Week Z

Final Proposal:

I plan to make lamps

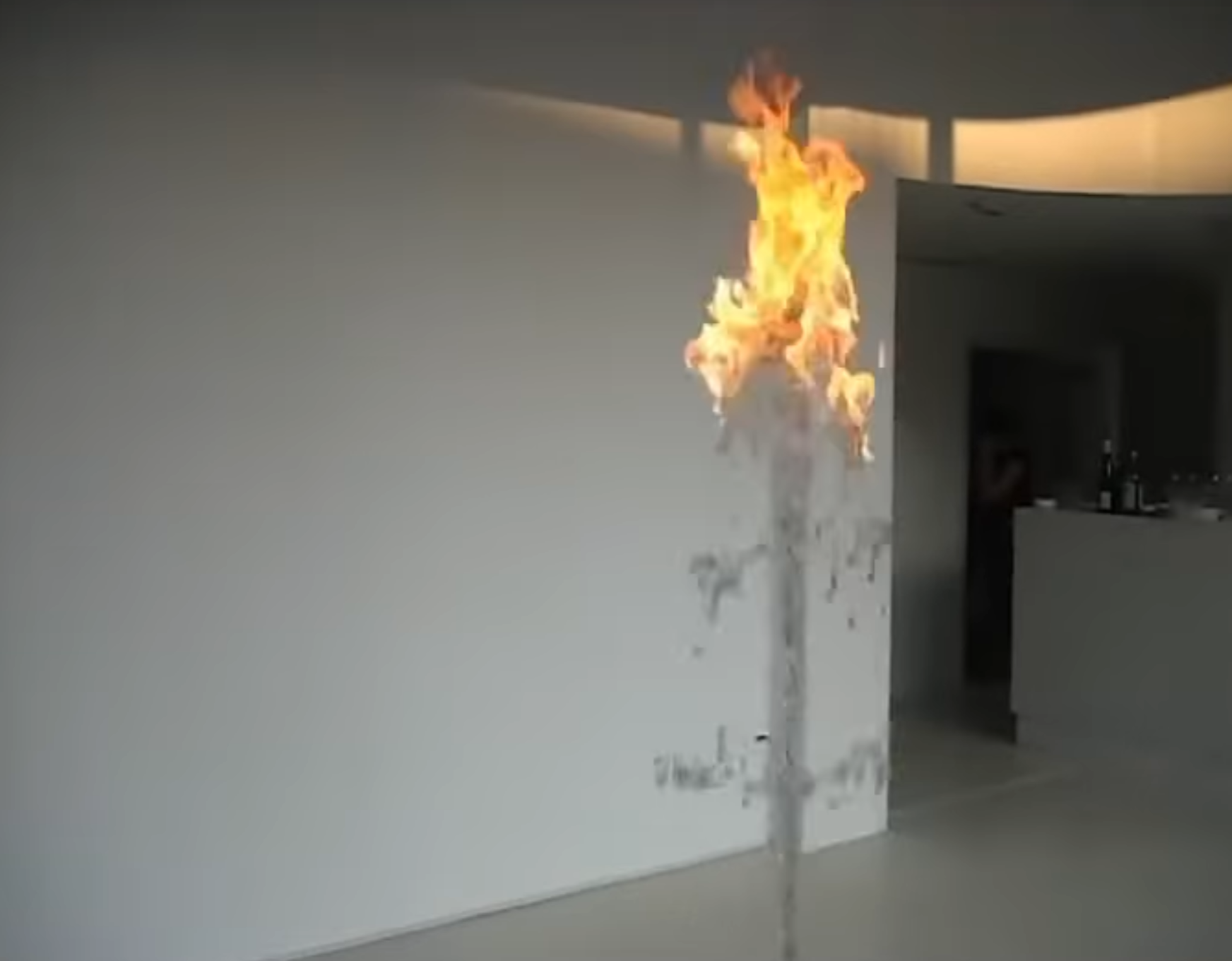

David Lynch made some lovely lamps during covid and I have been captured by the idea of being able to turn objects into fixtures. Its too simple for the scope of the class but I expect there to be oppotrunities for high tech in some capacity, afterall the lynchian surreal is some intertwining of the crude and timeless with the sophisticated and fragile. Lets see how we can channel it and get weird and well-lit.

Gold Leaf Lamp Concept

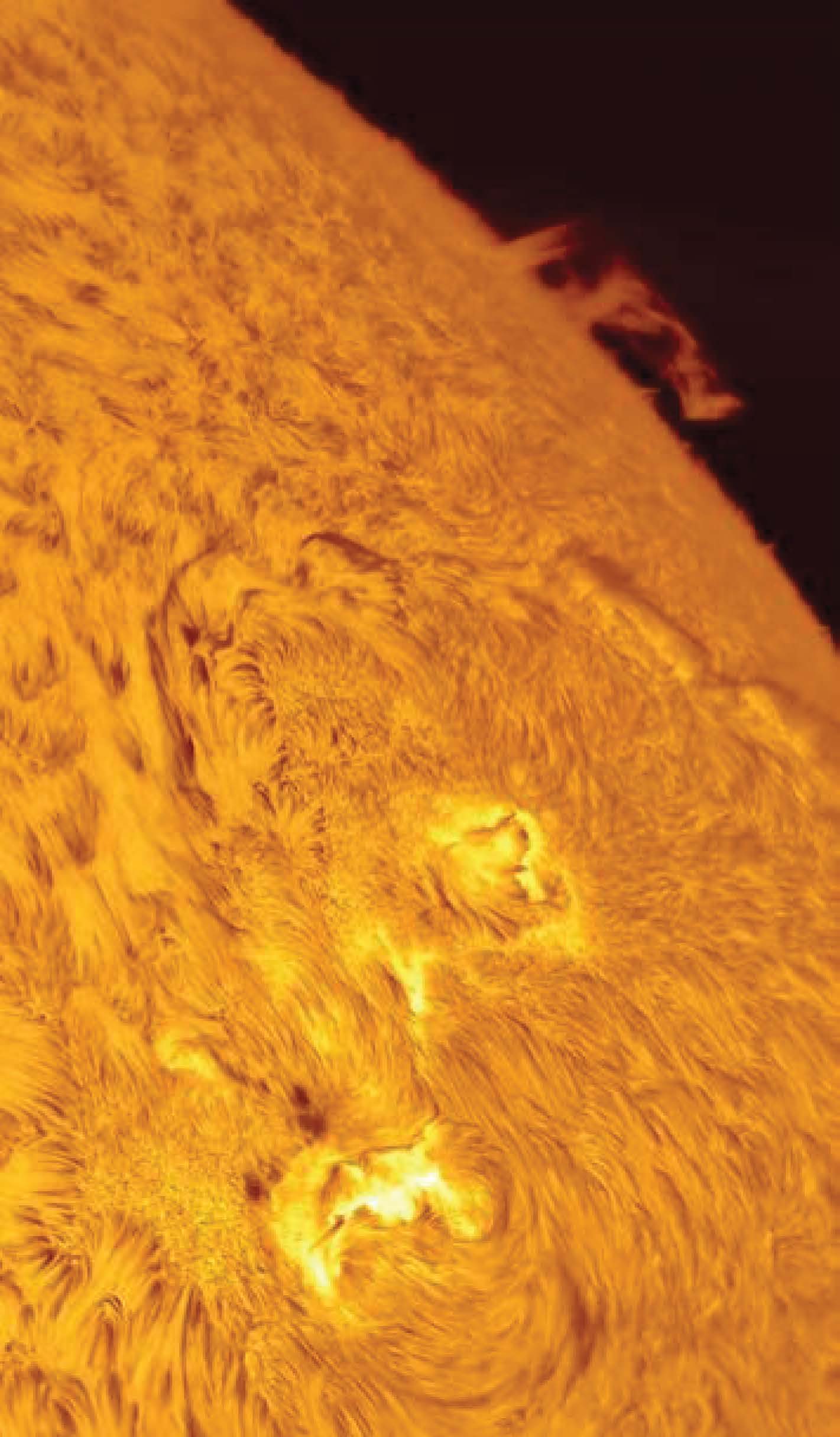

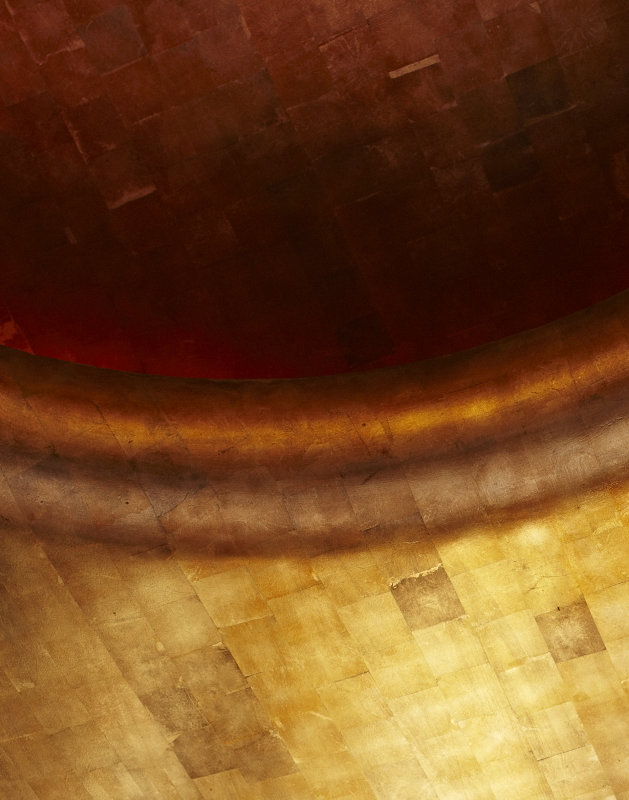

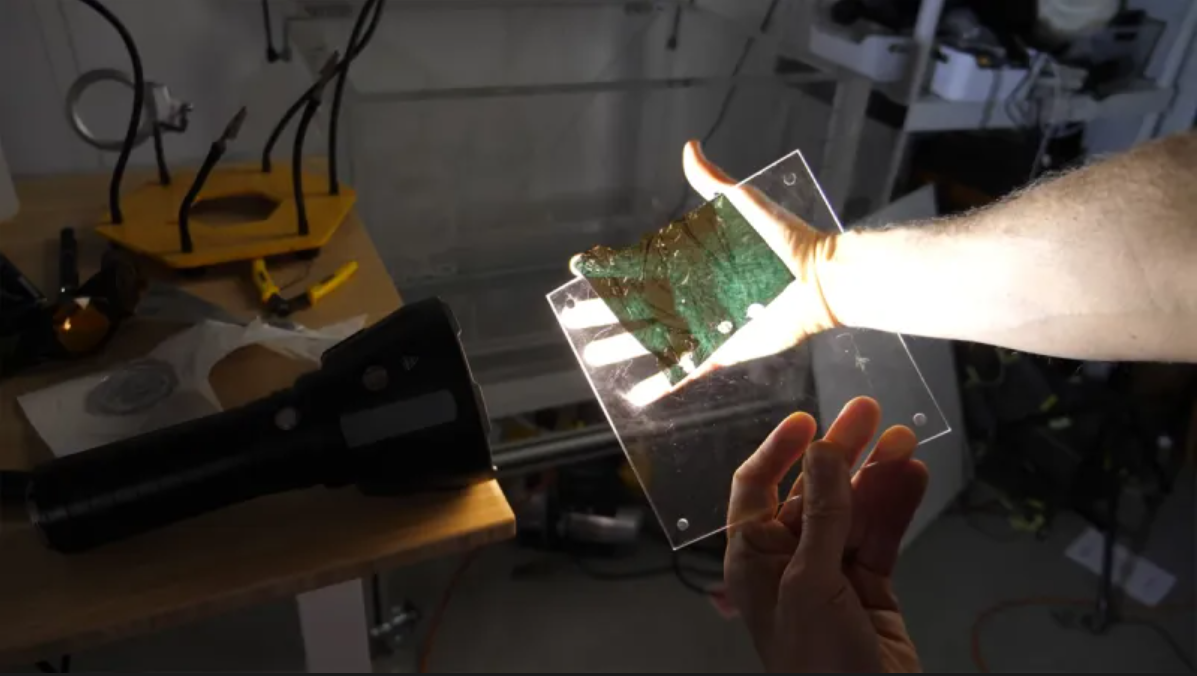

I have forty leaves of gold leaf from Kanazawa that are hammered by hand. Something that really excited me when I was purchasing it was the demonstration that light can shine through it. The foil is hammered so thin—around two to four microns—that you can see the swirling atomic crystal structure.

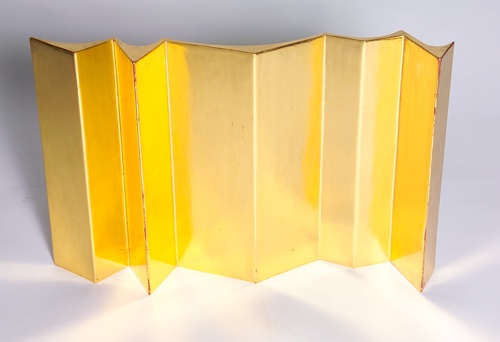

The transmitted light is a deep blue, which I loved because it’s the inverse of what gold usually represents. In daylight, it has the warm, reflective luster of metal; when backlit, it shifts toward something murky and aquatic—like muddy pond water. I thought it would be interesting to create a lamp that backlights the gold leaf and explores the play between the natural brilliance of gold and its deadened, translucent blue under illumination.

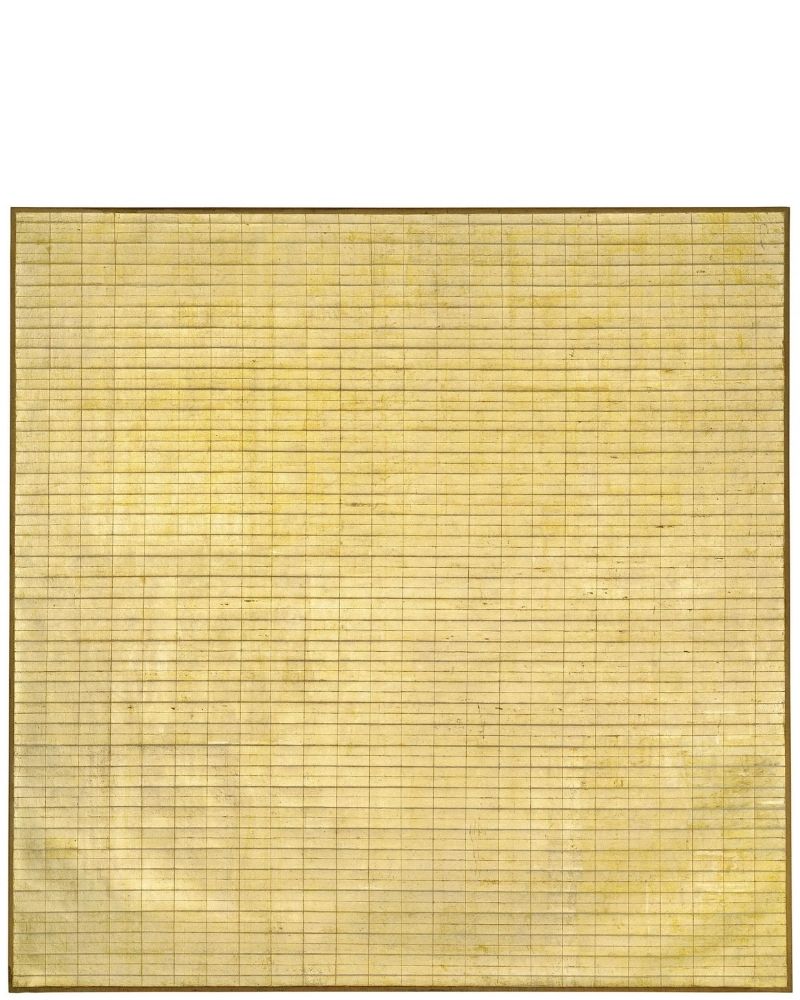

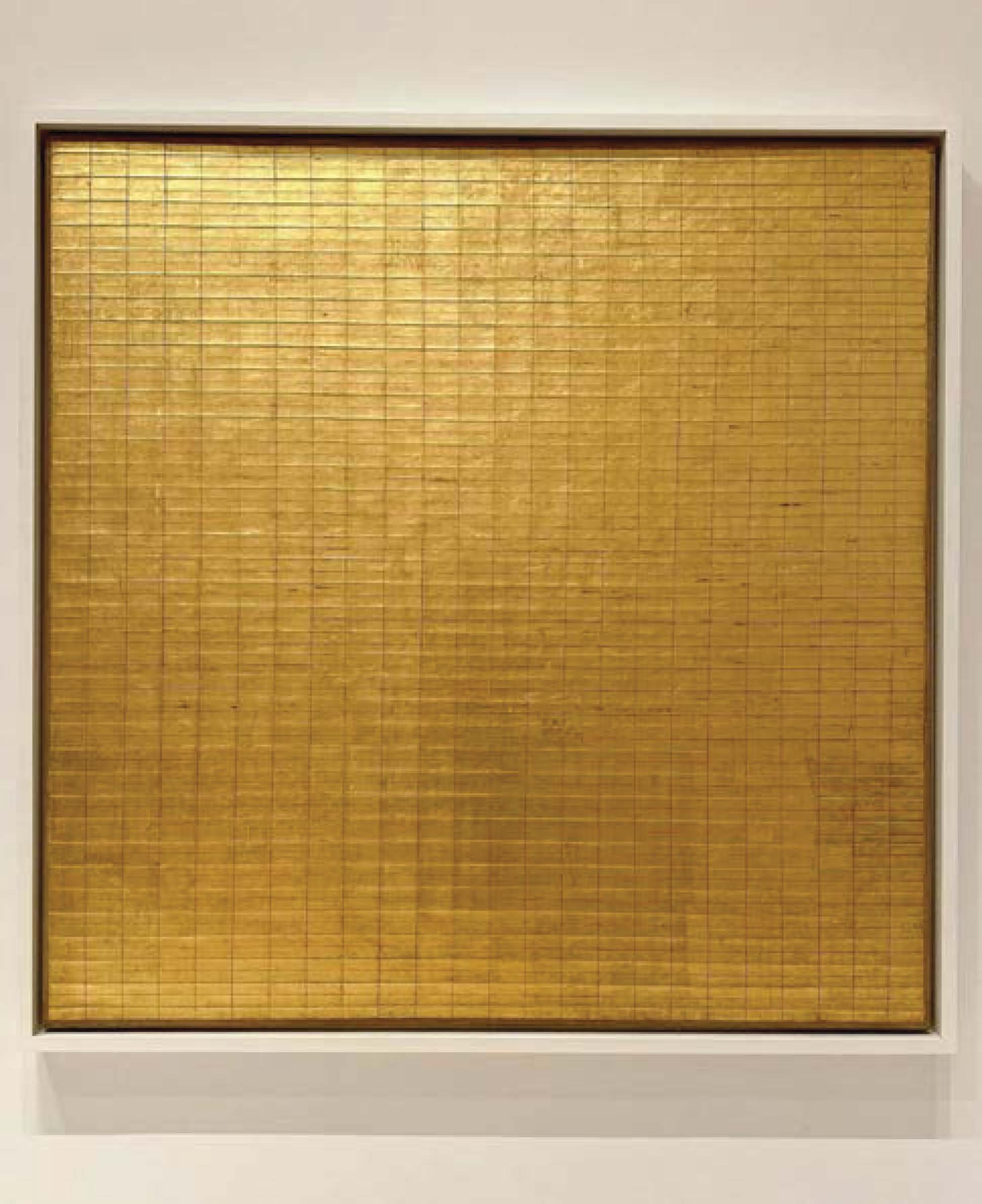

I’m inspired by several existing examples of gold leaf in the art canon, though none are used as lighting. I don’t believe there’s any major work that explores backlit gold leaf, but there is an Agnes Martin painting titled Friendship that I’m deeply fond of. It’s one of her few moments of extreme material change — a gilded surface that carries a sense of spontaneous affection and gratitude for her friends. That kind of gentle euphoria feels central to me lately. I’ve been feeling increasingly lucky for the people around me, and that piece resonates as one of my favorite works of all time.

I first saw Friendship at MoMA, in a room opposite a set of experimental MIT 3D-printed artworks — a juxtaposition that struck me. The pairing of something so minimal and emotional with something so engineered felt almost prophetic to me.

I also have a deep affection for the Mexican modernists, especially Mathias Goeritz, who created incredible gold-leaf works — geometric, platonic structures and panels, one of which was installed in Luis Barragán’s house to reflect golden light into a dark stairwell and foyer. It’s one of my favorite uses of material light in architecture, and it’s what I was thinking of when I bought my own gold leaf. I wanted to make a similar panel — something that transforms an entire surface into a light-altering presence within my space.

I’m also interested in the possibility of producing a gold-leaf glass that’s sturdy and durable enough for use in a lighting fixture.

.jpg)

.jpg)

