# Week 6

## Electronics Production

### Group Assignment

> characterize the design rules for your in-house PCB production process

The ideal is to not have any traces that are below 0.02 of an inch.

From recitation last week, Quentin said to have 0.4 mm or 1/16th of an inch minimum, so I went with that for the board design last week.

As we can see from the test made by [Ayah Mahmoud](https://fab.cba.mit.edu/classes/863.25/people/AyahMahmoud/), the machine cannot create gaps between traces for anything below 0.02 inches. Note that it can still machine traces individually until about 0.01 inches of thickness.

|  |

|:---------:|

| *Closeup of precision test made by Ayah* |

> submit a PCB design to a board house

### Individual Assignment

> Make and test an embedded microcontroller system that you designed

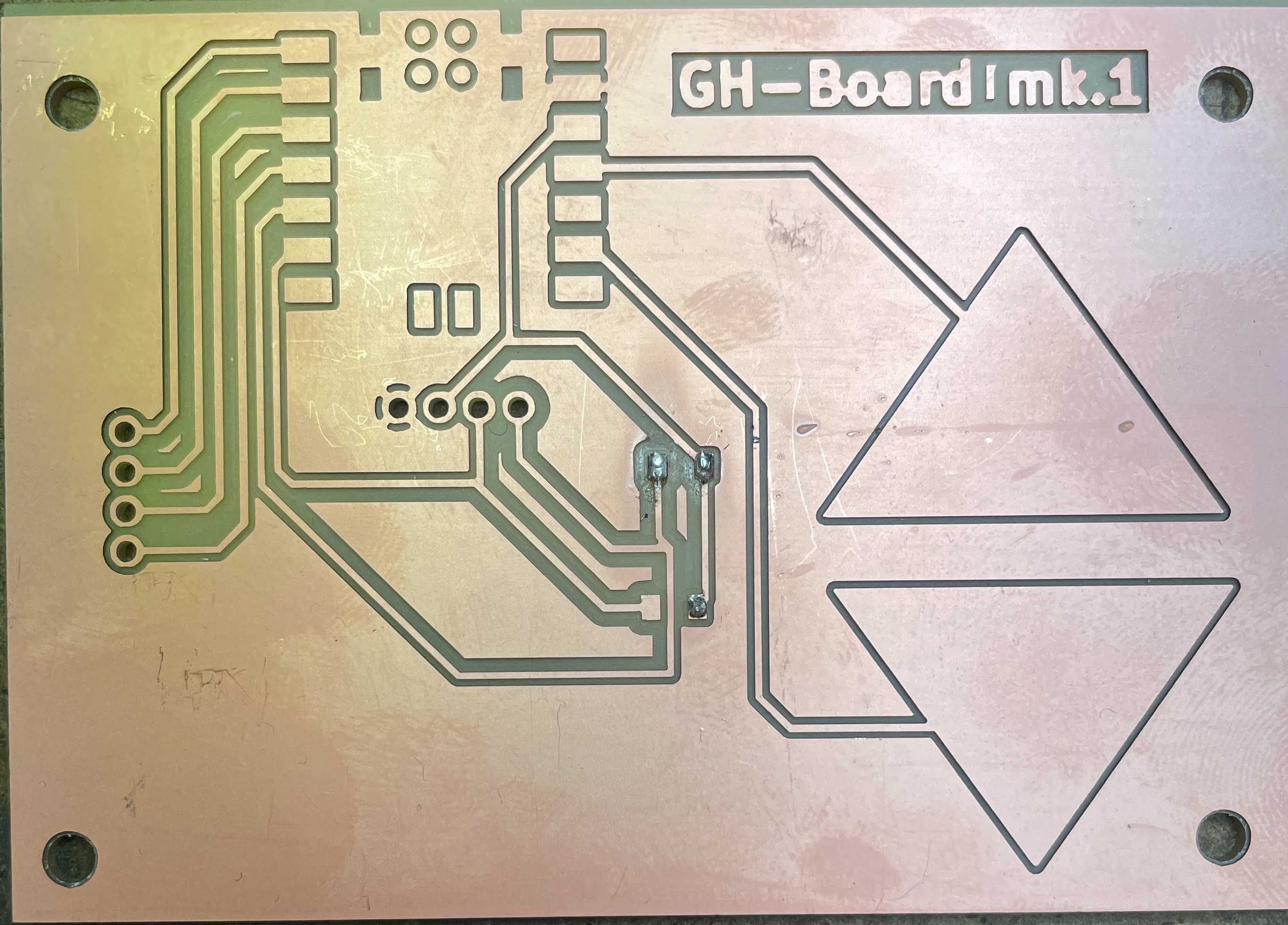

I used the Modela SRM-20 to mill my PCB. Gert kindly helped me get set up, and I followed the [archshops tutorial](https://archshops.mit.edu/modela.php) to use the machine which is comprehensive.

