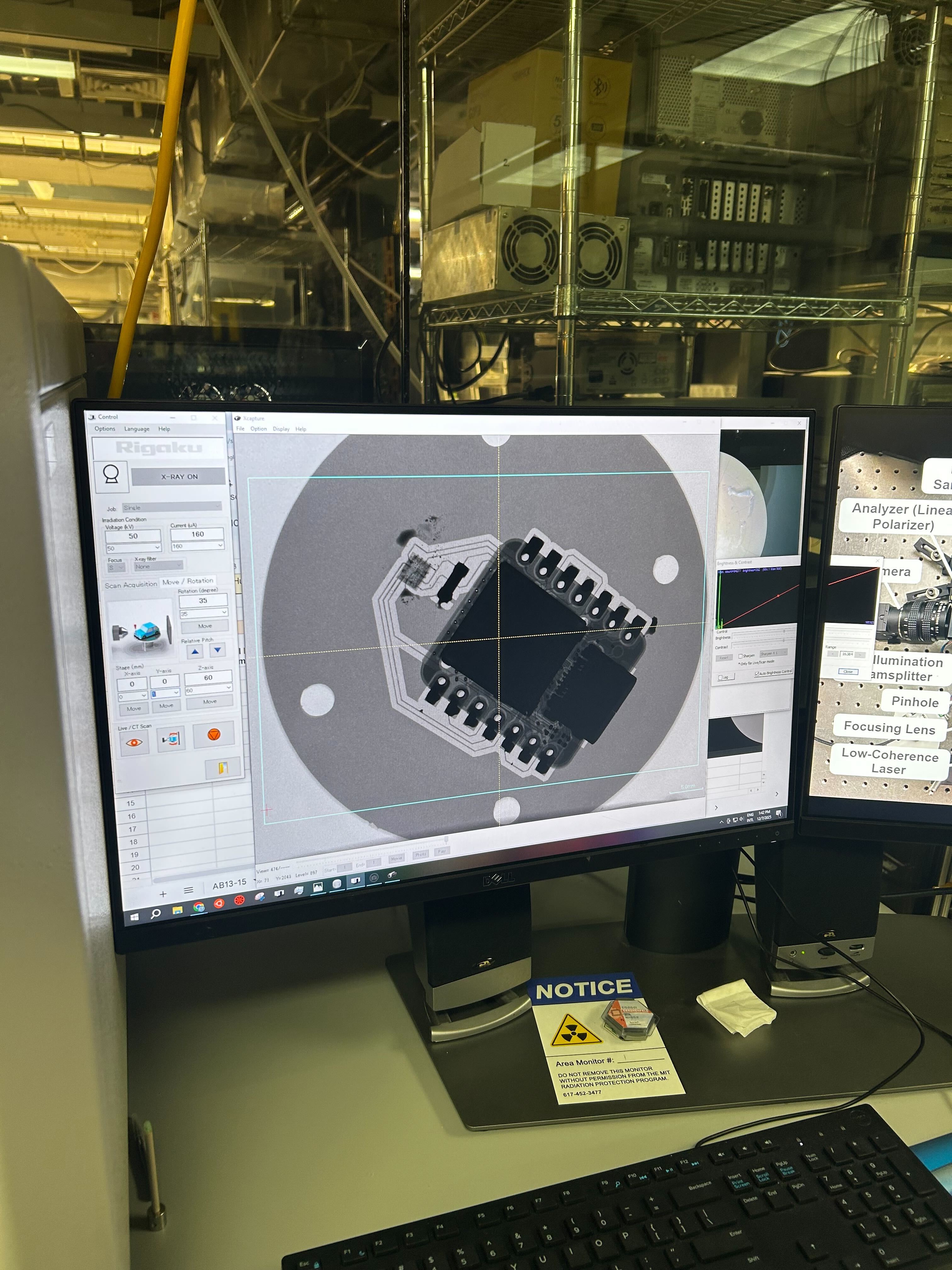

CT scanning provided unique insights into the internal structure of the laser-engraved PCB, helping identify issues and verify the quality of the rotational tracking traces.