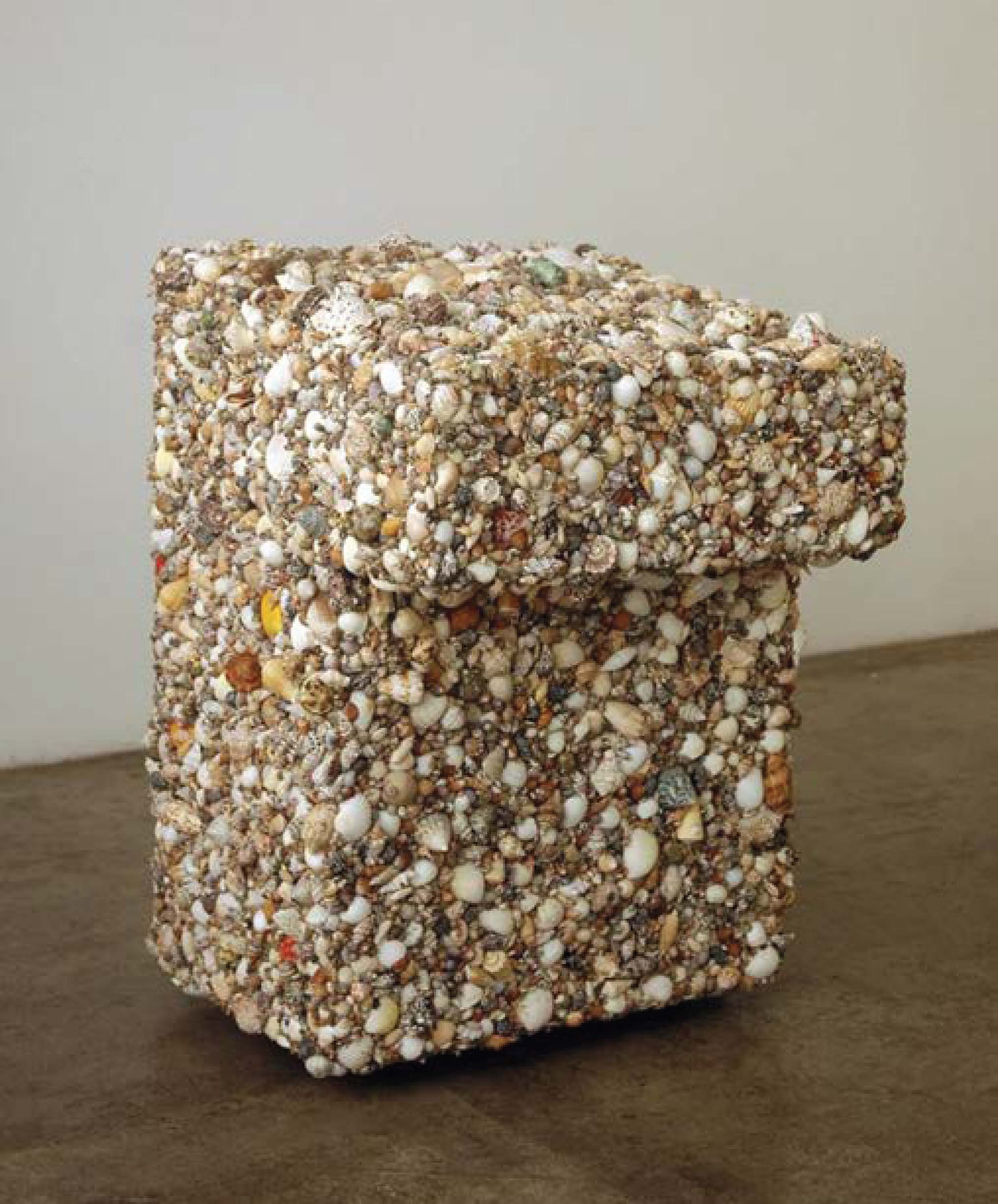

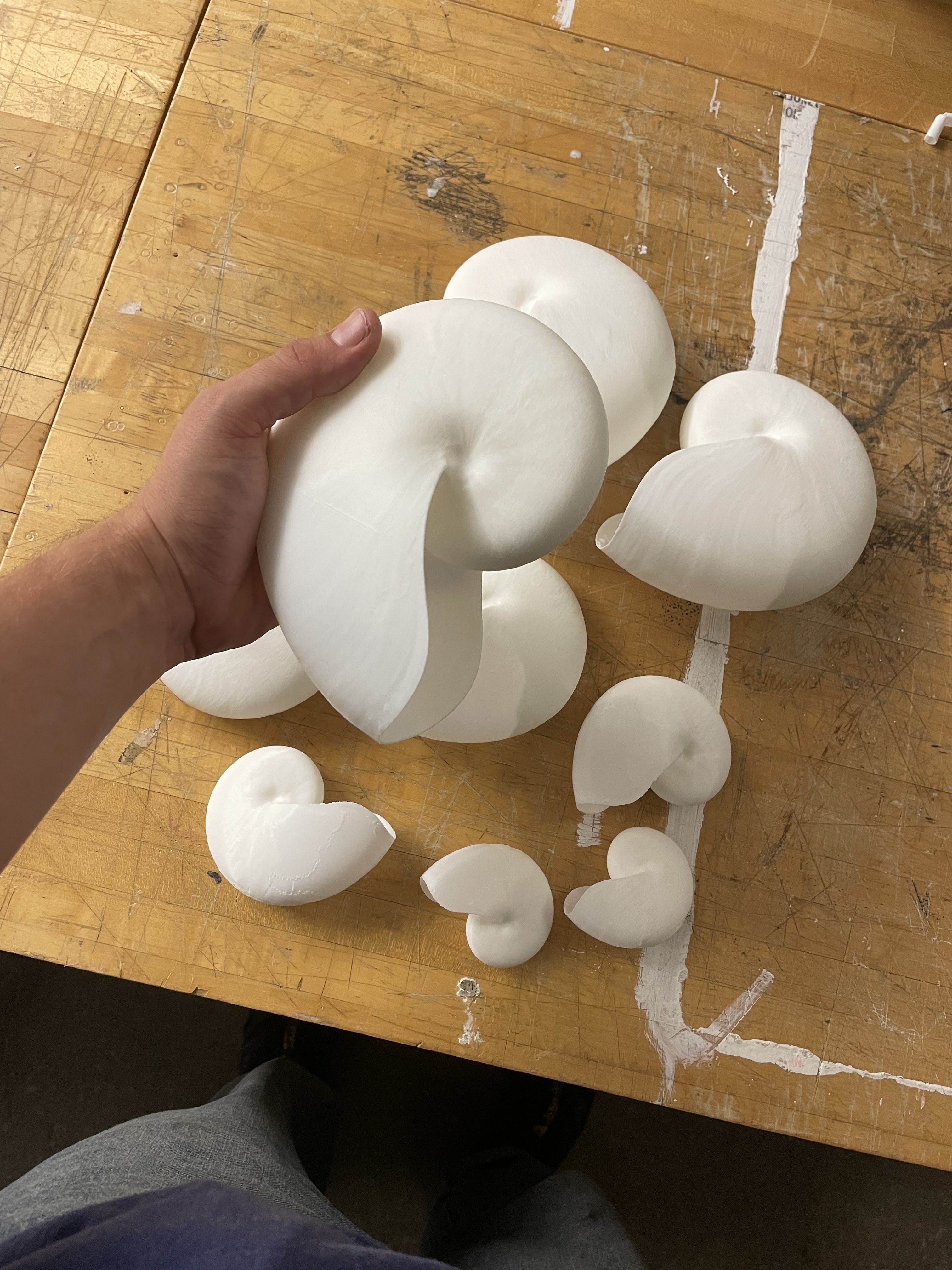

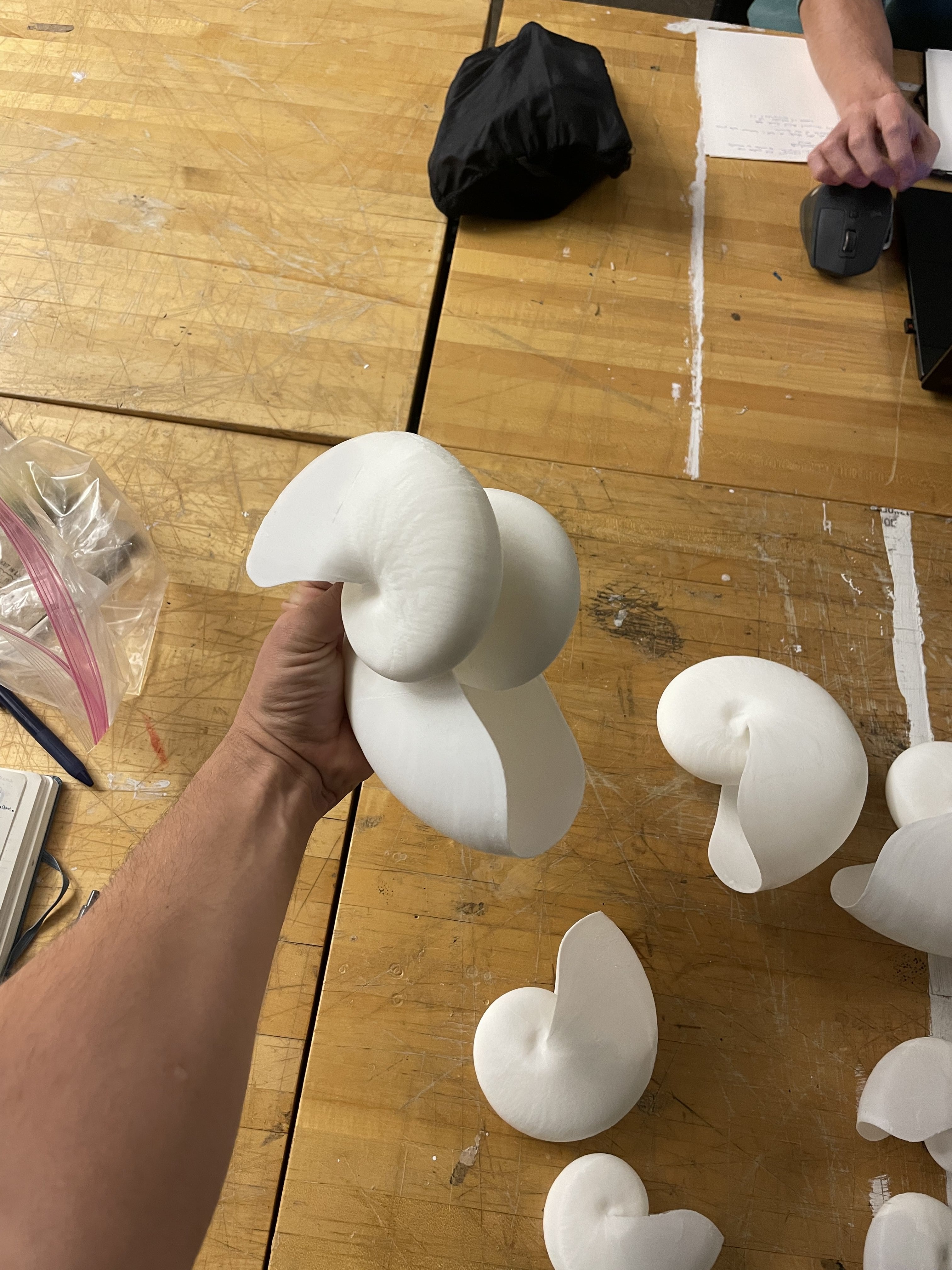

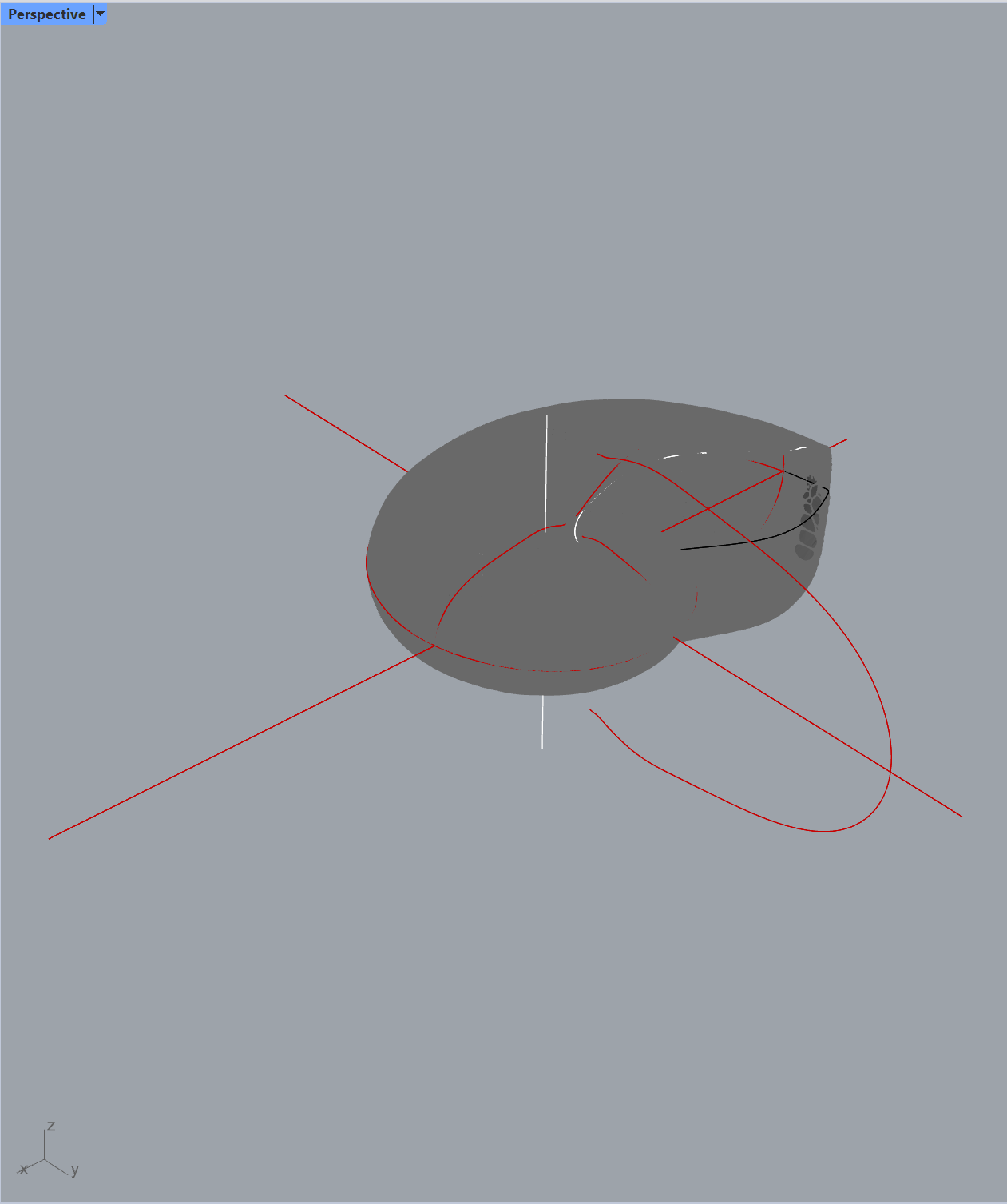

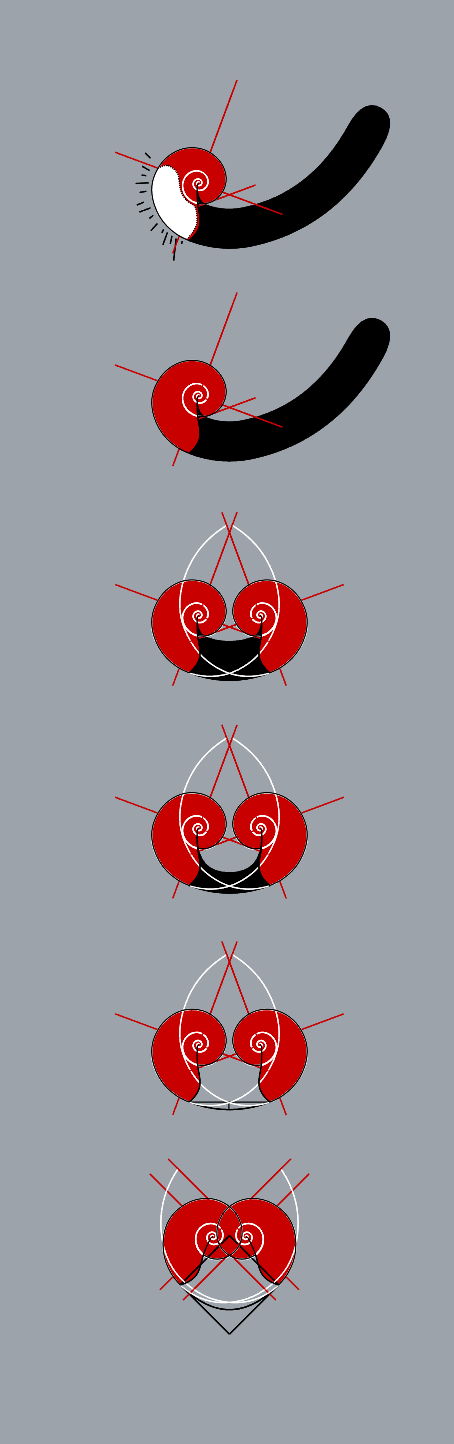

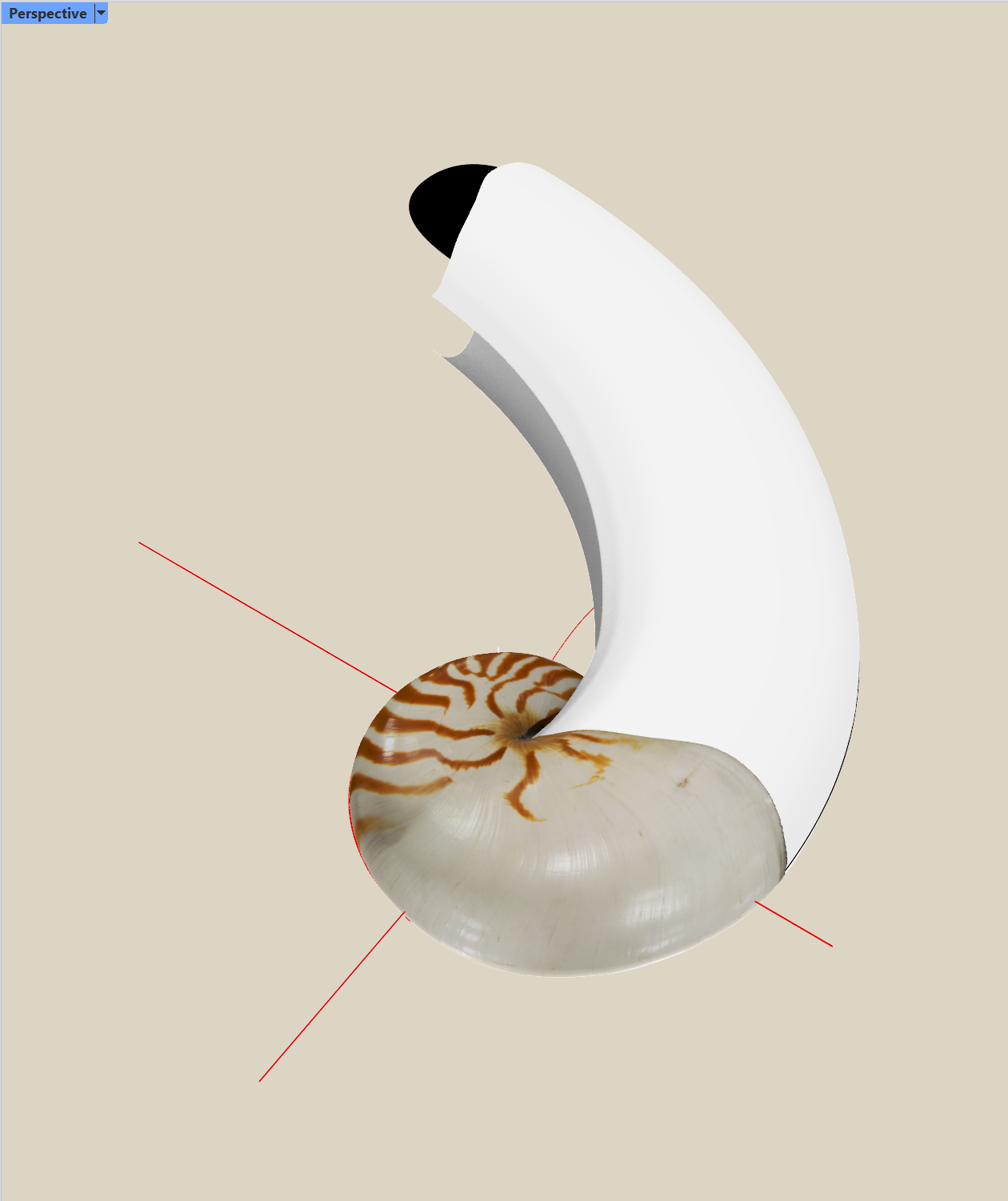

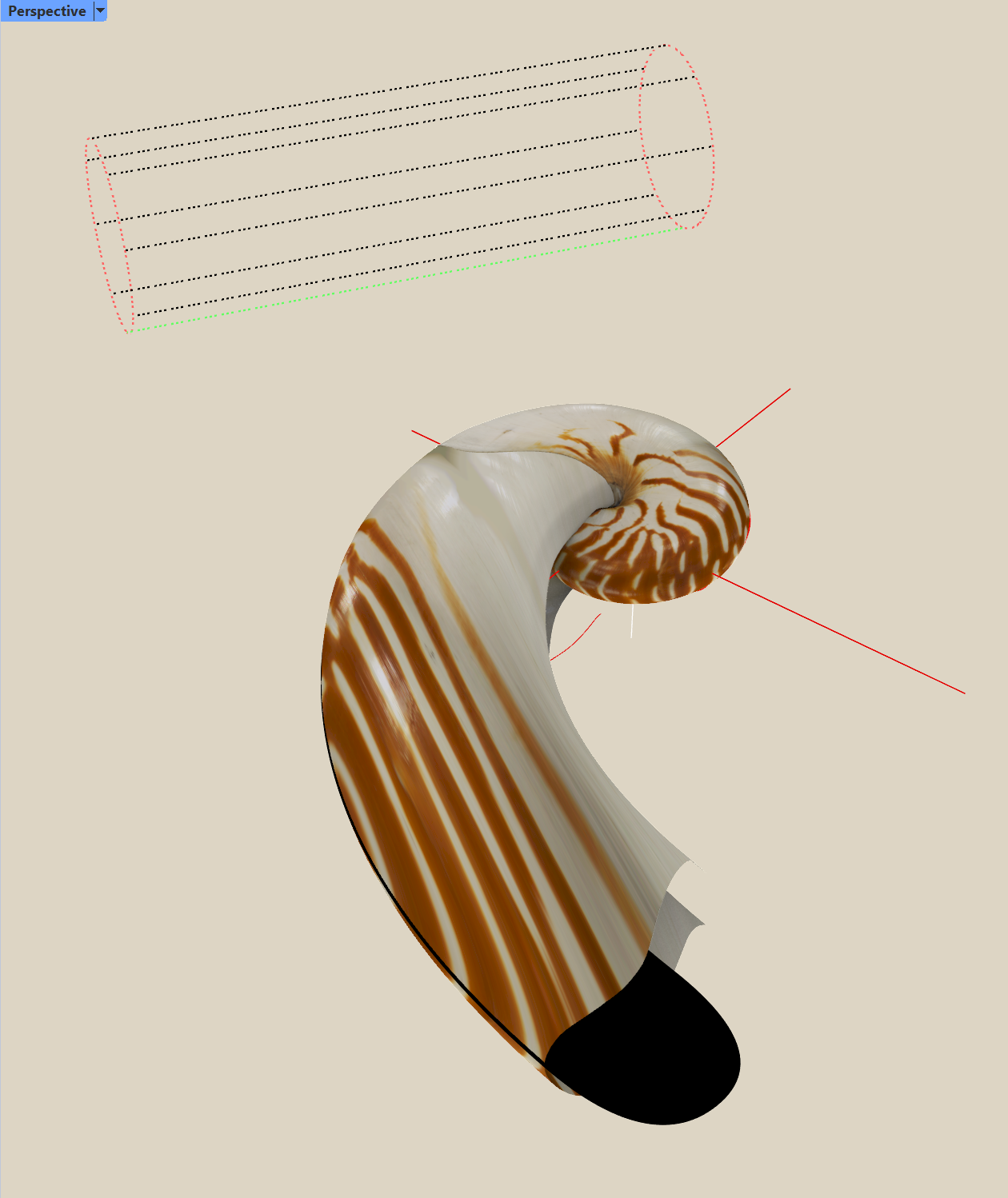

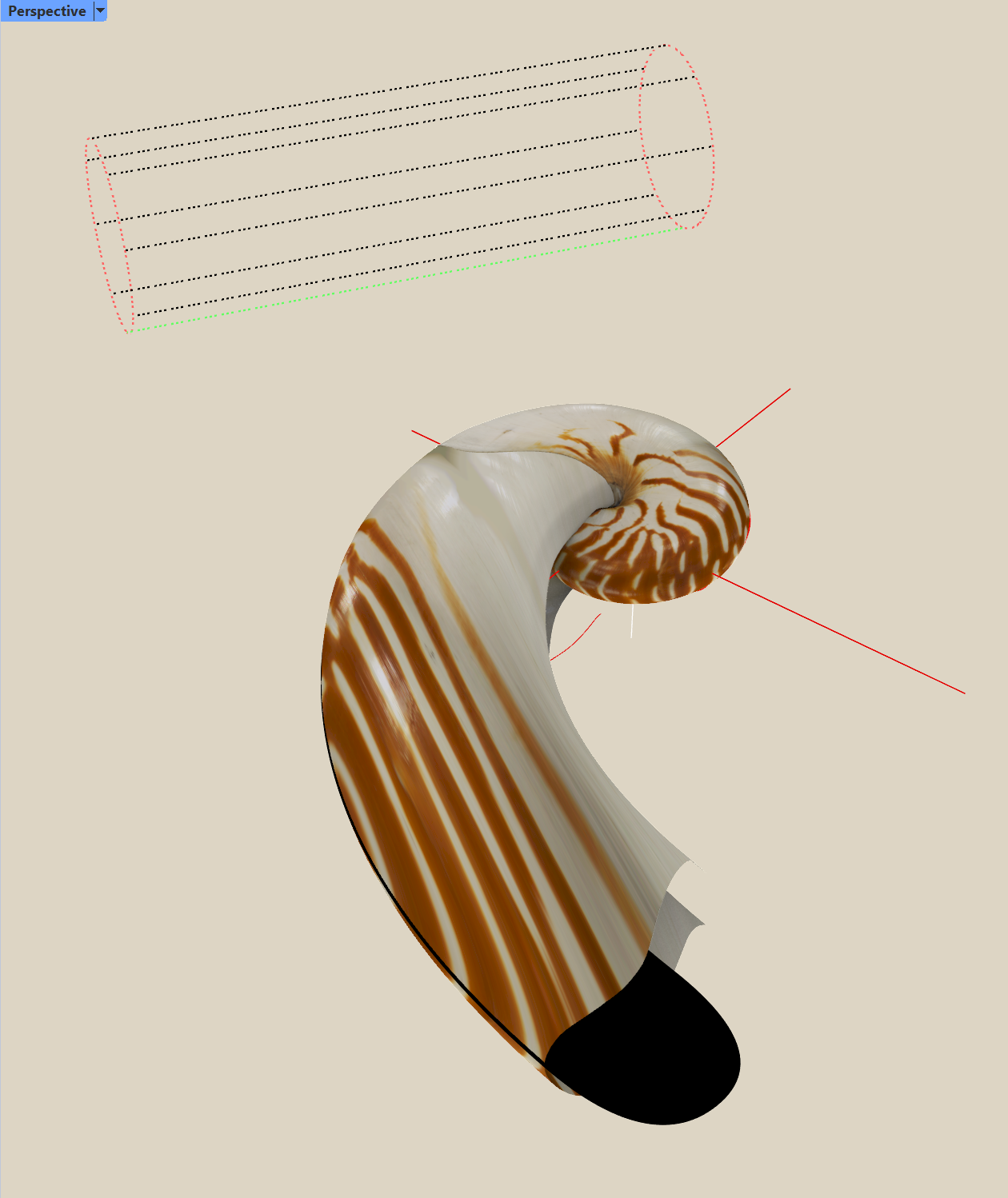

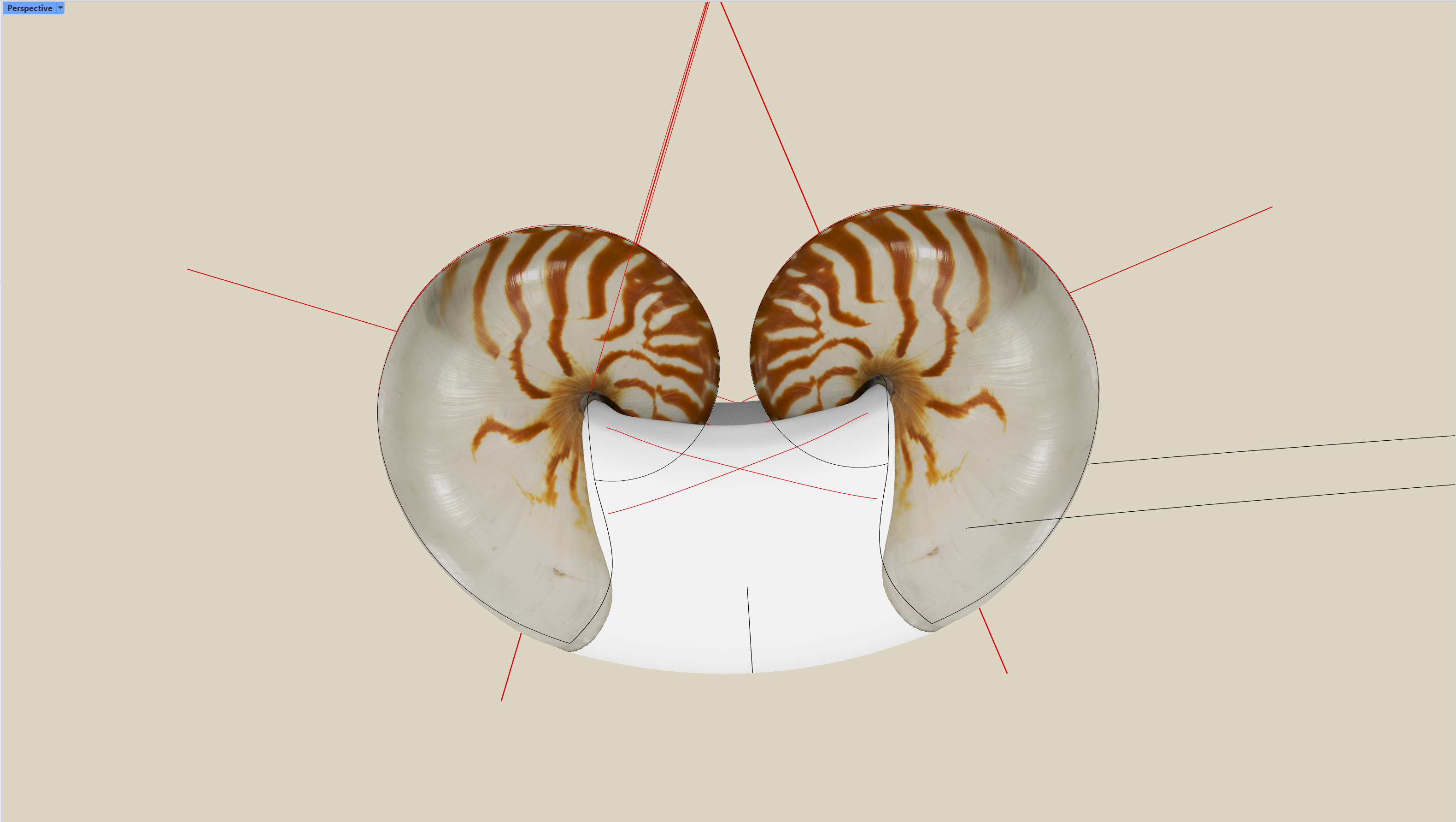

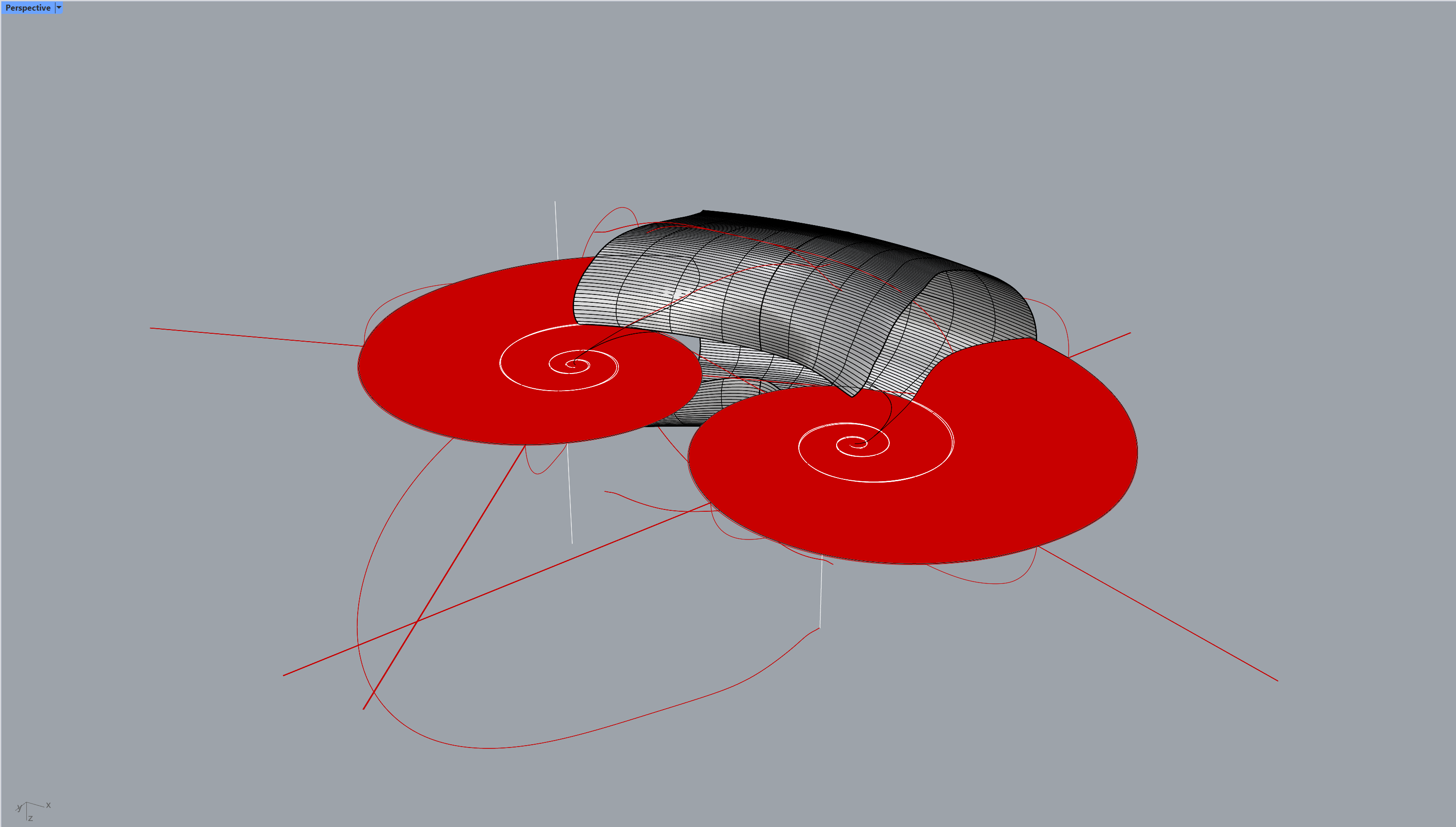

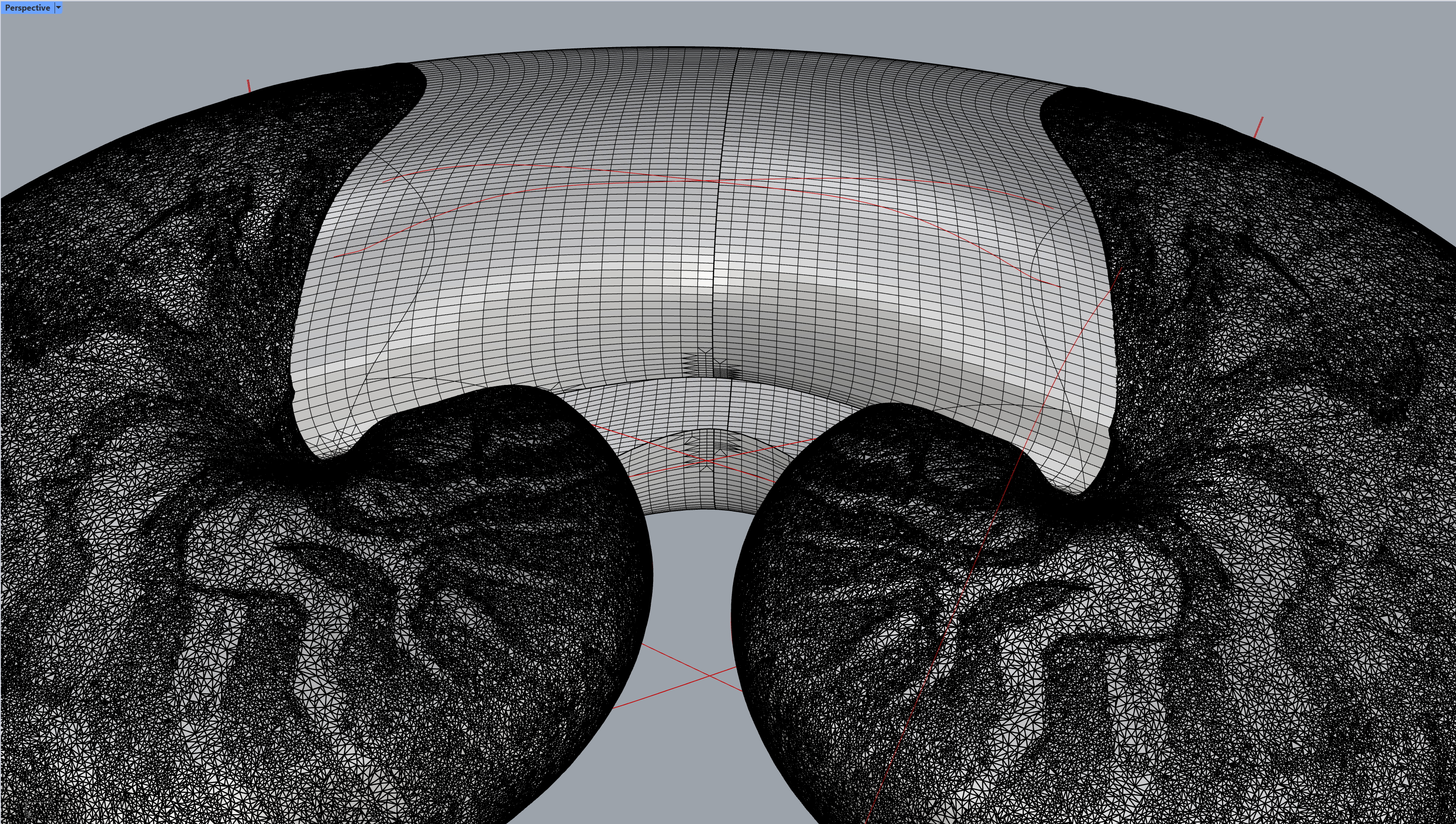

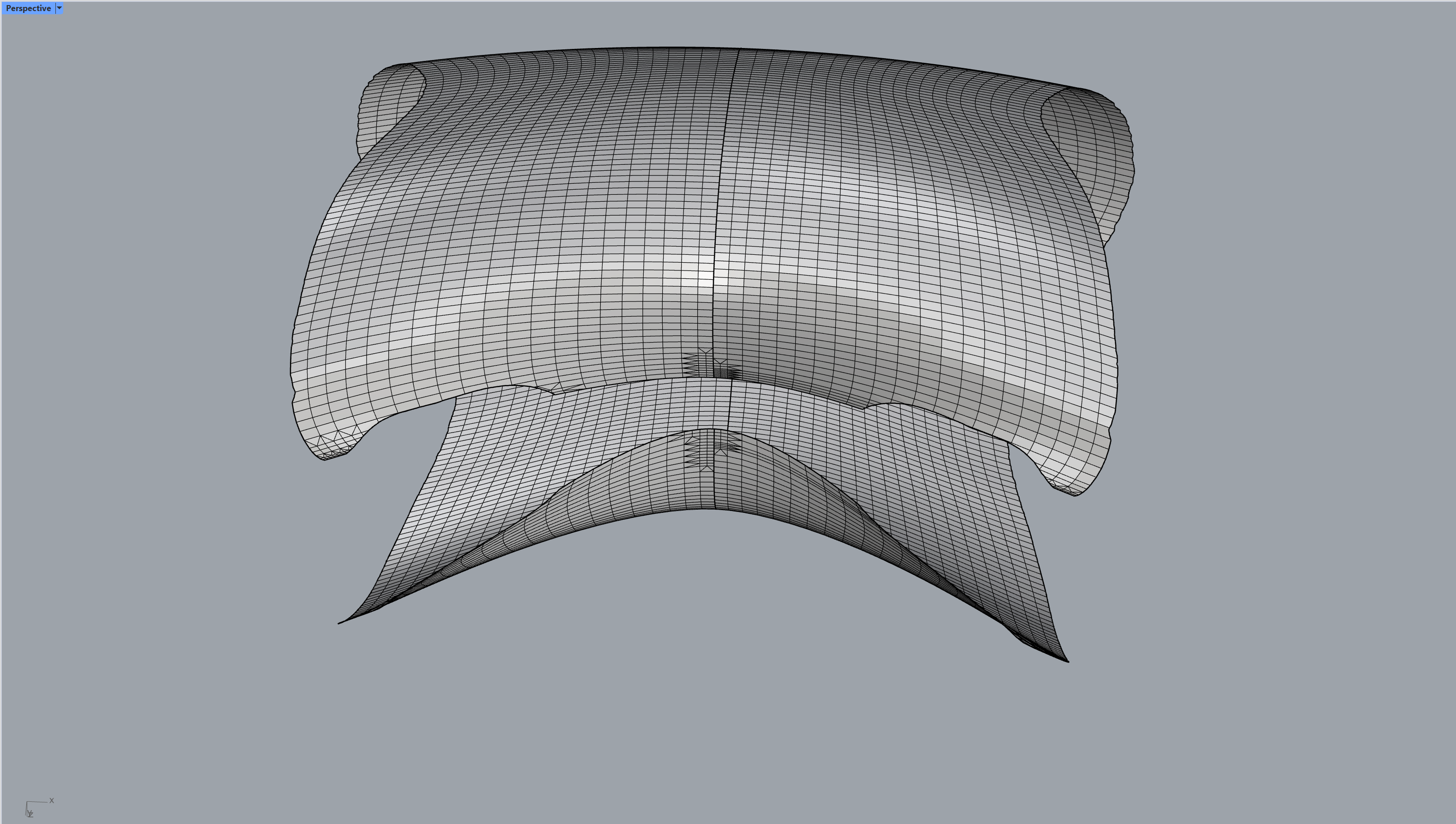

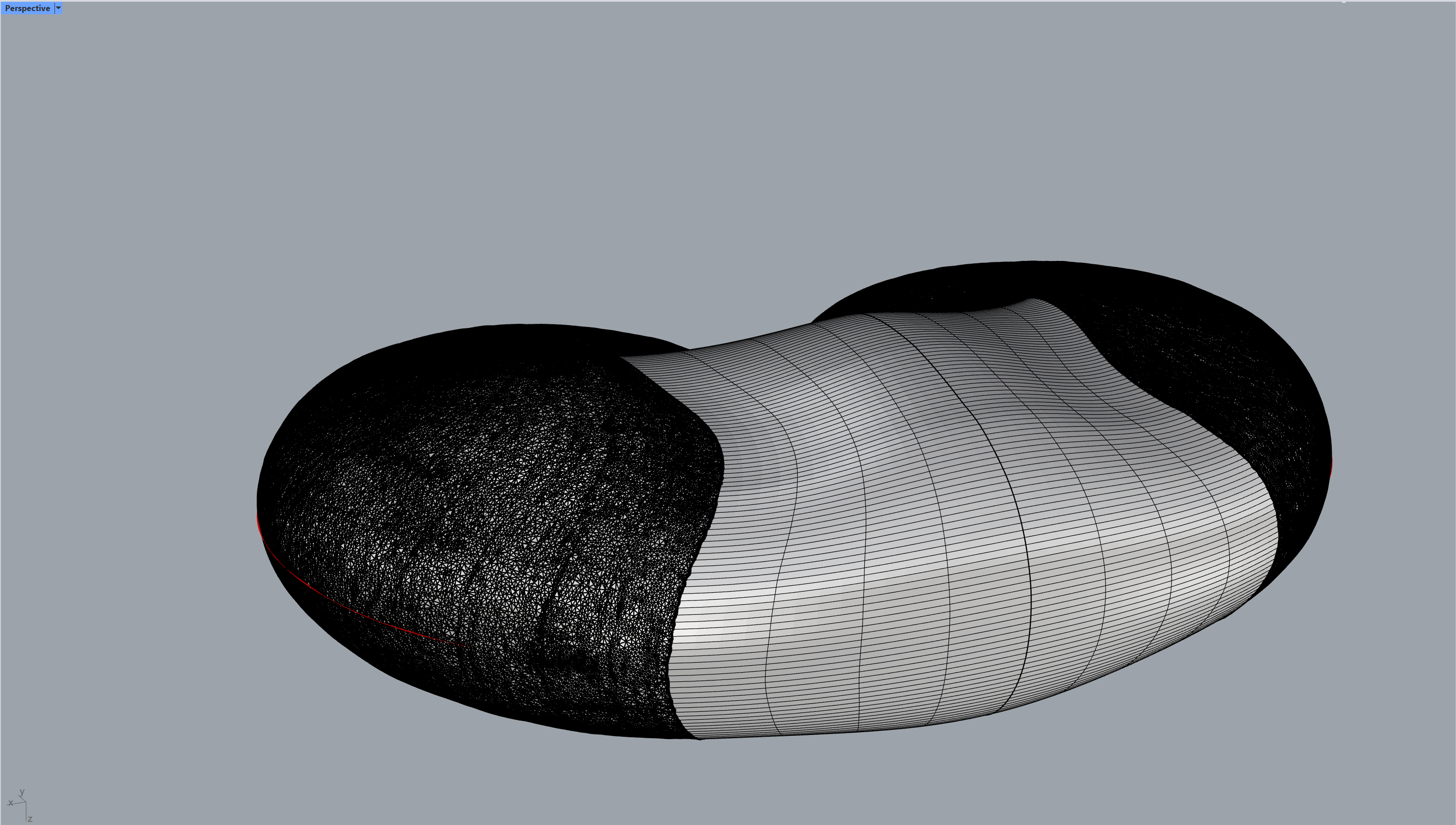

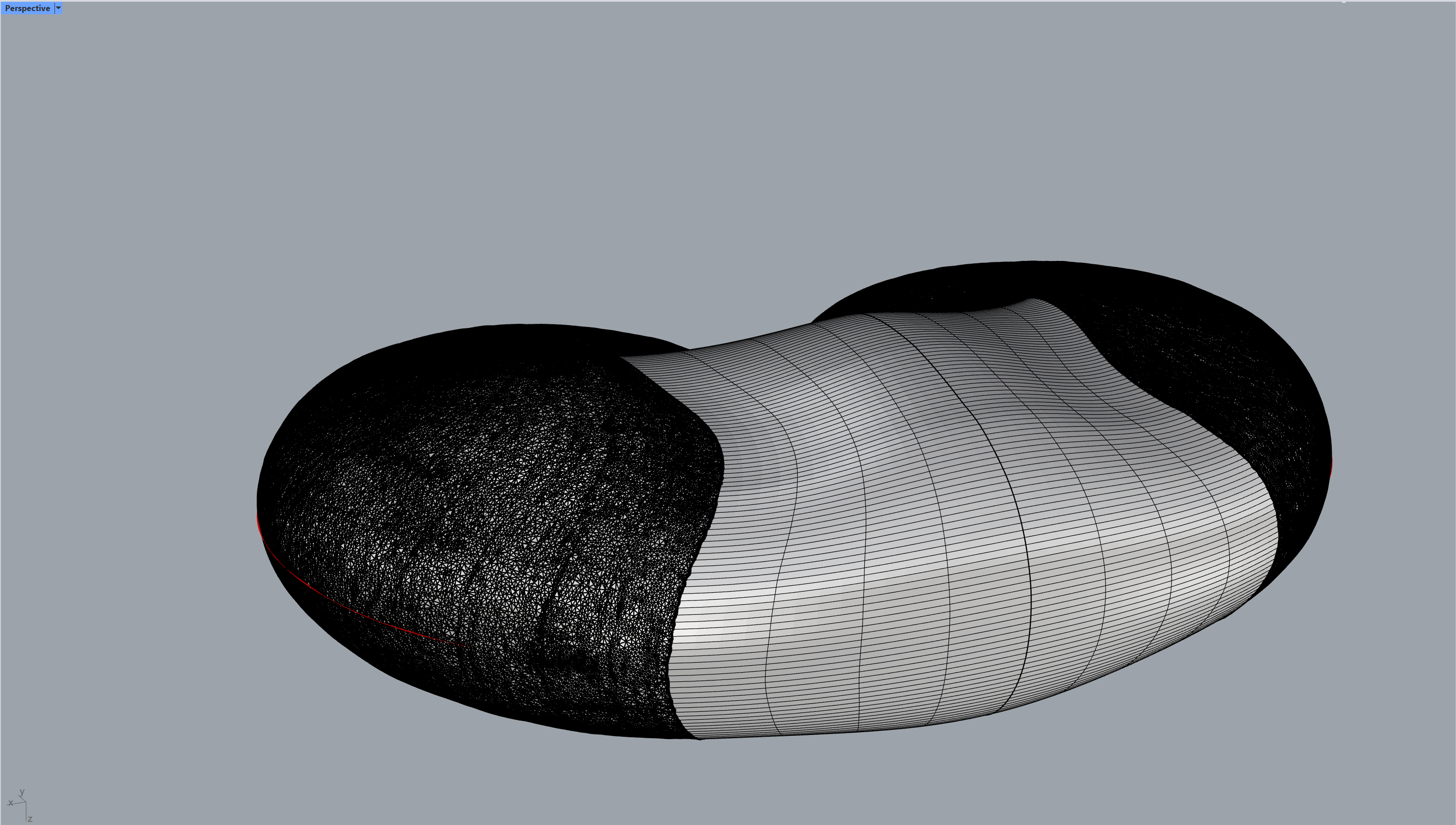

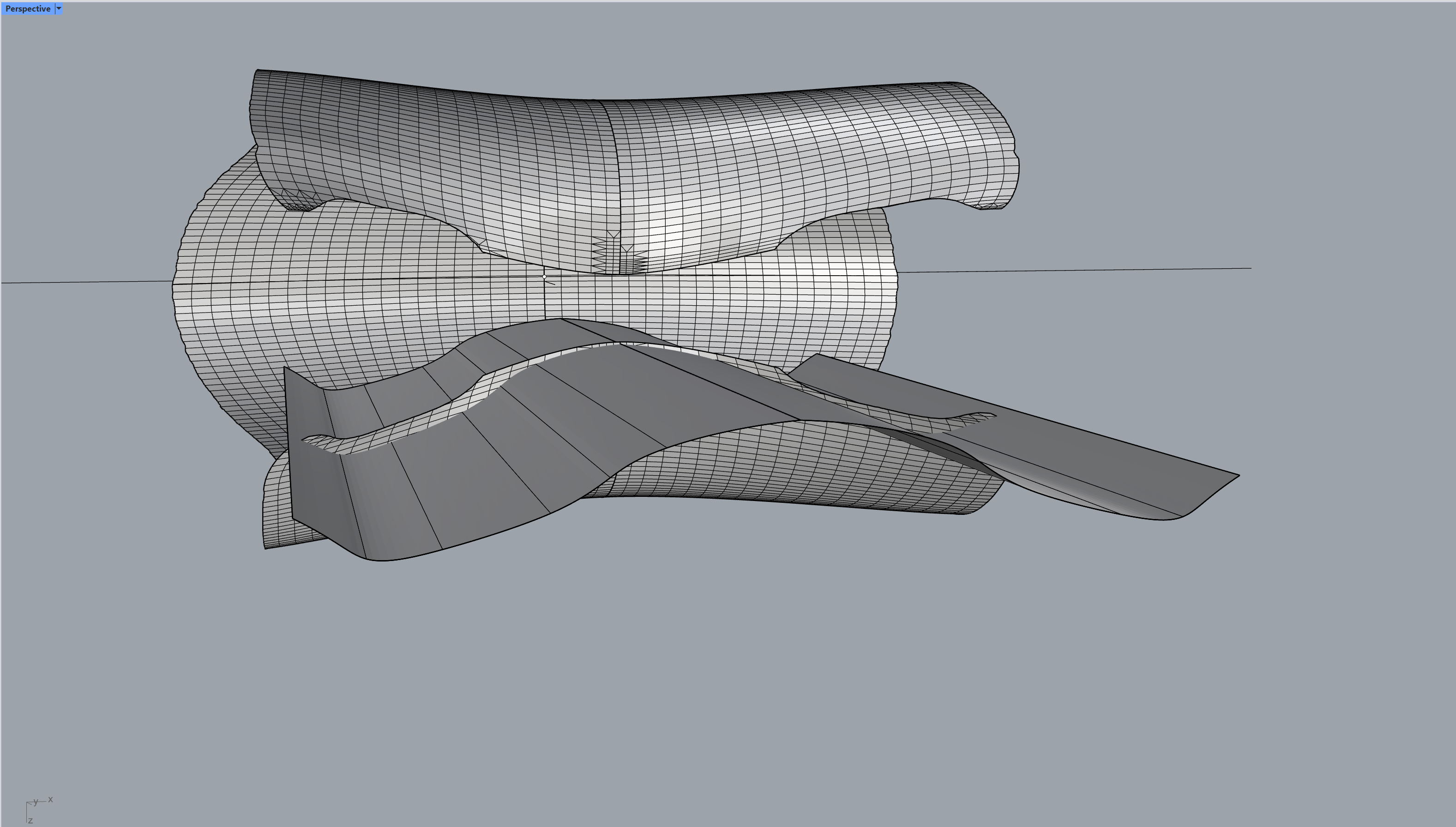

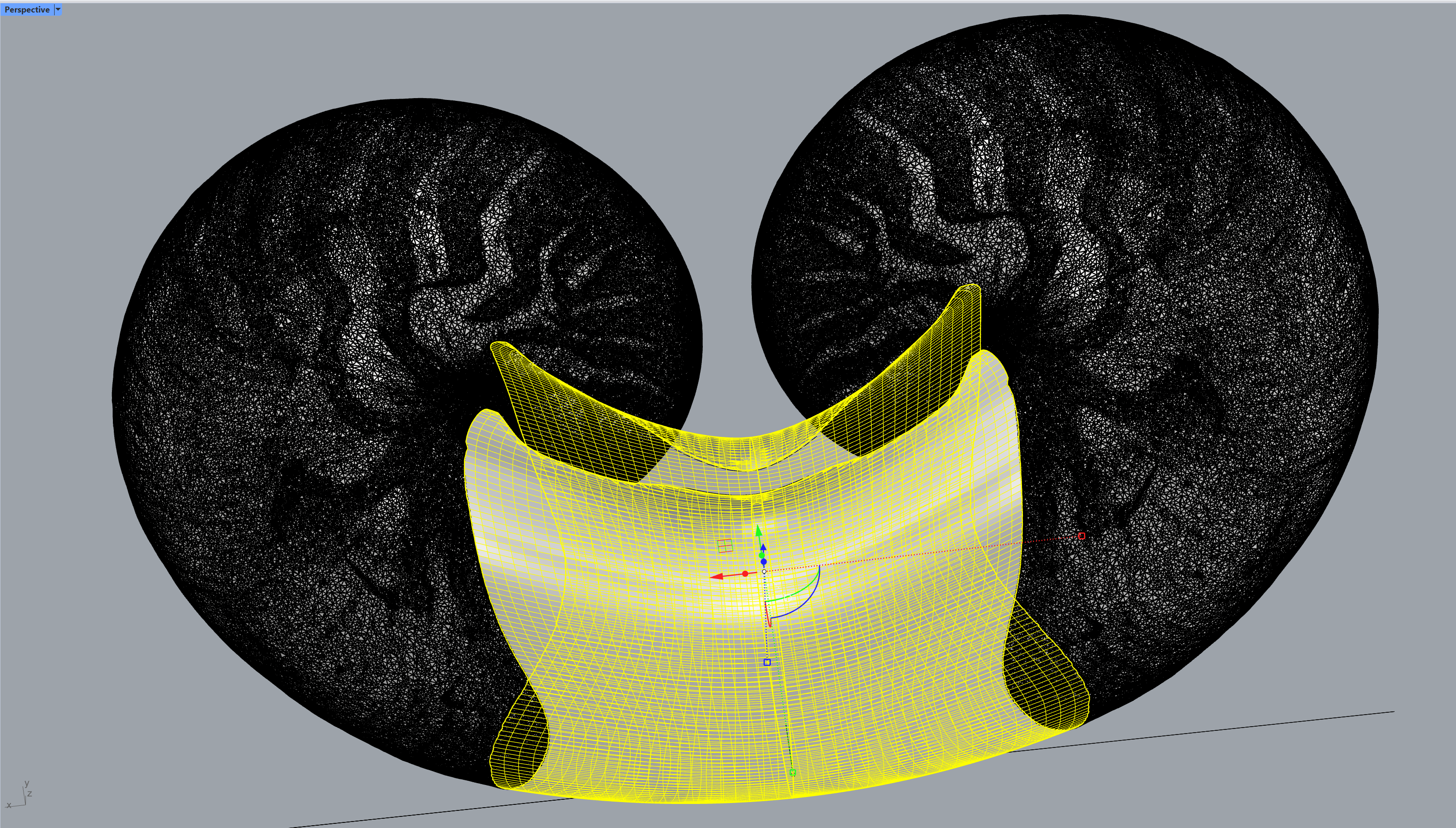

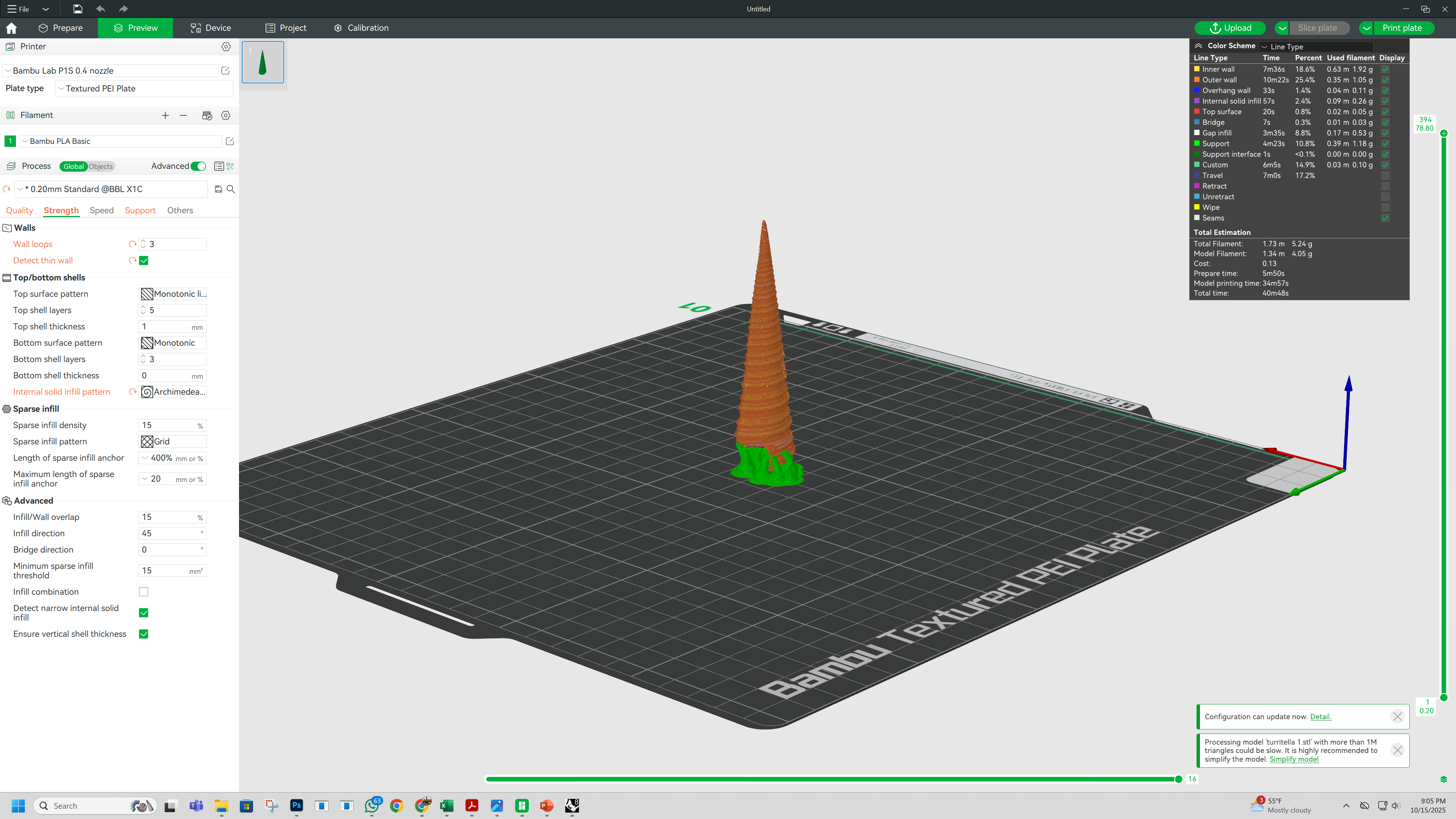

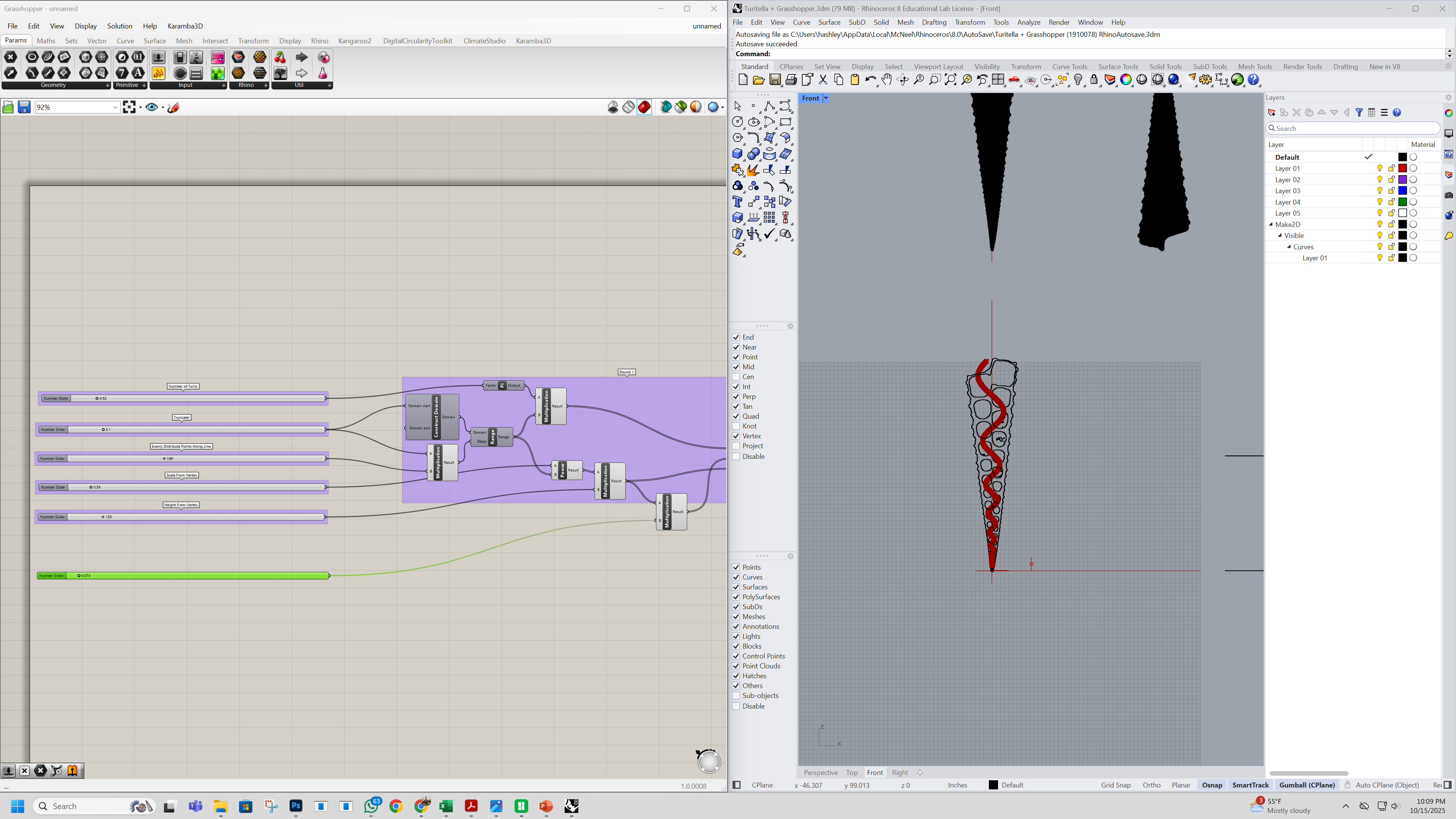

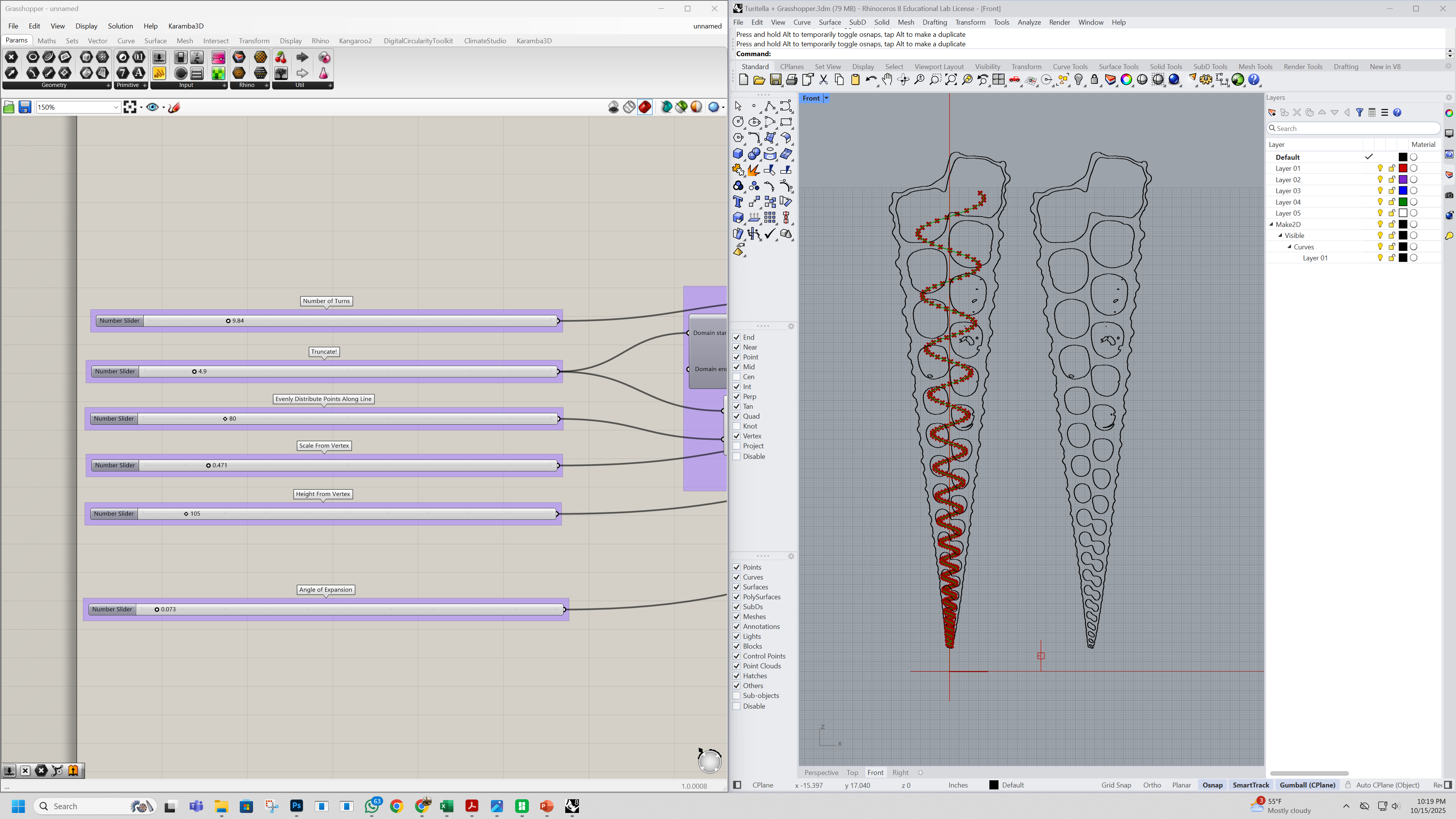

