Week 7

Assignments: Computer-Controlled Machining

group assignment:

• do your lab's safety training

• test runout, alignment, fixturing, speeds, feeds, materials, and toolpaths for your machine

individual assignment:

• make (design + mill + assemble) something big (~meter-scale)

• extra credit: don't use fasteners or glue

• extra credit: include curved surfaces

• extra credit: use three-axis toolpaths

Jonald Dudd

rhino file is here: file

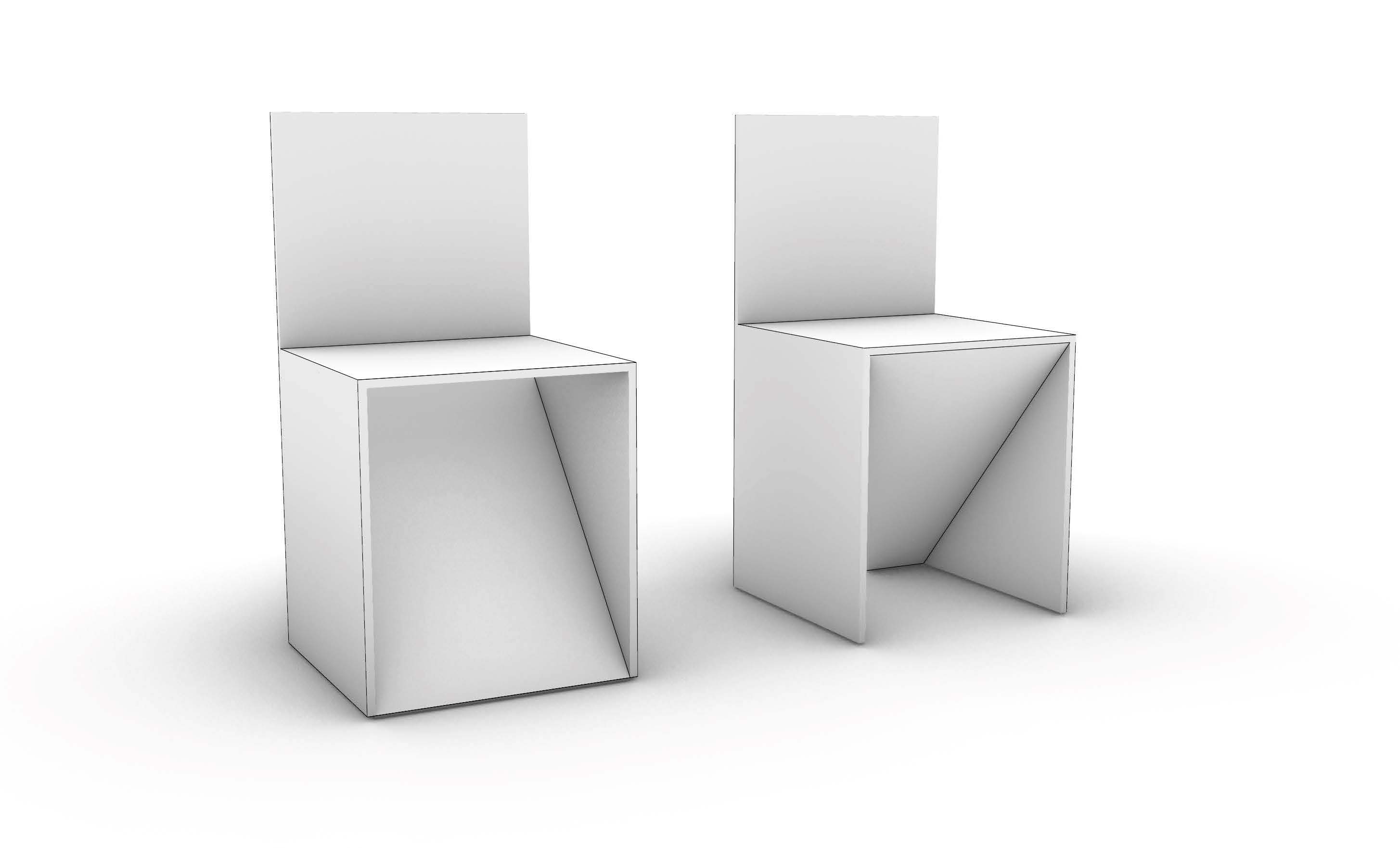

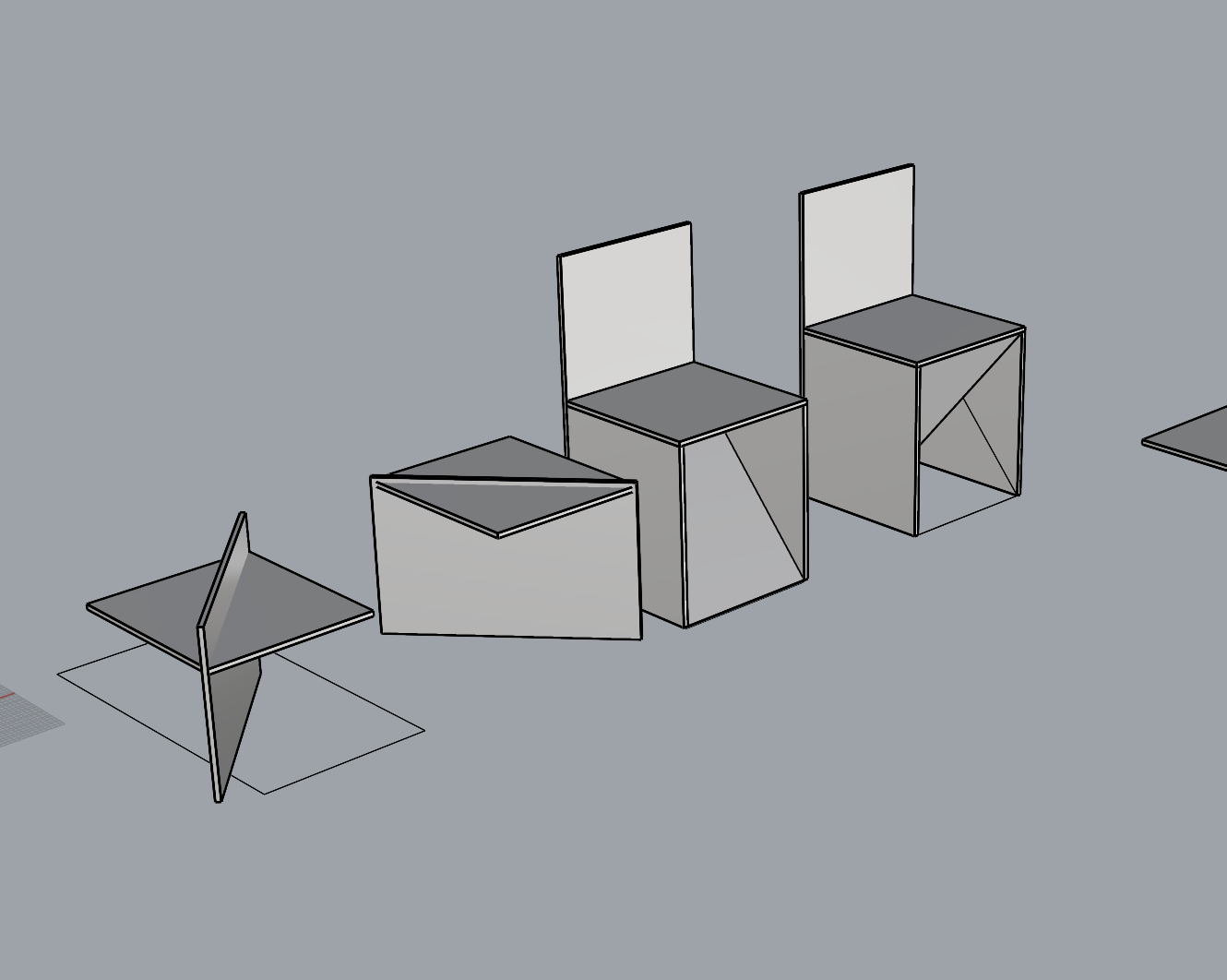

This week I worked on several more complex milled objects that would have required a 4th axis or some more precise machine paths to cut chamfers etc., so instead I made a rip-off Donald Judd Chair set. The two I chose use the dimensions of his dining chair, and include the forward-slanted center piece and the backwards-slanted piece. My goals were as follows:

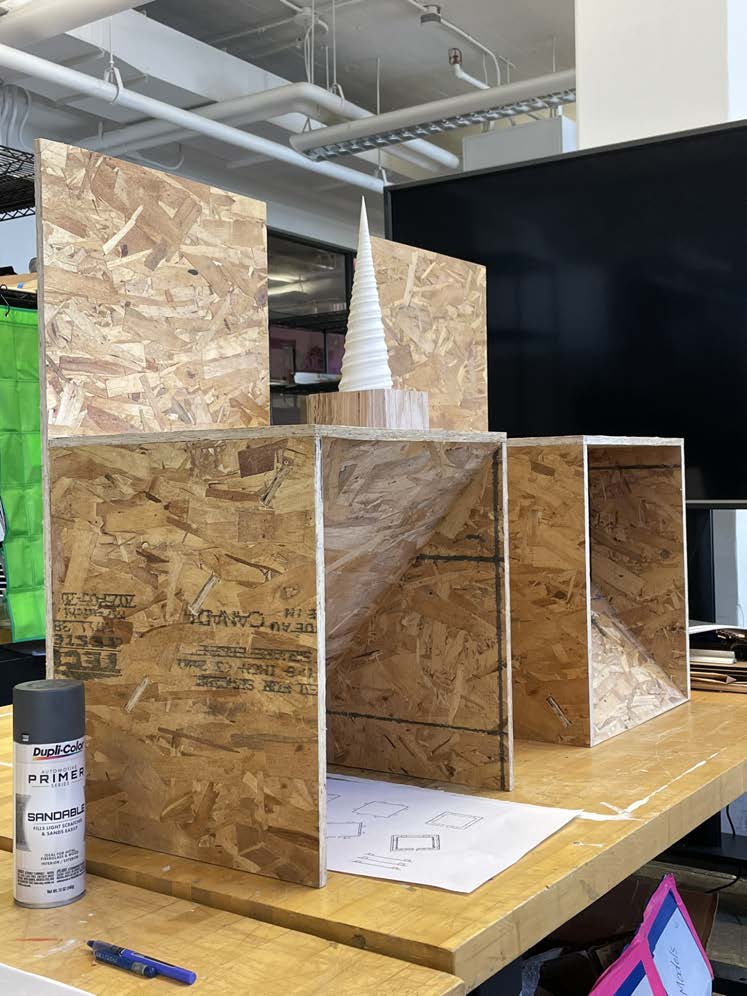

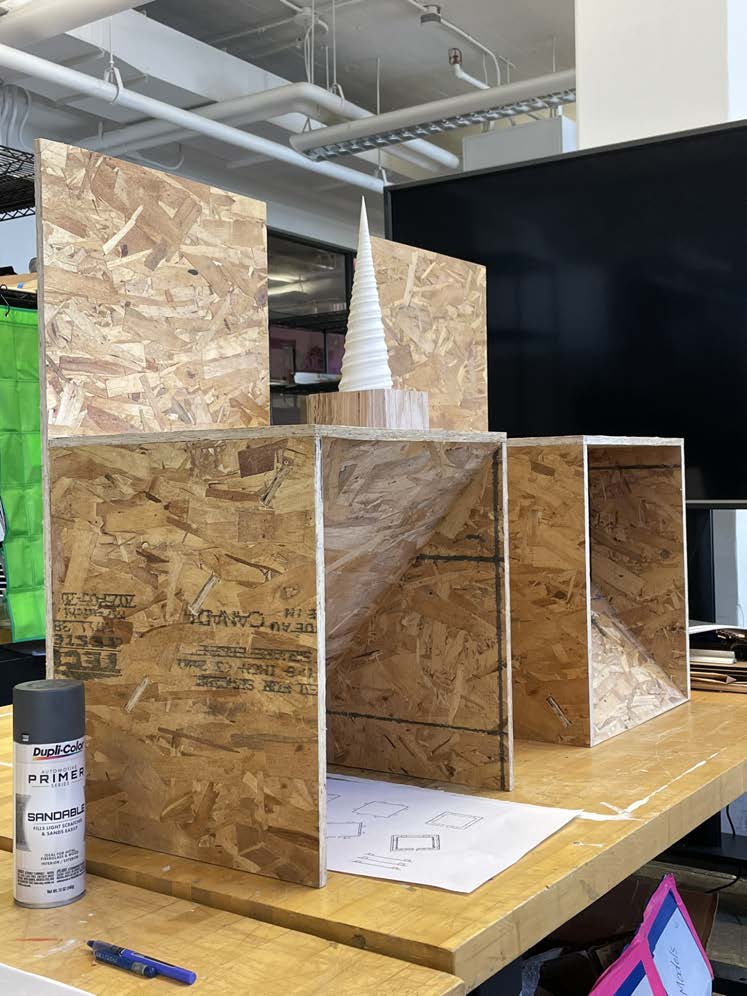

- show off the finish surface of the OSB (slight finish difference between top and bottom). This meant avoiding the onion-skin layer on the finish side, so I flipped the finish on top for my CNC cut despite the vacuum deficiency.

- Work true to Juddite learnings — this meant uninterrupted expression of the thickness of the material at the seams. Judd would not be into the press-fit connections at the seams of the material and would prefer a craft-dependent solution (hidden or diminutive screws and/or glue). Somewhere in the middle of the engineered and the Judd aesthetic, I chose to include a press-fit connection only where the material was intersecting orthogonally and not on an edge of the material. This happened in three surfaces on each chair — the sides and back.

Jonald Dudd

No offense, but I know the Judd dining chair dimensions off the dome. So I made this file in a second on my laptop in the shop after confirming the tolerance I wanted. I chose to go with (0.44 inch slots) that I would have to tap/hammer in because I wanted the joints to not wobble at all. I knew I would be gluing this but it was still important that as much material contact is happening, especially on the back since the back rest is just a cantilevering slab, and thinner than the typical Judd specs.

