Please see this link for the CBA group documentation for Machine Week. This is where you will also find all relevant design files for this project.

Machine week was an absolute whirlwind. I started on the electrical engineering team, ended up switching to mechanical design on day 5.5. Below is a brief summary of my contributions to the group project:

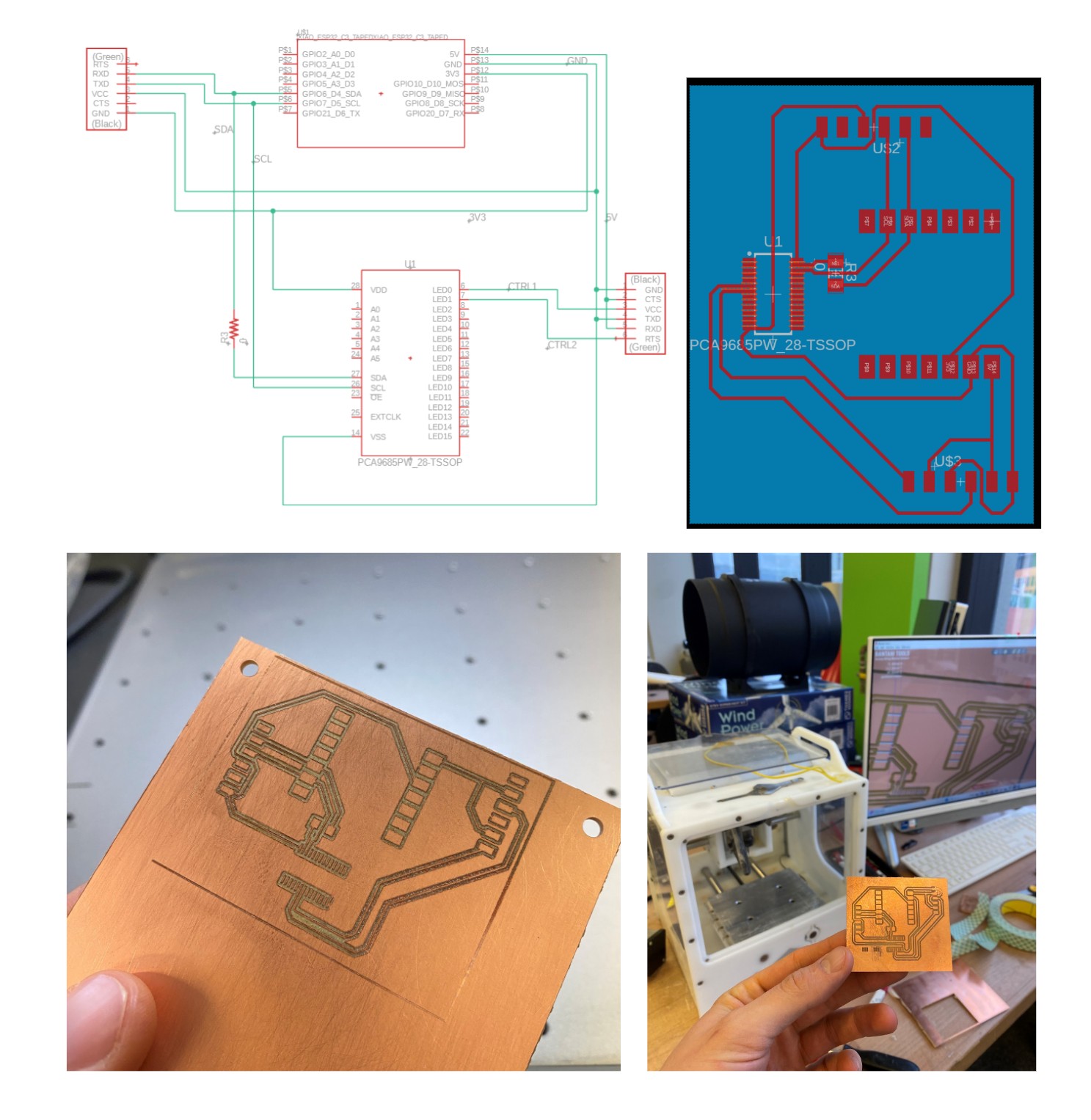

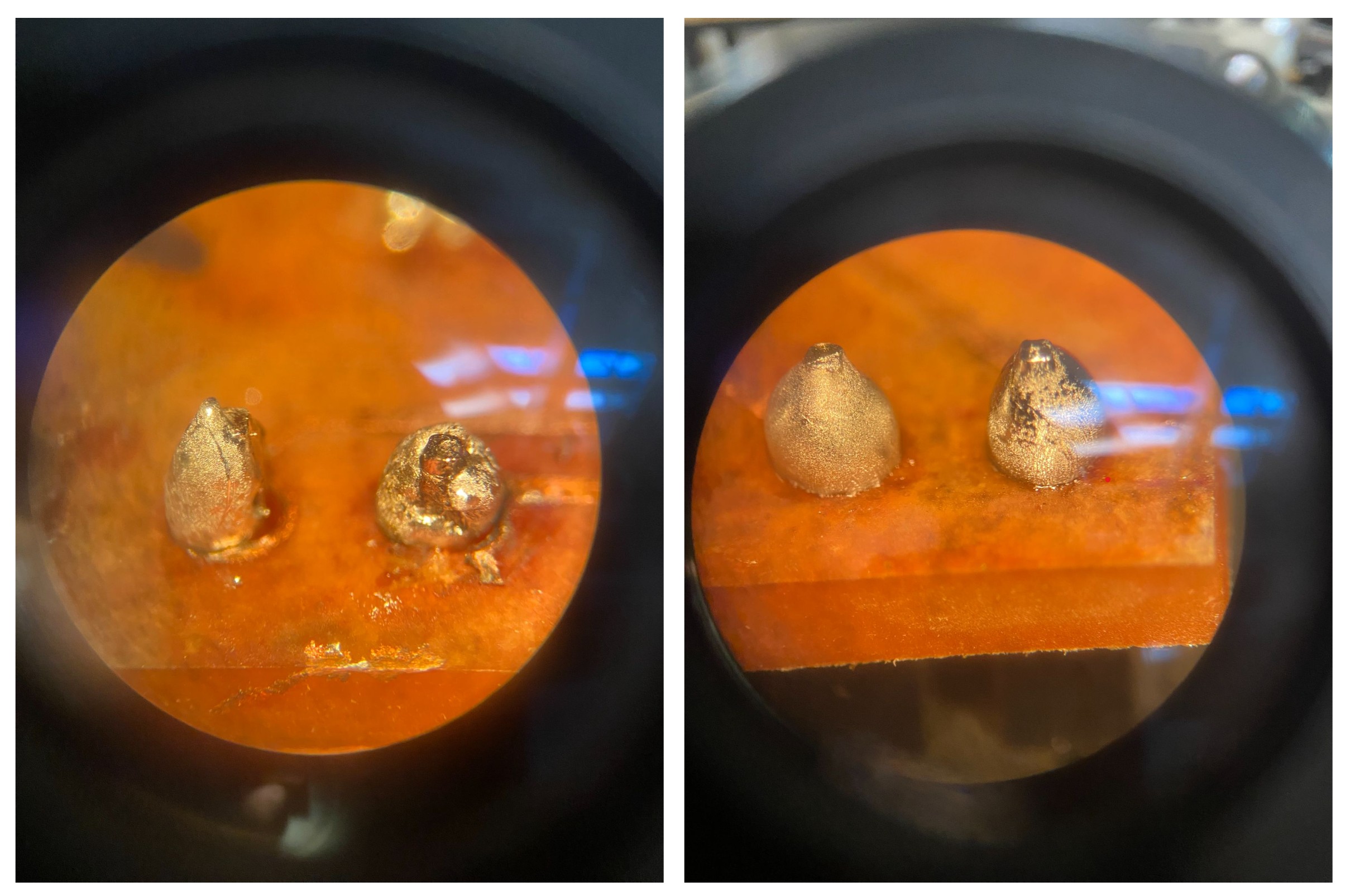

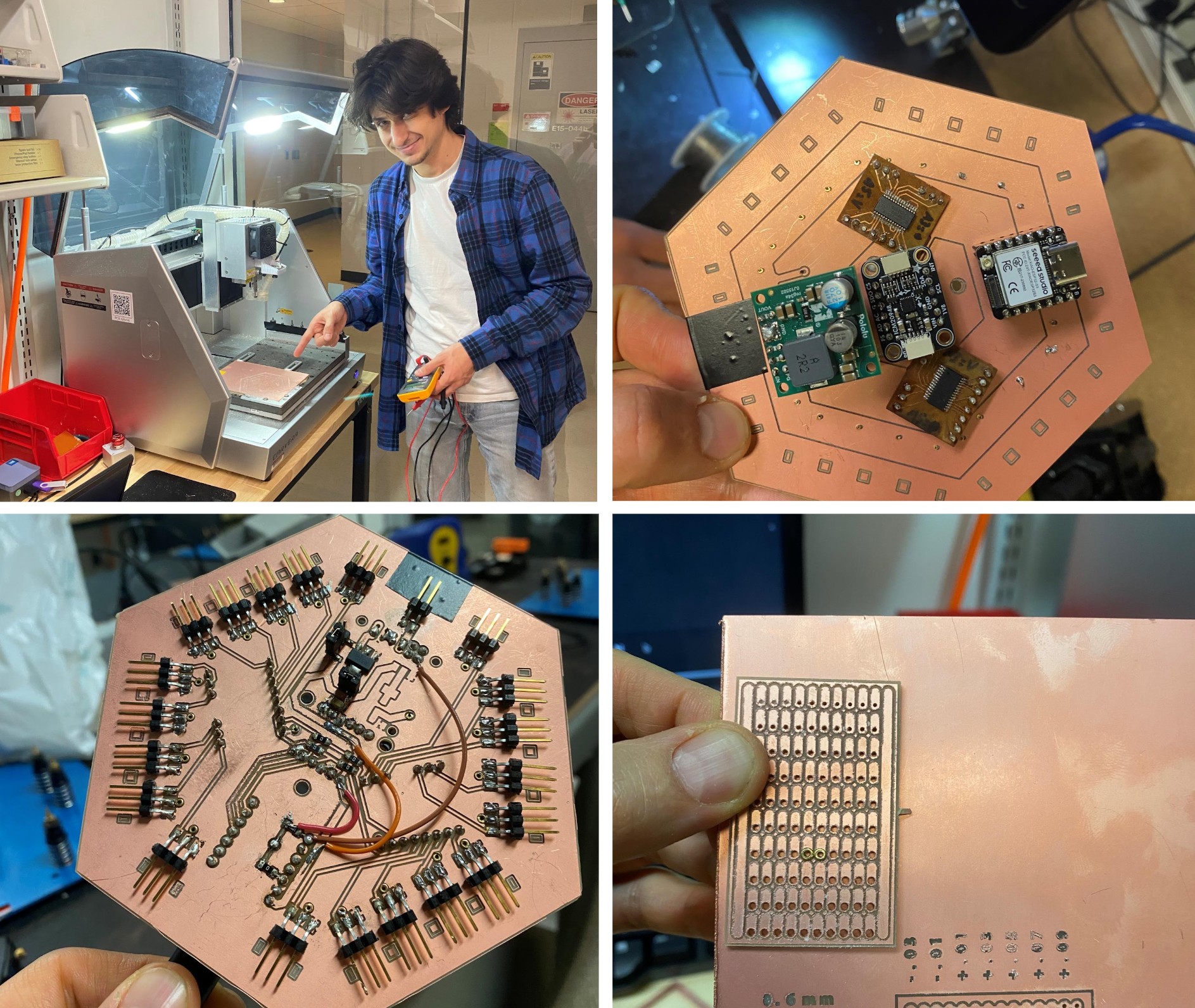

First of all, working with Dimitar and Tlyer on our little 3 person elecetroncis team was an absolute joy. We were extrememly efficient, effectively paralleled in process, and communicated really well. One of the challenges we faced was that the software team needed an MVP as quickly as possibel in order to get going. We also needed to sort out how to get the smallest component onto our board. A lot of top priorities that all needed to get done asap! The first task I took on was working with Anthony to better understadn the two work flows for lasering/millign small traces. The image below shows the v0 breakout board designed by Tyler, the laser cut board (on the left) and the milled board (right).

A few nuances anthony helped us figture out that I wanted to make sure to document:

Ultimately, we decided to miniaturize the laser engraved board as much as possible in order to save on time, making a small breakout board that clipped into the main board. We then milled the main board on the Carvera. Given the boards complexity, we also spent a lot of time fine tuning these parameters. See below for some of our insights.