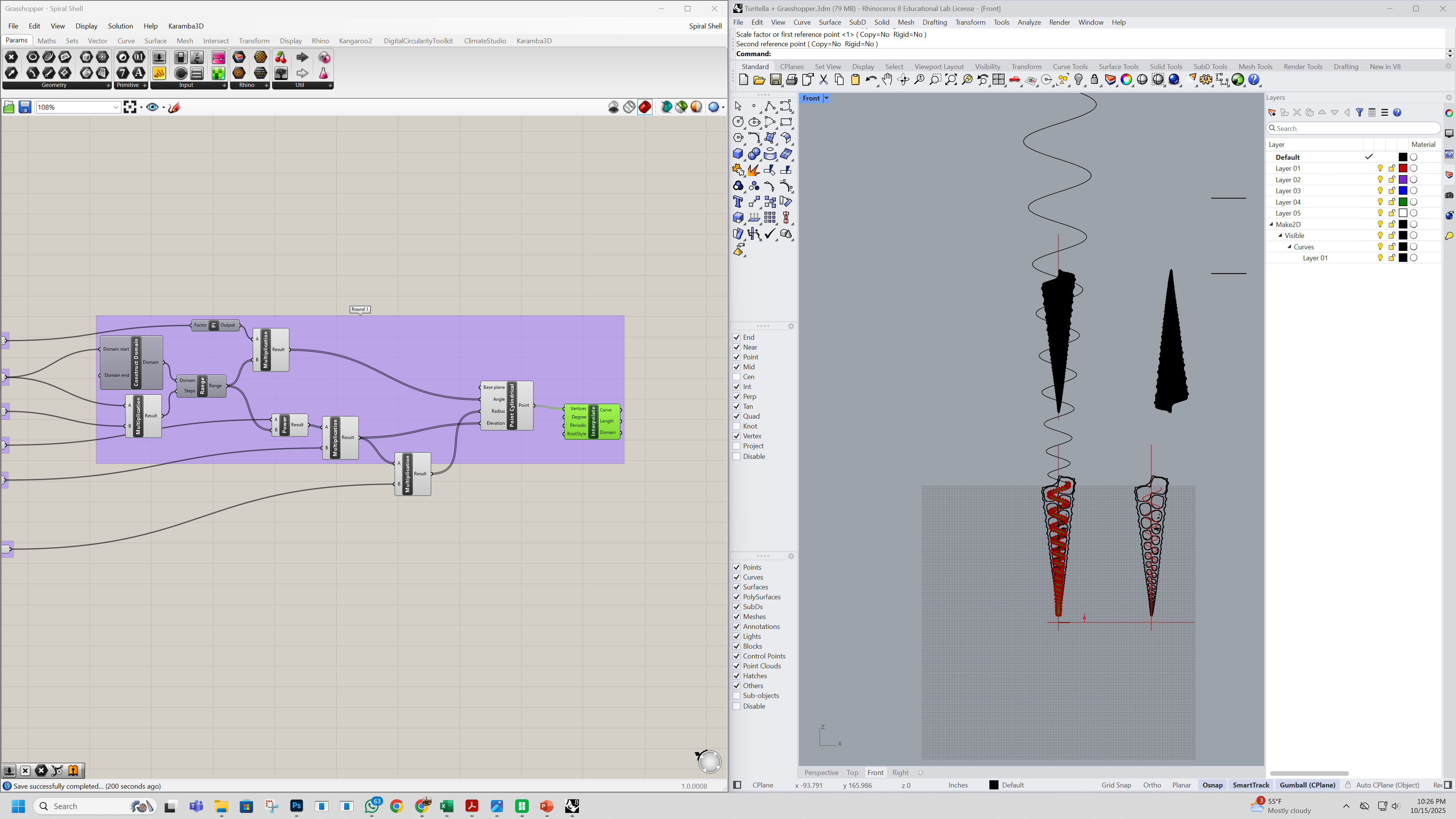

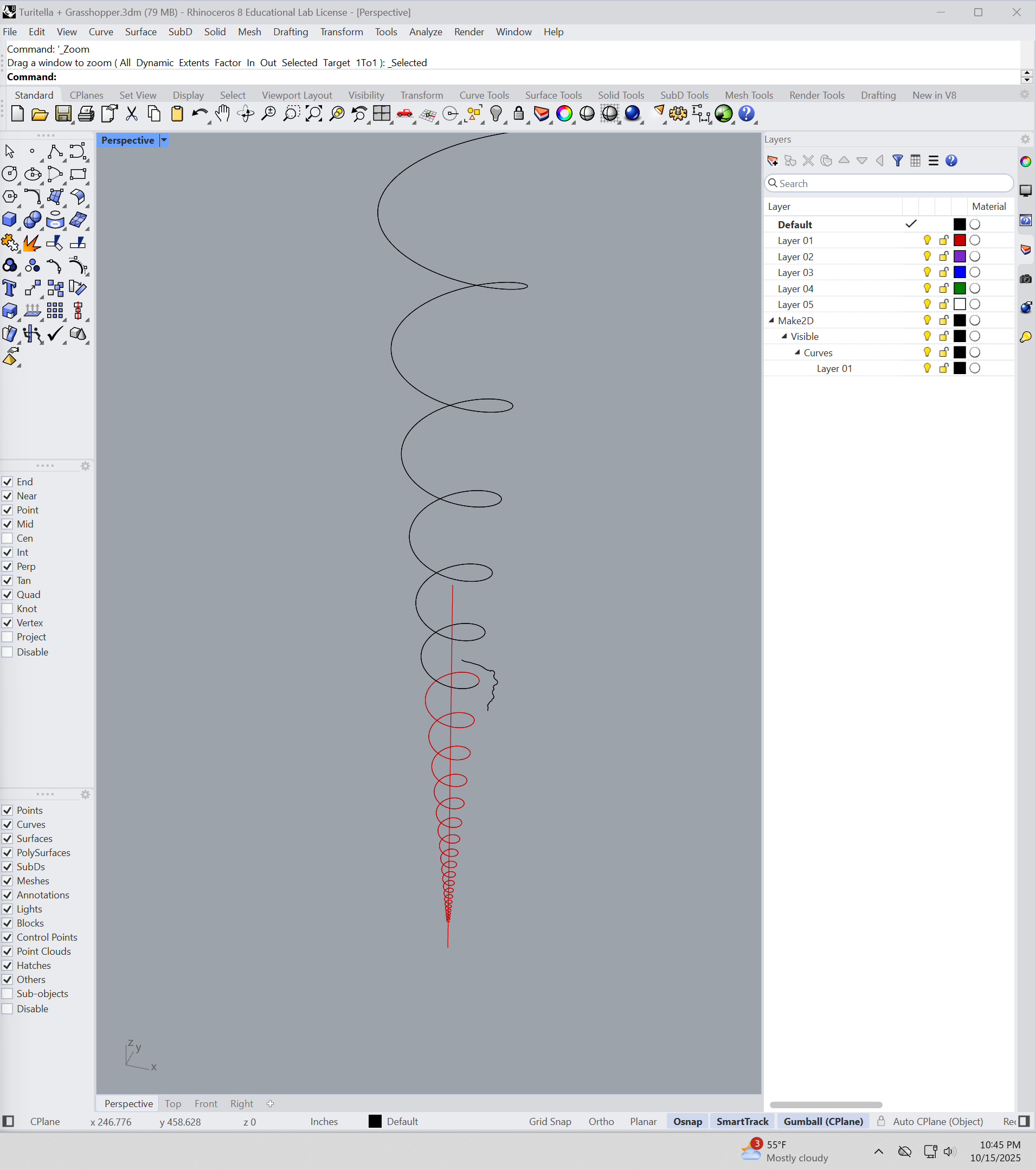

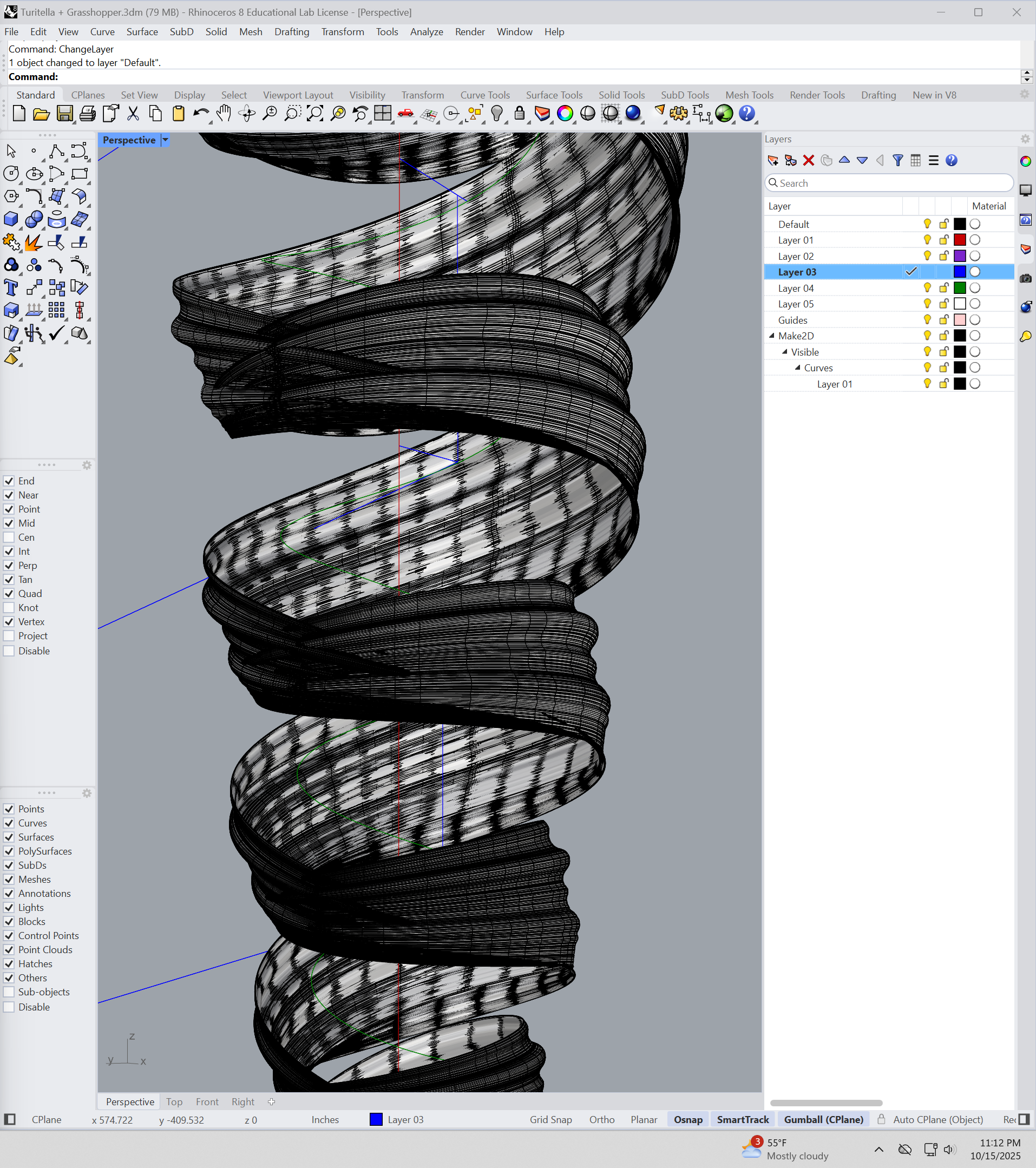

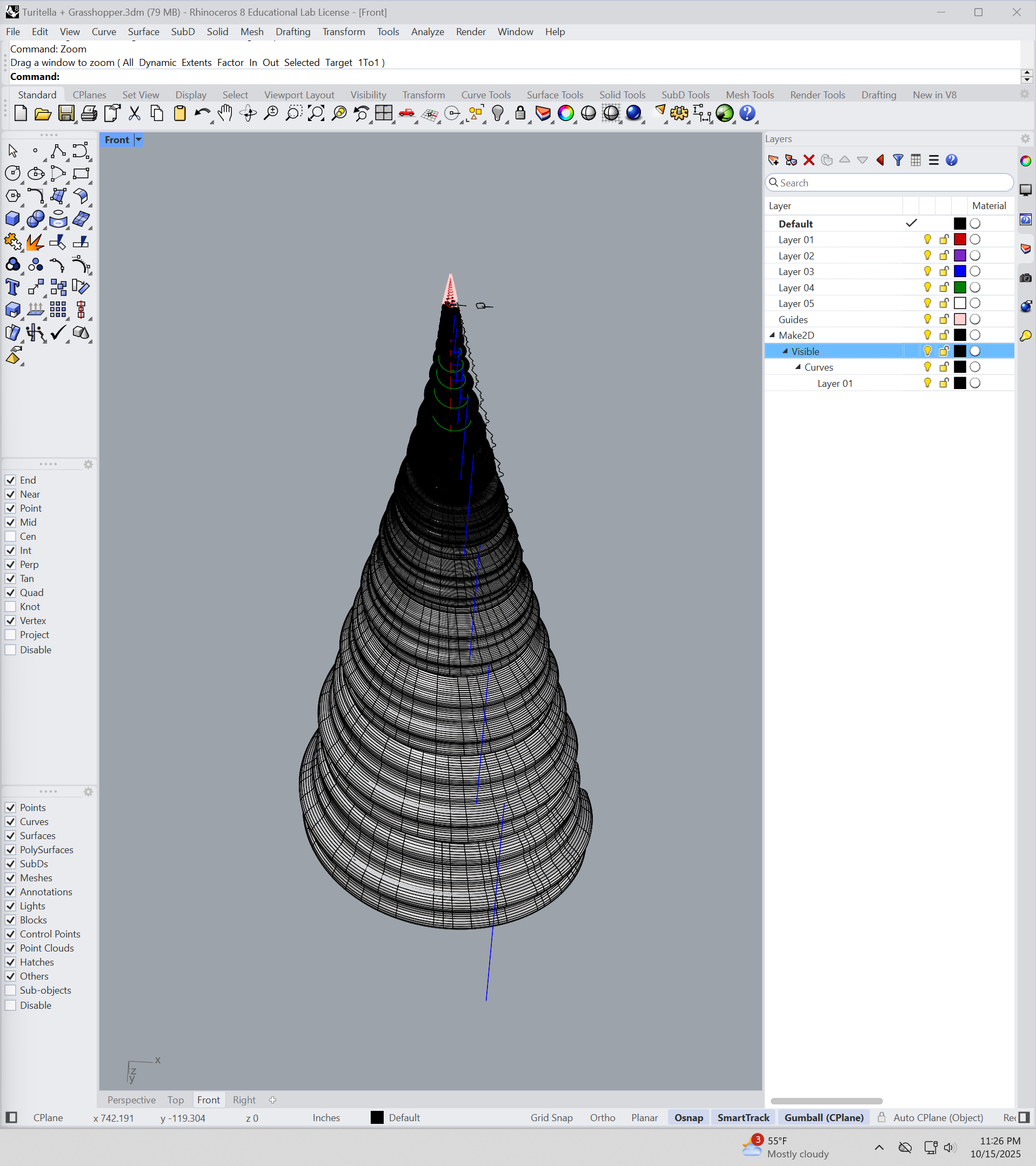

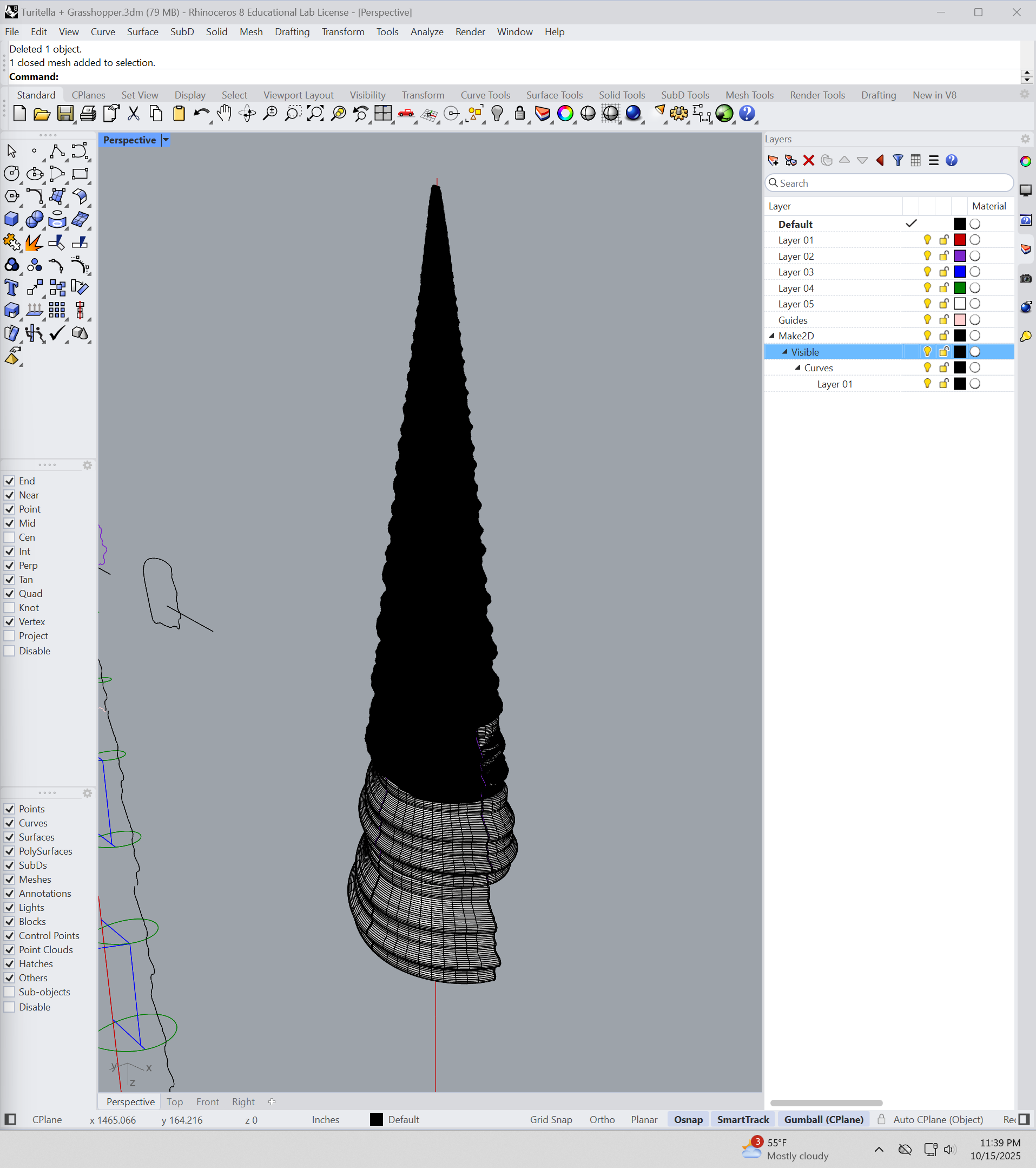

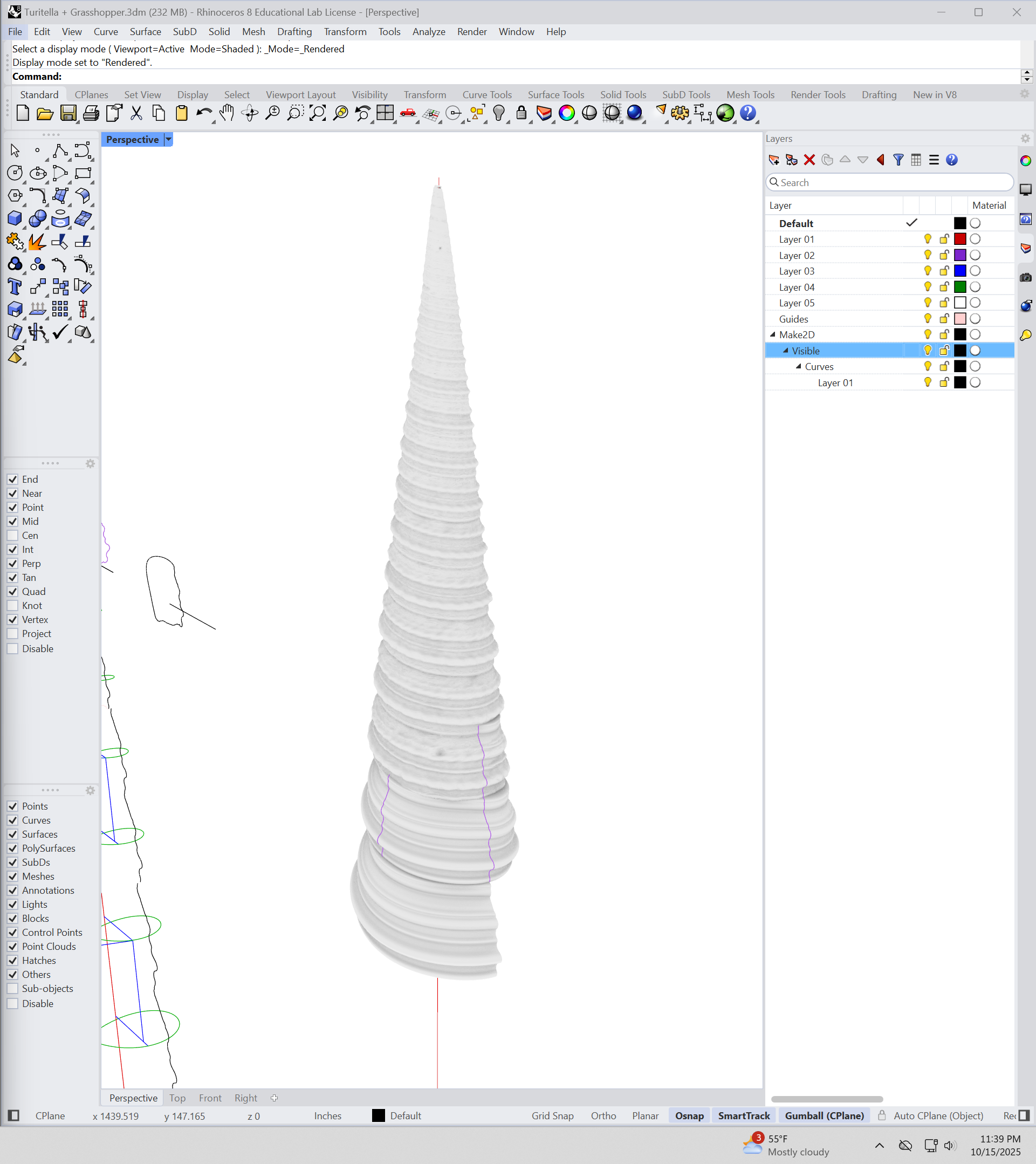

Shell Lamps and Parametric Design

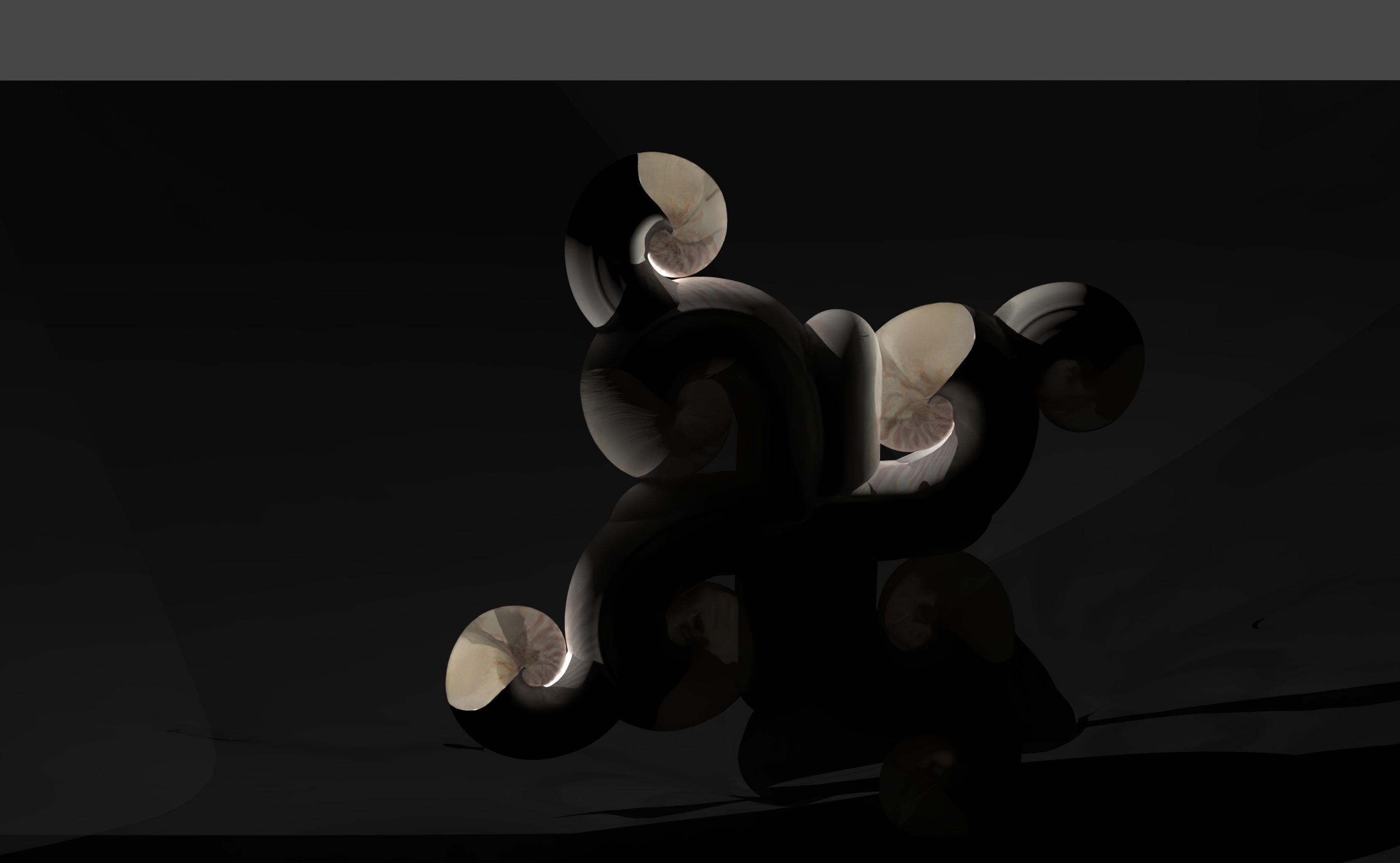

I have several shells — including a Nautilus shell and multiple Auger shells — that I’m excited to turn into lamps. I produced a parametric design program in Grasshopper to take 3D scans of these shells and recreate the scale and incremental growth of their spiral structures. From these digital models, I can extract cross-section curves and use Sweep1 to produce a full recreation of the shell with reasonable detail. This allows me to extend the natural spiral of each scan, generating a base that continues the growth logic of the shell.

