Please see this link for my group's assignment (group 1).

This week, my whole life was focused on learning how to make big things! In addition to our assignment, I was already designing something VERY large for a 99F installation (a massive cylindrical projection screen) and attending a ceramics workshop in upstate NY over the weekend about large korean fermentation crocks.

Since I knew I would be working pretty much around the clock on Thursday/Friday on my 99F project, and given that I would be out of town Saturday-Tuesday for the ceramics workshop, I knew I needed to hit the ground running on this assignment

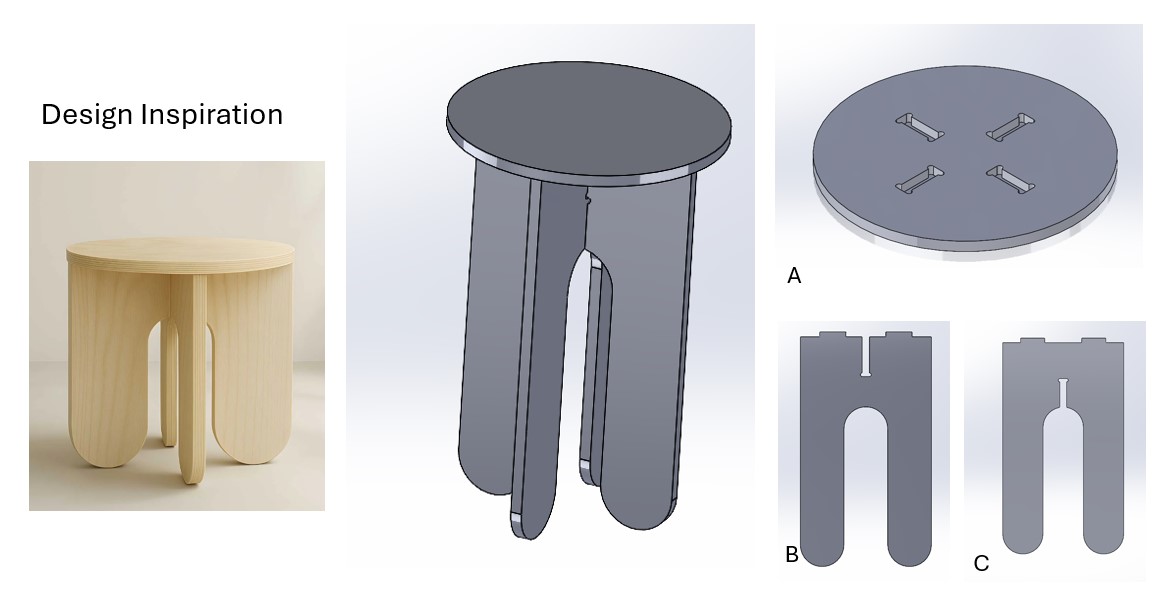

On Wednesday night, I designed a piece of furniture I saw online. In fact, I feel like I've been targeted by their marketing campaign for years. The company is called Unfinished Furniture and I really like their ethos. The design I wanted to replicate was their regular sized Side Table. I was able to gather all of the views I needed of the individual pieces from their assembly video.

