Week 11: Machine Week

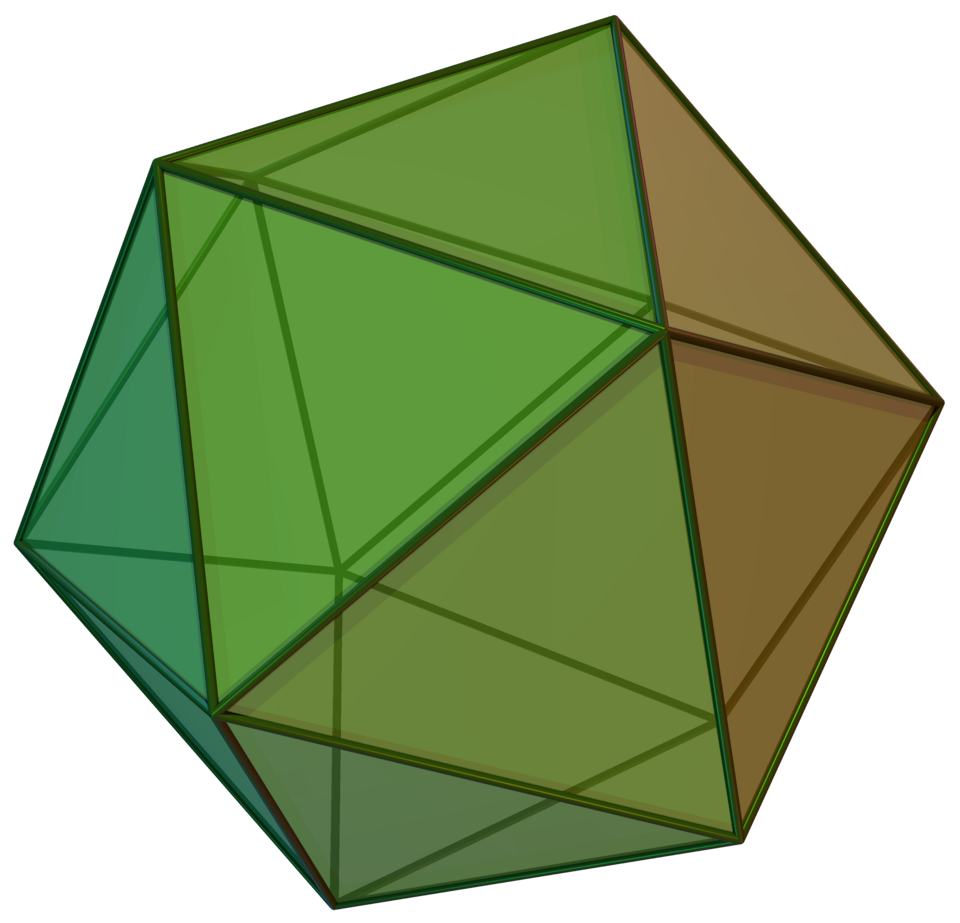

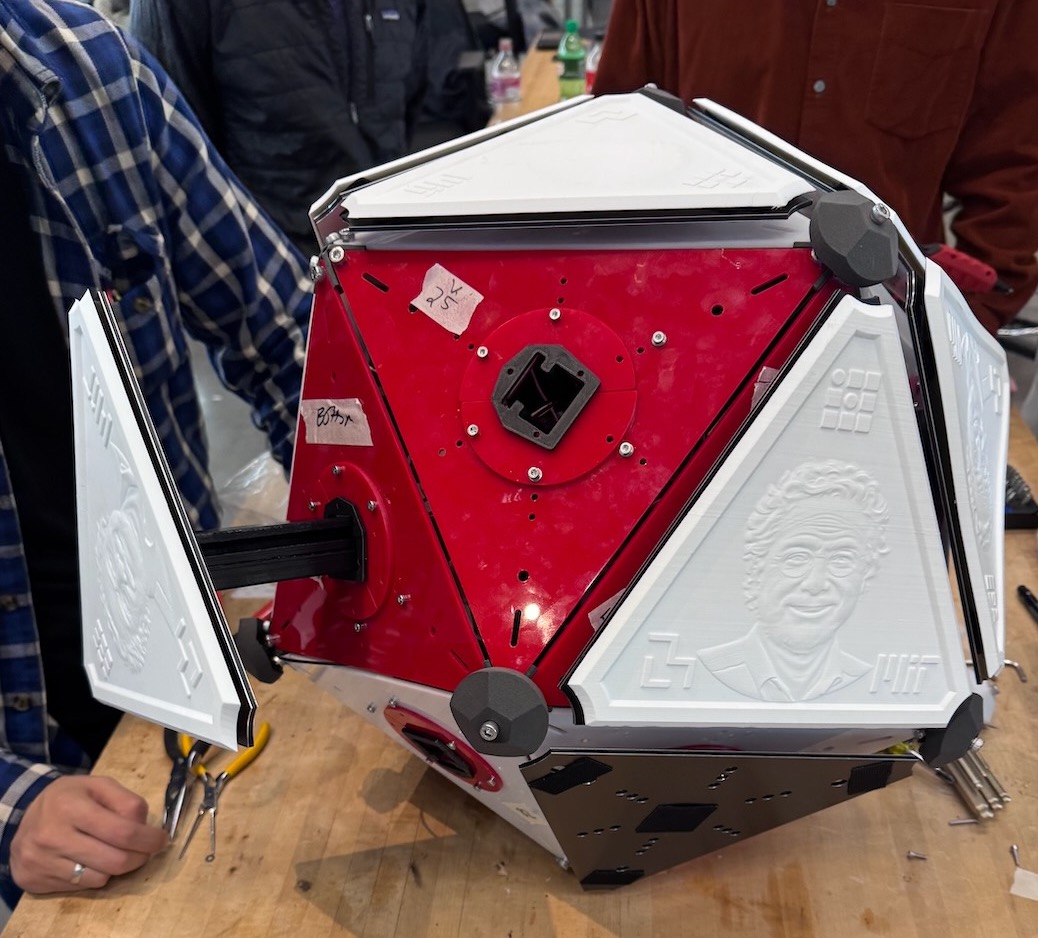

For the group project, I was part of the MechE team working on building the hardware for the Media Labubu ball, a regular icosahedron with 20 servos that actual each triangular face plate.