Within Rhino, I can then augment, truncate, and sculpt these geometries — essentially continuing the evolutionary process of the shell through design.

Nautilus shells have been utilized as lighting elements since at least the Victorian era, when Tiffany Studios popularized their form by fitting incandescent bulbs inside their open chambers. However, I don’t believe that parametrically spiraled bases have ever been used to transform shells into complete light bulbs.

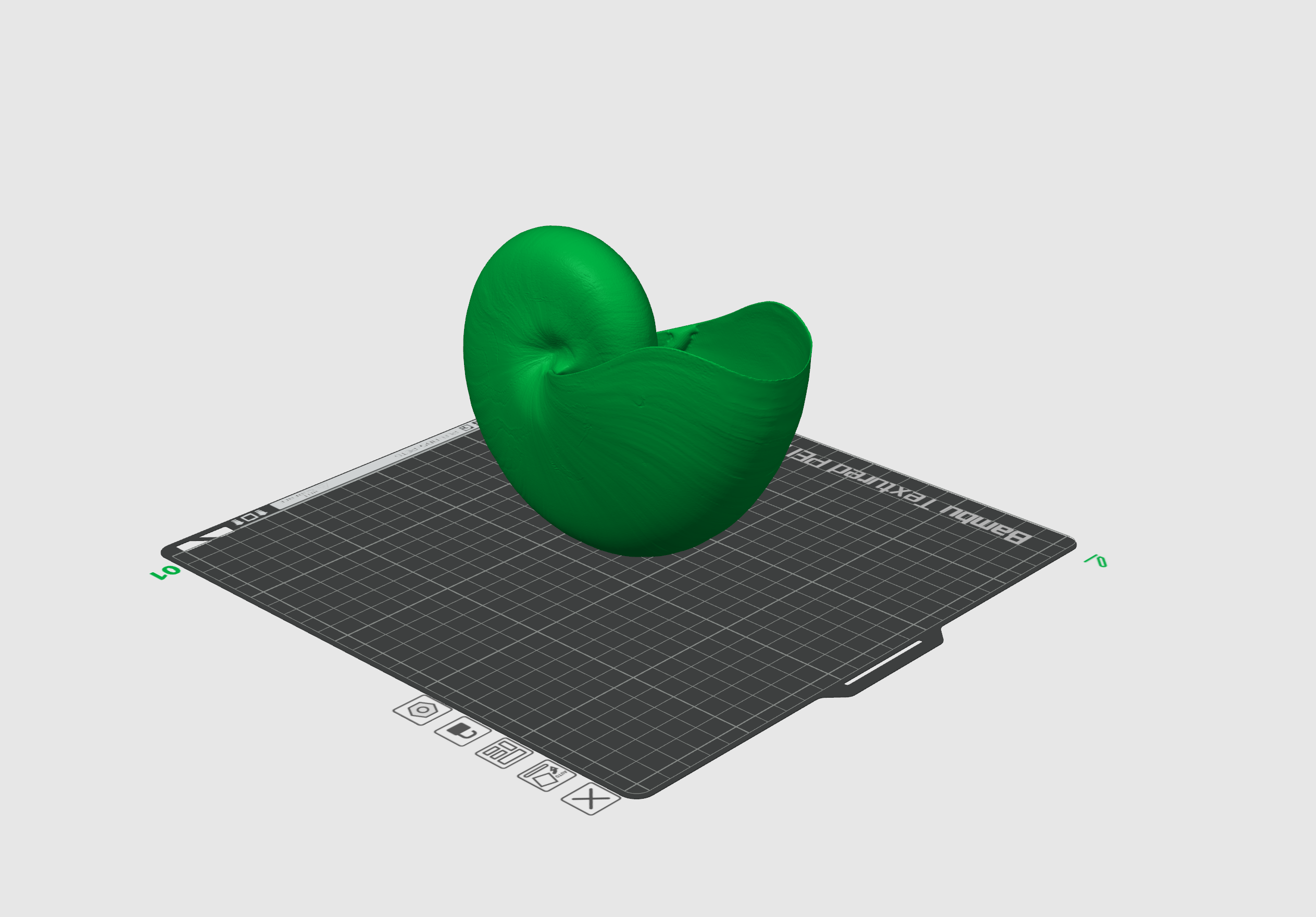

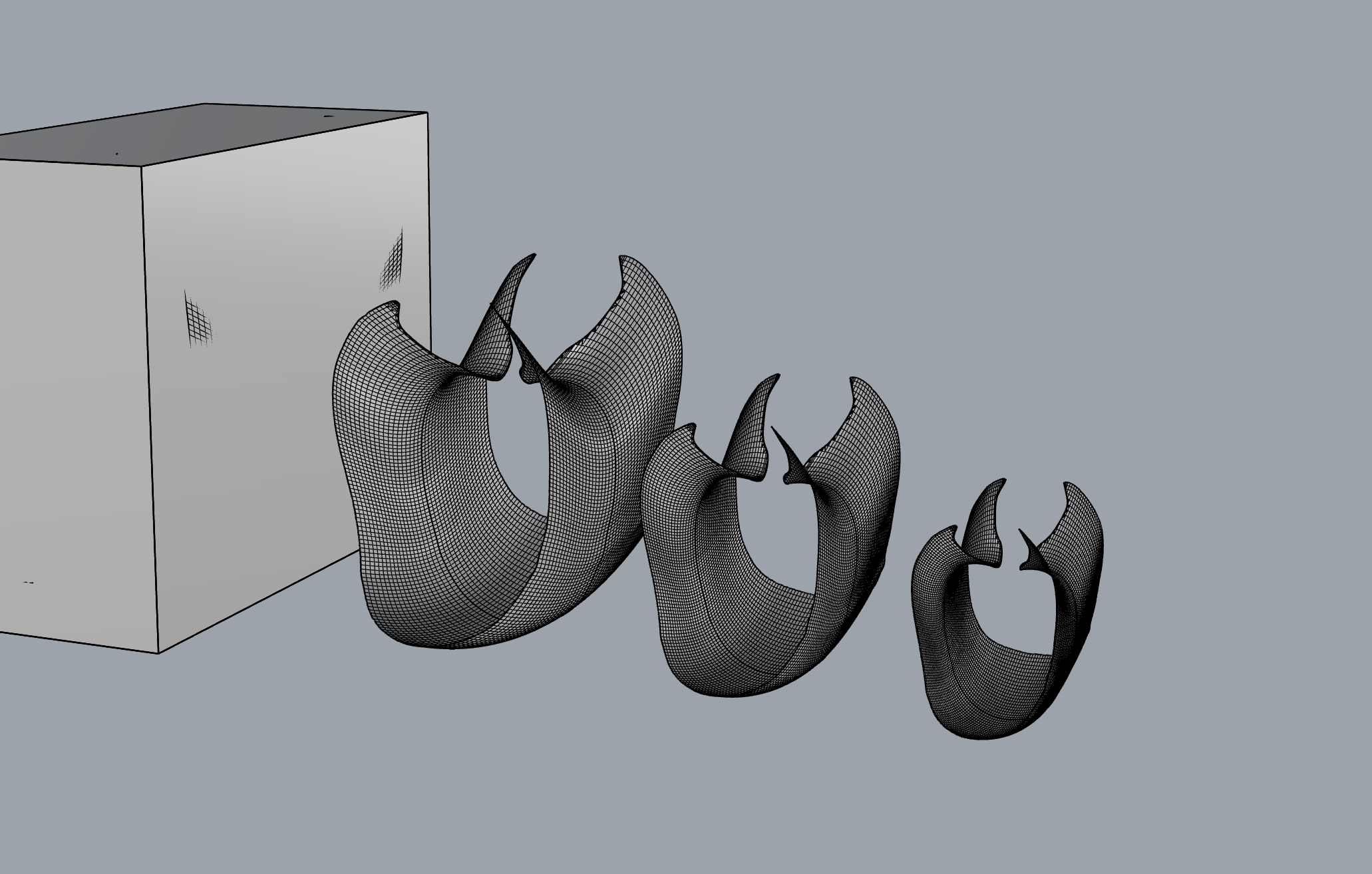

I’ve purchased a selection of LED filament strips to test inside the shells, and I’ve also 3D printed connector pieces that unite multiple shells into new composite forms. You can see several of these 3D printed Nautilus segments from my scans below.