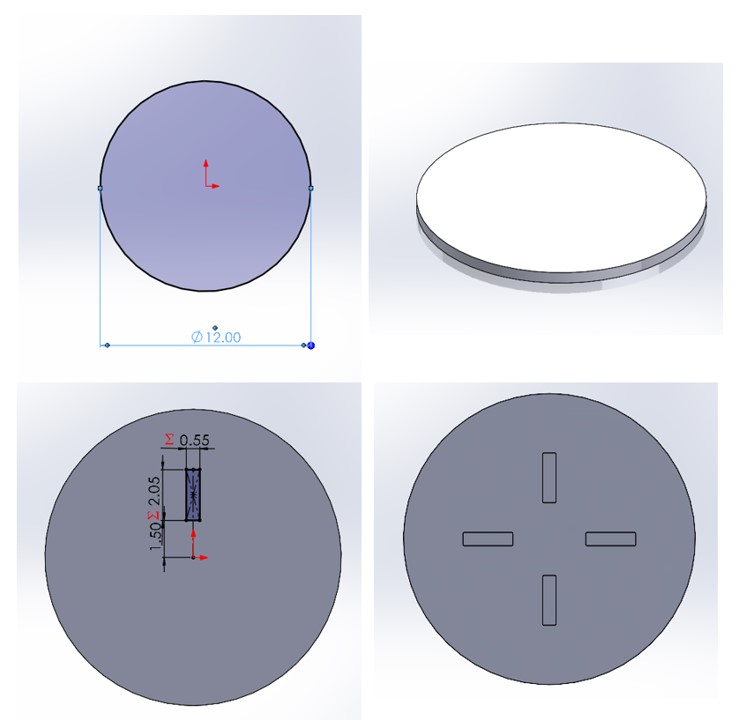

First, I modeled the top of the stool as a circle with 4 rectangular pockets.

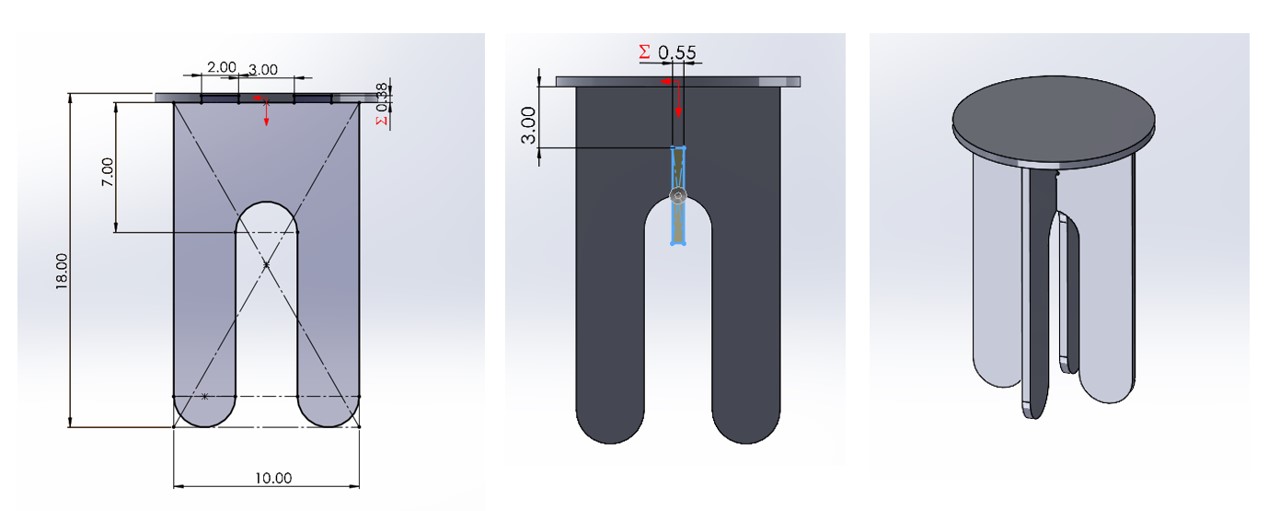

Next, I modeled the legs. The only difference between the two legs is the orientation of the slot. The first leg's slot starts at the bottom and goes up to the middle. The second leg's slot starts at the top and goes down to the midpoint.

