Week 11

Machine Week

11/14/2025-11/21/2025

Idea

With my CBA group cohort, we wanted to build a 20 face robot

Calculation

To help my mechanical team understand how much we need to push the icosahedron to make it move, I did some initial calculations. Icosahedron has a

However, the calculations soon get

3D Modeling

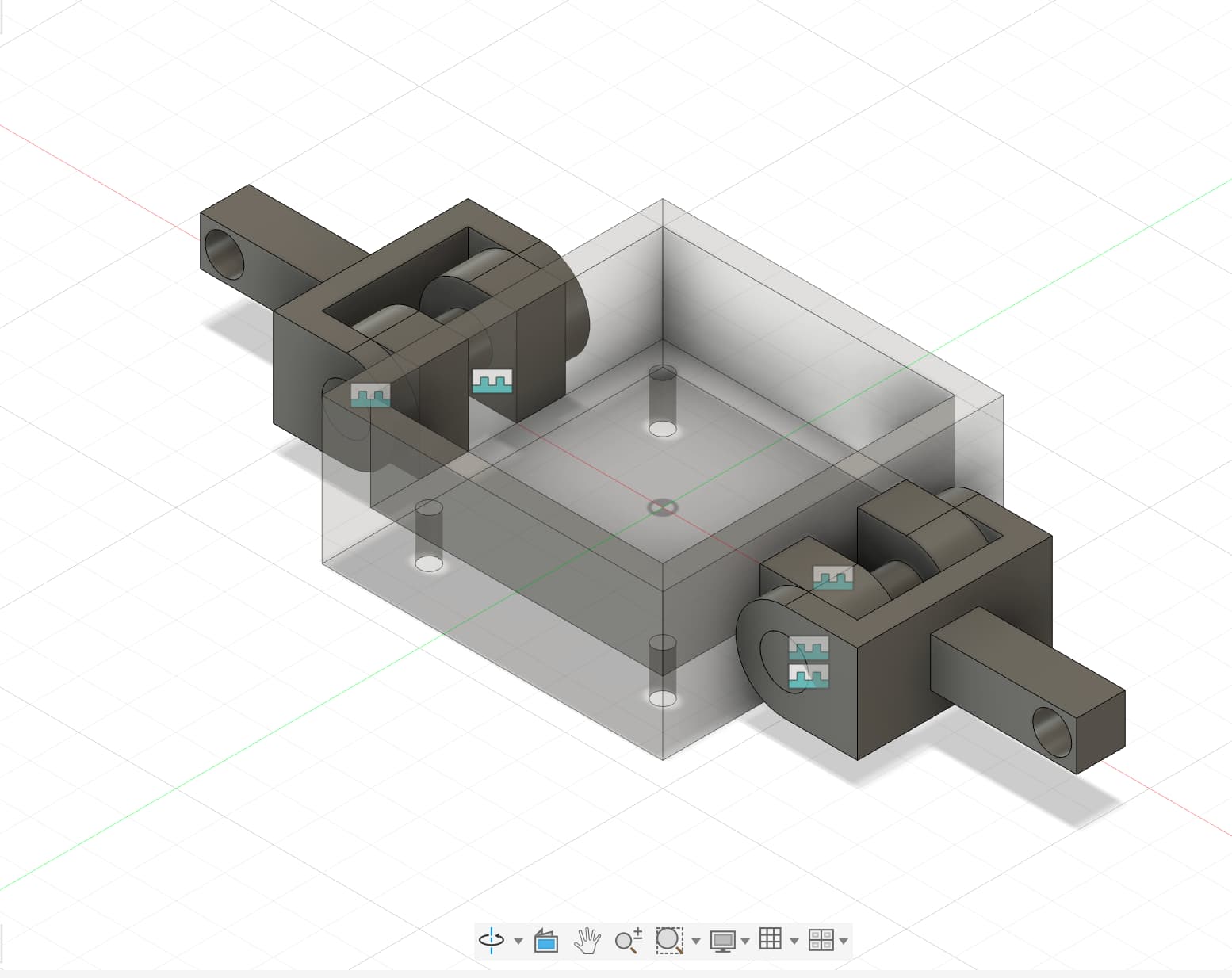

I first designed a few version of the box to hold the PCB and the battery. Without knowing the exact dimension or the design of the icosahedron, I went with a more flexible design of using rotatable arms that can rotate to attach to the frame.