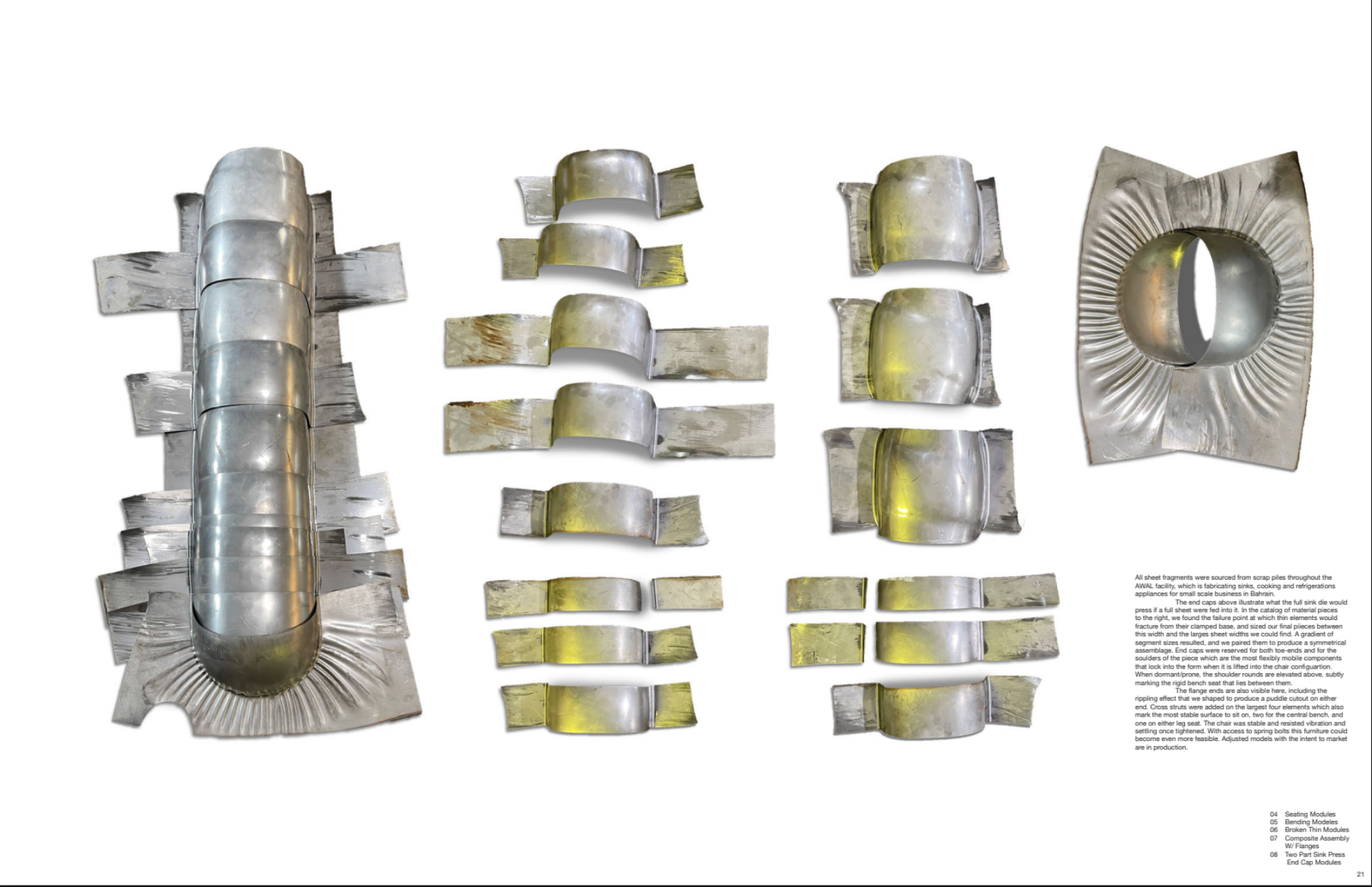

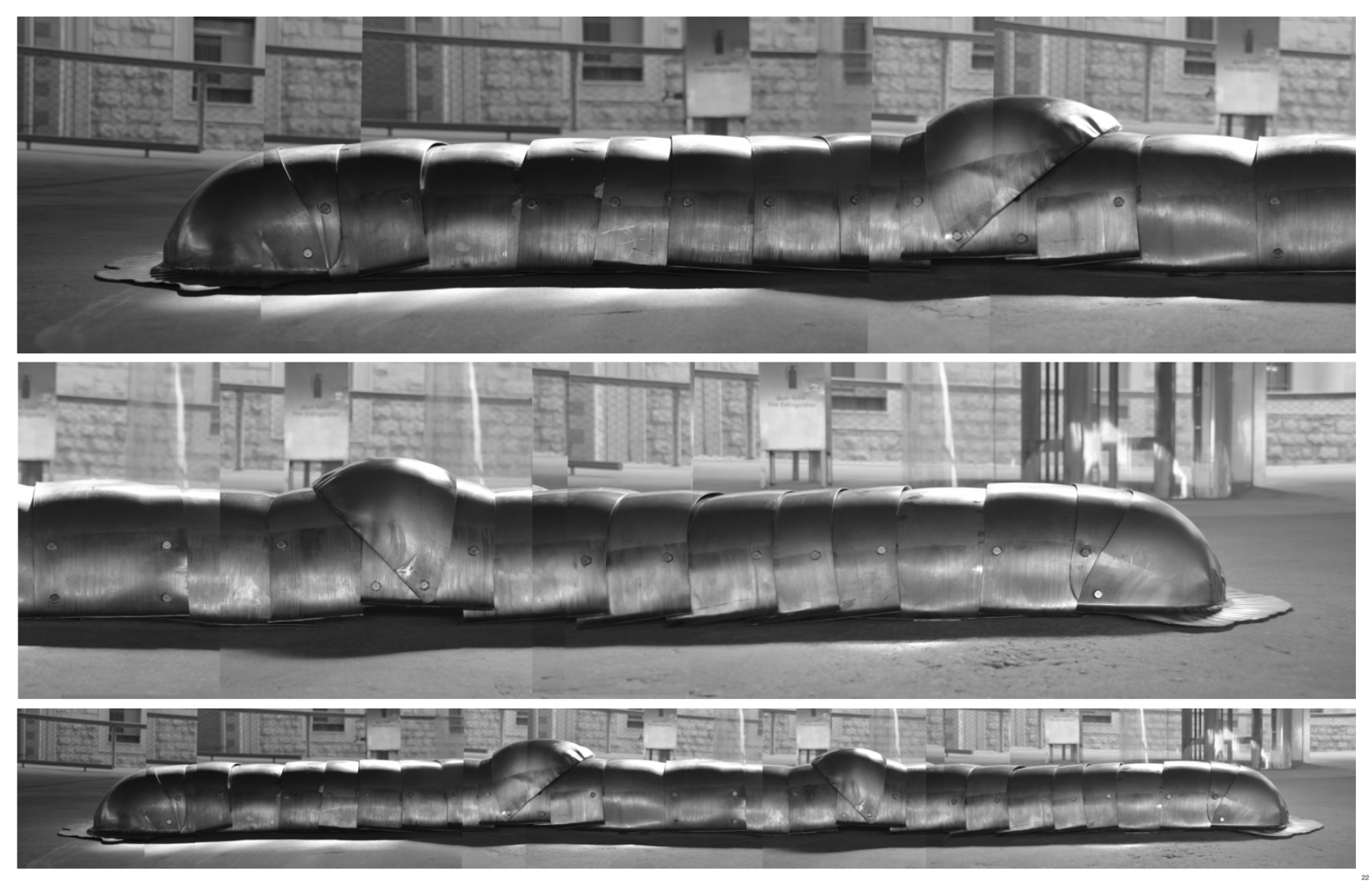

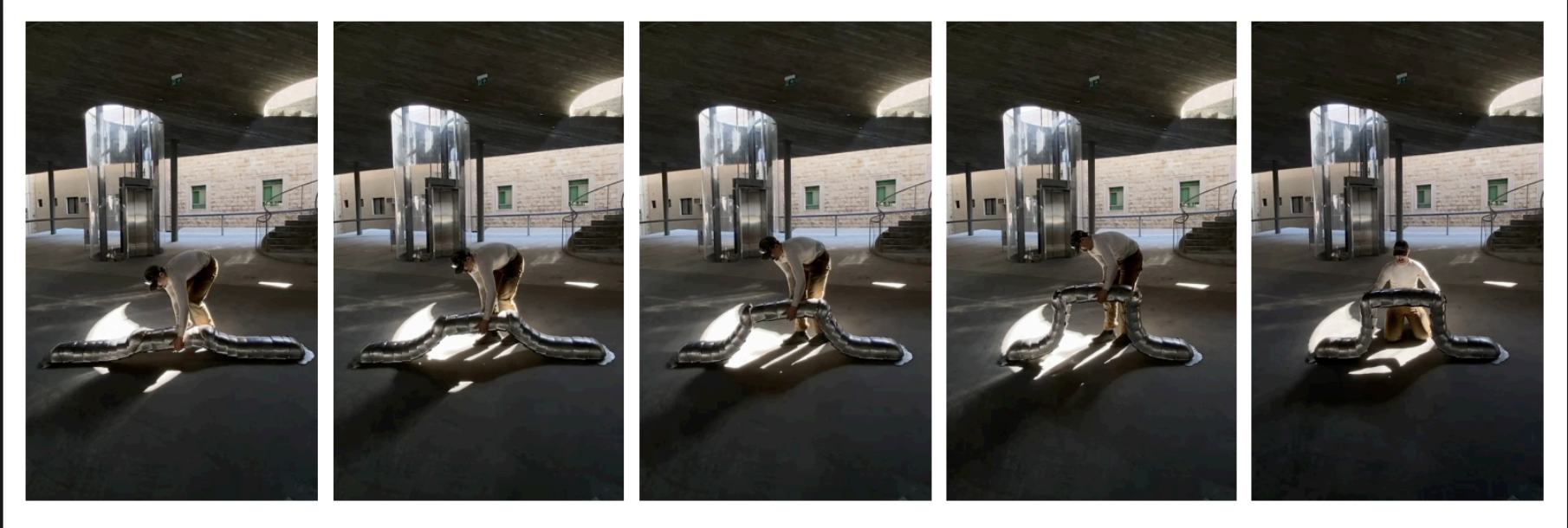

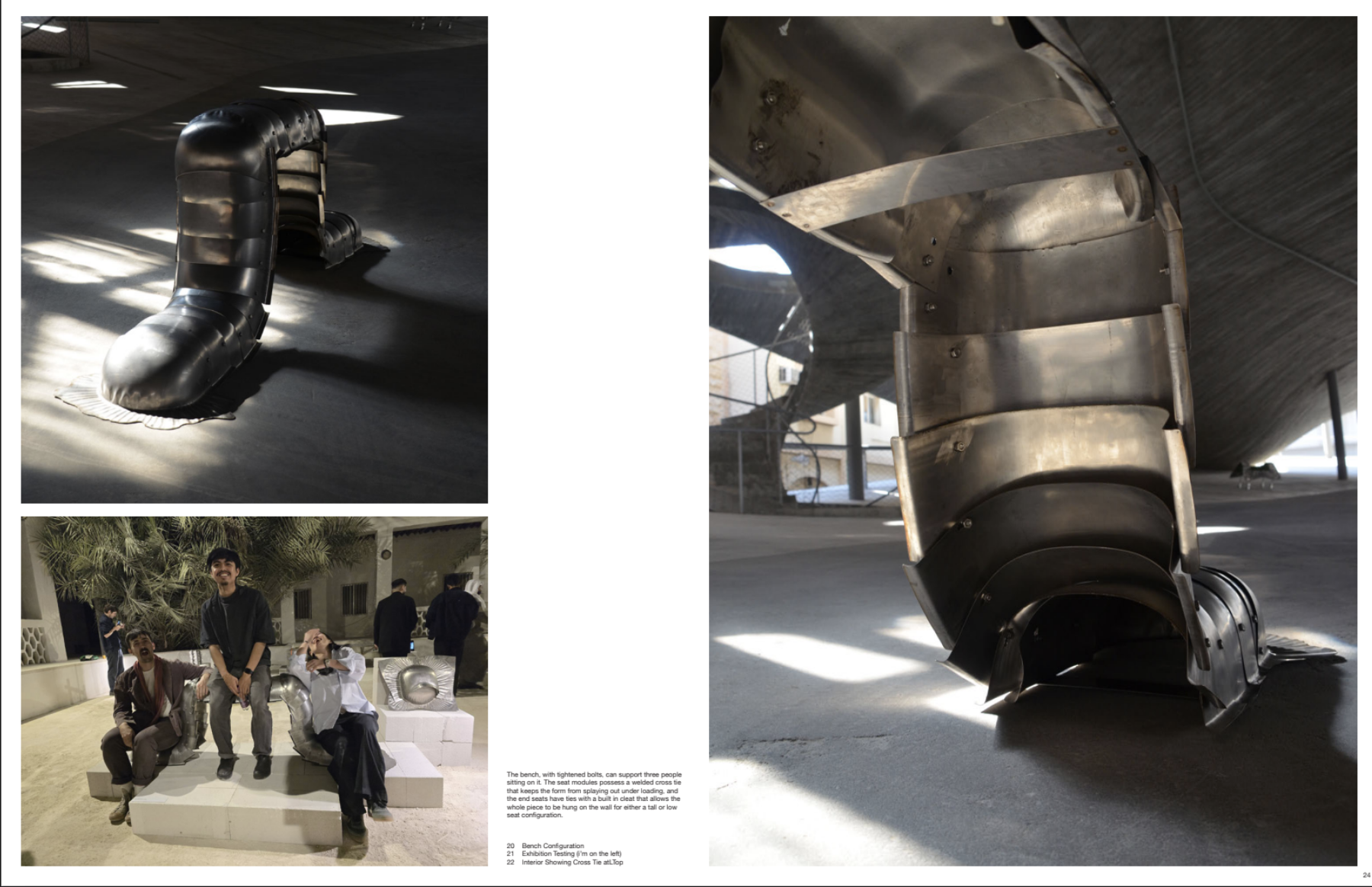

I’ve had experience milling large aluminum pieces as well as milling wood and producing finely tuned metal objects—both small and large. In some of these photos you can see a “Gauntlet Chair” that I made using the same hydroformed sink piece. I created sectional cuts of the sink that could slide past one another like armor, forming a kind of rapid prefabrication method for articulated structures. The resulting extrusion had elbows, toes, and a mechanical rhythm—it made the best sound when it moved.