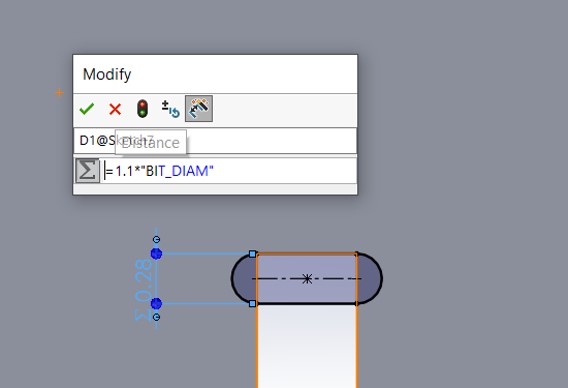

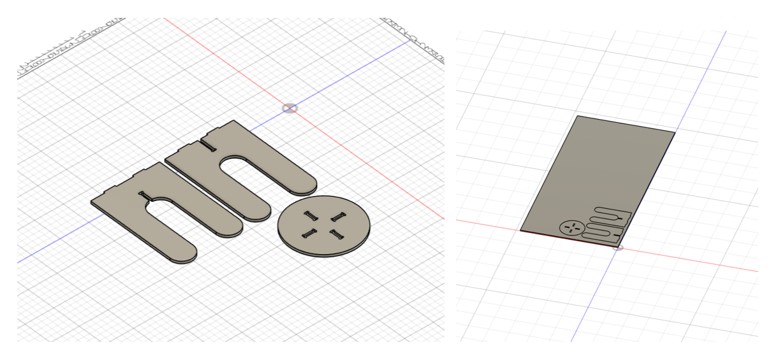

I then realized that the sharp corners on my slots couldn't actually be milled out due to the radius of the end mill. I found a really helpful video online which explained the different kinds of relief patterns used to solve this issue.

At this point, I was happy with my design.