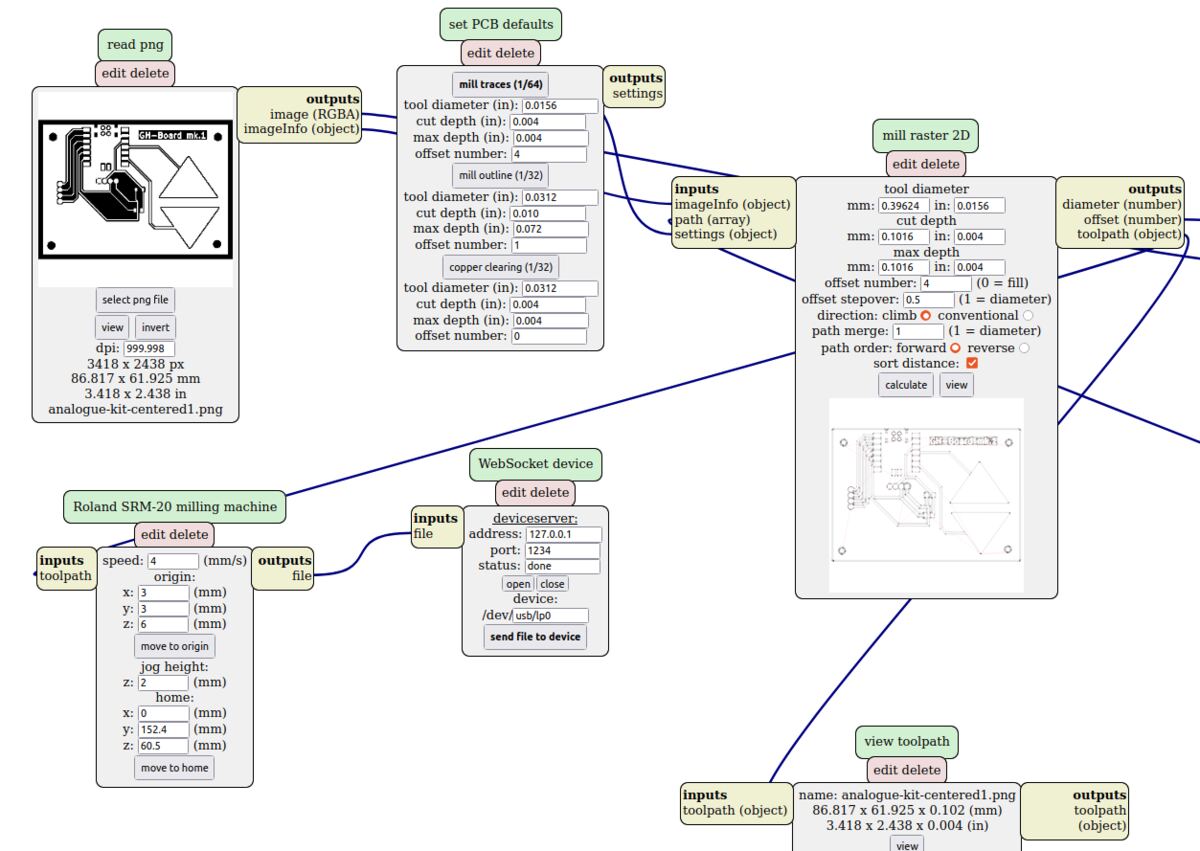

|  |  |

|:---------:|:---------:|

| *Setting up the trace cut file in mods* | *Inspecting the toolpath* |

|  |  |  |

|:---------:|:---------:|:---------:|

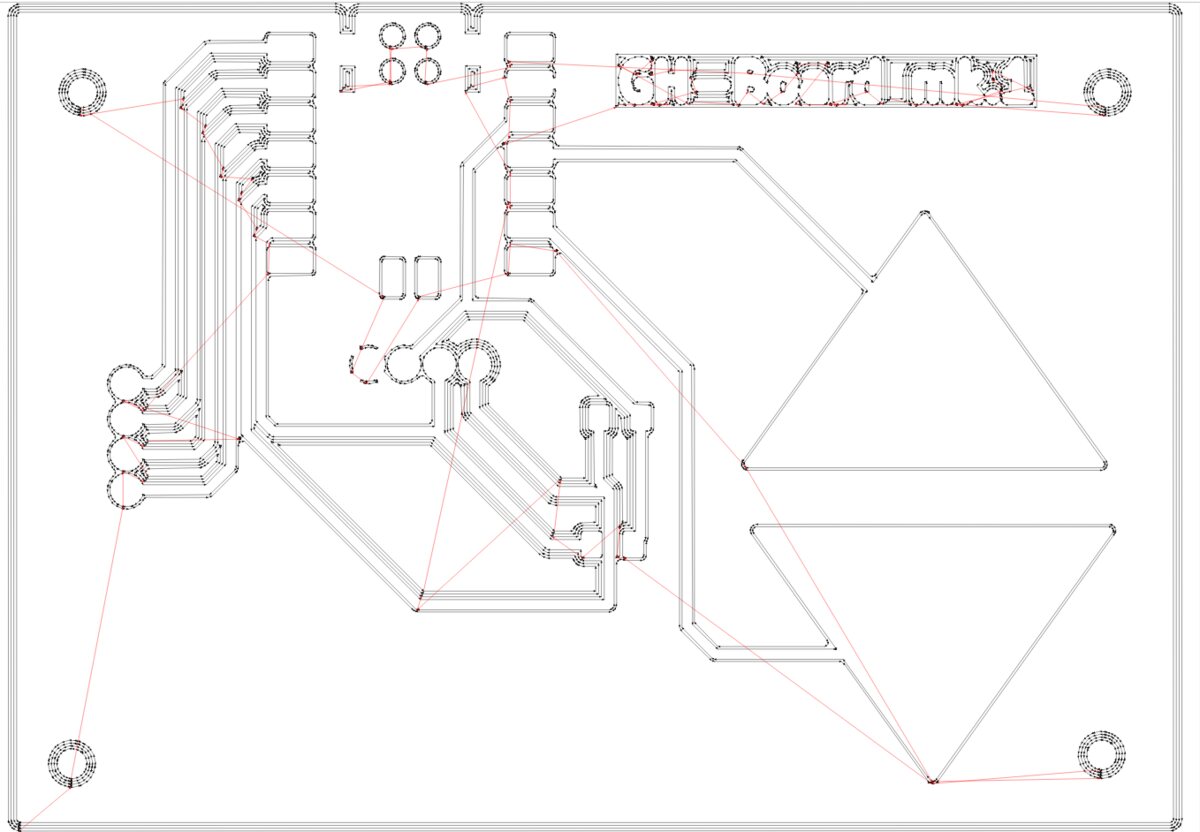

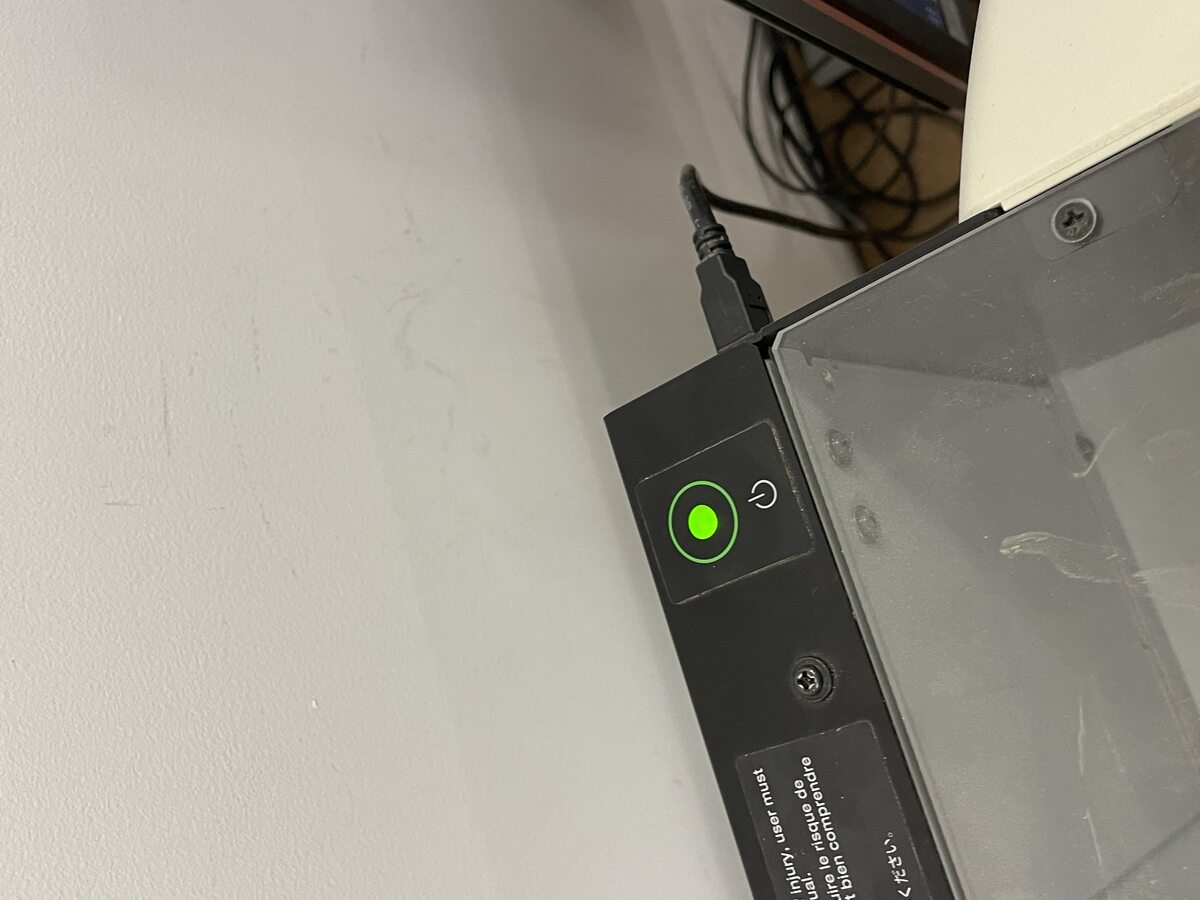

| *Turn the machine on and off by pressing this button if the door is opened when running a command, It will have a blinking light and not want to continue.* | *Press the bit gently down into the board and tighten the hex at the top to set it to the right height* | *This is what the bit should look like to start milling* |