Part of me keeps thinking about translating that sensibility into the Nautilus shell—taking the curves of its open maw and maintaining the S-curve that’s reminiscent of articulated armor. I imagine producing a formed metal housing that might even move, something kinetic or transformative. It would be incredible to unroll the nautilus, letting its voluted structure unfold outward—like armor revealing itself—to power on the lamp.

In addition to hydraulic pressing, I imagine that it would be straightforward to produce a fourth-axis milled base for the Auger shells—a way to bring the organic spiral into a controlled machined continuity.

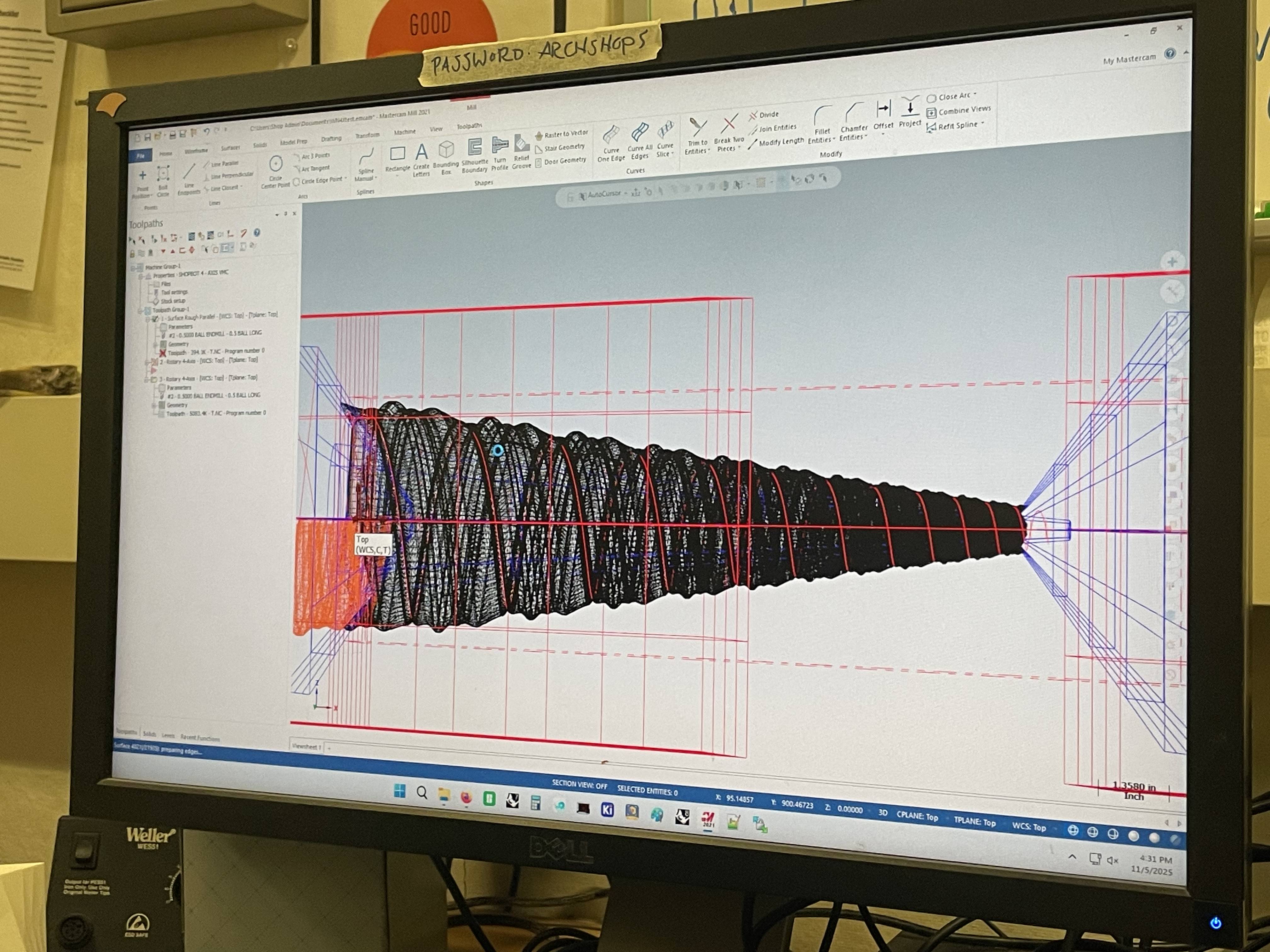

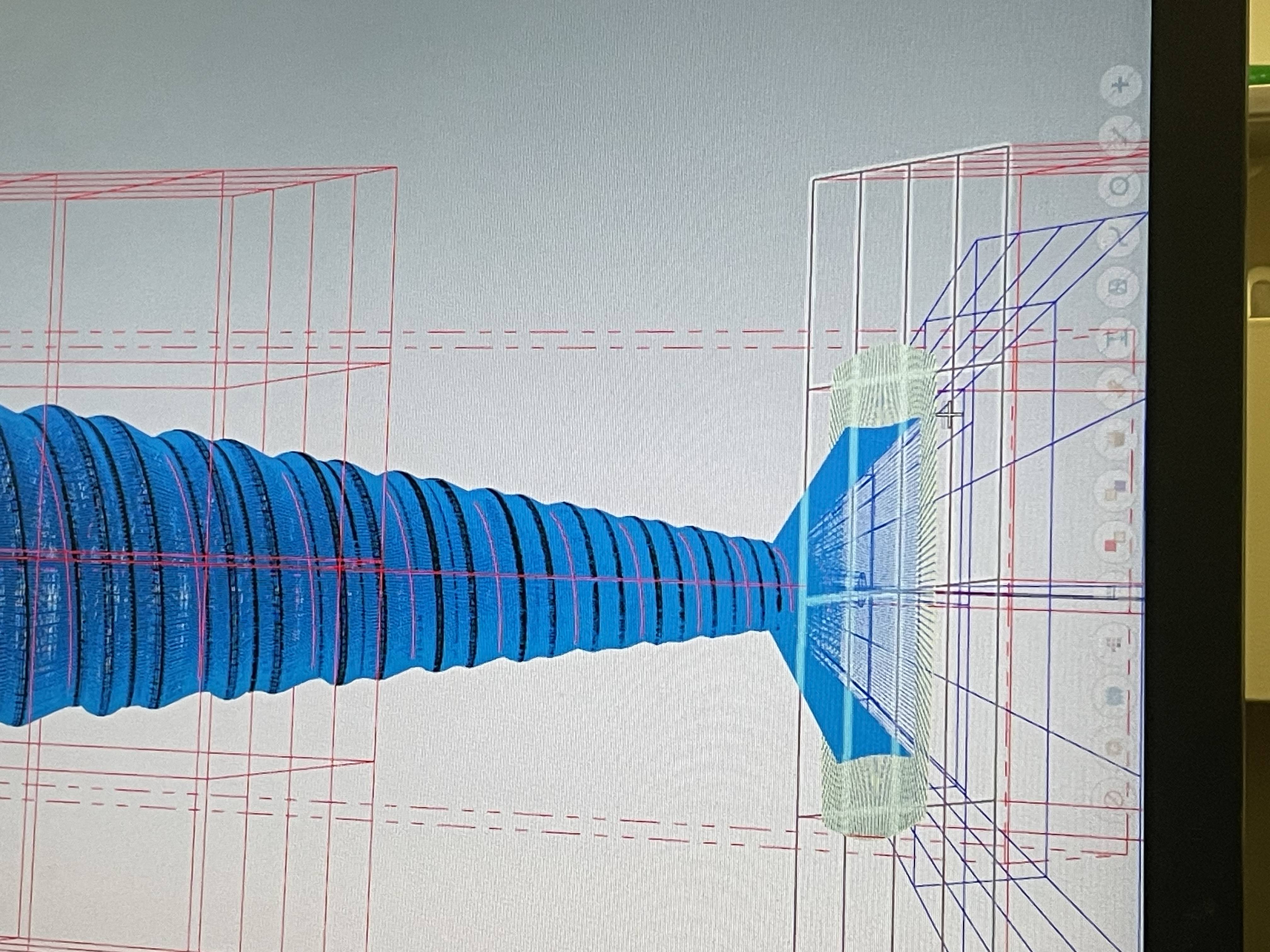

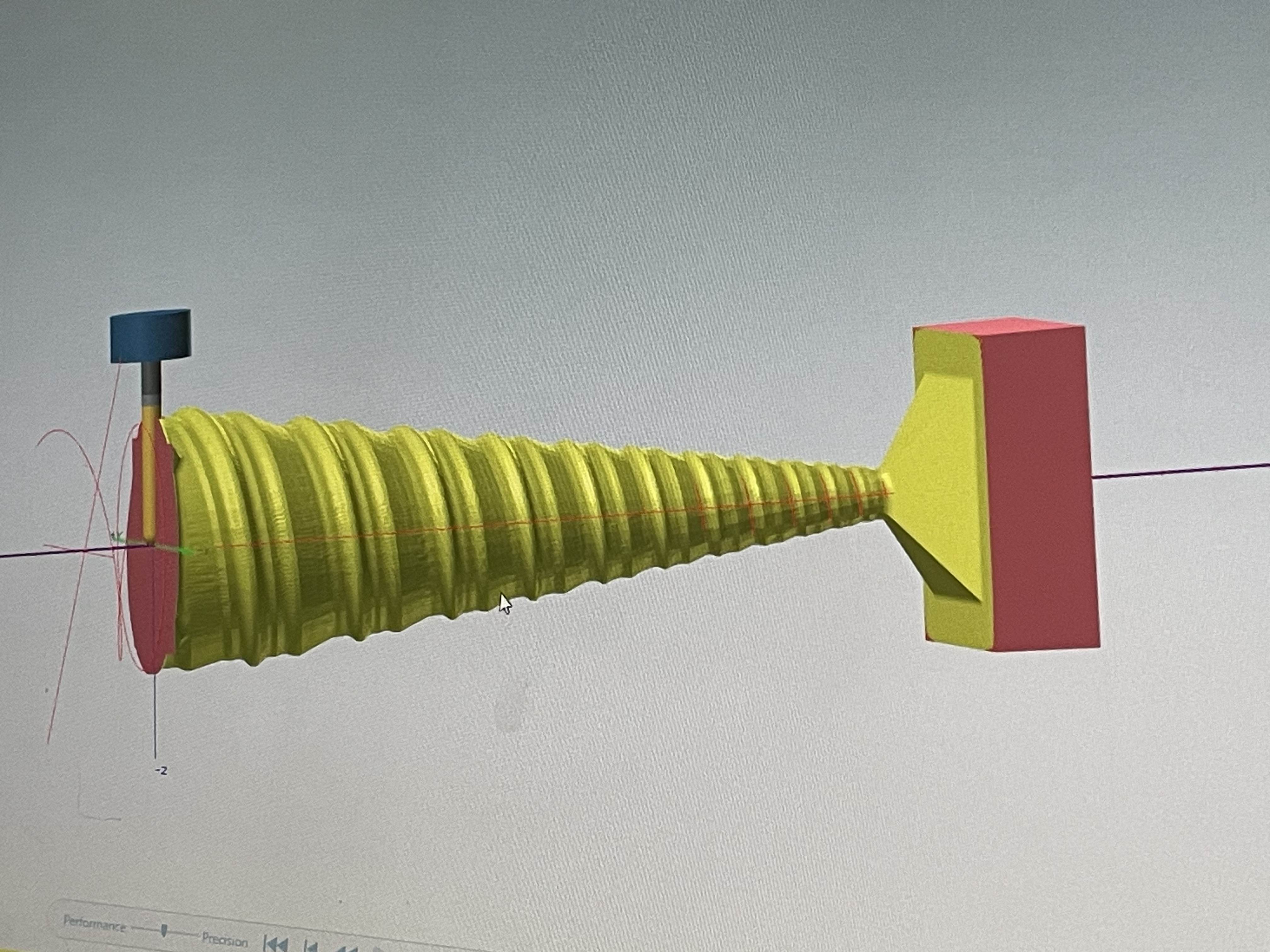

For Milling Week, I decided I would use a fourth-axis or fifth-axis mill to rotate material while carving a complex CNC job. After spending time thinking through possibilities, I realized I could apply the same shell-extending workflow I’ve been developing to spiral shells. I immediately imagined a lamp base that continues the parametric spiraling of auger shells.

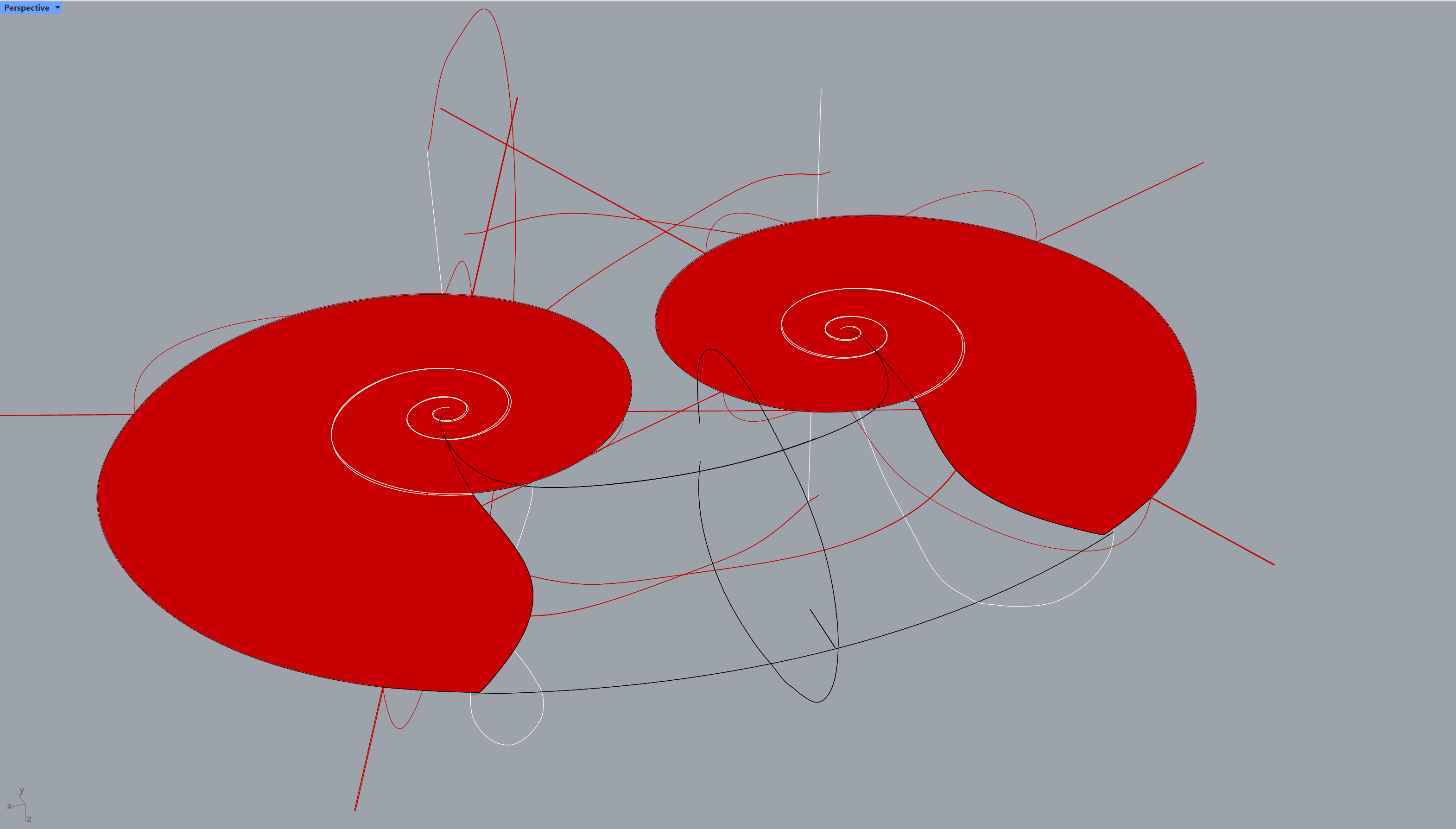

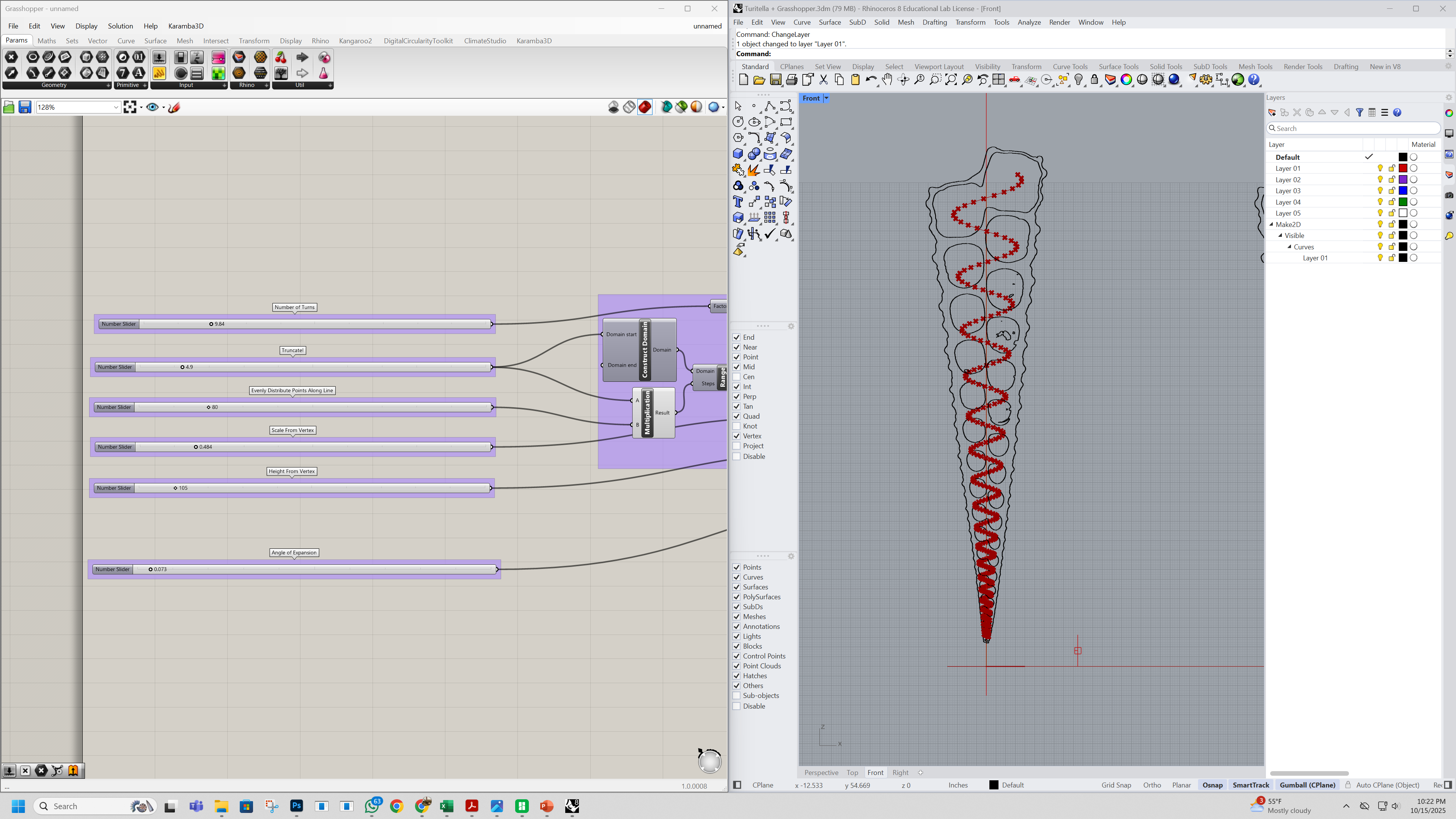

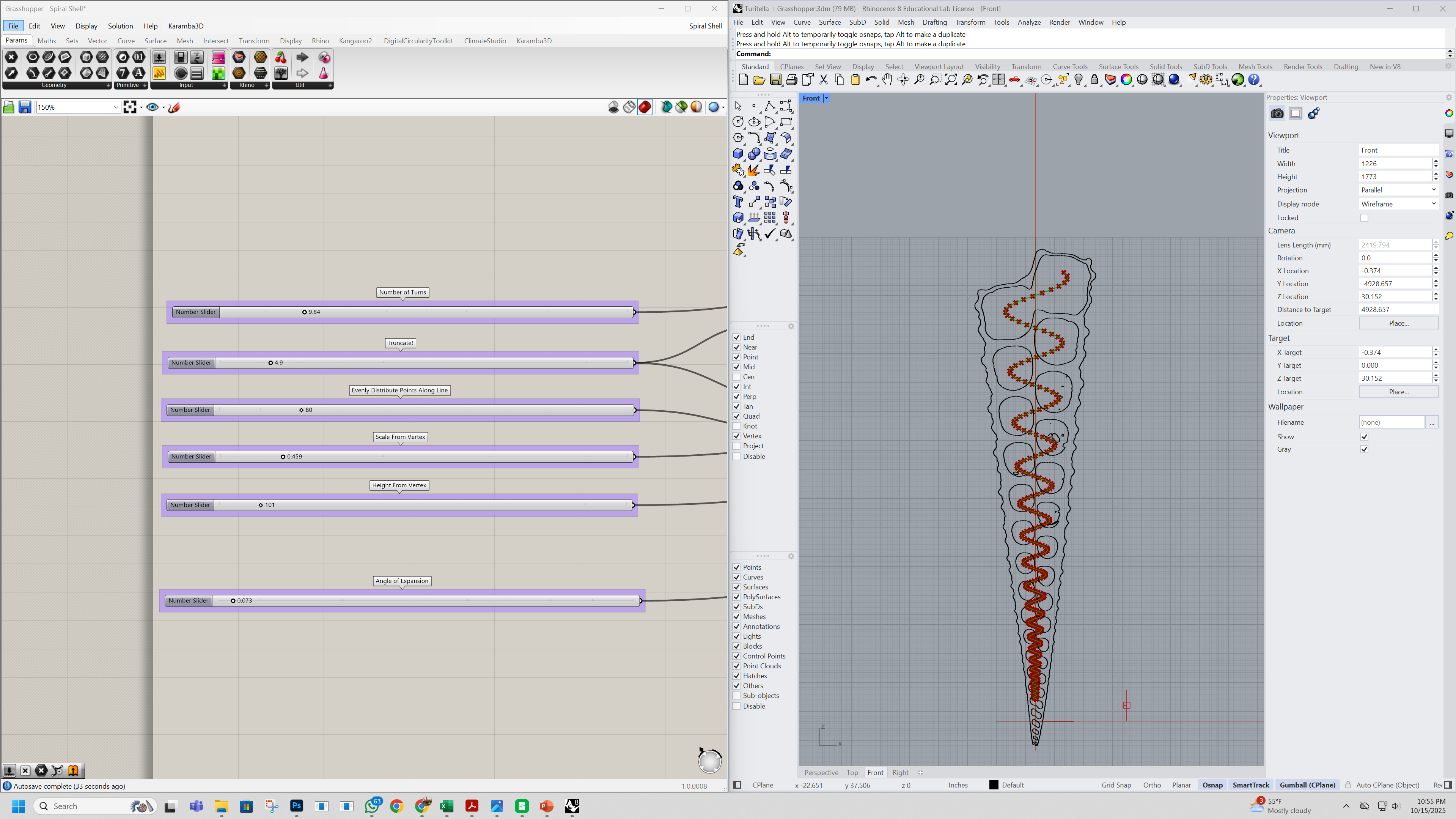

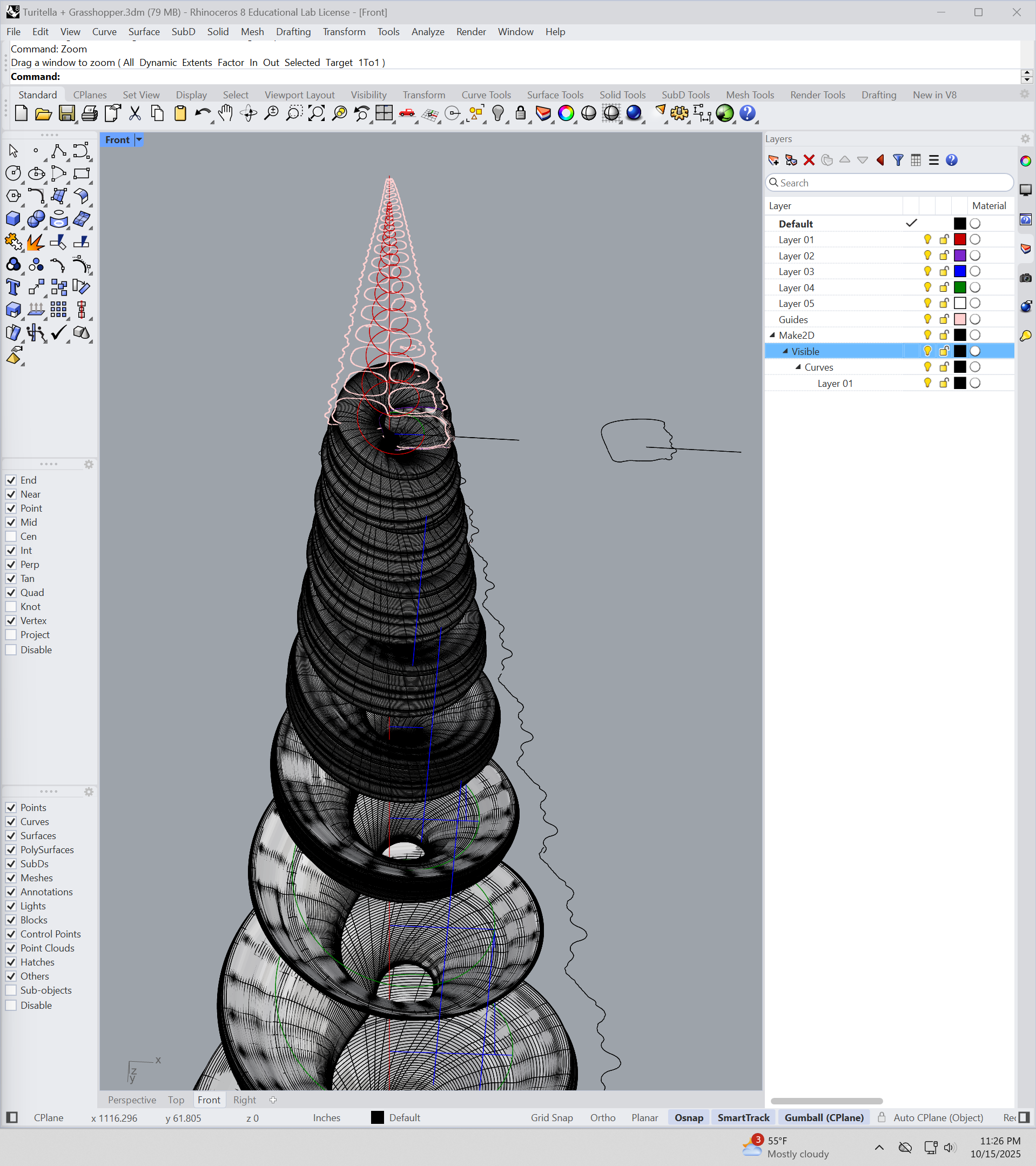

I went online, found several scanned turritella and auger shell models, and began building a parametric system that could reproduce the incremental expansion of the spiral that describes the shell’s growth. The process was fairly straightforward, though it will need refinement with components I haven’t fully mastered yet, especially when a shell’s growth pattern isn’t linear. Fortunately, many shells do grow consistently, essentially forming a cone, which made the parametric modeling much easier.