Using CT scanning to debug the laser-engraved PCB, examining internal structure

Additional CT scan views providing insights into laser engraving quality

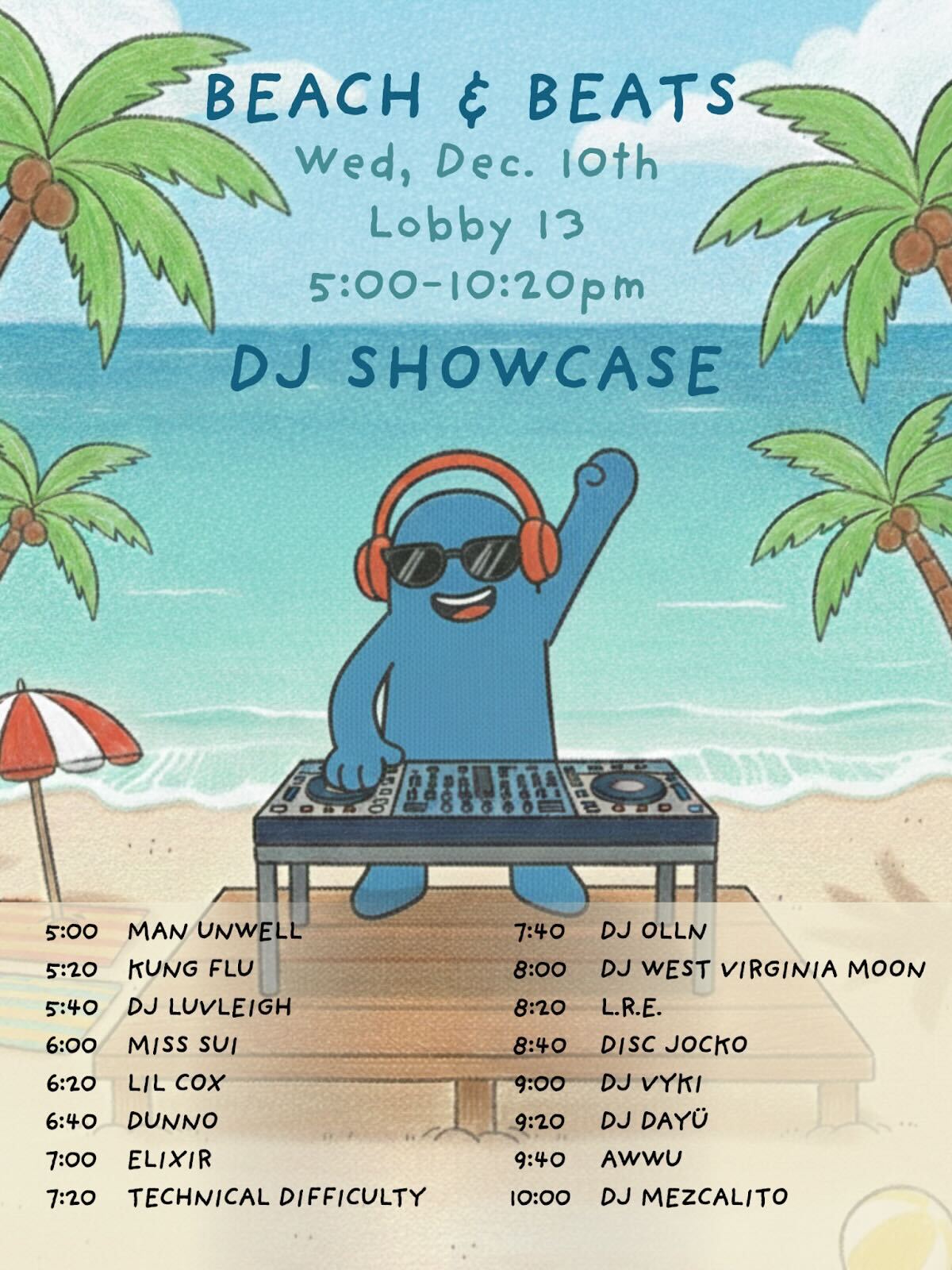

On the day of performance, due to hardware concerns around residue smell on the mixer, we decided not to mount the scent mixer directly on top of the DJ mixer. We found out the morning of the performance that we couldn't mount the device on the mixer and had to engineer a new solution by detaching the existing IMU setup. We took out the IMU sensor and attached it directly onto the DJ mixer, thereby separating it from the scent mixer but still allowing the turning motion to control the scent mixing. This was a testament to our ability to quickly adapt and solve situations under time pressure.

Making of Scent DJ

Working demonstration of the scent DJ device showing the rotational tracking PCB controlling different scents in the modular rack

Modular scent diffuser system designed and fabricated in collaboration with Richard Zhang from TMG

Live DJ performance

Cover art for the DJ showcase as part of the How To DJ Final

Scent DJ team

Reflection

This week focused on laser engraving a PCB designed by Quentin to create a rotational tracking system for the scent DJ device. The wildcard format allowed experimentation with laser-based PCB fabrication and understanding its capabilities in a practical application.

The choice of laser engraving was driven by the space constraints of the DJ device—we needed a very small PCB to fit within the compact form factor. The IMU sensor is already very small, requiring a compact PCB design that could accommodate fine-pitch traces. Laser engraving proved ideal for this application, as it allows for precise, fine-pitch traces on a small board that would be challenging to achieve with other methods like milling.