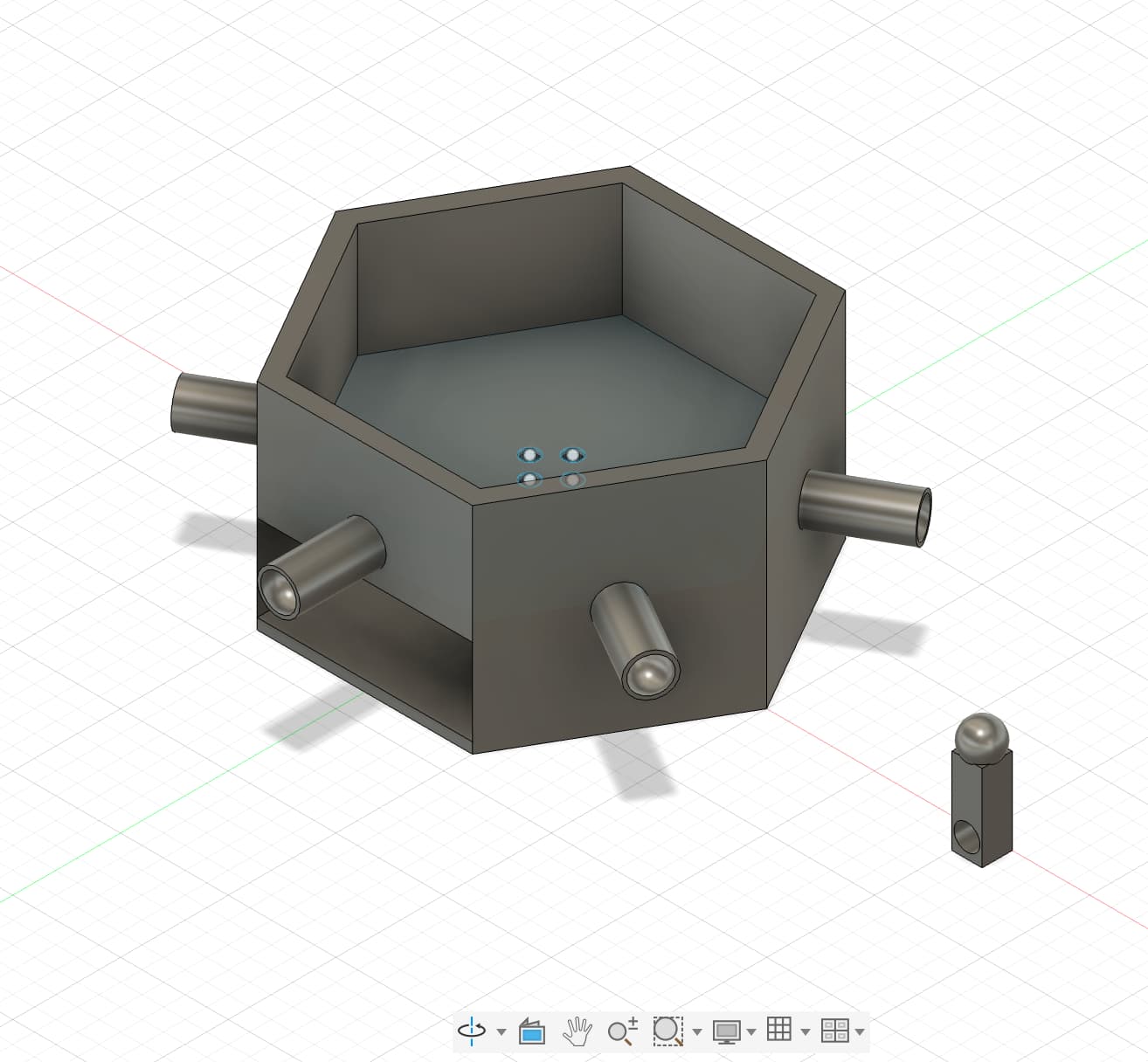

Later, I learned that the electrical team wants to design their PCB in a hexagonal shape. Thus, I changed the base chape to a hexagon. I also changed the joint mechanism to ball and socket joint to make the arm more flexible.