My Grasshopper script (shown below) can generate a series of cross-sections along a spiral path, which can then be used with Sweep 1 or Sweep 2 to produce a swept solid that closely approximates the original scanned shell. A few important things were needed to make this work: a high-resolution scan; a clean centerline; and a section of the shell that would allow me to align the apogees of the spiral in elevation with the shell’s natural growth rhythm.

I’m now planning to repeat this process with the shells shown in the attached photo. Each one has a slightly different growth rate and cross-section, which will allow me to produce four or five variations of a conical lamp. The tip of each shell will act as the bulb, with the extended spiral forming the lamp base.

I need to produce proper high-resolution scans of the physical shells I ordered—probably something better than Polycam—and then practice the fourth-axis milling workflow. I’ve already spoken with Jen about this over the last two weeks. The plan is to mill the forms from baseball bat blanks (3" × 36"), a material I’ve used before to make carved “club” sculptures.

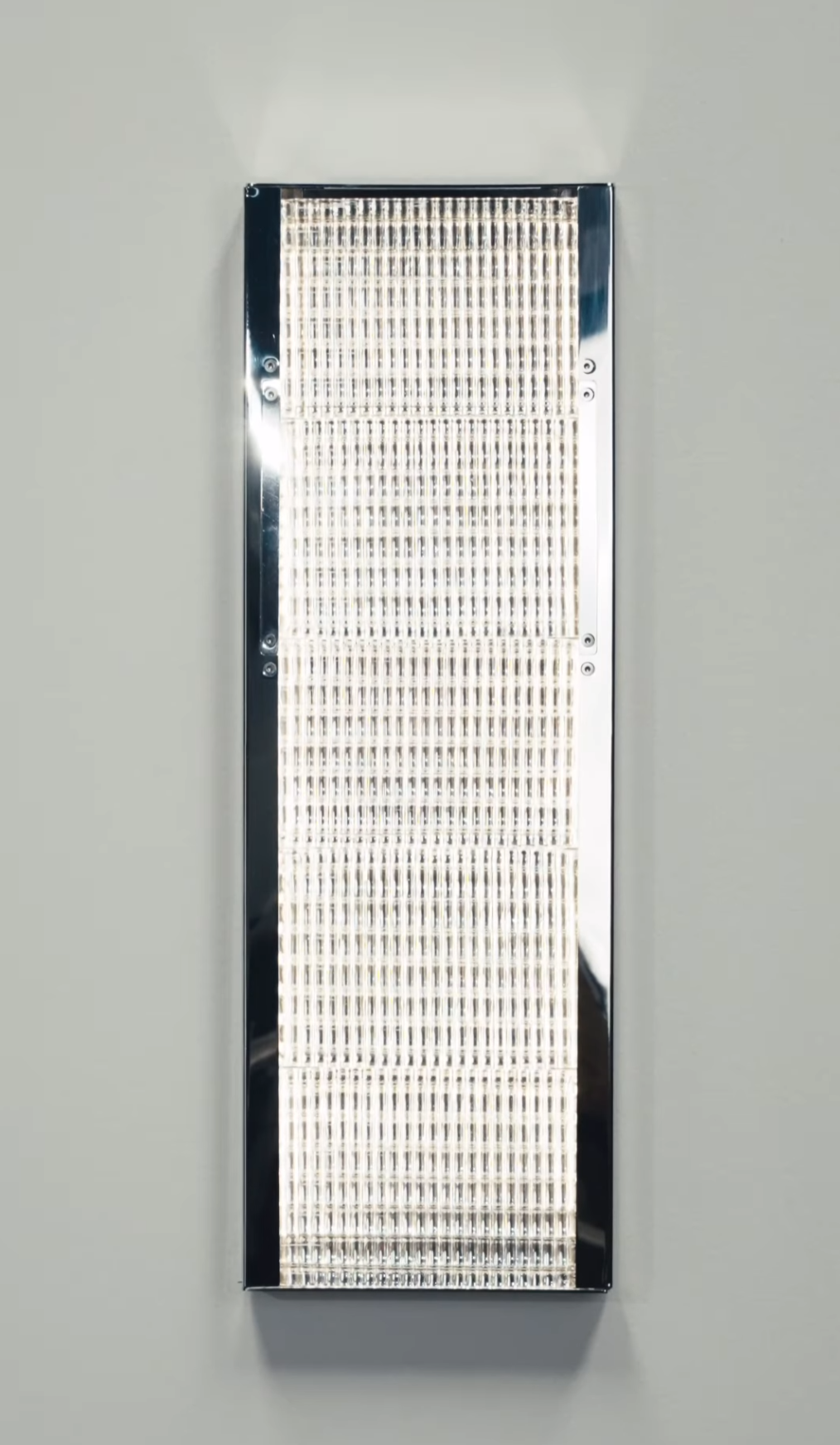

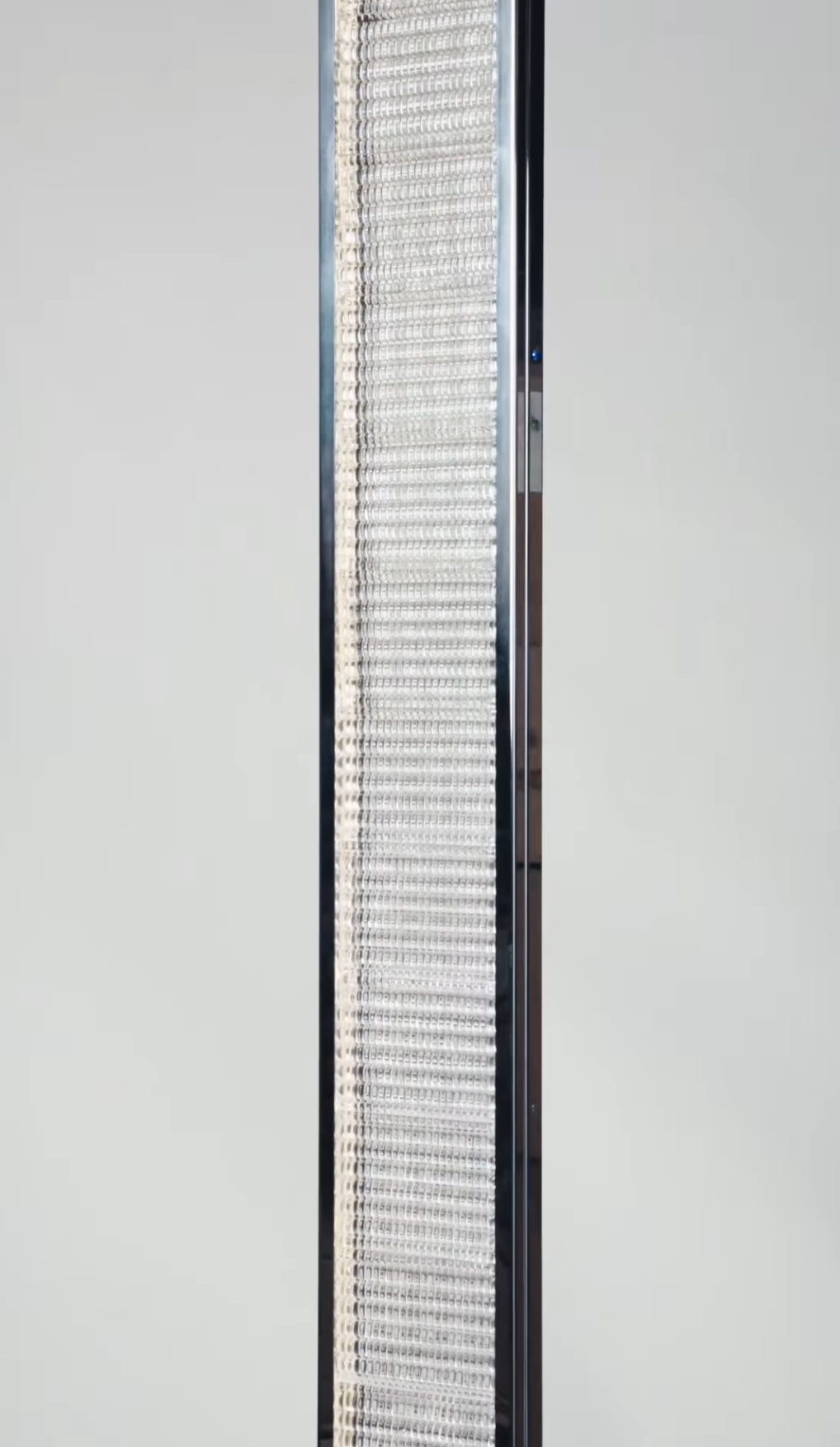

For illumination, I ordered LED filament strips from AliExpress (shown in the third photo). They appear bright and rigid enough to feed several inches into the shell. Heat may be a concern, but I’ll address that once testing begins.

MOCKUP

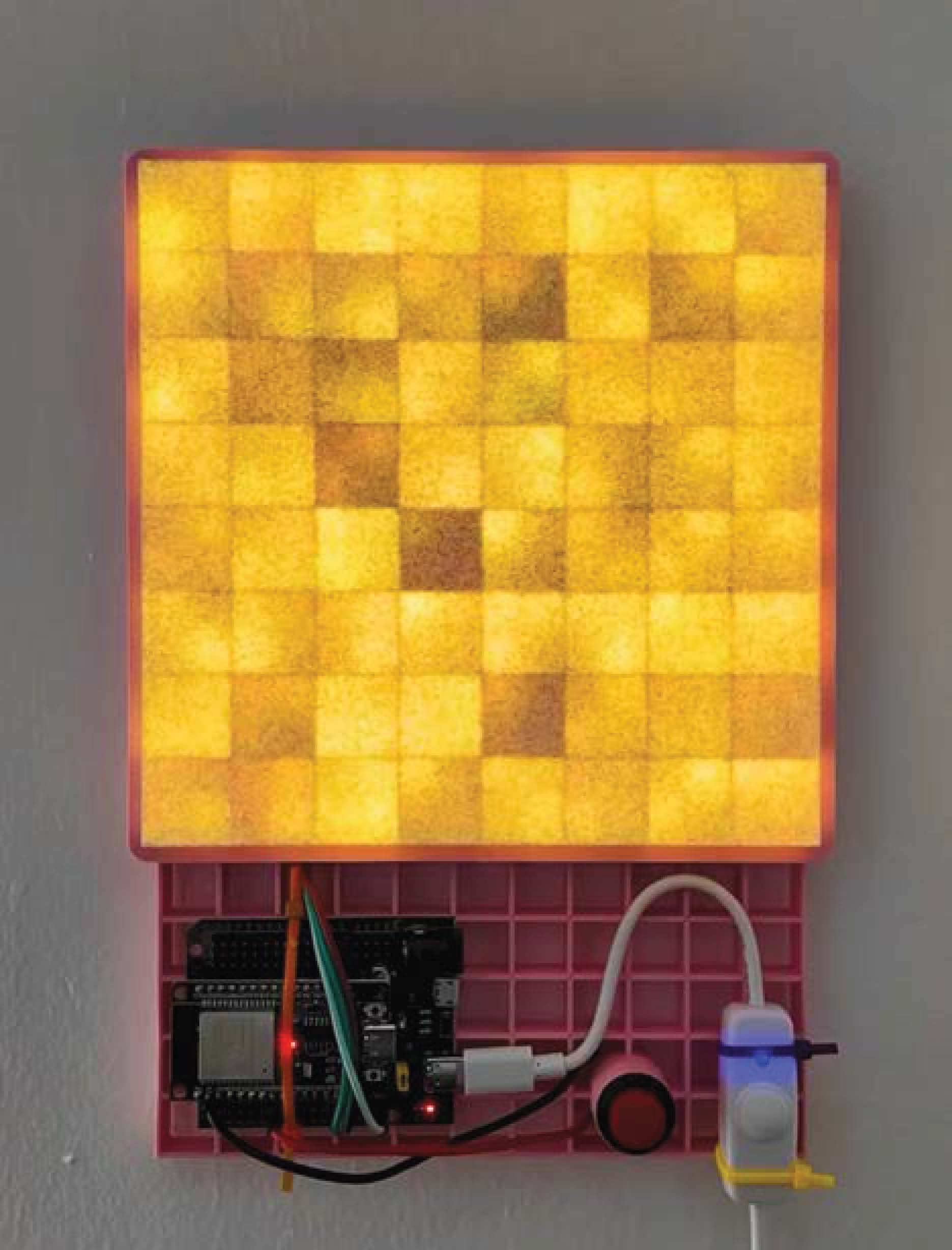

Fourth-Axis Setup, Shell Scans, and LED Control PCB

This week I made a lot of progress on my final. I worked with Jen to get a fourth axis CNC mill set up. Several processes included setting a taper, producing toolpaths, and making sure the toolpaths don’t intersect with the milling material or that material kerfs hit the tool in its assembly. The piece of wood that I was going to use was not set up to make this happen, so I’m re-gluing a piece of wood with a channel down the middle, a simple table saw channel with no glue in it, so that we can turn this piece this week. In fact, I need to do that today after class. In addition, I’m going to be scanning and parametrizing a bunch of turritella shells that I’ve found that are going to become lamp bases. There’s so much to do and it’s a little crazy.