The precision of laser engraving was essential for creating accurate sensor traces needed for reliable rotational detection. The most significant learning was understanding how laser parameters must be carefully tuned—balancing power, speed, and focus to achieve clean copper removal without damaging the substrate.

The integration of the laser-engraved PCB into the scent DJ device demonstrated how fabrication methods can enable creative applications. The rotational tracking system, combined with the modular scent rack, creates an intuitive DJ-like interface where physical rotation controls scent activation.

On the day of performance, we encountered a practical challenge: we found out the morning of the performance that due to hardware concerns around residue smell on the mixer, the scent mixer was unable to be positioned directly on top of the DJ mixer. We had to quickly engineer a new solution by detaching the existing IMU setup. We took out the IMU sensor and attached it directly onto the DJ mixer, thereby separating it from the scent mixer but still allowing the turning motion to control the scent mixing. This was a testament to our ability to quickly adapt and solve situations under time pressure. This adaptation demonstrated the flexibility of the modular design and the robustness of the laser-engraved PCB.

CT scanning provided unique insights for debugging and quality control, helping verify the rotational tracking traces. The successful integration validates laser engraving as an attractive option for rapid prototyping and custom sensor applications.

Note: This assignment documentation website was created with assistance from Cursor AI.

Note: This assignment documentation website was created with assistance from Cursor AI.