Part I: Prototyping the inner frame

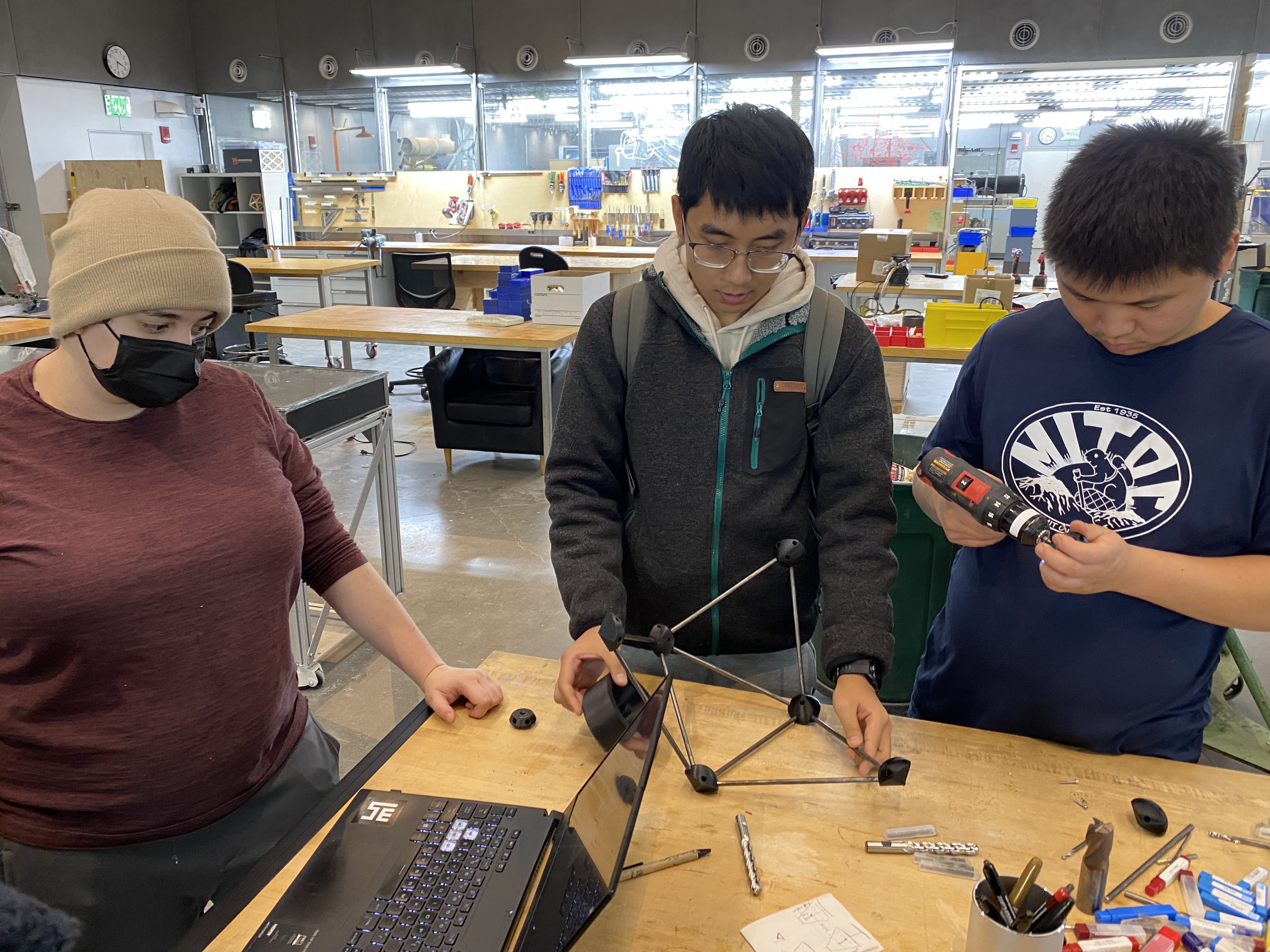

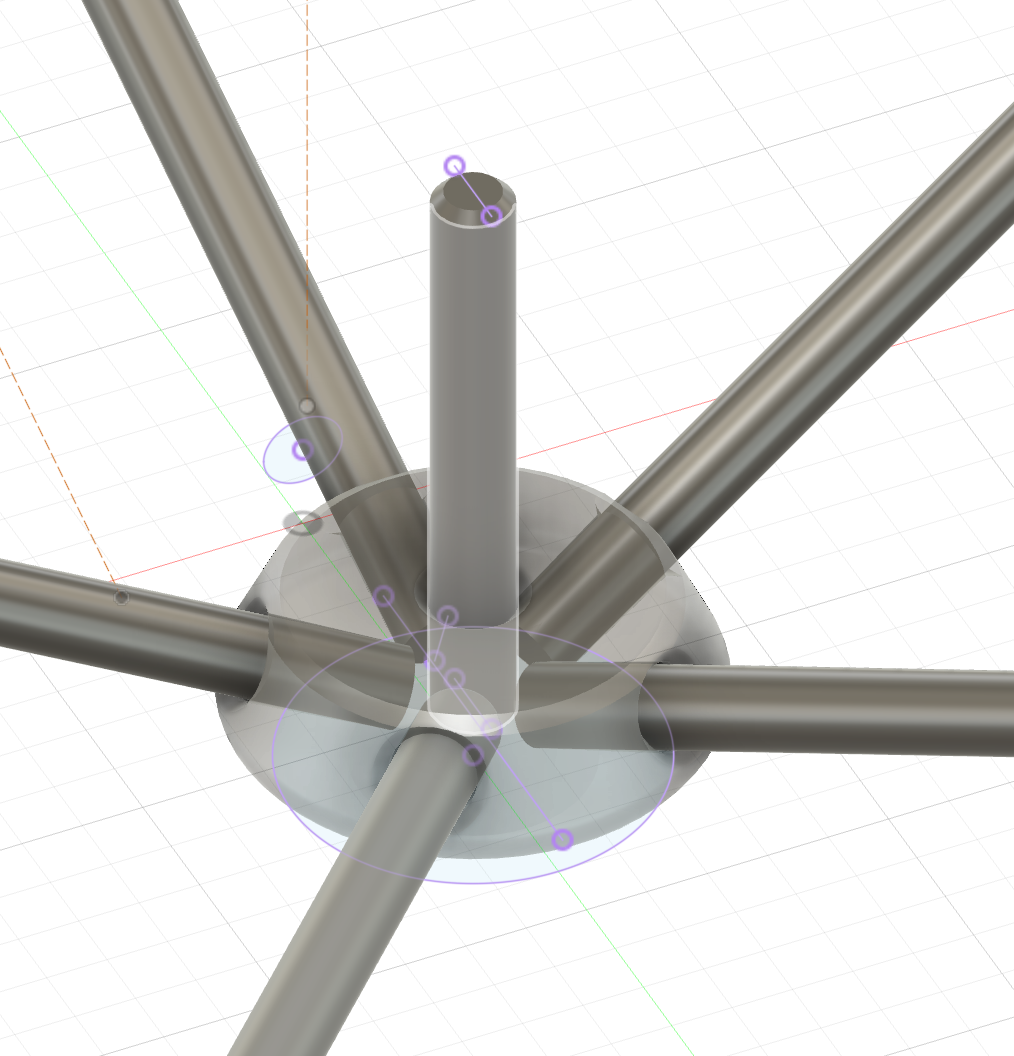

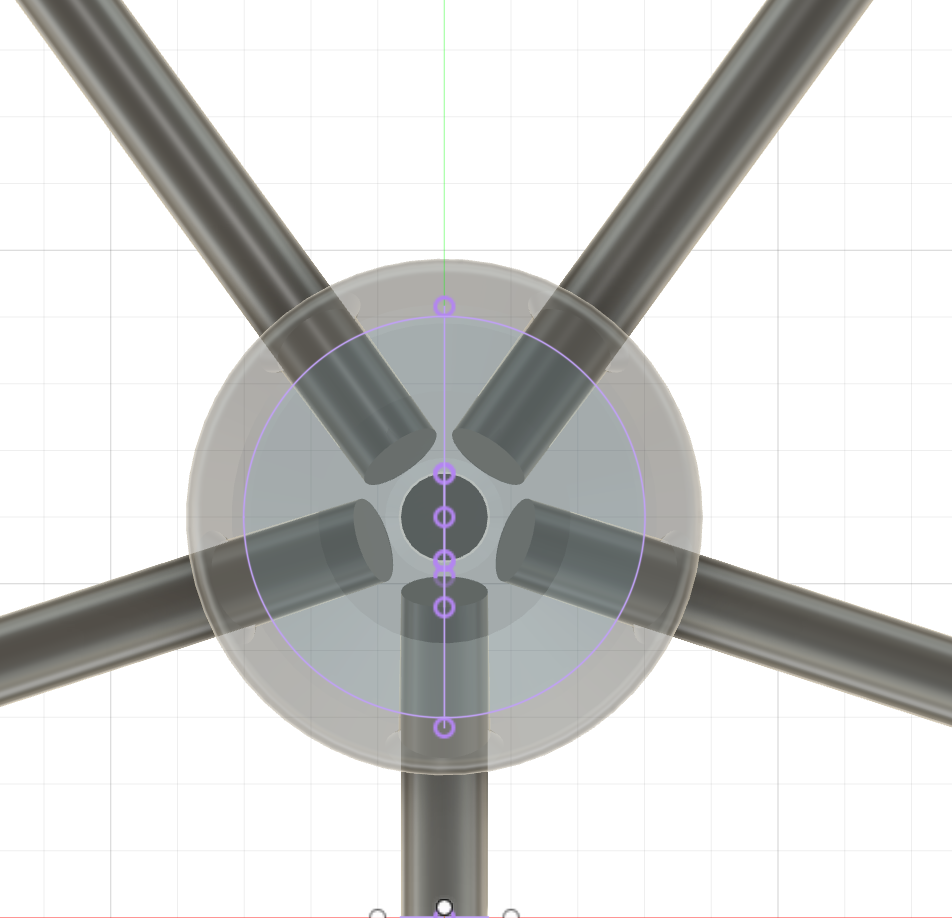

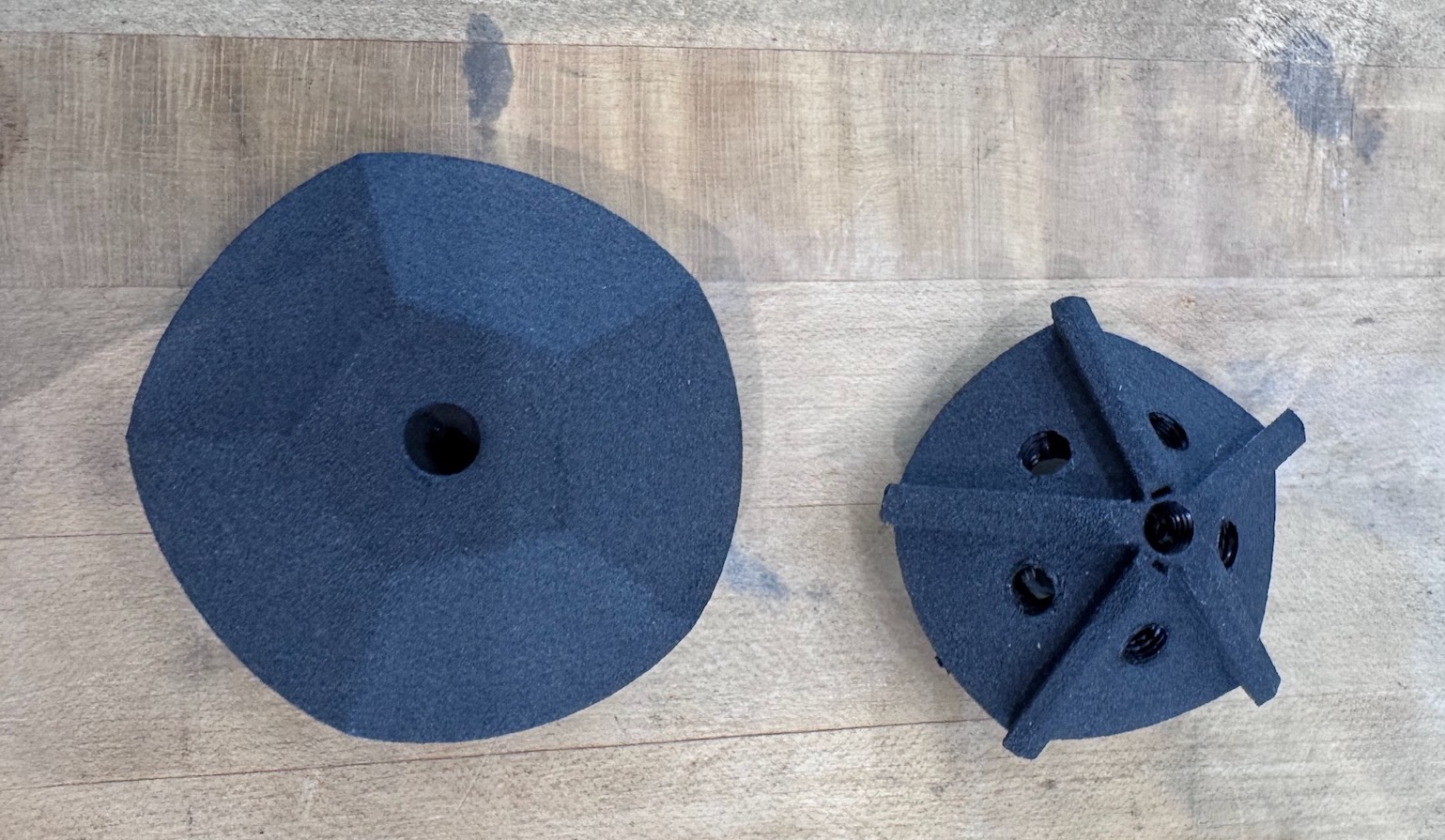