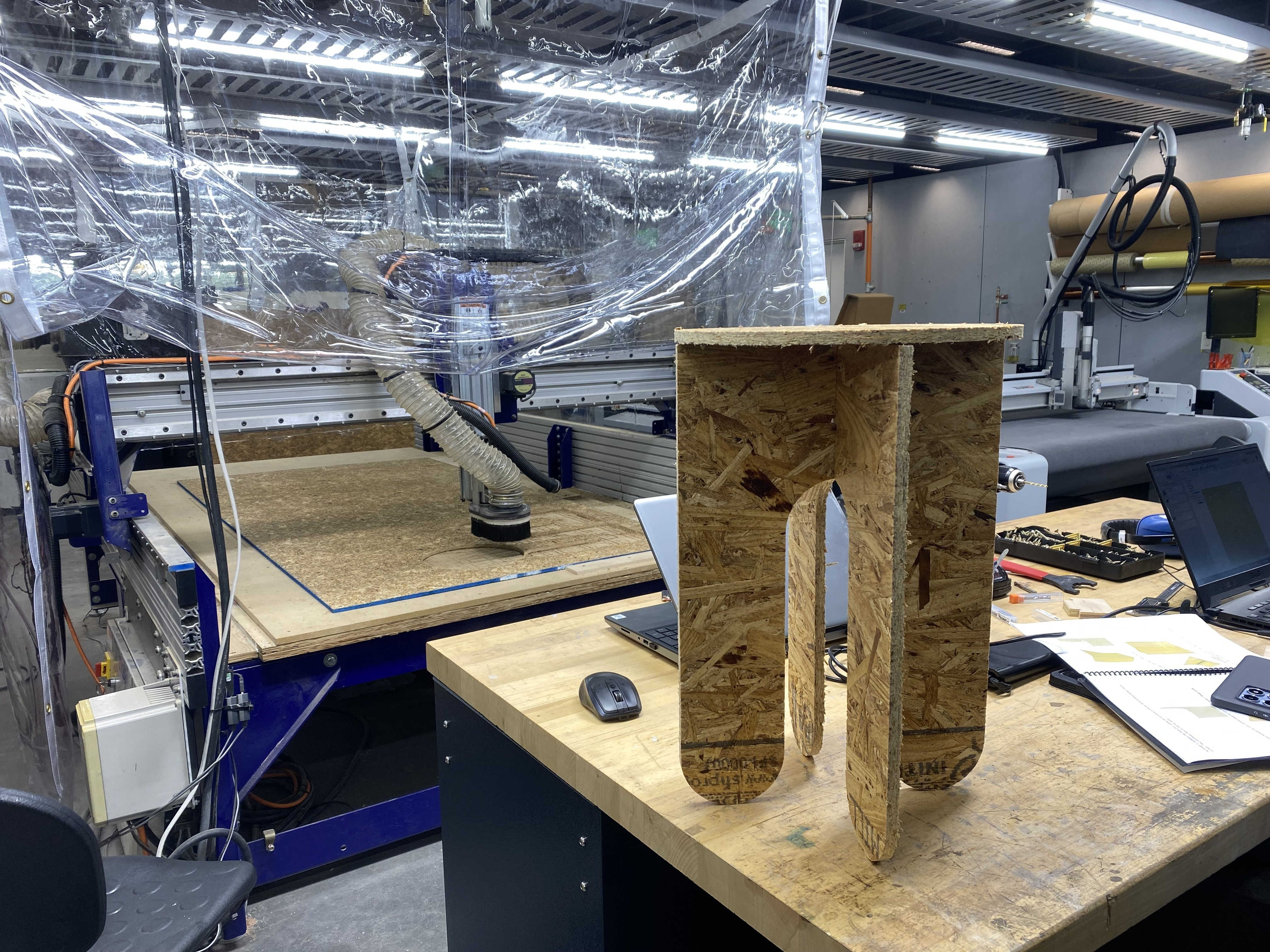

If you are interested in reproducing this work, please reference the CBA guide for the Shop Bot. It is extremely detailed and helpful. The next step was to mill.

The first time I tried to lay out my pieces in Fusion, I didn't realize that they needed to be embedded in a solid piece of stock. Make sure to do this!

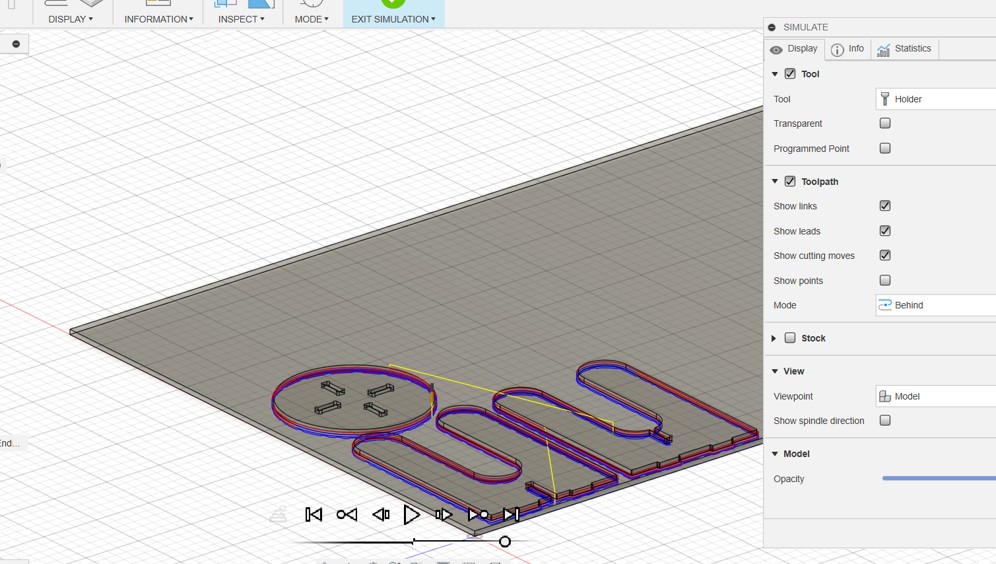

Shout out to the simulation tool. This was really helpful when I needed to debug a couple issues with my contour setup files.

In particular, I had an issue in which the mill was going down further than I expected, given the setting for the thickness of my material.

Finished product!

Unrelated to the assignment, but very much in alignment with the energy of make something big week, I had a great time making this big build for 99F with a bunch of my HTMAA classmates (Dimitar, Rui and Saetbyeol) and wanted to give them a shout tout.

Similarly, look how big this pot is! Excited to experiment with large scale ceramics. Perhaps during wildcard week.

All files for replicating this work can be found here.

Return to Home Page