Credits

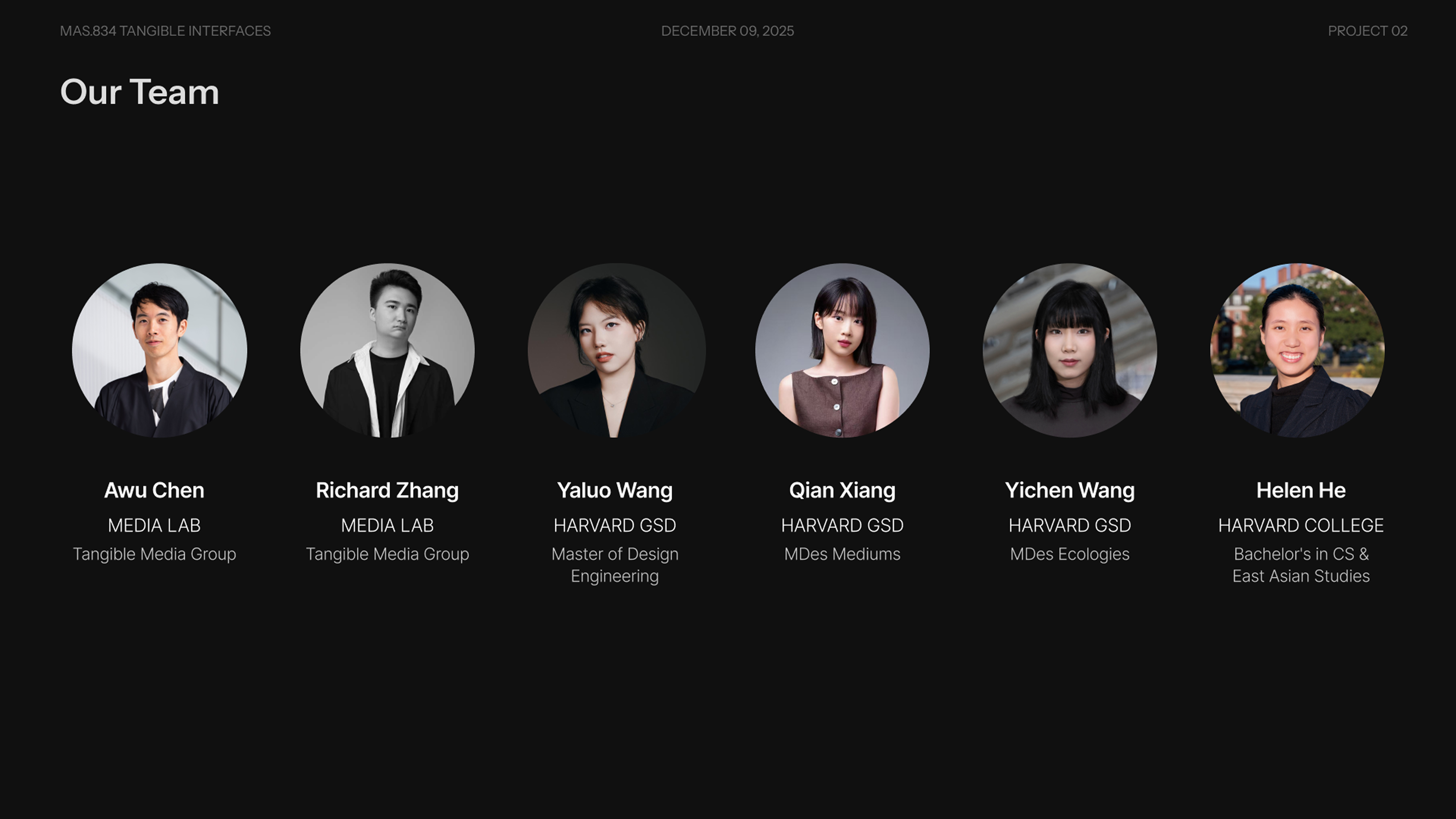

This HTMAA class work was used to build a component—the IMU PCB (made the day before)—for the final project of the Tangible Media Class, which was then used in the live performance of the How to DJ class (the next day).

Special thanks to the team from Tangible Media Class for their collaboration and support on this project:

Richard Zhang, Yichen Wang, Yaluo Wang, Qian Xian, and Helen He

Tangible Interfaces Final Presentation

Special thanks to the team from Tangible Media Class for their collaboration and support on this project:

Richard Zhang, Yichen Wang, Yaluo Wang, Qian Xian, and Helen He

Tangible Interfaces Final Presentation

Attachments

PCB design files original design by Quentin (KiCad):

vibration_xiao_lsm6.kicad_pcb

vibration_xiao_lsm6.kicad_sch

vibration_xiao_lsm6.kicad_pro

vibration_xiao_lsm6.kicad_prl

vibration_xiao_lsm6.kicad_pcb

vibration_xiao_lsm6.kicad_sch

vibration_xiao_lsm6.kicad_pro

vibration_xiao_lsm6.kicad_prl

Links