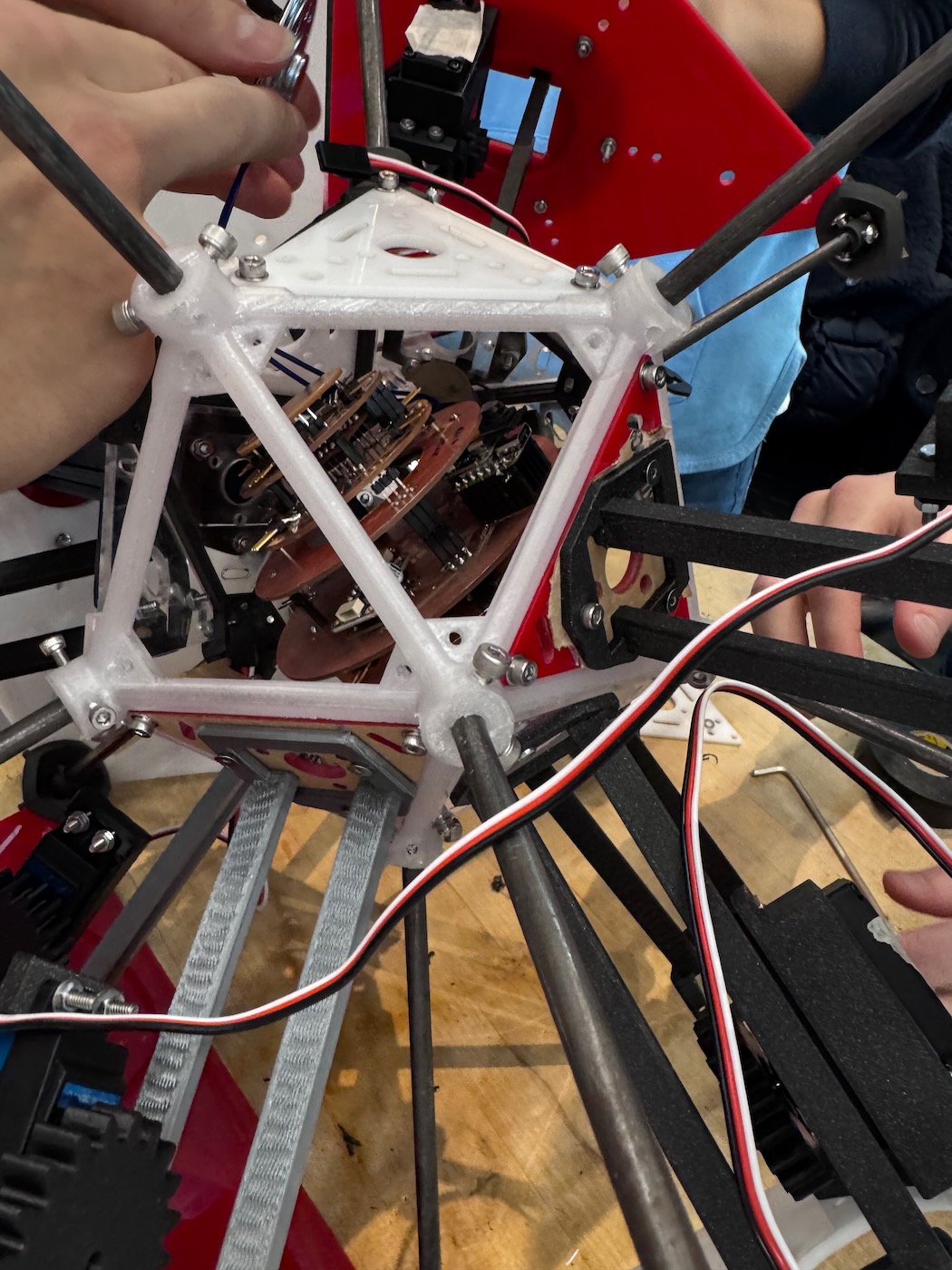

We were thinking to build the frame out of metal rods so designed a version of the joint in CAD. We first prototyped the frame using PLA with the Prusa MKS4 printers with the idea to switch to the SLS nylon later. We later switched to a two-piece design for the joints. I helped cut out metal rods with the mitre saw and used a belt sander to grind down the ends.