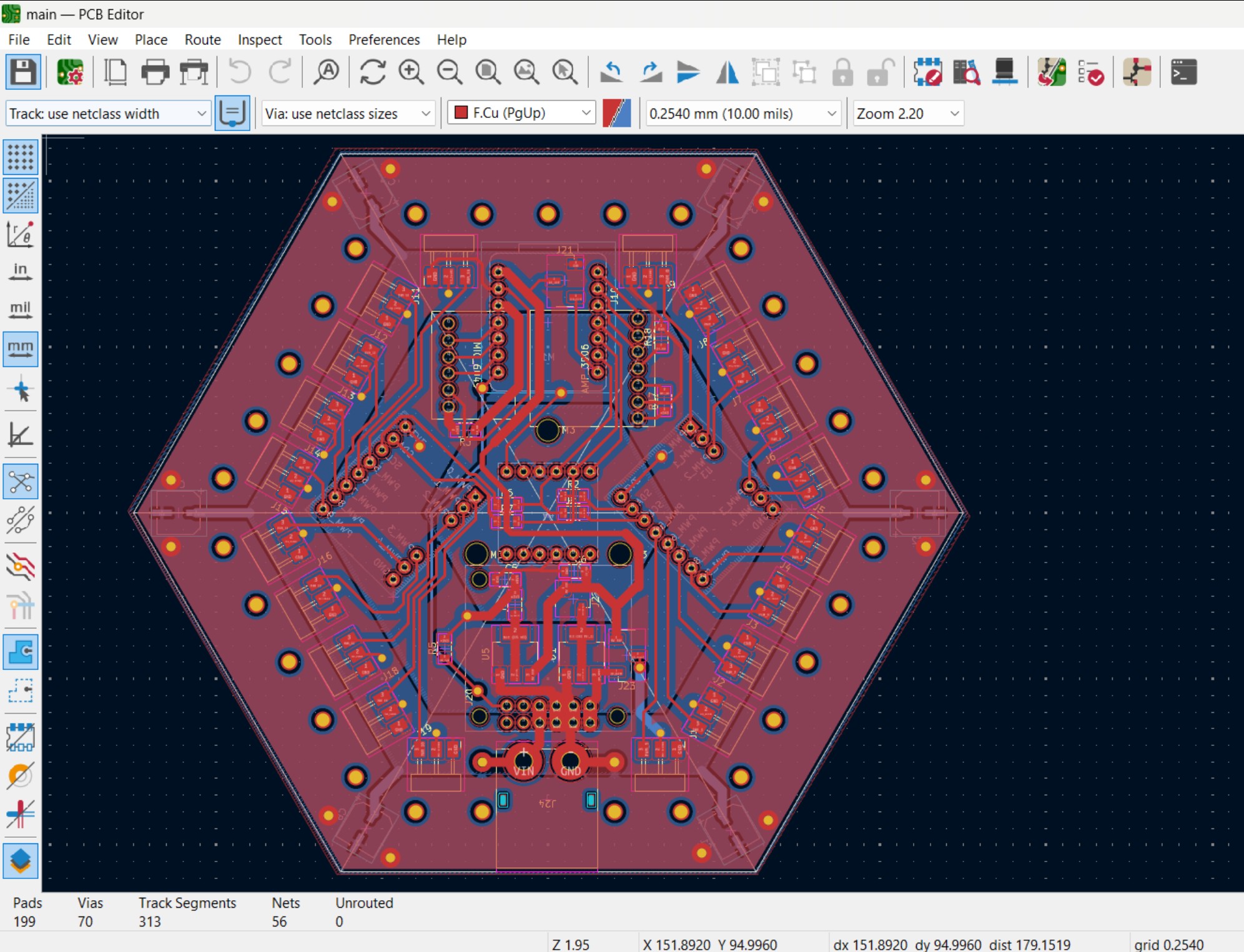

The other contribution I made to the EE team that I wanted to note was adding the audio components (an I2S microphone and audio amplifier) to the v2 board that Dimitar designed. This was an extrememly educational experience. Having to work on Dimitar's board (which was far more complex than anything I'd done up to that point) helped me better understand what a REAL EE can accomplish with these tools. At first, I got lost in the multi-layered nature of the schematic, but in time, I came to understand it. Figuring out how to add these components to the schematic (choosing approariate pins) and the physical PCB layout was a challenging and rewarding process. This was also the first time I was using git in a more collabrative way, going back and for the with Dimitar. Huge shout out to him for teaching me all the ins and outs of this with abundant paitence

With about a day and a half left in the build, I recieved a mayday signal from the folks working through the mechanical design. We still didn't have a functional prototype of the central actuator, and we were running out of time. Originalyl, I chose to be on the electrical team becasue I wanted to push myself to learn more about circuitry. My background in mechancial engineering means that I was pretty confident in those skills. It was hard to pull away from the electronics, but it was clearly the right choice in the name of the group's success!