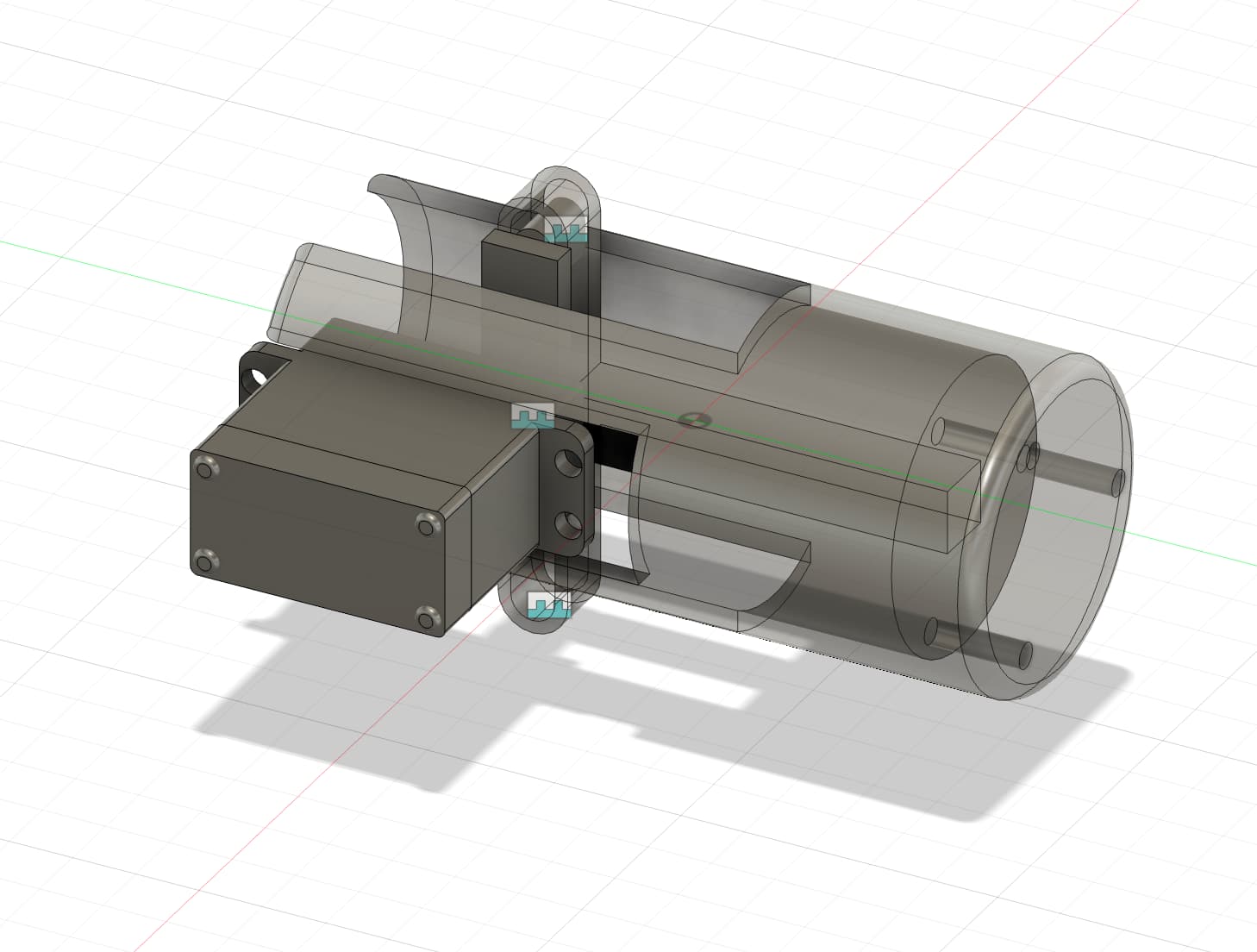

On Sunday night, the team was debating on the mechanism used to push the face out. The previous mechanism that Jessica was working on had issue pushing the face out and wasn't consistent enough. I found the scotch yoke mechanism and created a demo in Fusion 360 to propose to my team.