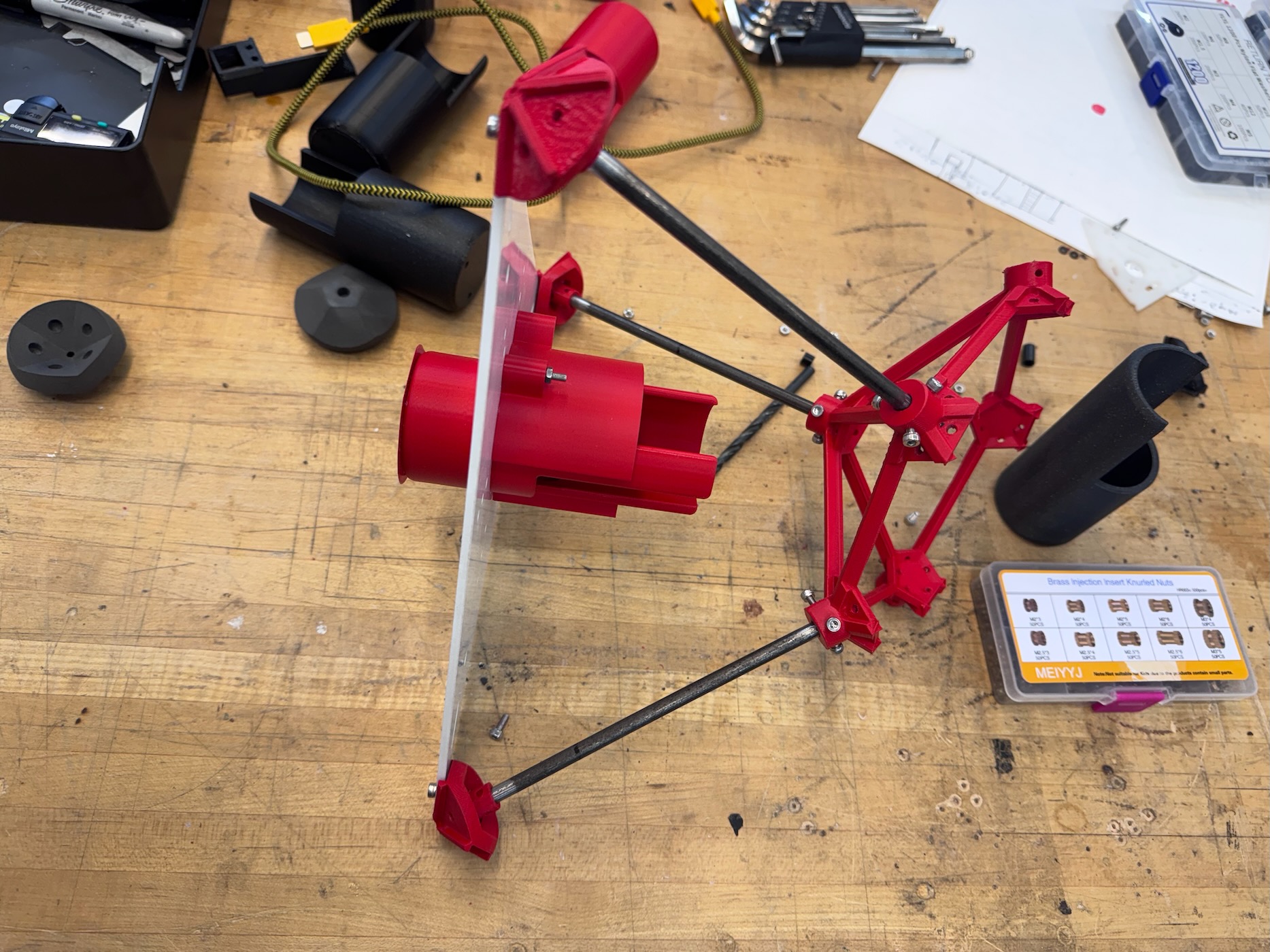

Part II: Pivoting from the piston to pinion mechanism

We realized that the current mechanism using the servo to drive a piston would not give enough throw, so we switched to the rack and pinion design. While I did not help much with the CAD, I contributed performing miscellaneous physical tasks like cleaning the SLS prints and drilling/tapping screws for the frame.