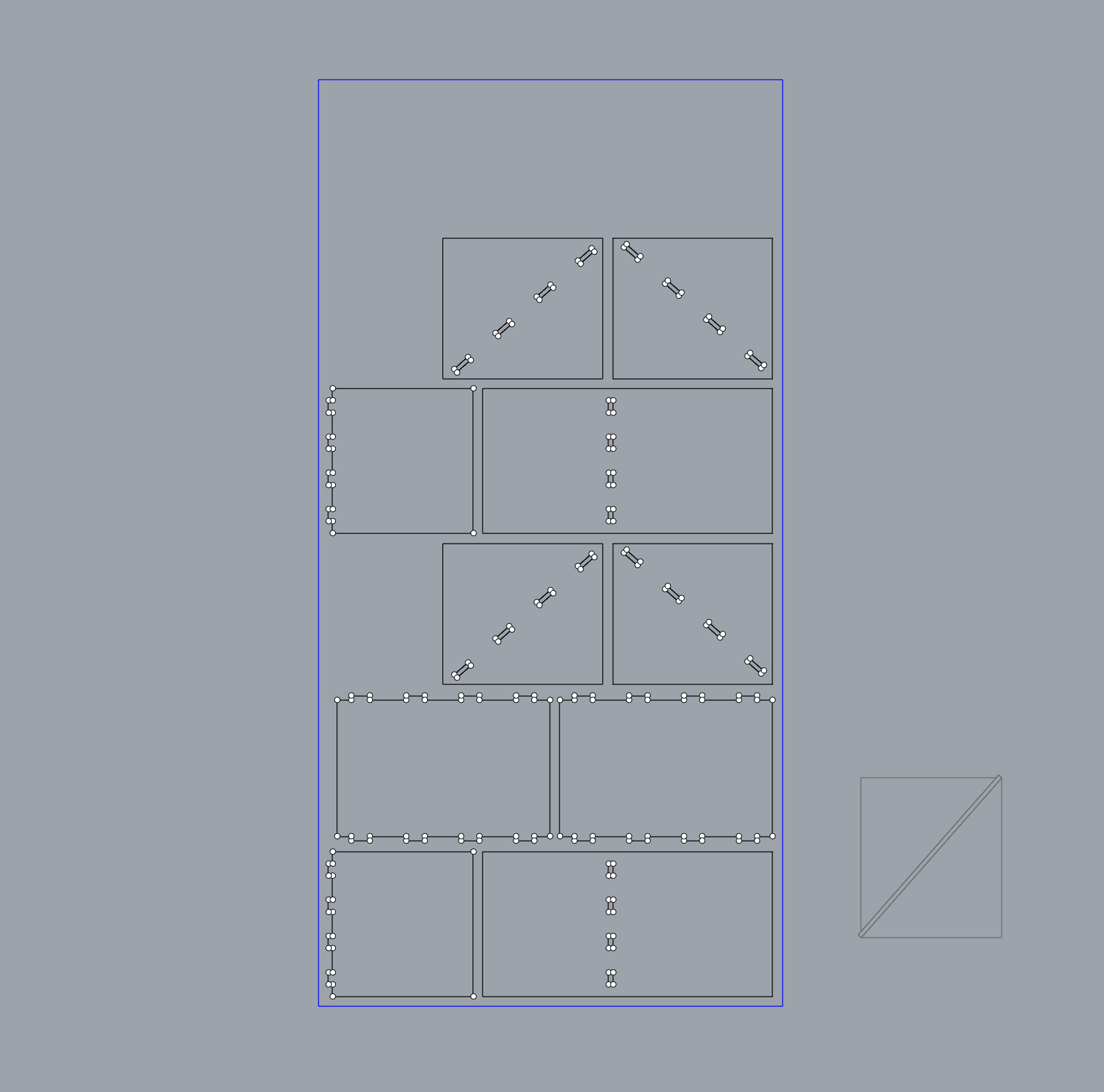

- 0.44 in slots, to be hammer fit (fig 0)

- Points left at corners where drill bit can’t reach (fig 1)