Upon revisiting this idea, the slider yoke could be long and hard to fit inside the compact icosahedron. Our team also went ahead with a more stable and consistent design of gear driven movements.

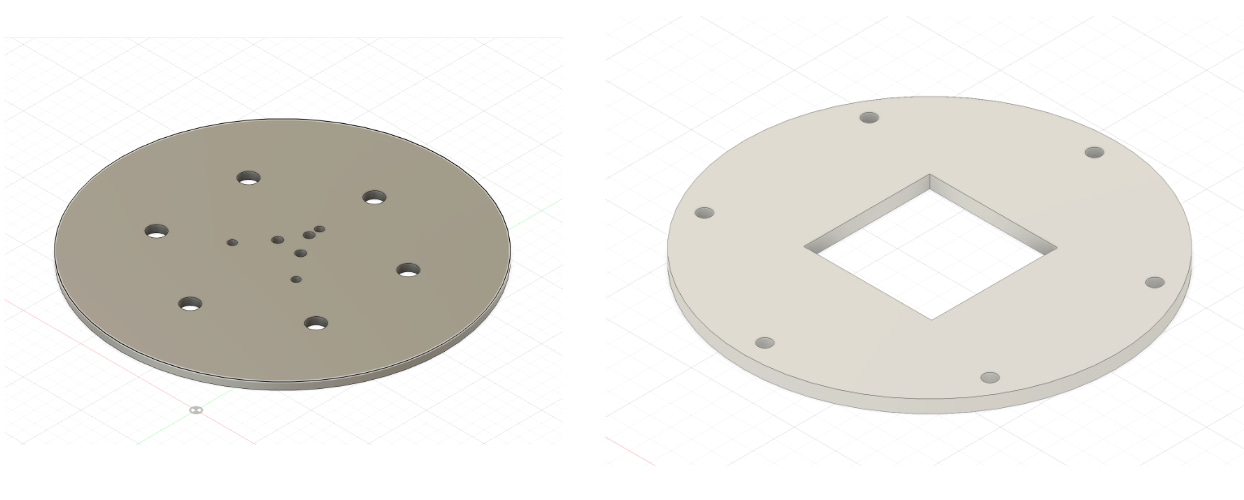

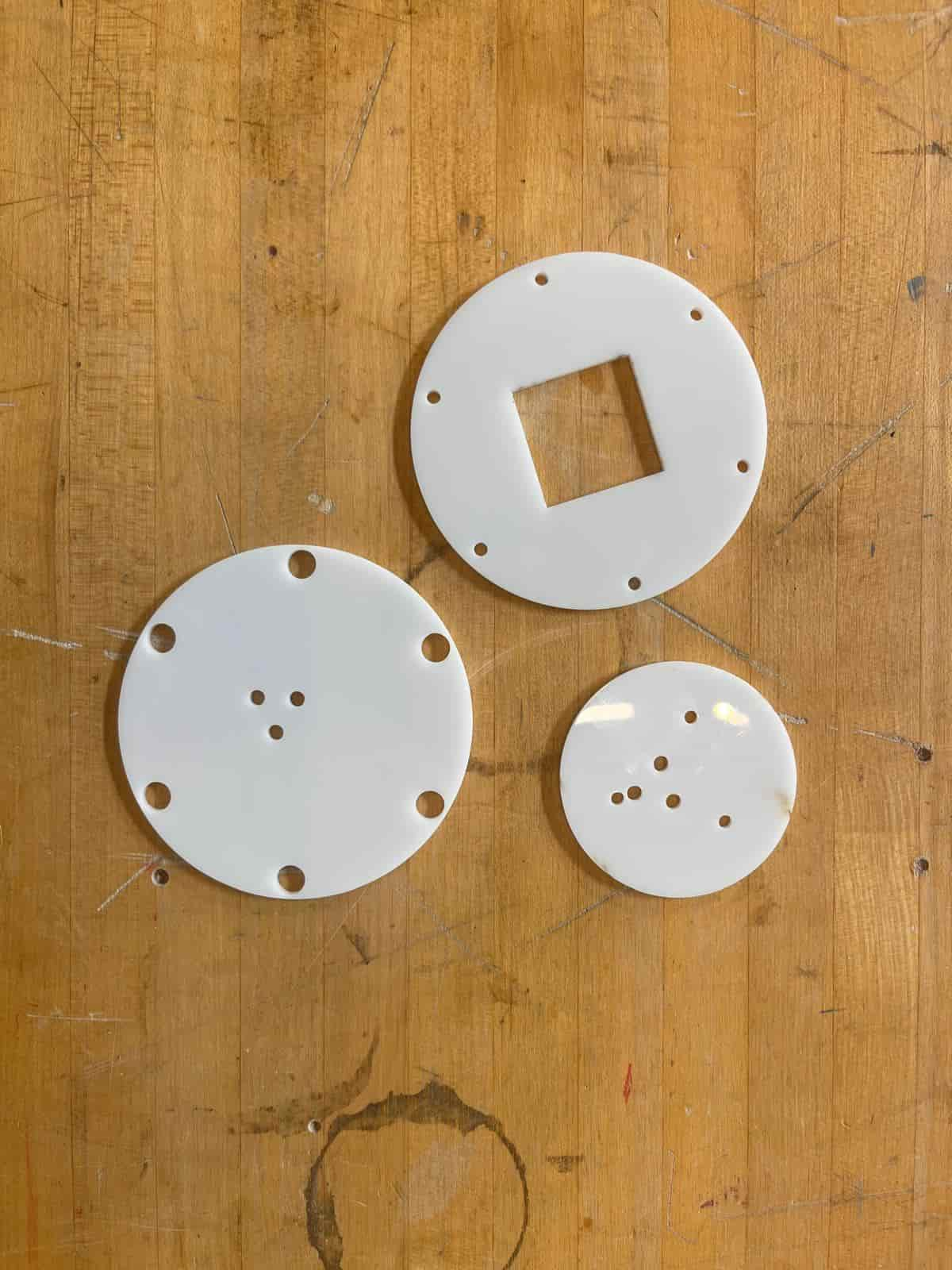

With the new gear movements designed by Ben and Abby, we need to build adaptor plates for it to have identical screw hole placements as the faces have already been designed and produced. I volunteered to help with the design

I also laser cut my design with acrylics to have physical copies for Ben to see the fit with their 3D printed parts.

While none of my work made it into the final version of the robot, I still felt that I was helping and providing ideas to my team through my design in Fusion 360.