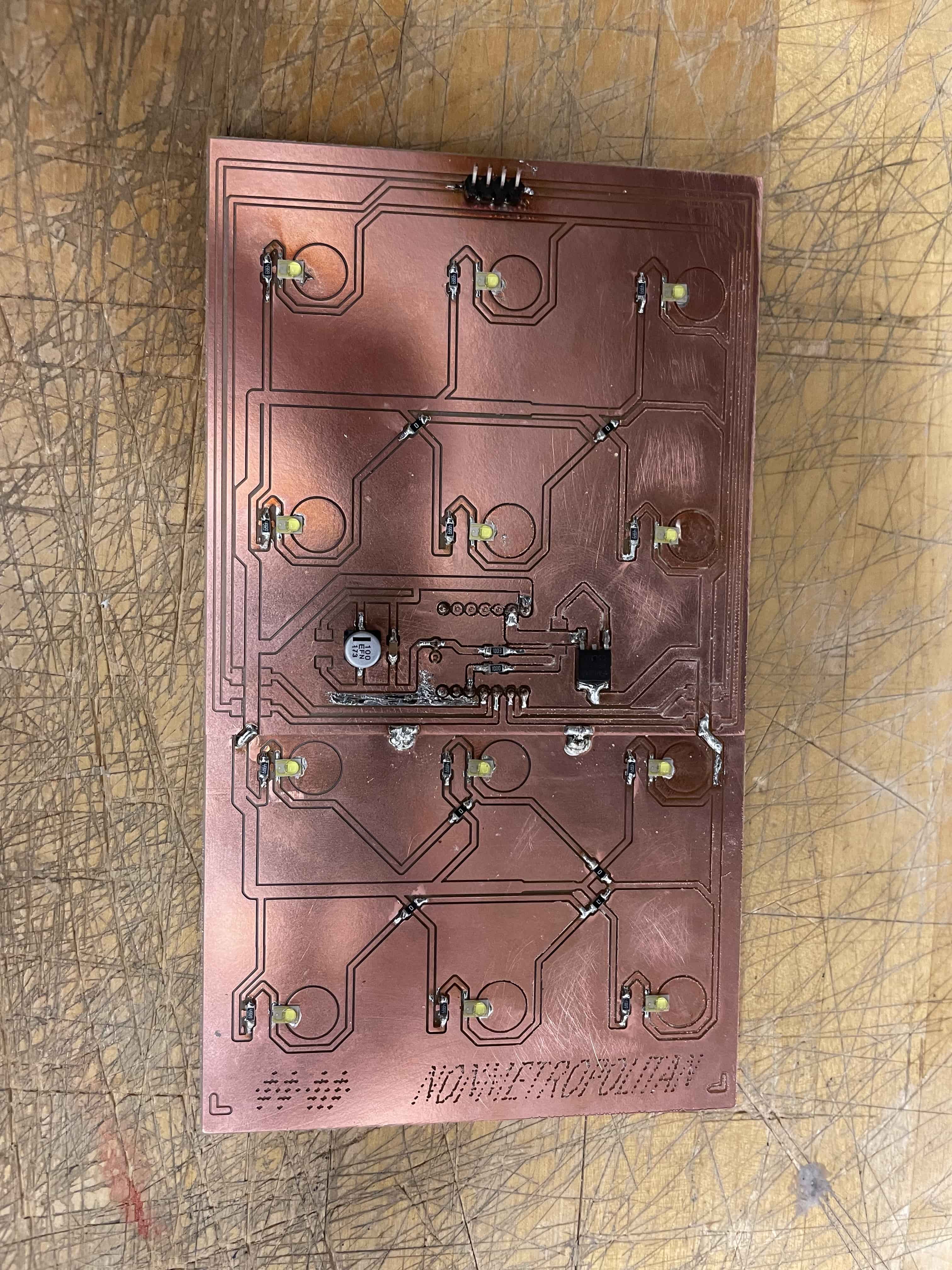

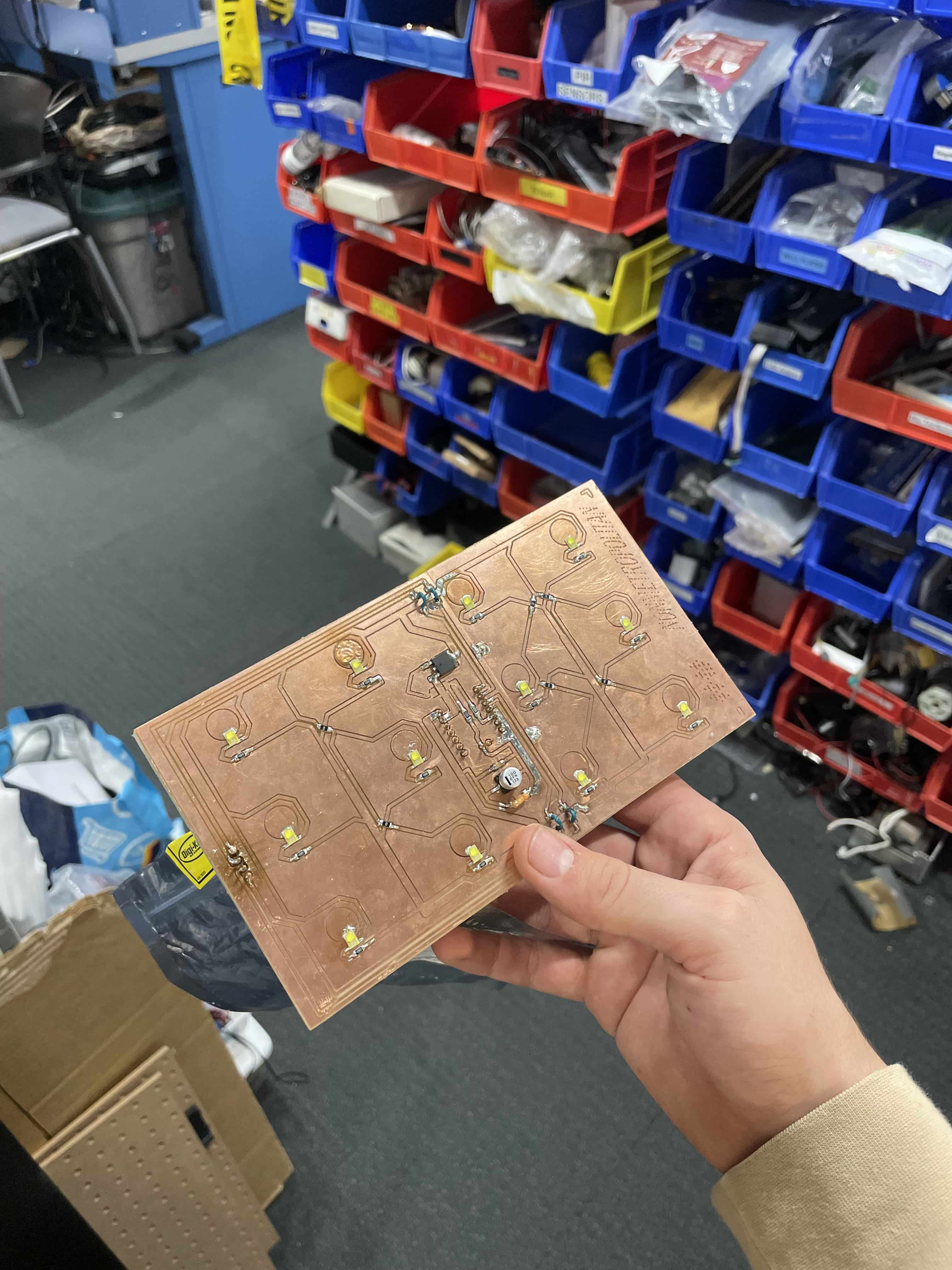

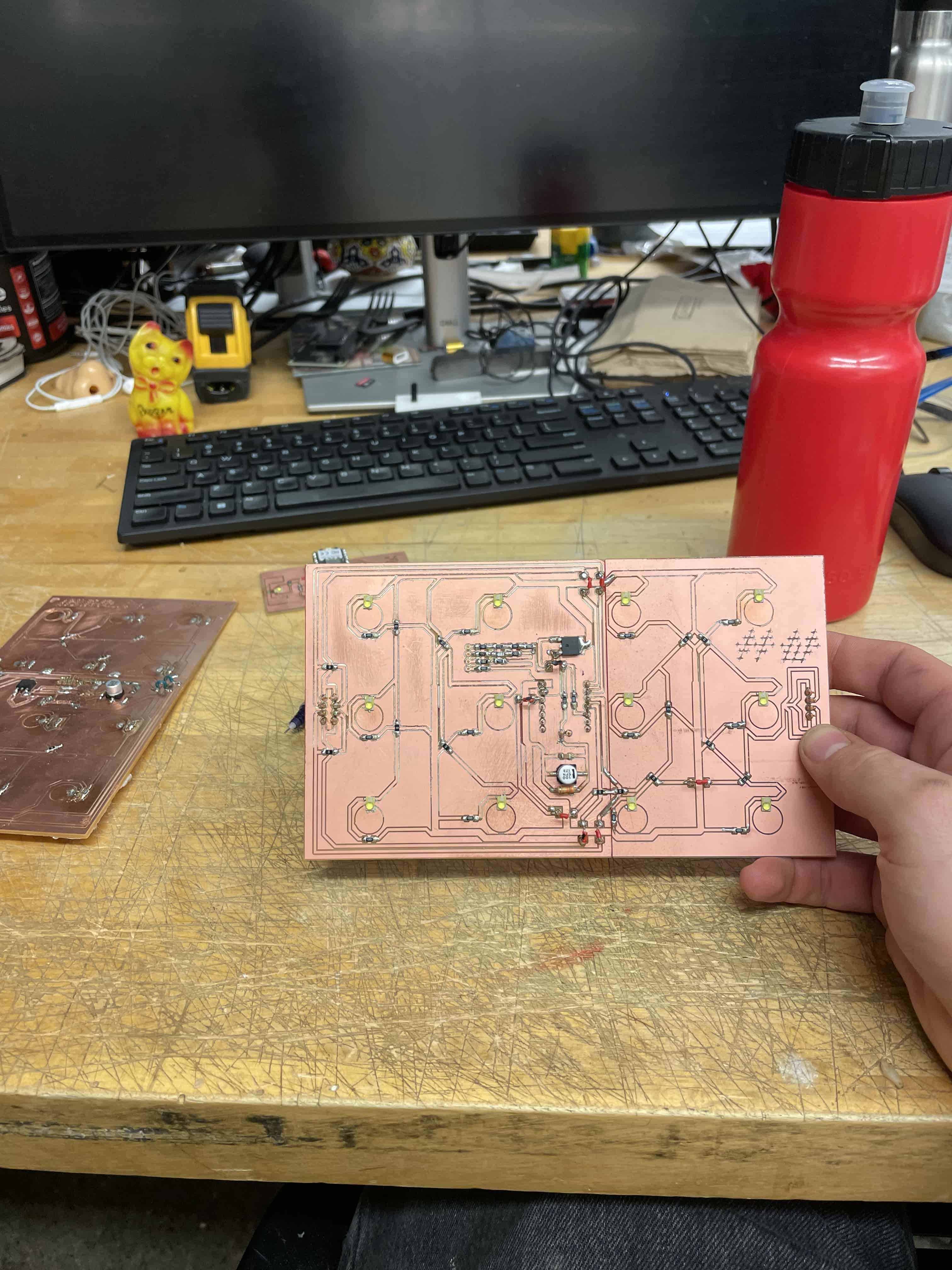

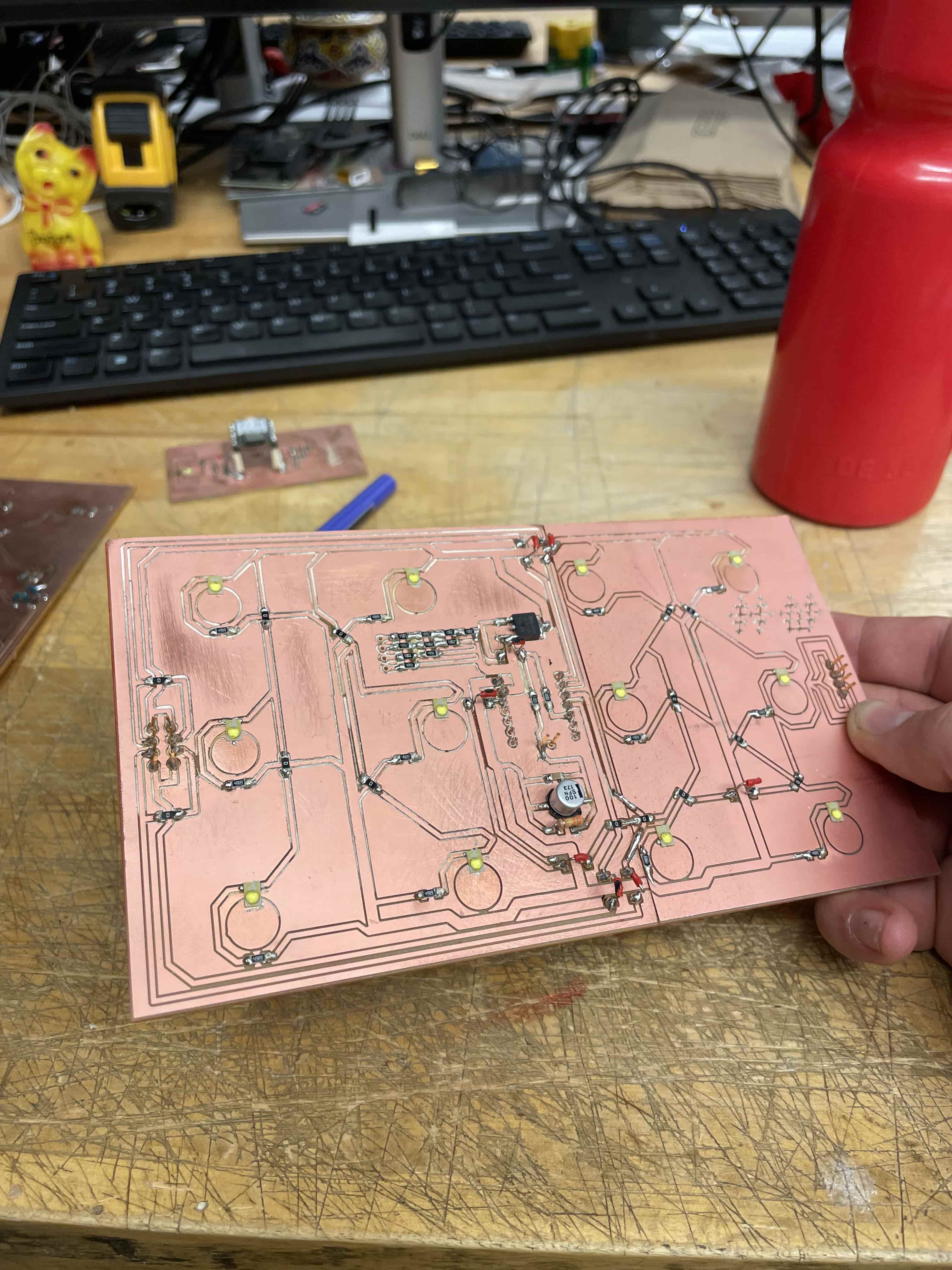

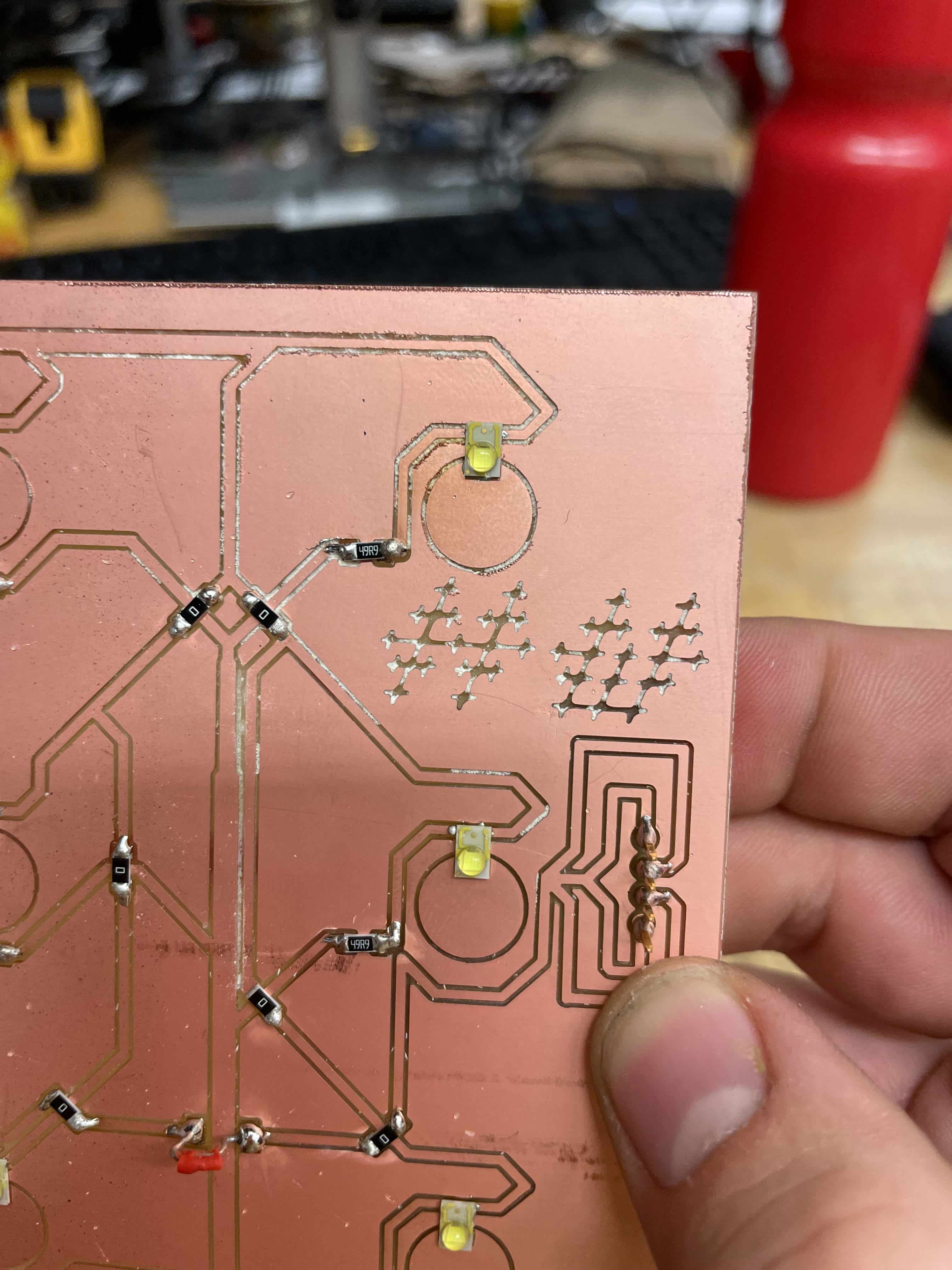

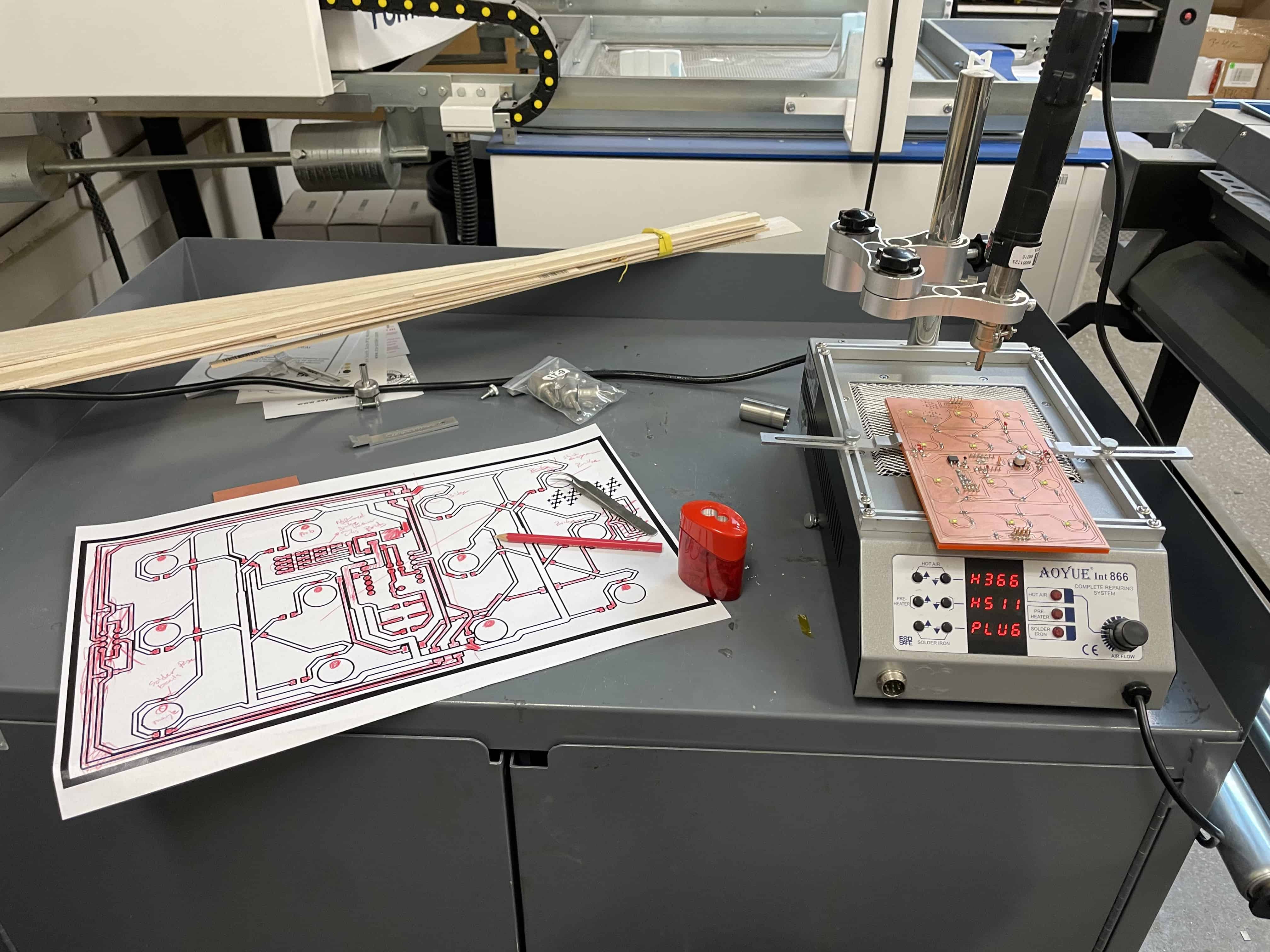

I also made a lot of progress on milling my PCBs for these LED arrays. I produced all the schematics in KiCad, did one version where my LEDs were backwards, and had to restart. That felt amazing. I’ve also been developing this lightbox and asking people what they think about its orientation. The current idea is to use the flat side and gild the whole thing so that there could be a window of blue light that shines out of a larger golden panel. This wood face is very flat and very nice; it might be better than gilding just the surface of the little stick-out chunk. That said, I really like the stick-out chunk. When I bought this piece and honed it, I assumed I’d be using it in the other orientation. We’ll find out. I don’t know. I need to make a small test of the gold leaf, so perhaps I test it on the small side and then we do a flip-a-roonie and do it on the other side if it works. Maybe that argues for the gold tester to be inset just a bit so the gold doesn’t rub against the wall or get touched, giving it a kind of protective border against damage.

The other thing I’m thinking about is that perhaps the gold won’t work very well unfinished without a protective layer over the top. I don’t know what’s typically done in gilding, so I need to look that up. Something tells me it’ll be nicest without any protection—which I’m conceptually very into. I don’t know if that will actually be a good idea because how will I move the thing? We’ll figure it out.

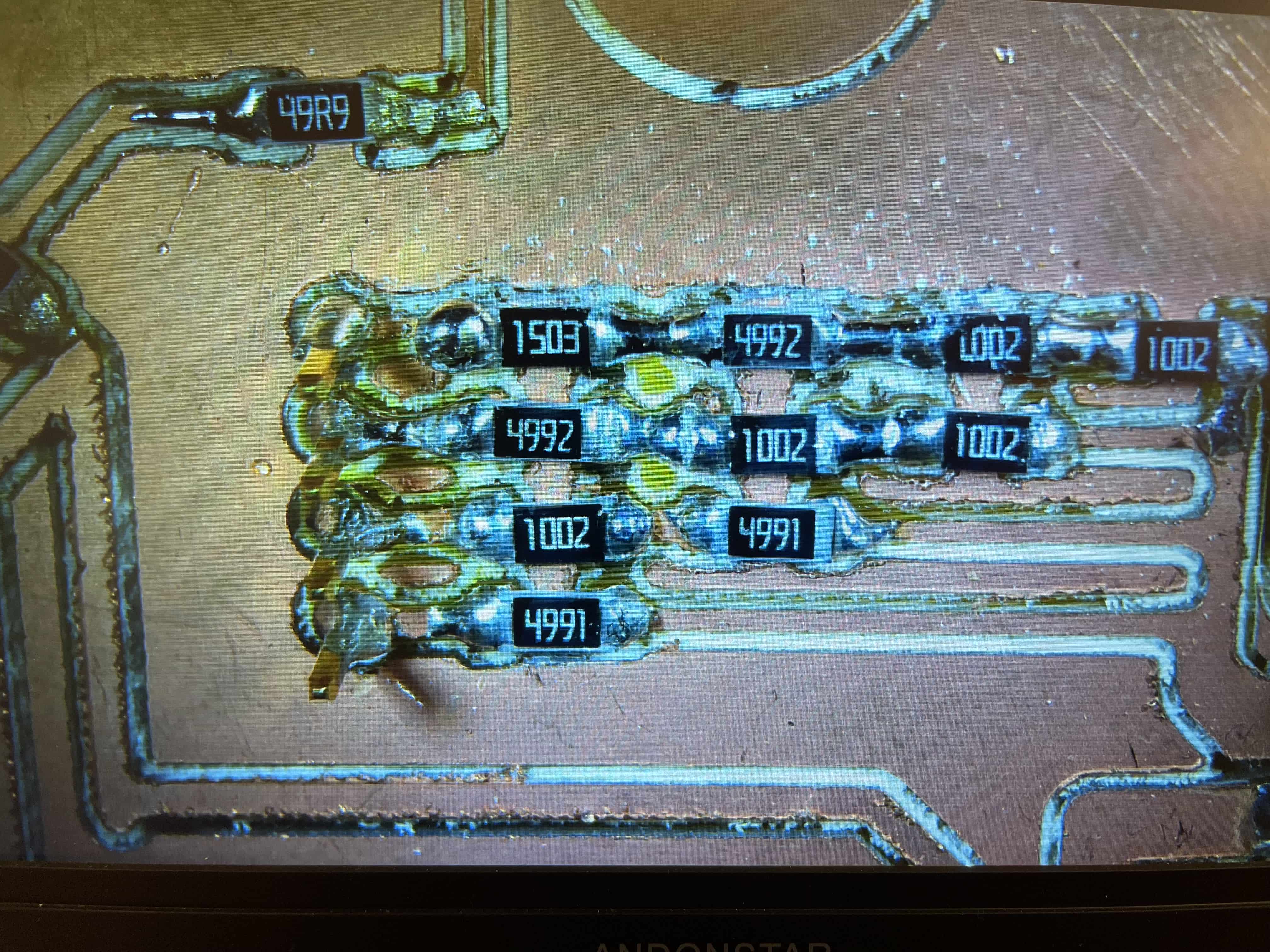

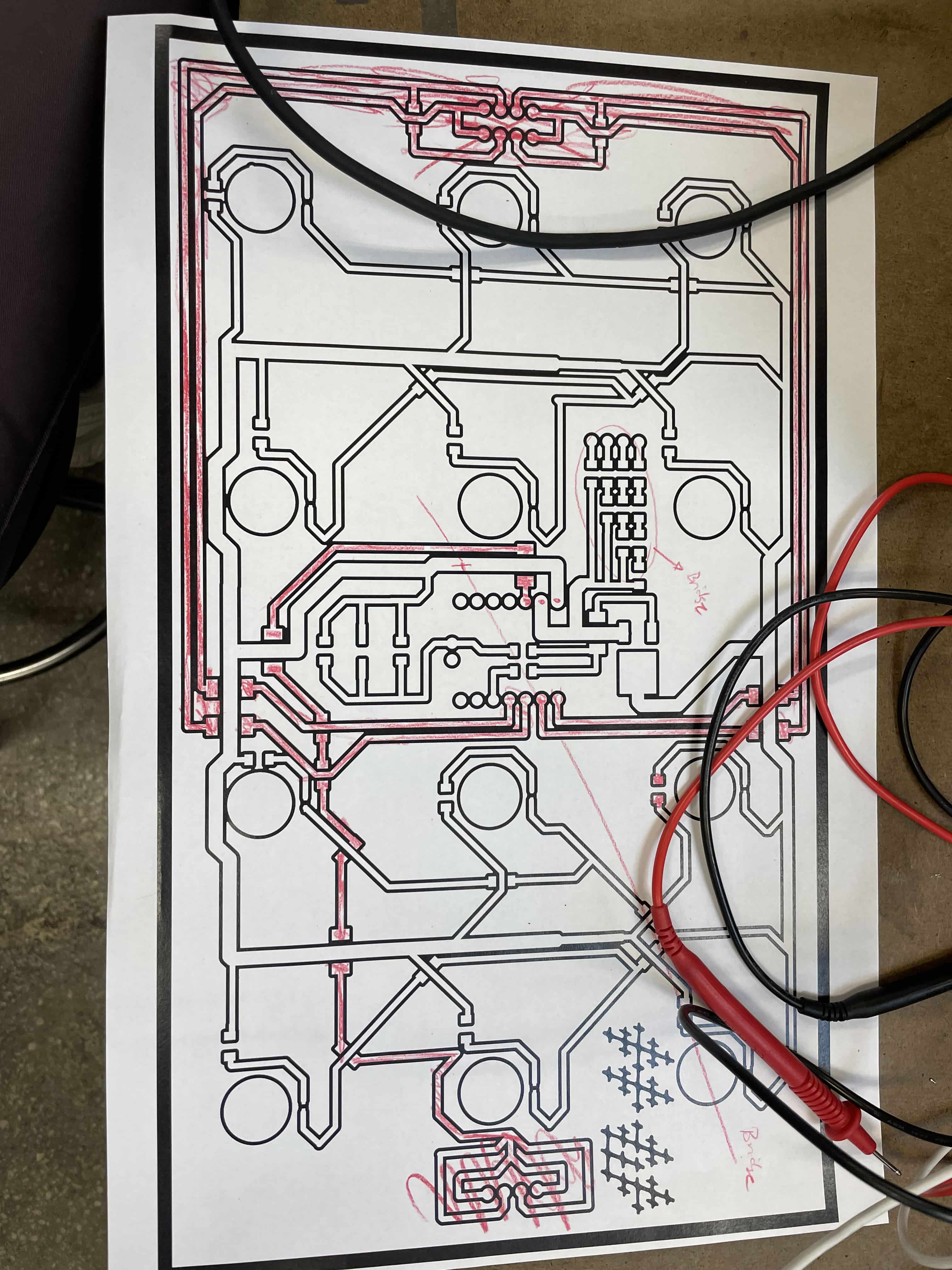

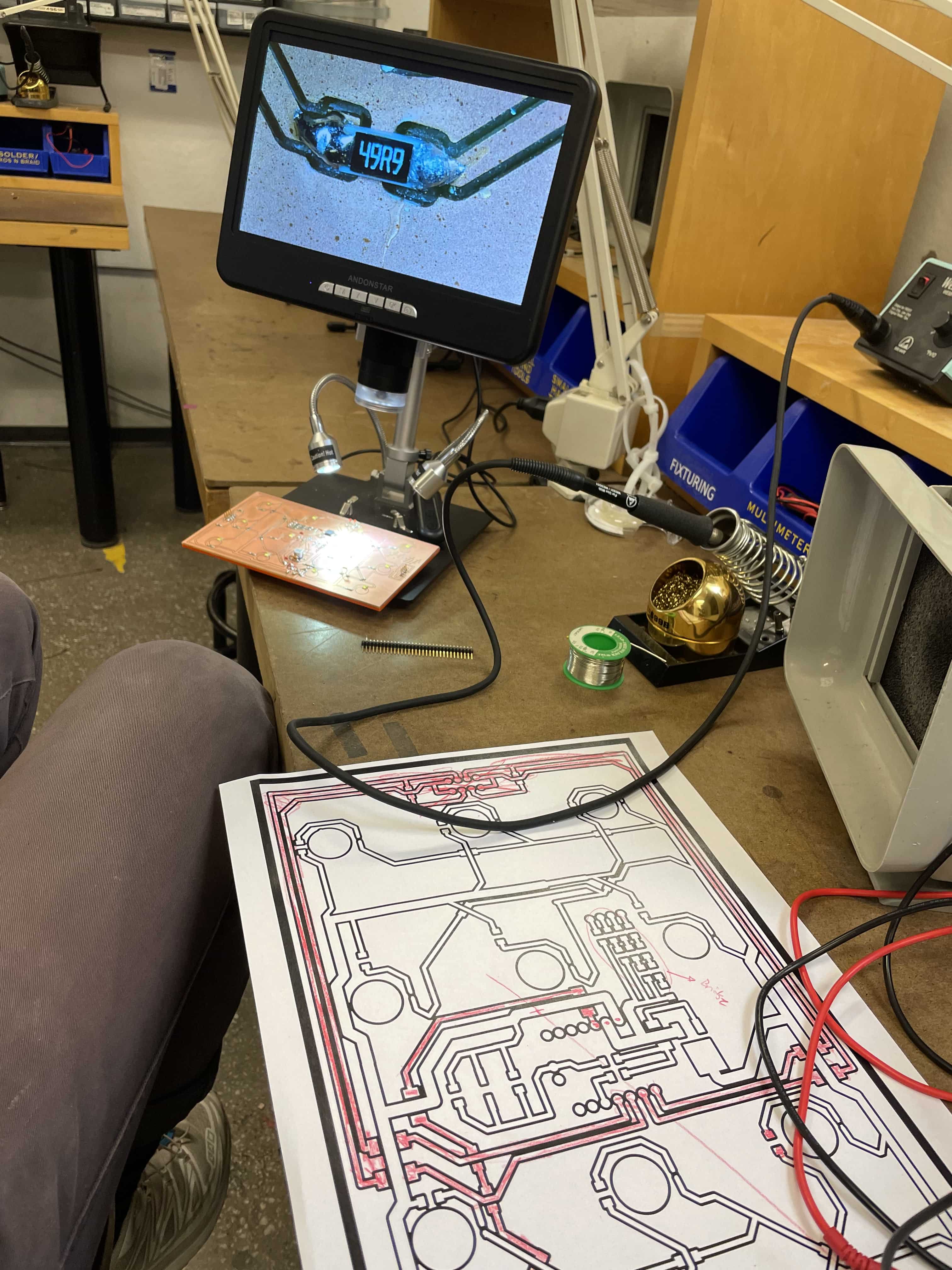

You can see in my array—I'll share a schematic photo—where I’m debugging. I’m using a red pencil to test connections, continuity, and resistance. I have an array that goes through the 5-volt pin to power my LEDs with 49-ohm resistors, and then that transitions through the LEDs into a bus that goes to ground. But before it goes to ground, it goes through a MOSFET, the big one in our fab library, and then that gets resisted on its way to a data pin as well as on its way to ground. One of those resistances is 100 kiloohms, and one is 100 ohms.

Additionally, just south of the Xiao pins—reversed because I’m mounting it on the back of the plate, and I’m proud I kept track of that reversal—is a trio of components in series. One is a very large resistor that allows the board to power off slowly over time through the two capacitors, which are the other two components in that little series. One is a bulk cap, a large aluminum capacitor that keeps current steady after turn-on, and the other is a very small capacitor, around 0.1 microfarads, which keeps the initial high-frequency blip from affecting the lights and causing flicker.

I can tell my board is not very efficiently designed and there are probably many ways I could have saved space, but I tried to make the LEDs and their heat sinks—those circles—nice and pretty, and I used a lot of zero-ohm resistors to bridge gaps. I didn’t think too hard about consolidation. There are also pinouts on the back of the board for all of my sensors, which need four different resistance values. You can see little arrays of resistors tightly packed just to the left of the Xiao; I’m not sure that works well because my multimeter testing shows a ton of bridges. I probably need help figuring out how to fix that, but I’m working on it.

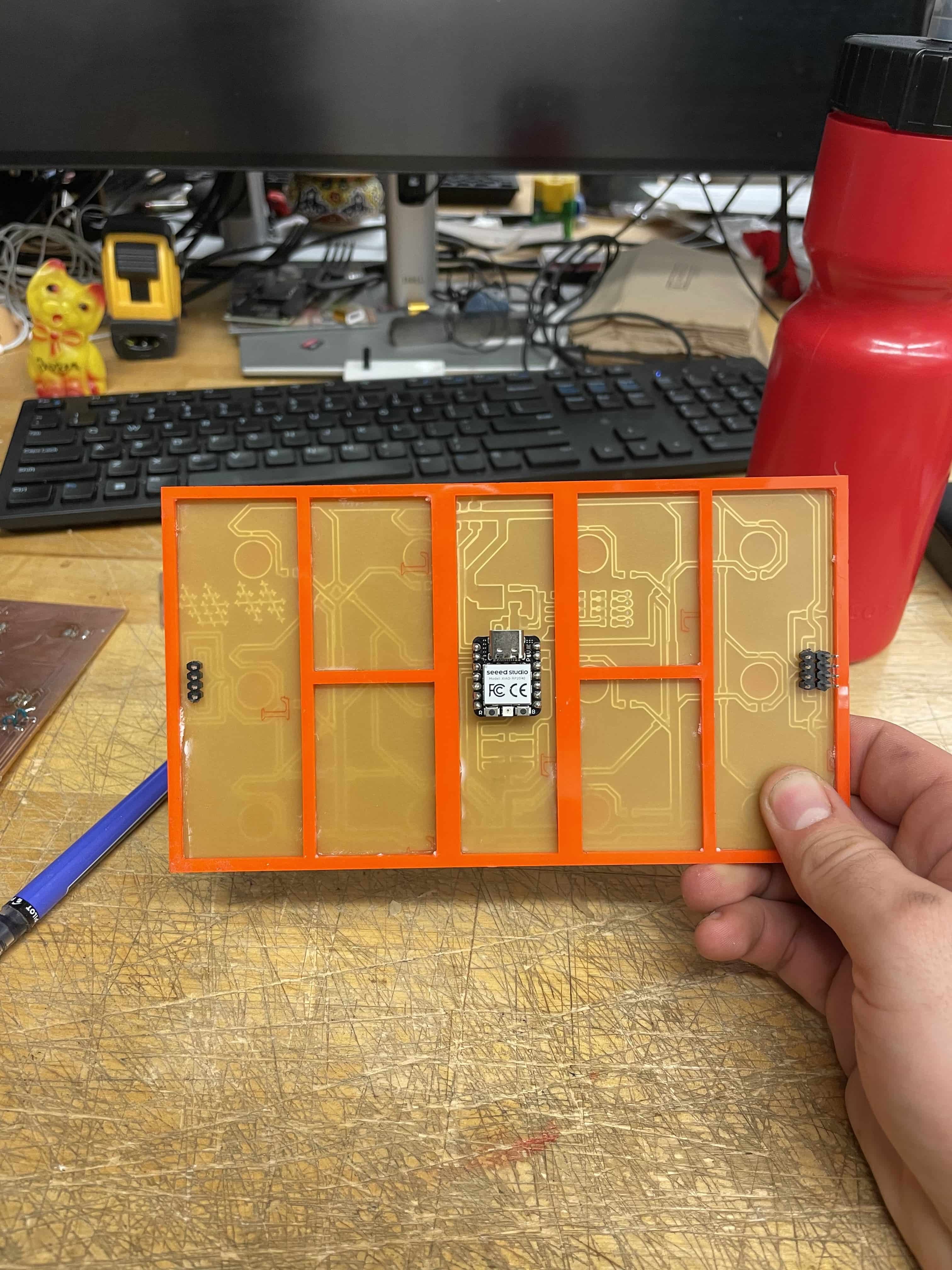

I also laser cut a little brace for the back in orange that holds the two parts of the board together. I tried to mill it out of one piece using our big machine, but couldn’t figure that out in time, so I produced a PNG that I thought only had three sides of cut, yet it still cut out the whole PCB on all four sides. Apparently, even if it doesn’t show up in the toolpath preview, the code still cuts it, which is frustrating. Anyway, I figured out how to connect it, and I spent a ton of hours on it this week, so I’m happy. I’m proud. Hopefully it has to work. It has to work. It has to work. I don’t know how bright or even it’ll be, but the glass I’m using is foggy, so I have a feeling it’ll be fine. Debugging to continue.