|  |  |

|:---------:|:---------:|

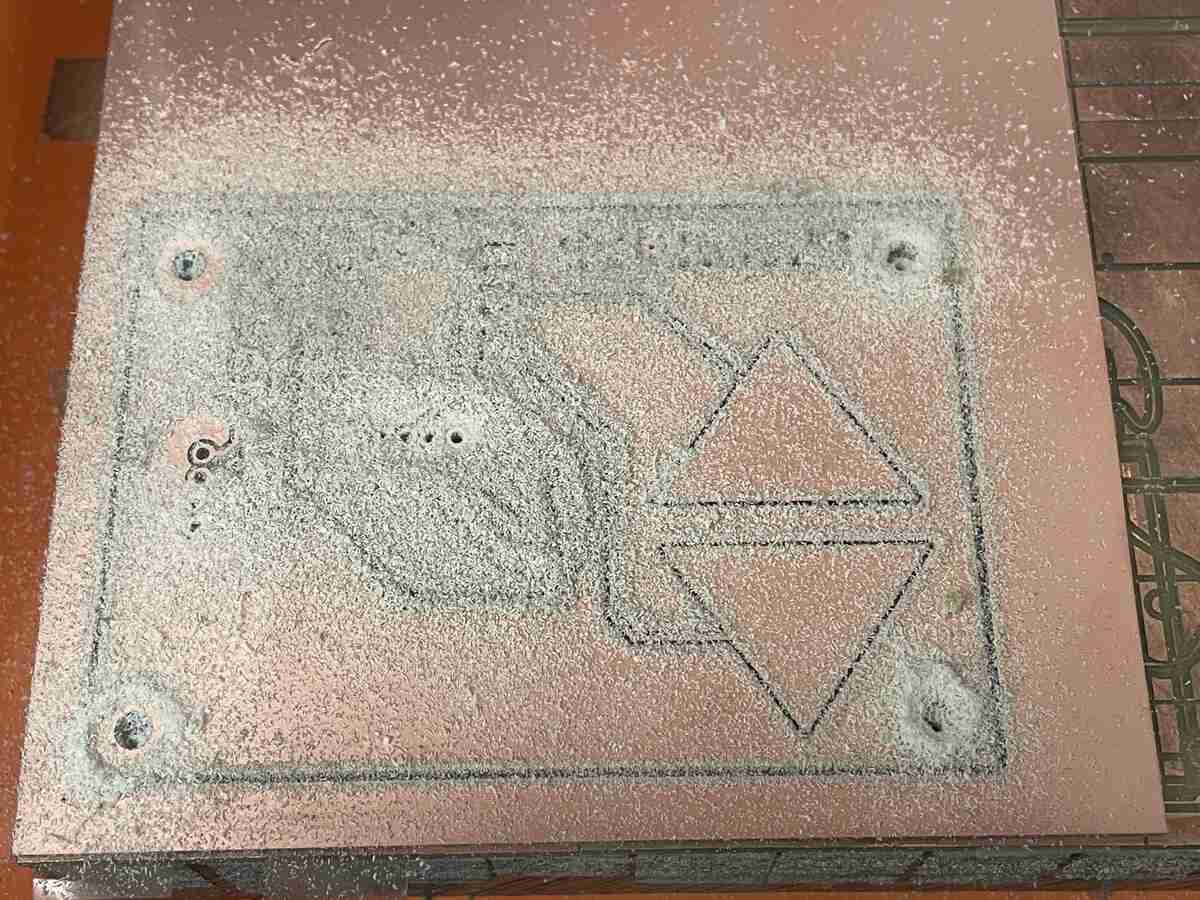

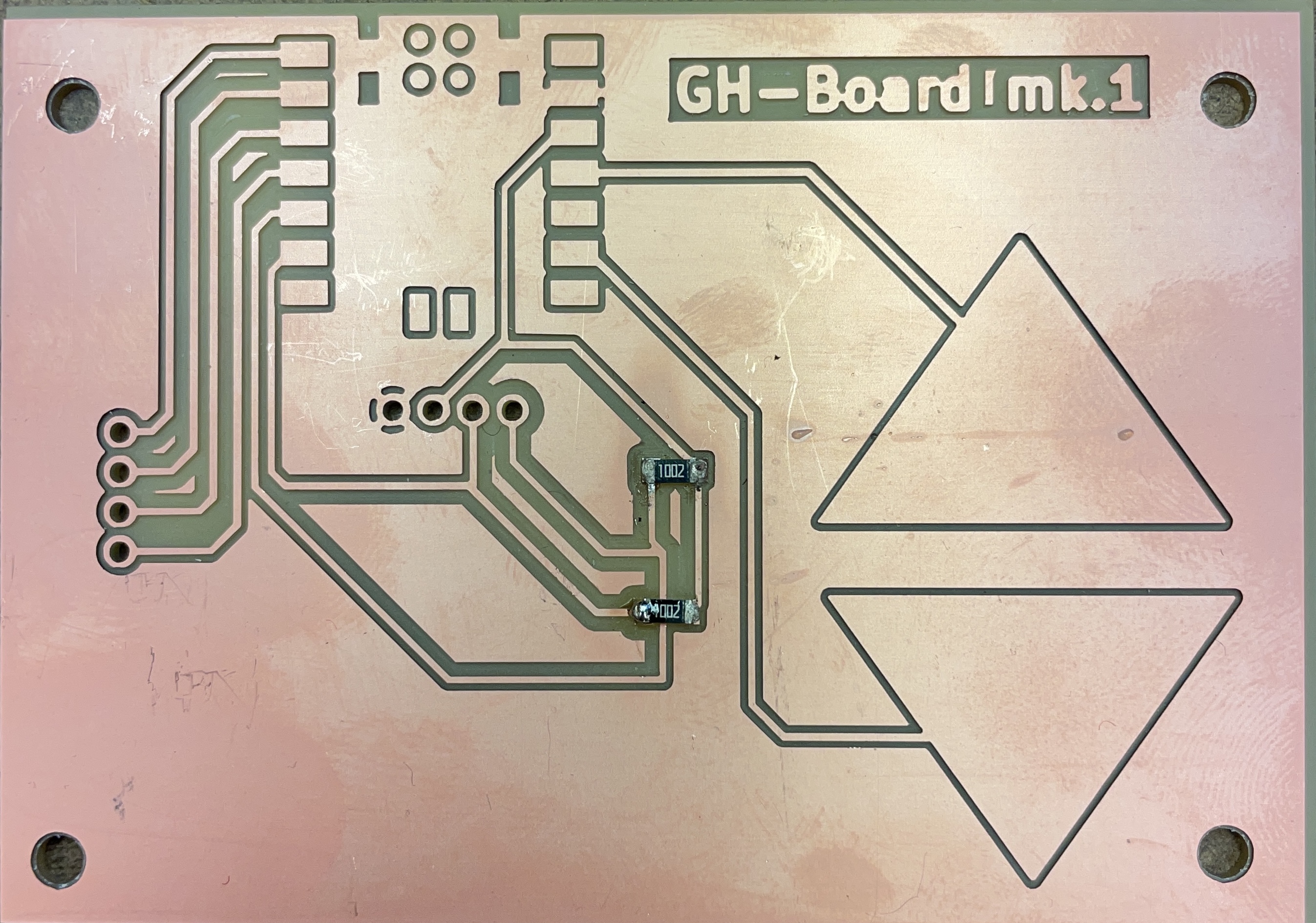

| *Right amount of "chipping" residue means things are running smoothly.* | *The completed board with the holes and outline cut.* |

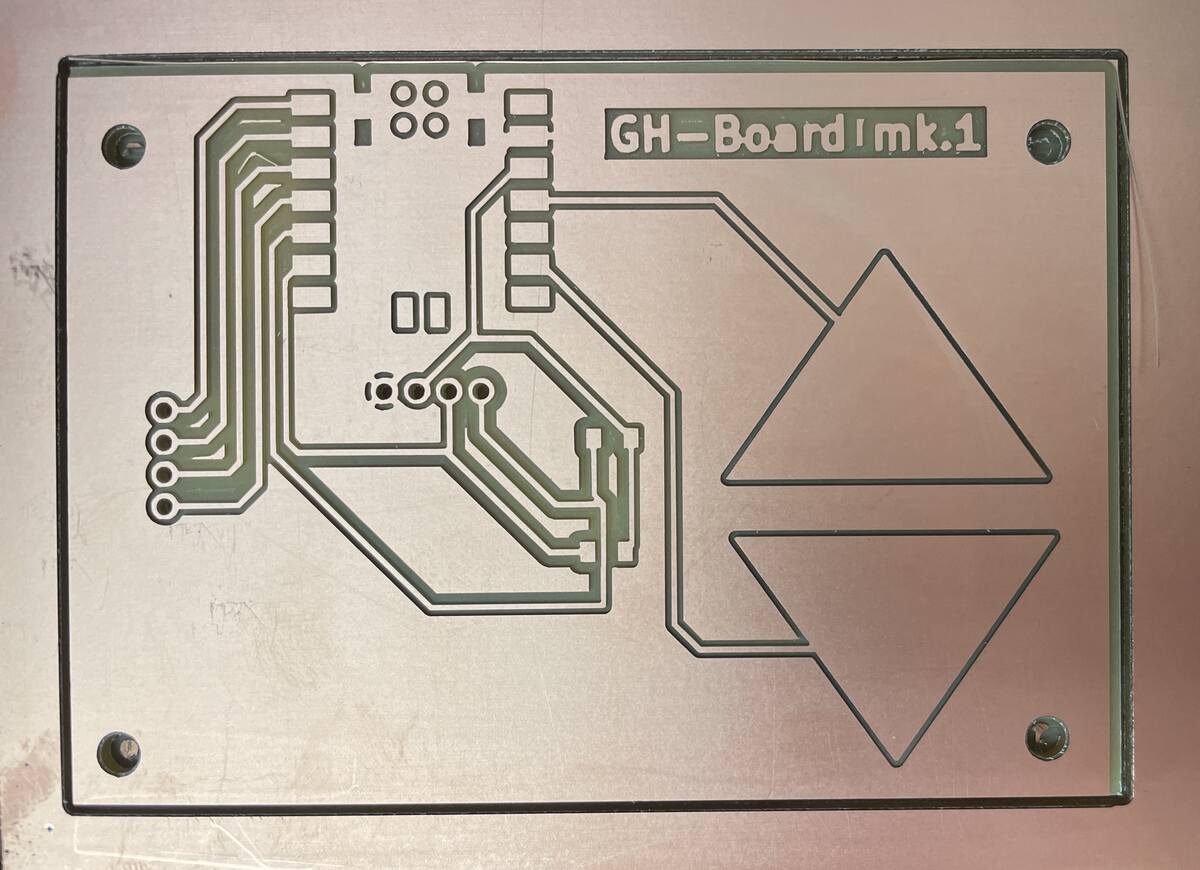

I found that the board did not need any scraping or finishing, but did that there was a bit of copper that needed to be removed between traces at the top right.