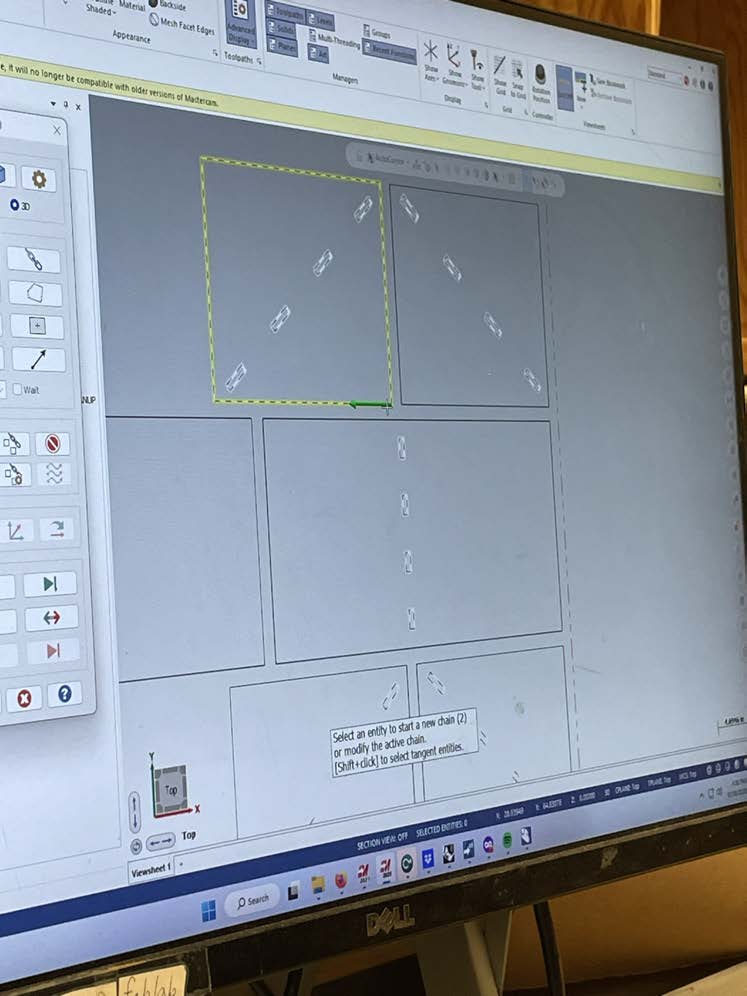

- Setting up file for CNC template, applying three tool paths with an onion skin (fig 2)

- Efficiency tracking — this will be negligible (fig 3)