Helping the team

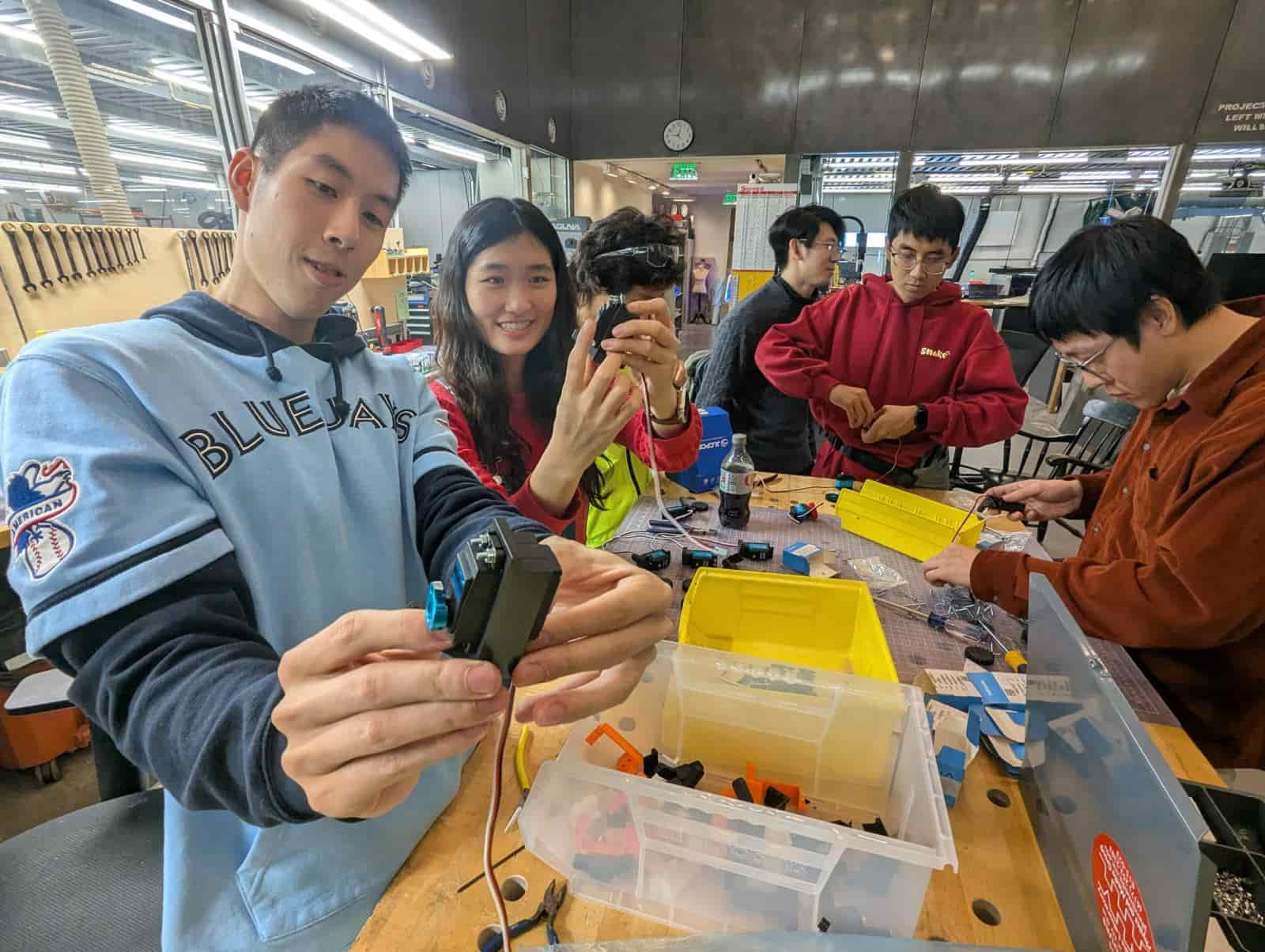

Then, it was time to help the team with anything needed.