|  |

|:---------:|

| *The milled board right out of the machine* |

|  |

|:---------:|

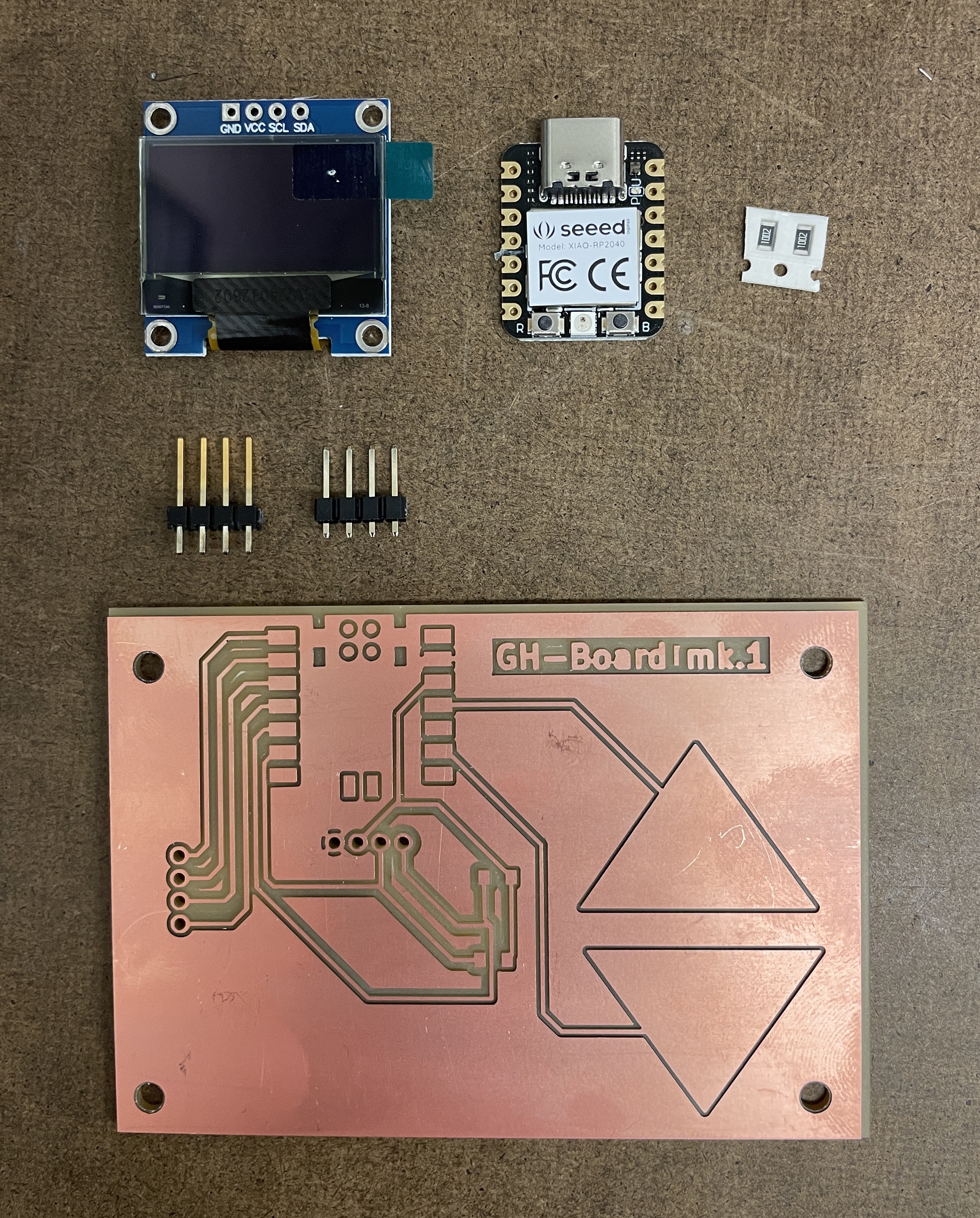

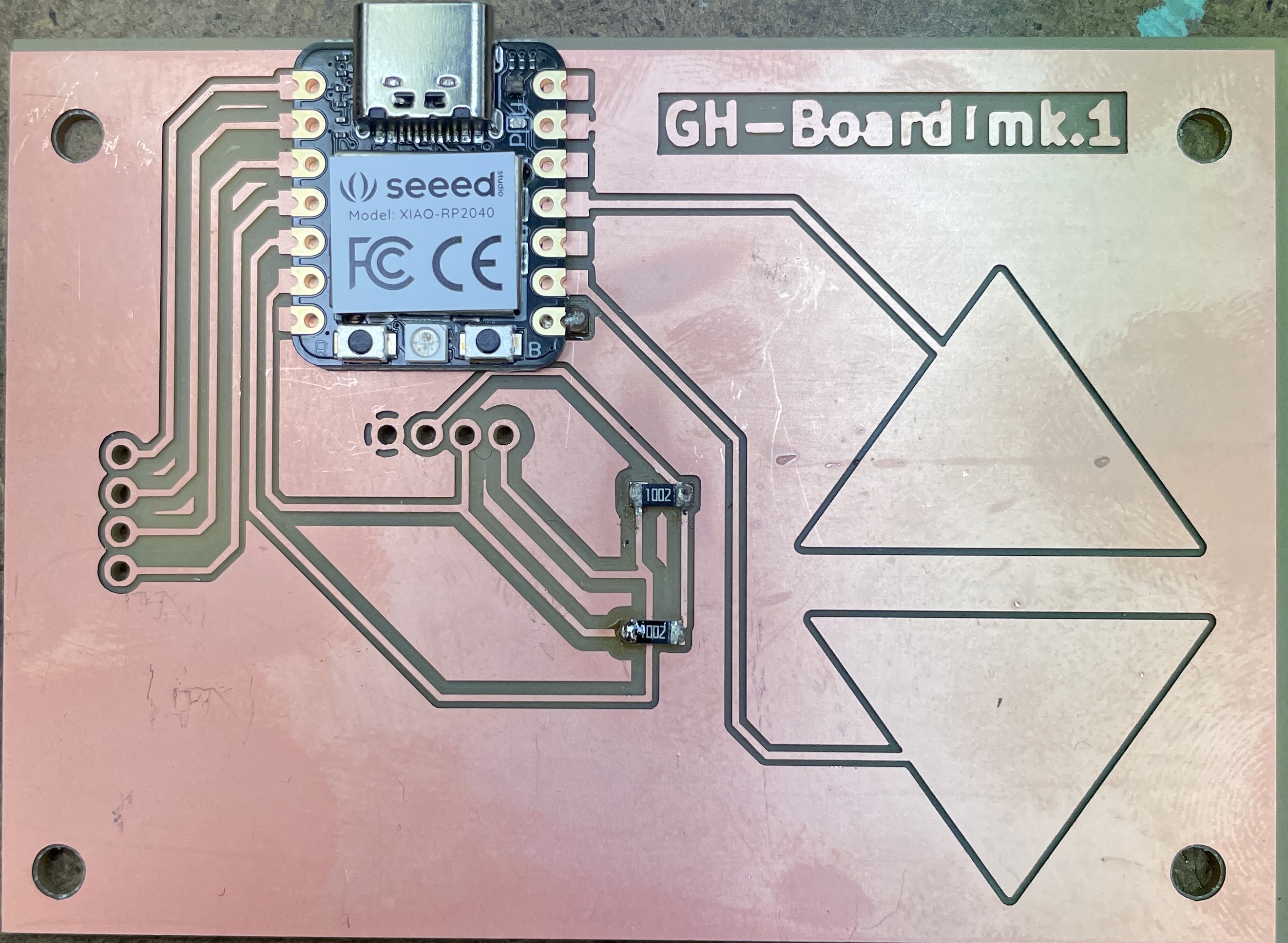

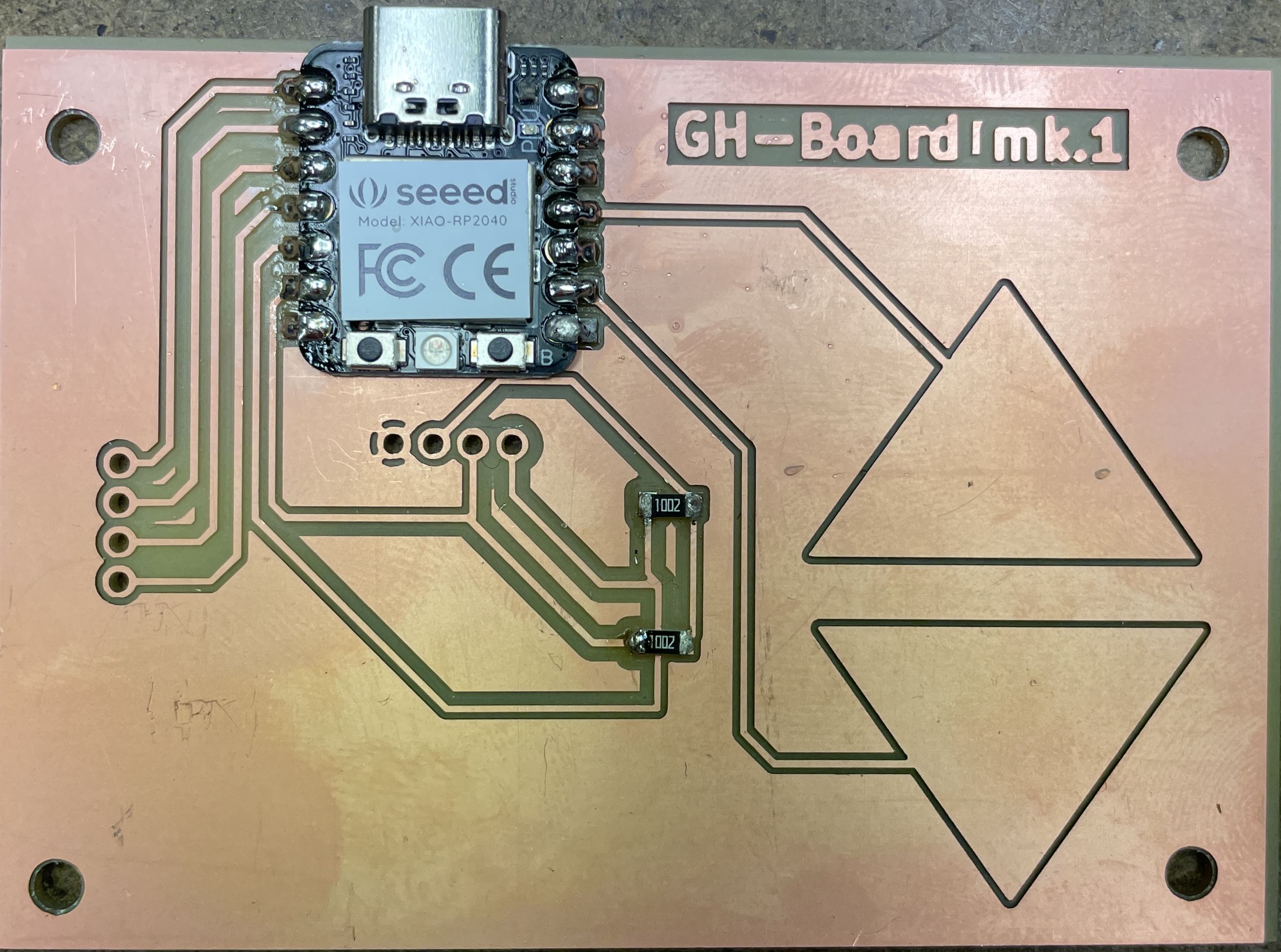

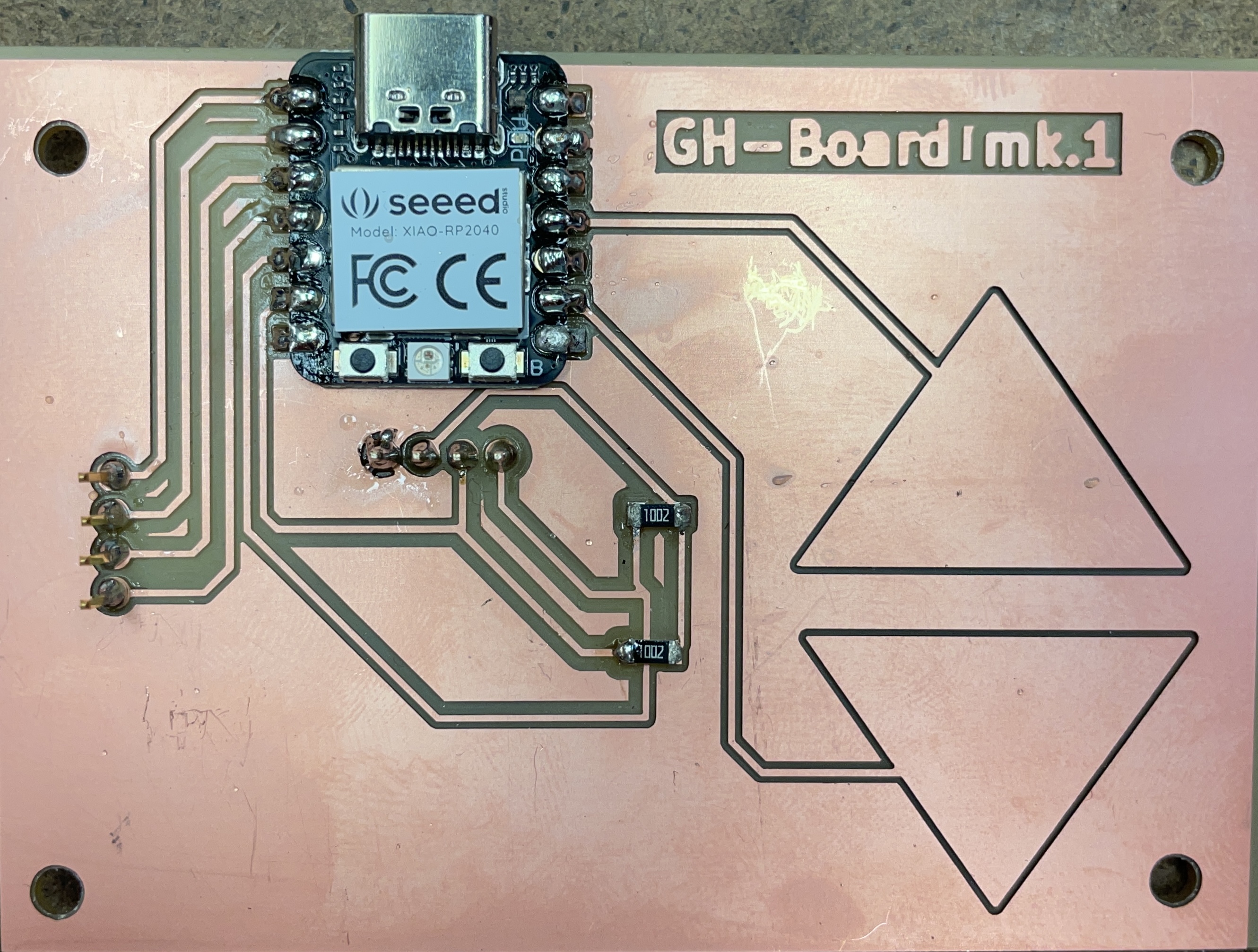

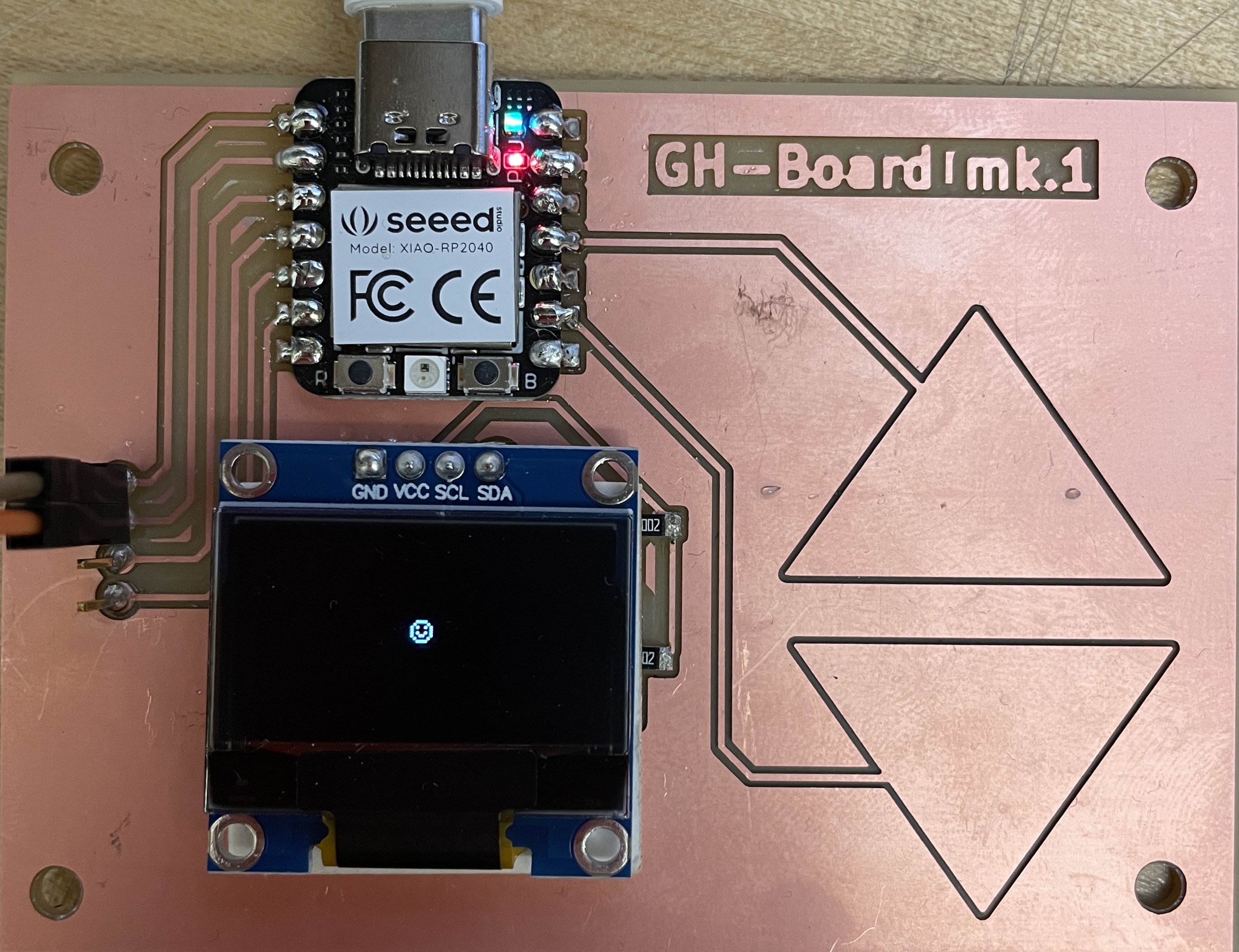

| *The board with all the components* |

The components I used include:

- two 10k resistors

- Seeed Xiao Breakout Board with RP2040 processor

- [B09JWN8K99 0.96 Inch OLED Module 12864](https://www.amazon.com/Self-Luminous-Display-Compatible-Arduino-Raspberry/dp/B09JWN8K99/?th=1)

- two breakout pin connectors, of 4 pins each

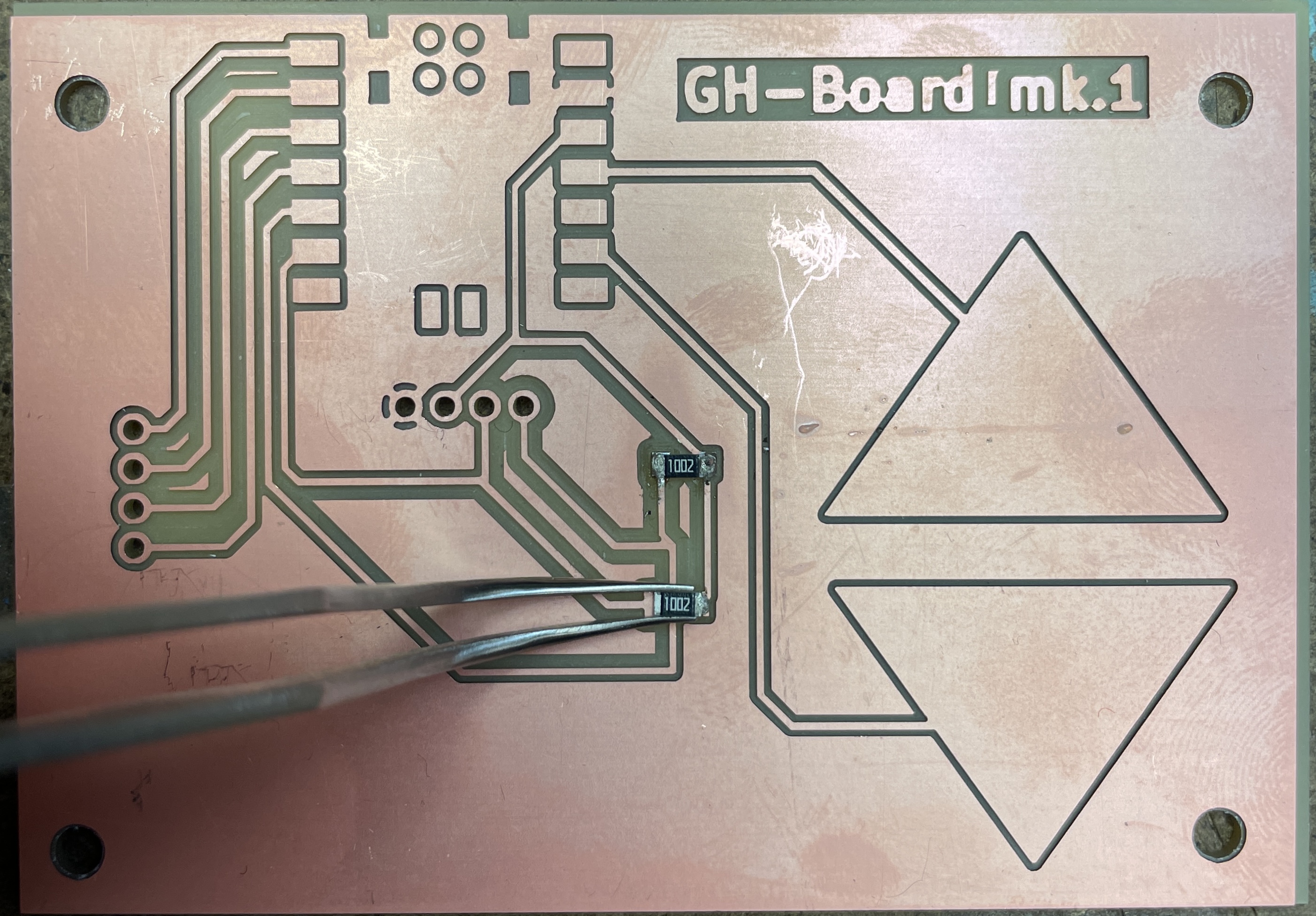

Here is the process of soldering it:

|  |  |  |

|:---------:|:---------:|:---------:|

| *Tinning the contacts for the resistors, best to do just one side* | *Placing the resistor down with tweezers and soldering one side* | *Soldering the other side* |

|  |  |  |

|:---------:|:---------:|:---------:|

| *Placing the XIAO down with just one pin* | *Soldering all the other pins* | *Adding the two physical breakout pins* |