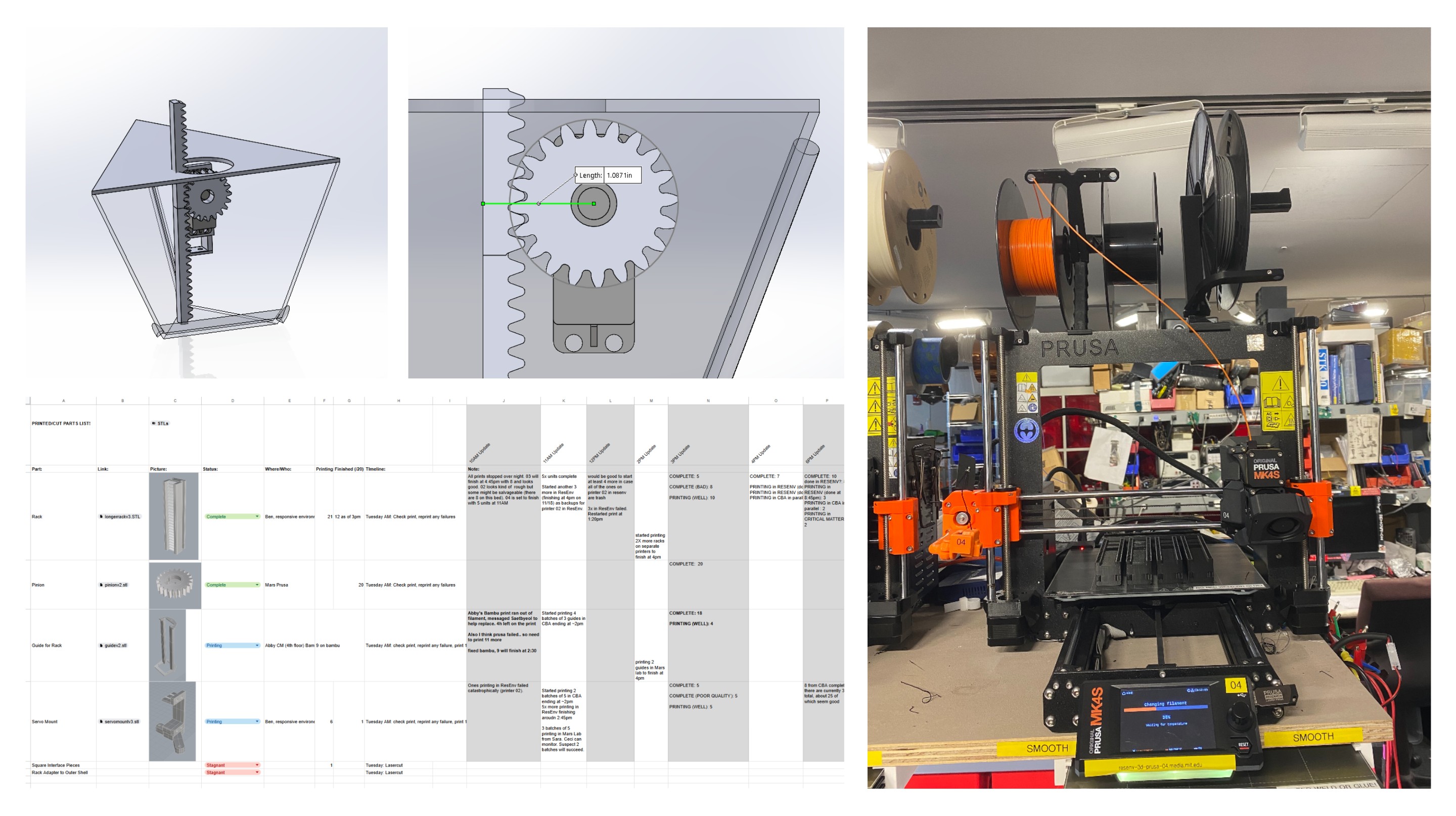

We made an emergency pivot and decided to go a completley different direction on the deisgn. Previosly, they had been trying to get a crank shaft mechanism working, but the linkage was underconstrained and overly complicated. Fortuatly, Abbey had already designed a rack and pinion as a backup! I largely played the role of integrator: bringing models in from 3 different people into a single ecosystem to ensure that the mechanism fit within each of our sub units, attached to the face planes, and actuated a reasonable length. I had a great time working alongside Abbey. Despite the heat of the moment, we managed to have a lot of fun.

Once we had a working prototype later that day, it came time to manufacture. Each unit of the Icosahedron would require 4 individual parts to get printed. 4 * 20 = 80 parts that needed to get printed in a very short amount of time + some spare parts accounting for failures. I used a master spreadsheet to track across 4 different spaces where we were printing parts, adding hourly updates to ensure we were on track. Sara, from CBA played a huge role in keeping the printers going. Although this wasn't really a "technical" task, I found it to be really satisfying to perform a kind of management role. Helps that the folks I was working with are all absolute delights!

Finally, I just wanted to say that this was one of the most challenging and rewarding projects I've ever been a part of. Finishing our funky little robot was a massive achievment, given all othe moving parts (both literally and in the sense that this 20 person team worked extremly well together)! I am very proud of what we accomplished and was happy to contribute to both the electrical and mechanical teams. Please see our group site for more.

Return to Home Page