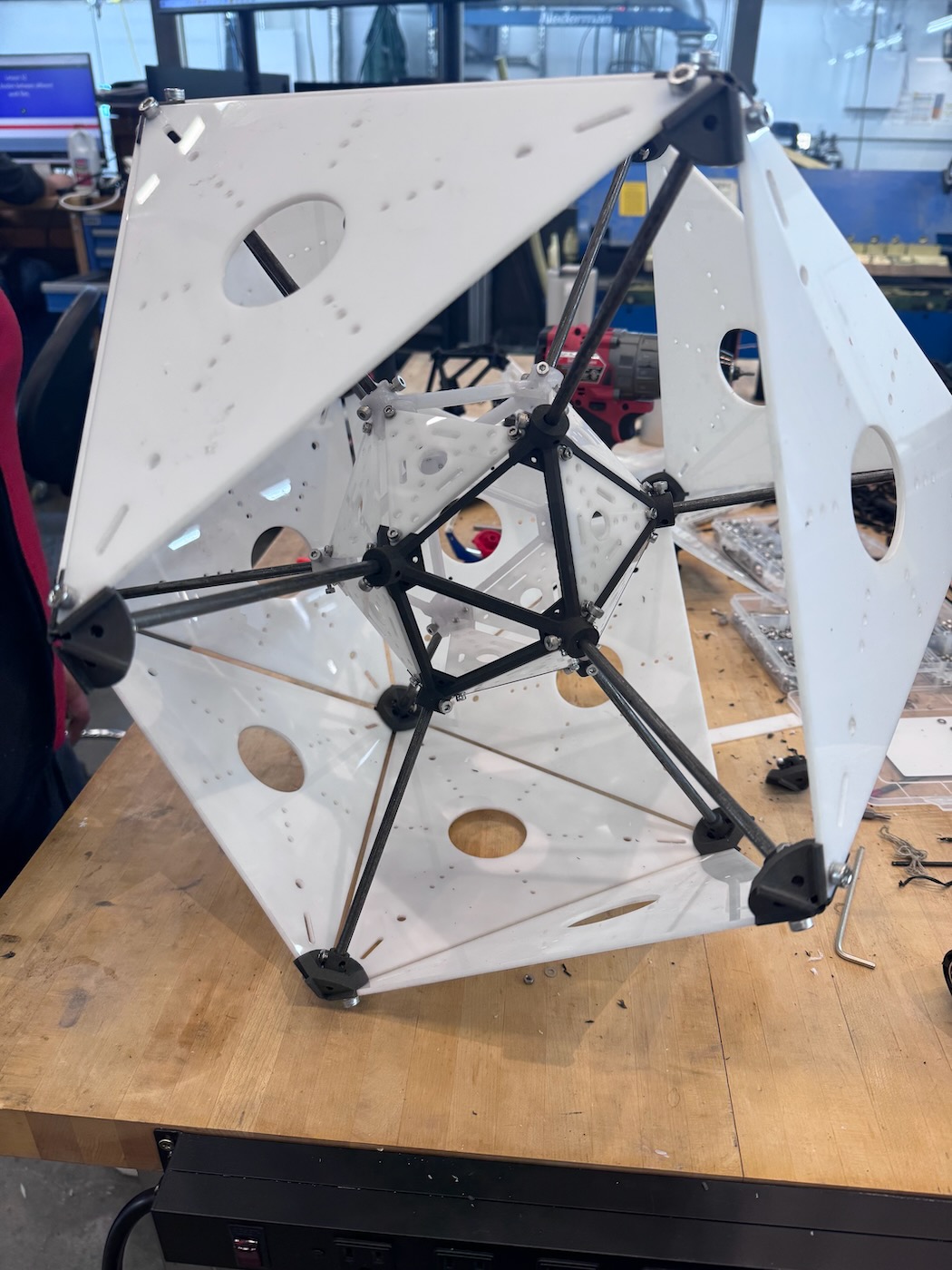

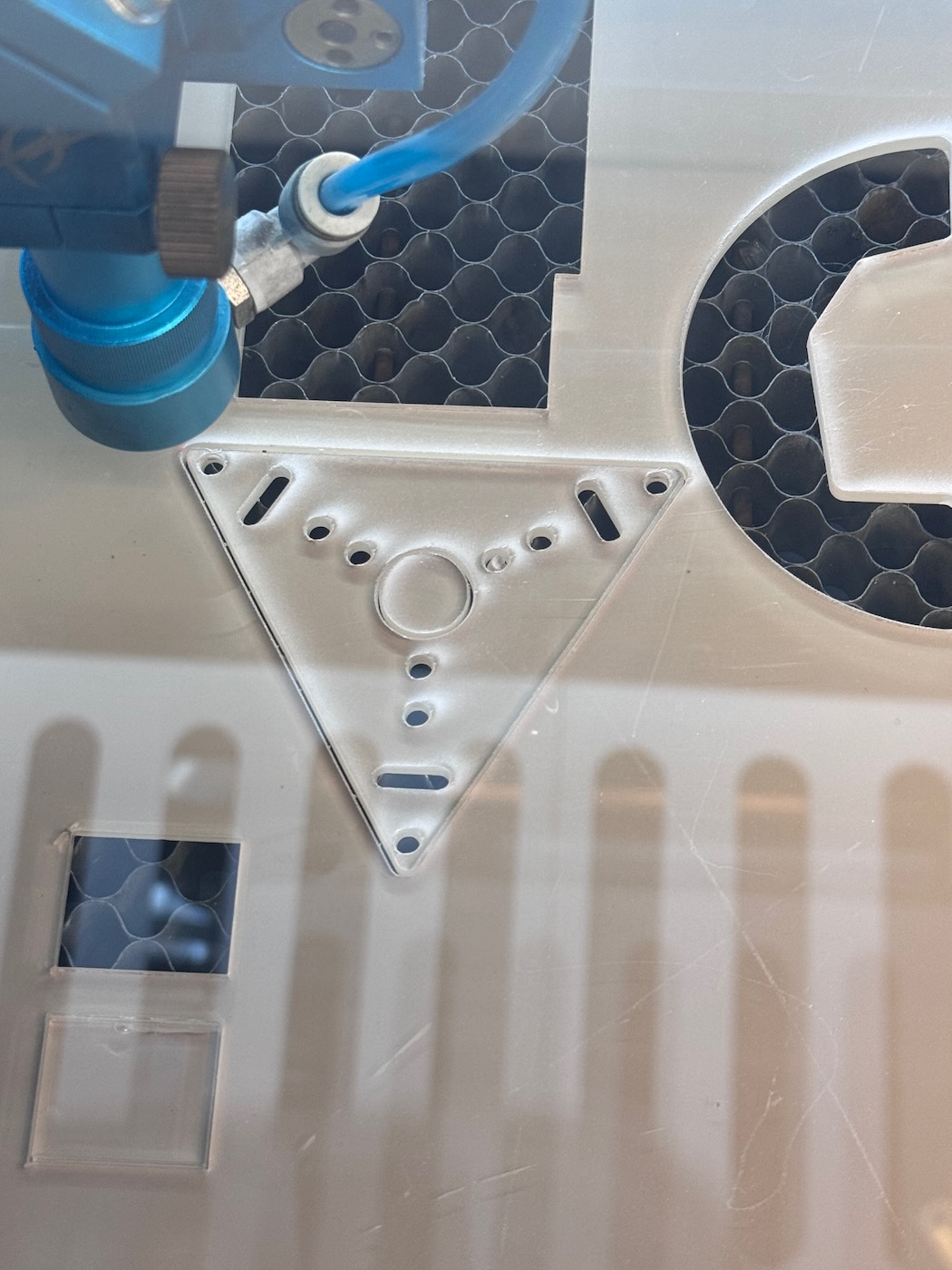

Part III: Iterating on the outer frame

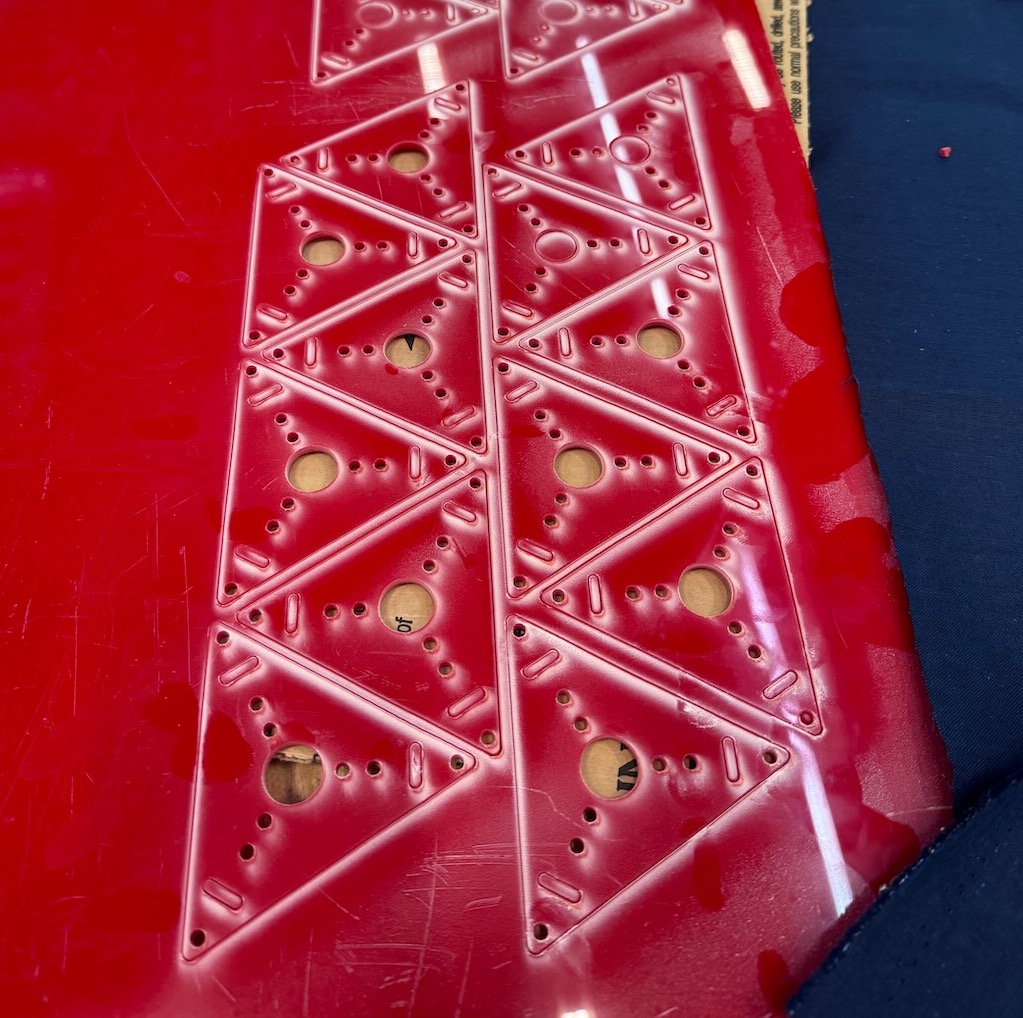

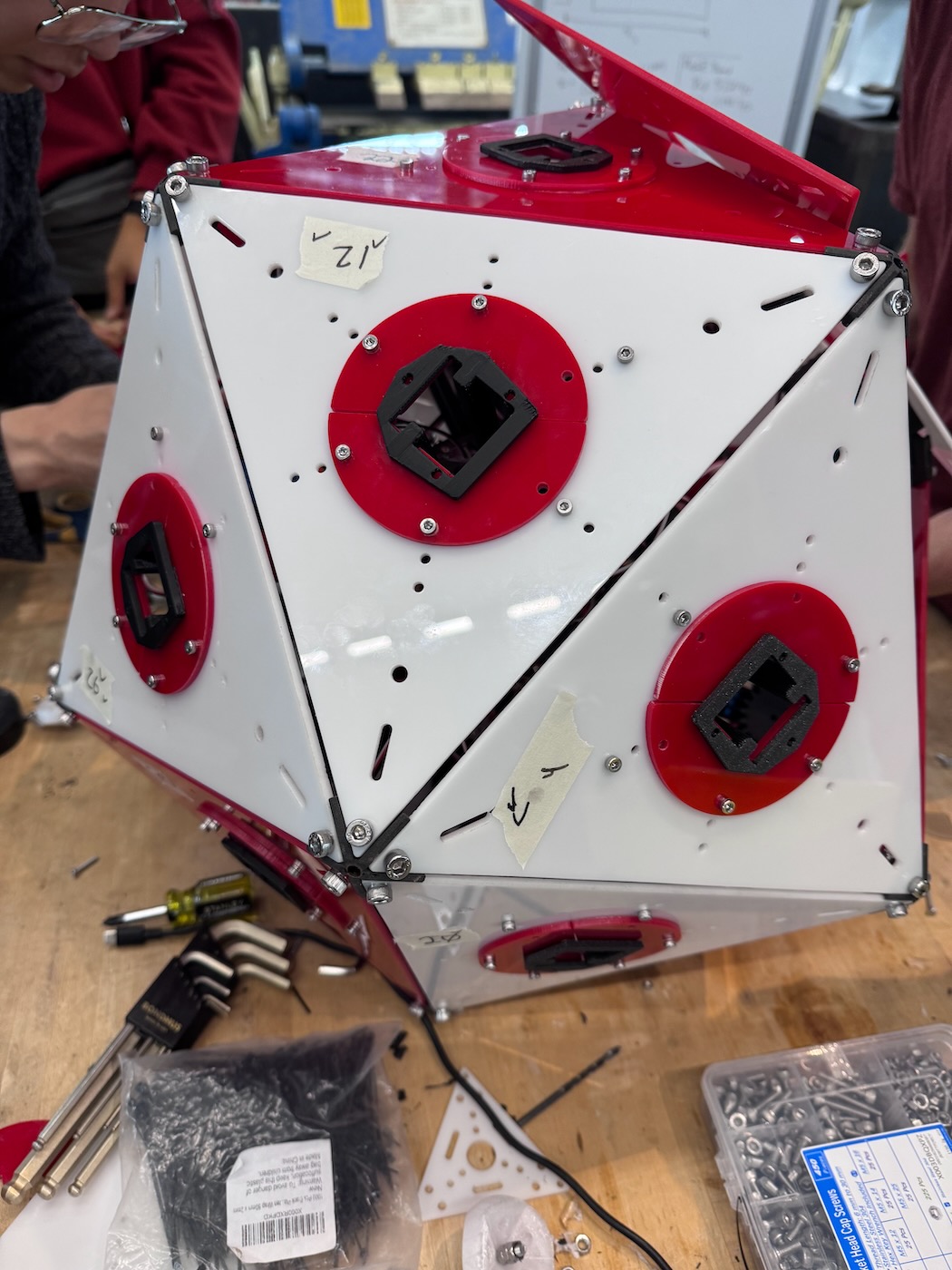

I spent many hours on the Thunder laser NOVA51 to cut out panels for the inner and outer frame. I had trouble with cutting all the way through the red acrylic material and had to use multiple passes at 100% power to able to cut all the way through the stock. We also had to cut the rods slightly shorter from 16" to 15" to be able to fit all the outer triangluar panels. We were able to successfully tip the assembly frame by actuating one panel.

Part IV: Integration testing and final assembly

I helped with the final assembly of the inner and outer frames, as well as with installing the PCB and servos. Installing the last few outer panels were tricky and needed the screws to be held with tape and installed backwards. The final assembled machine turned out to be quite very with all the screws and servos installed.

Here is the website for this project and here is the documentation for the MechE team.