|  |  |  |

|:---------:|:---------:|:---------:|

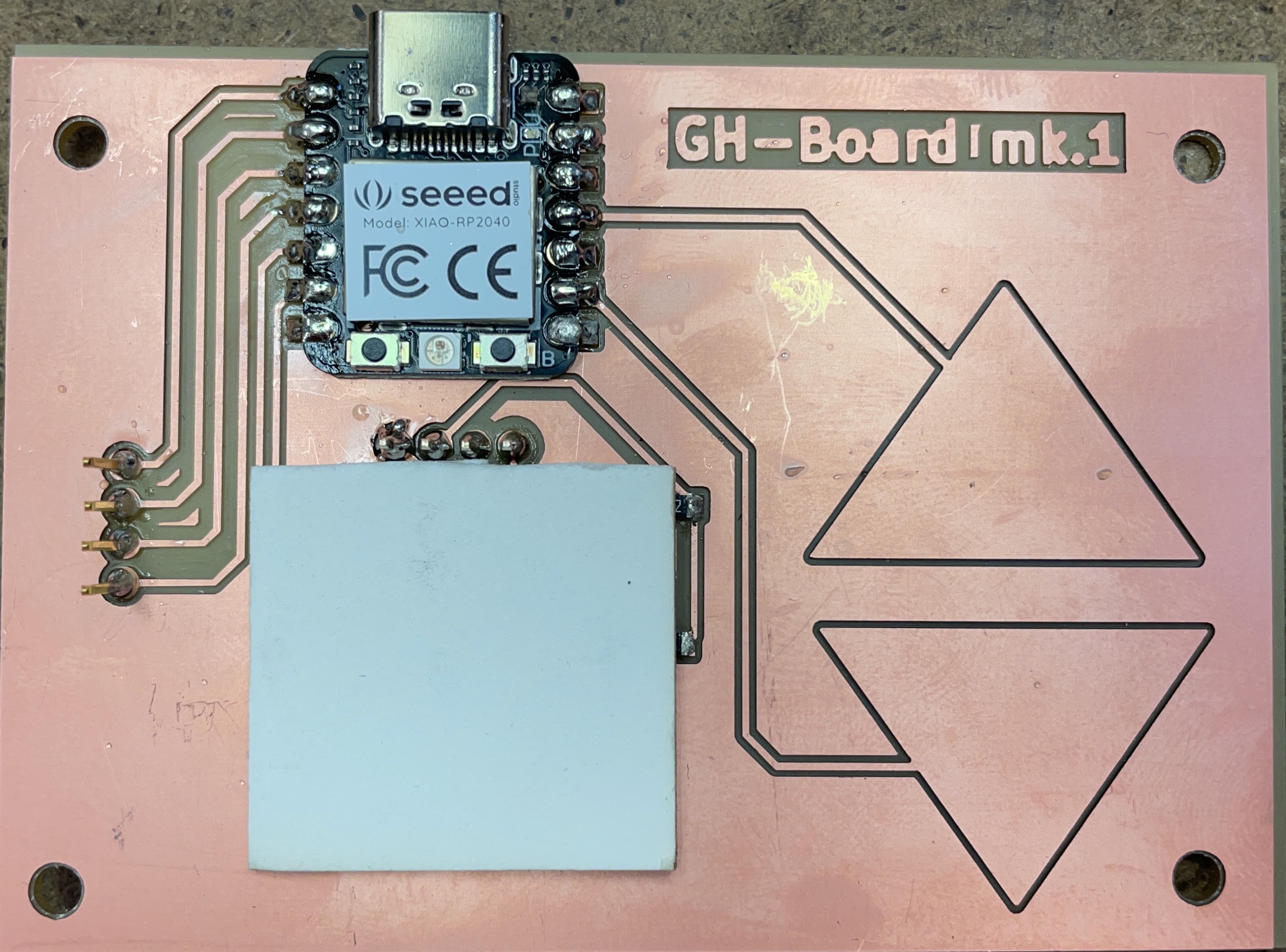

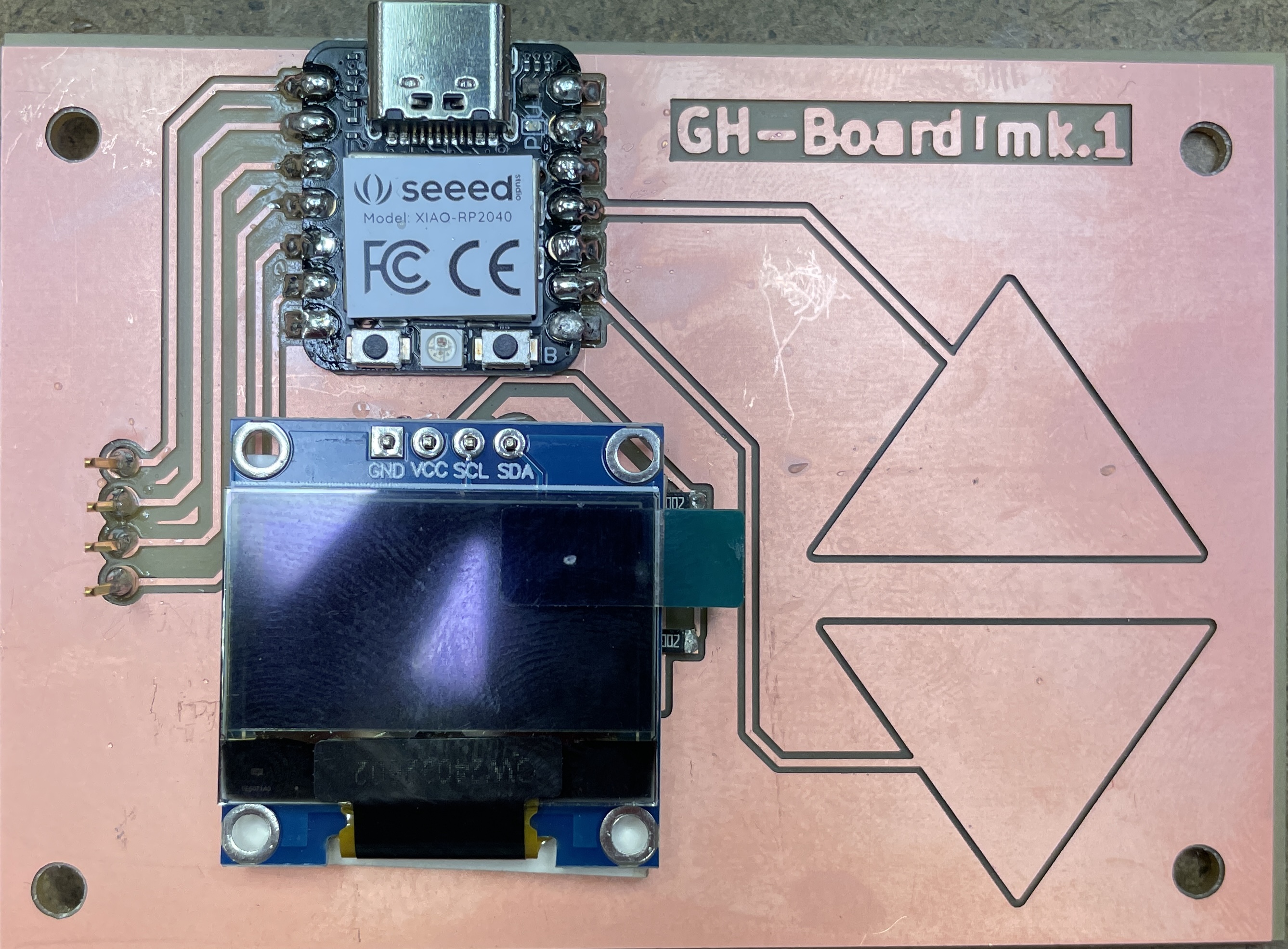

| *Adding a piece of cardstock to protect the screen from short circuits* | *Placing the screen down on the pins* | *Soldering the screen* |