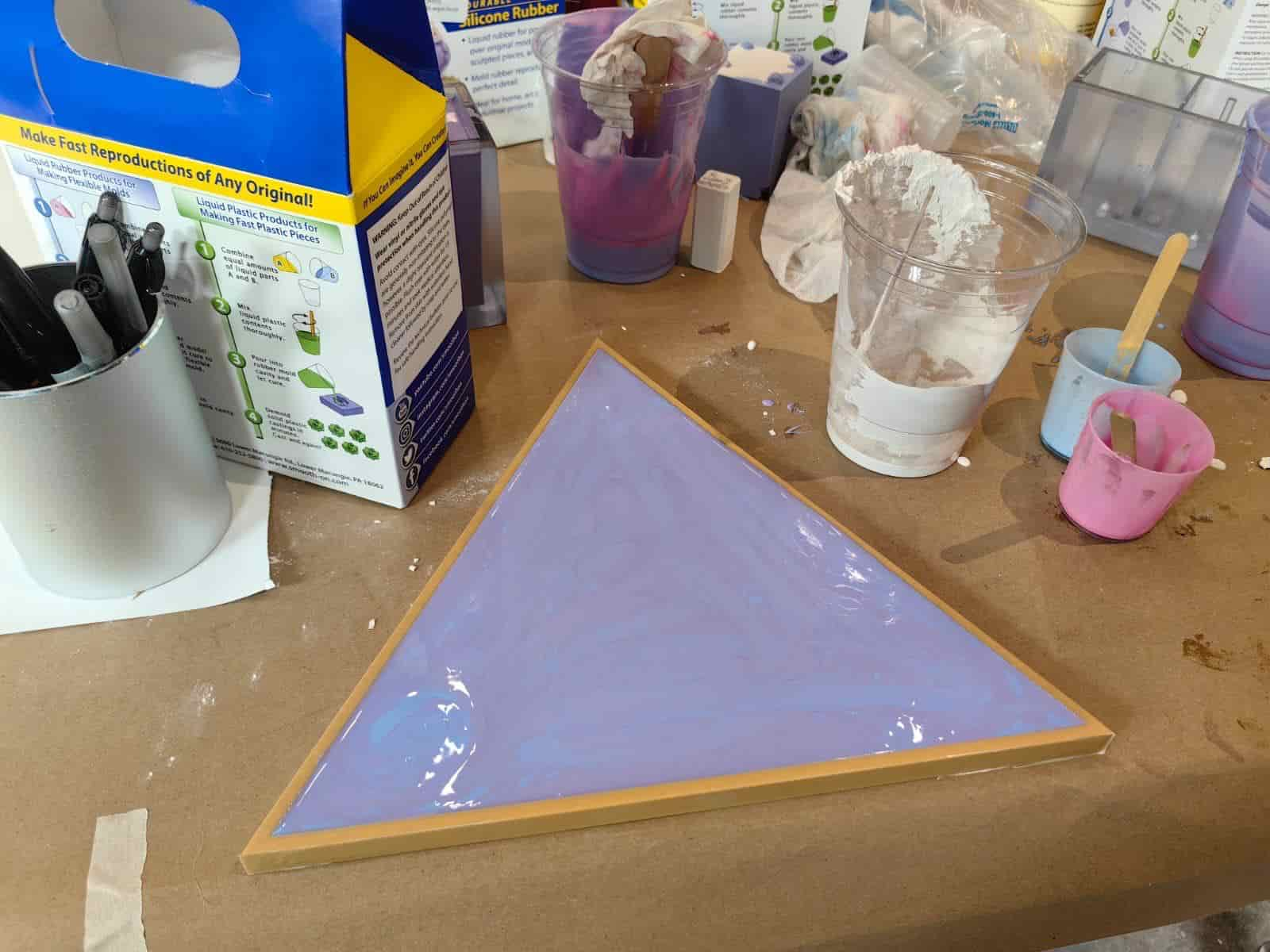

Huanyu designed the molding and casting, but casting 20 faces is tiring and time-consuming. Since he had to get some sleep, I helped with casting 9 faces, each taking approximately half an hour.

I also helped with taking off the support from 3D printed parts.

Then, I worked on drilling the center holes on all 20 outer plates, which would allow us to use screws to connect the outer plate to inner plate.

I helped with adding in the screws to its screwholder.

Lastly, I helped closely with assembling the parts for the final icosaheron.

Reflection

Something I learned is that working in a large team is challenging because of the different scheduling and coordination between different people. In this regard, thanks to the people taking charge in developing the core features and leading the communication amongst teams.

Some of the failures I encountered was that I designed versions of PCB mount and servo-piston system that didn't get applied in our final version, which I think is completely fine. I learned a lot about using Fusion to create more complex designs. I also believe my design contributed more perspectives for the team and could work.

Resources and Acknowledgements

Tools used:

- Fusion 360