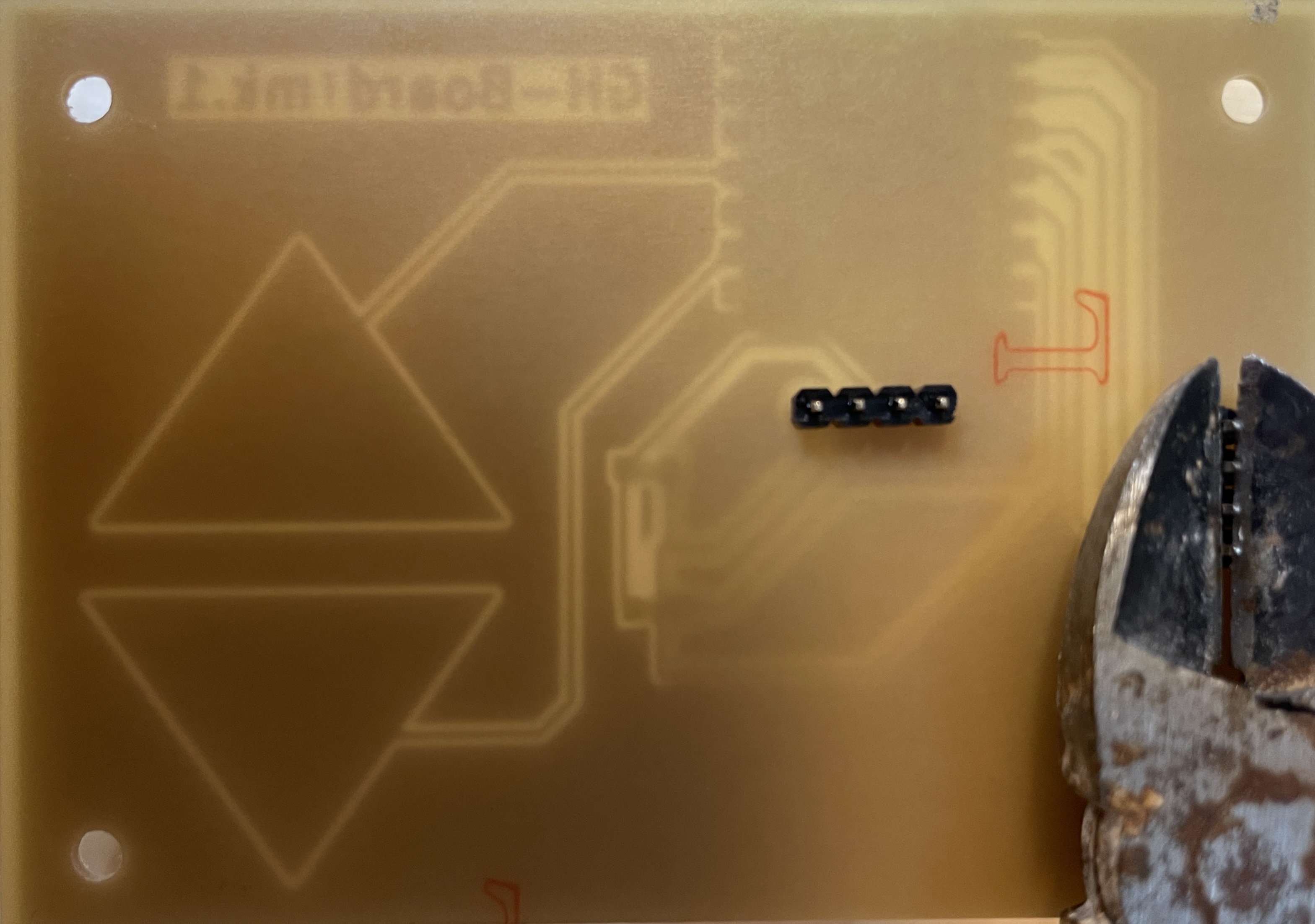

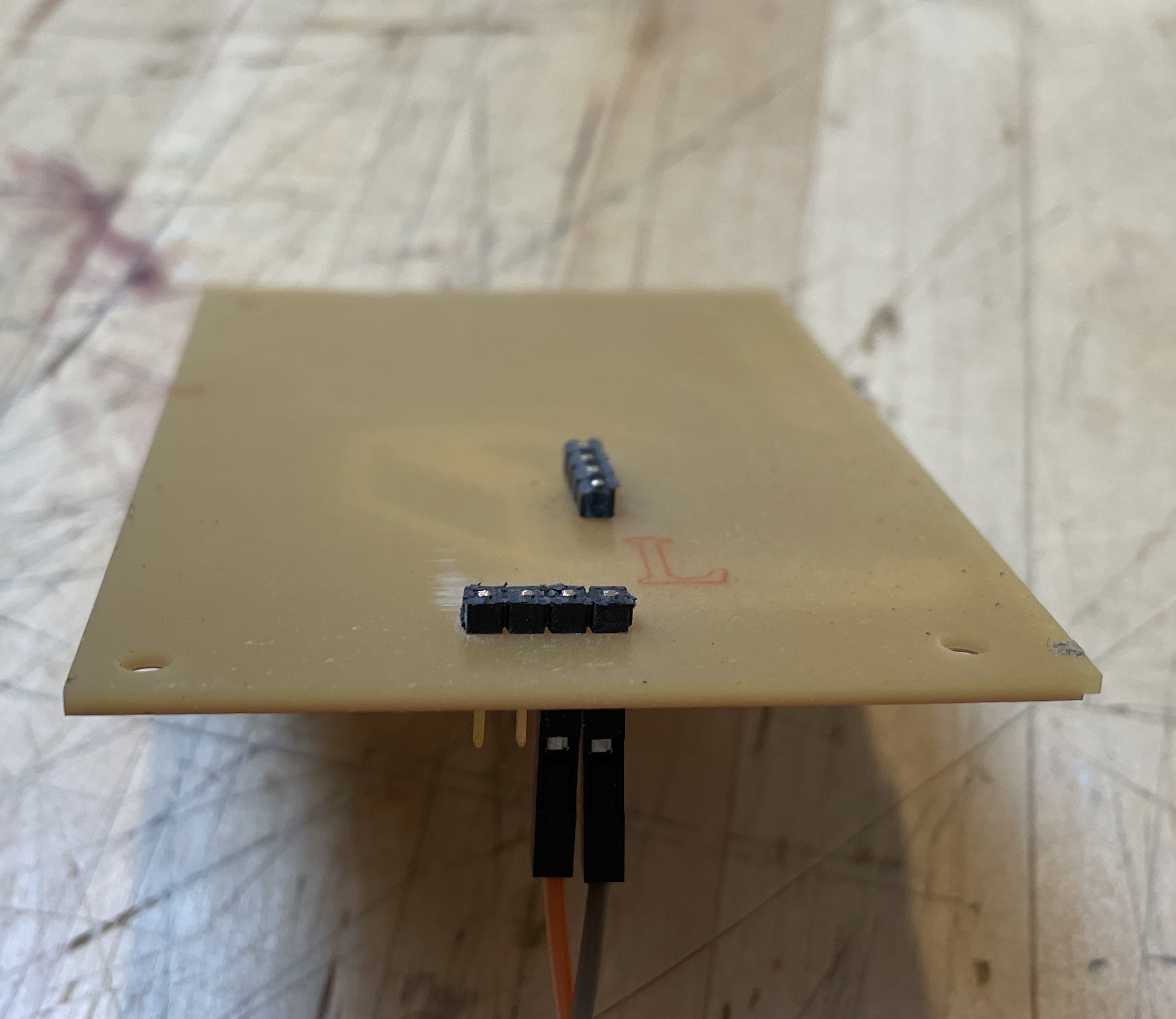

|  |  |

|:---------:|:---------:|

| *Snipping off the back of the pins with clippers* | *Filing down the back of the pins with a file* |

|  |

|:---------:|

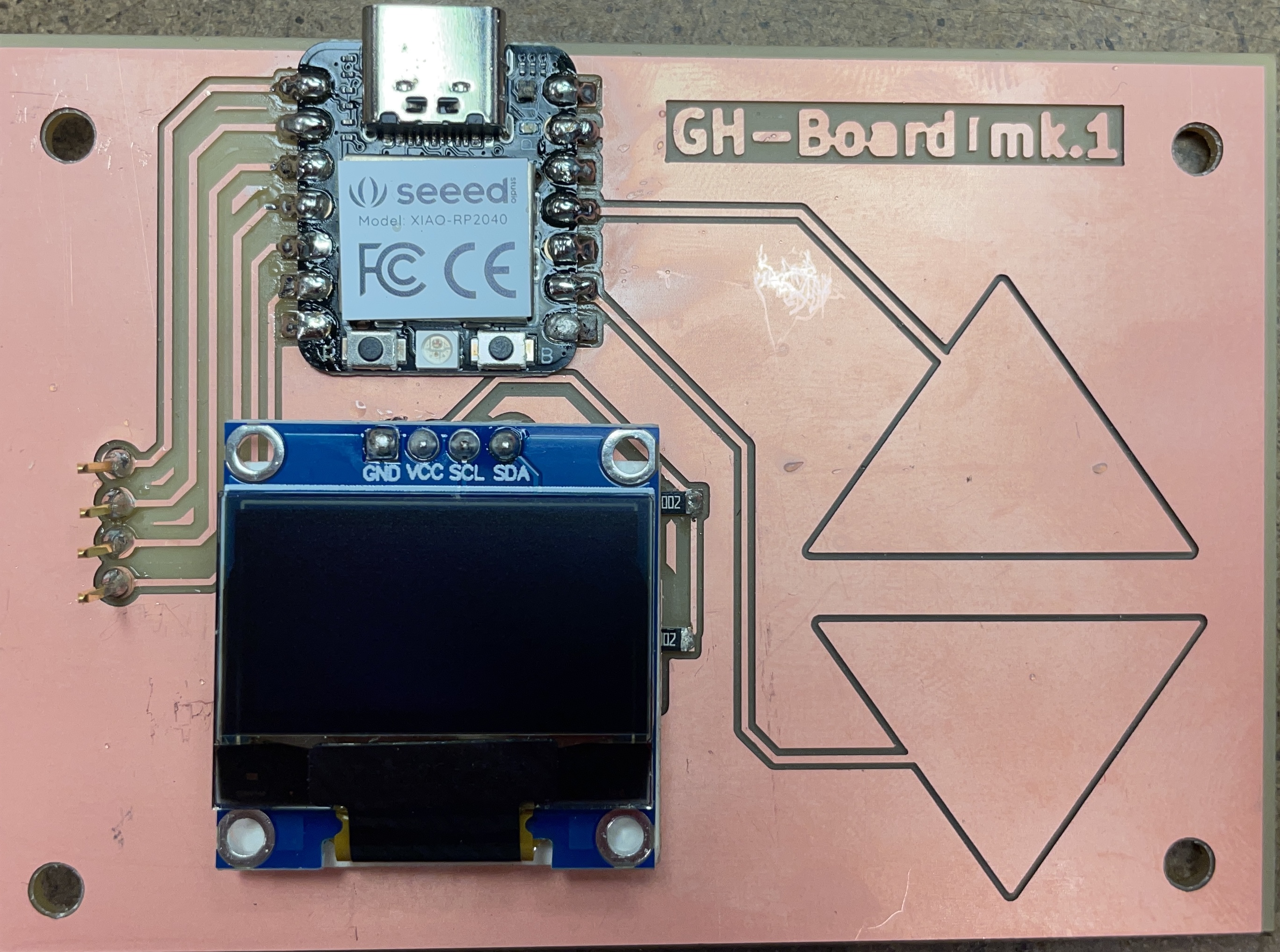

| *The completed board is up and running* |

> Extra credit: make it with another process

[link-title](https://fab.cba.mit.edu/classes/863.25/)

## Attachments

[attachment-1.ext](files/attachment-1.ext)

## Acknowledgments