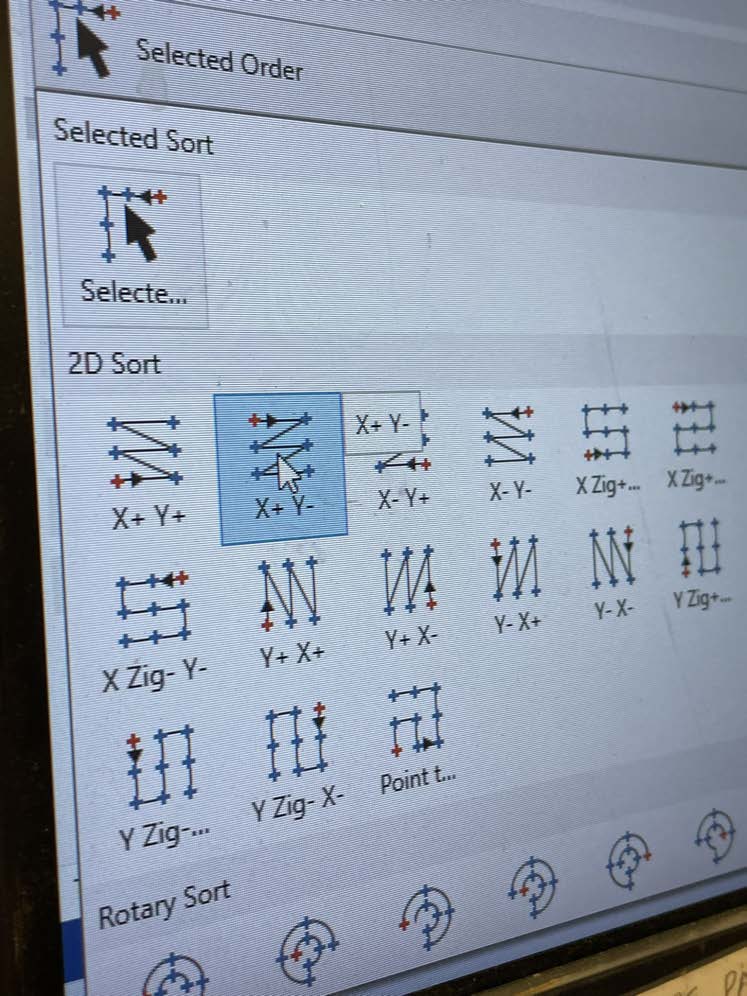

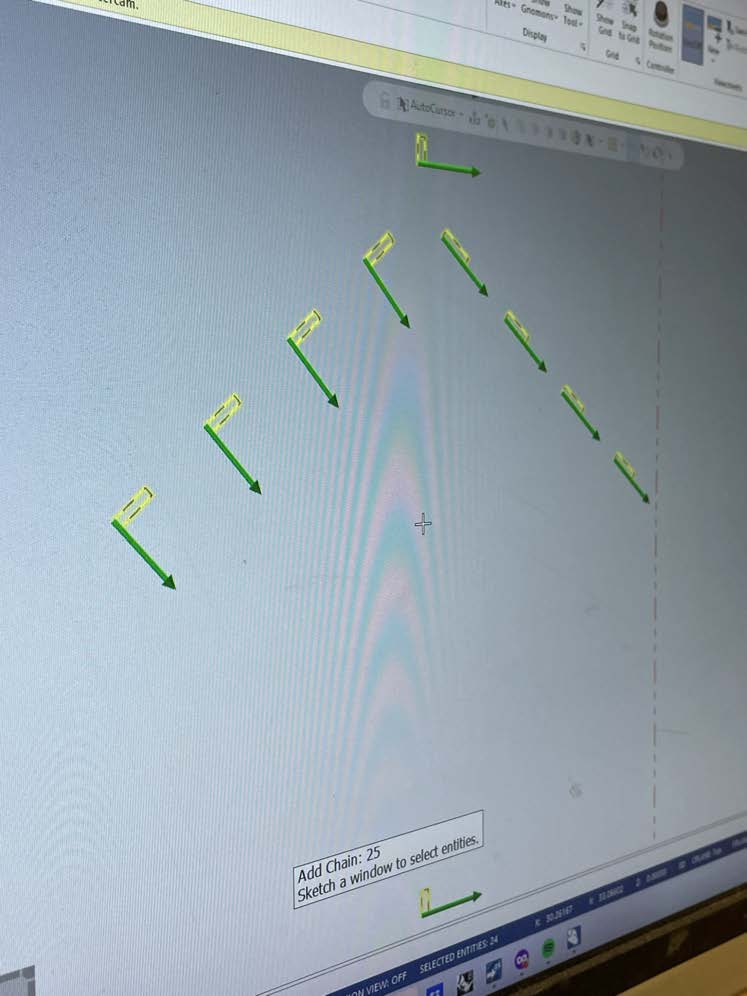

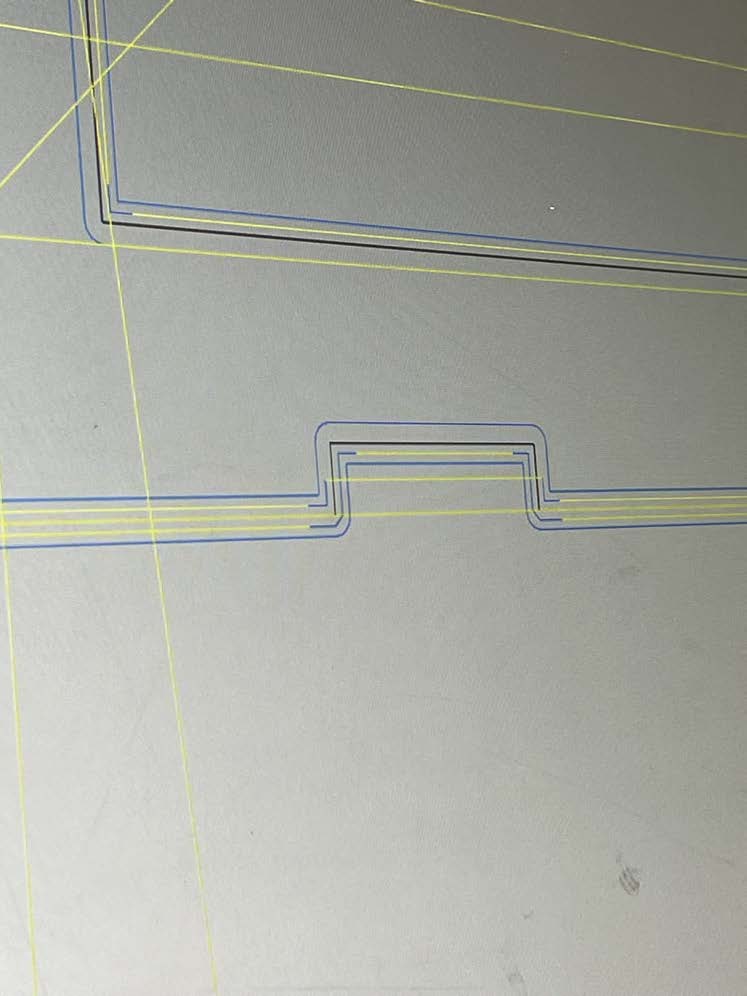

- Interior cuts set to rotate clockwise and outer cuts counterclockwise relative to the material for cleaner edges (fig 4, 5)

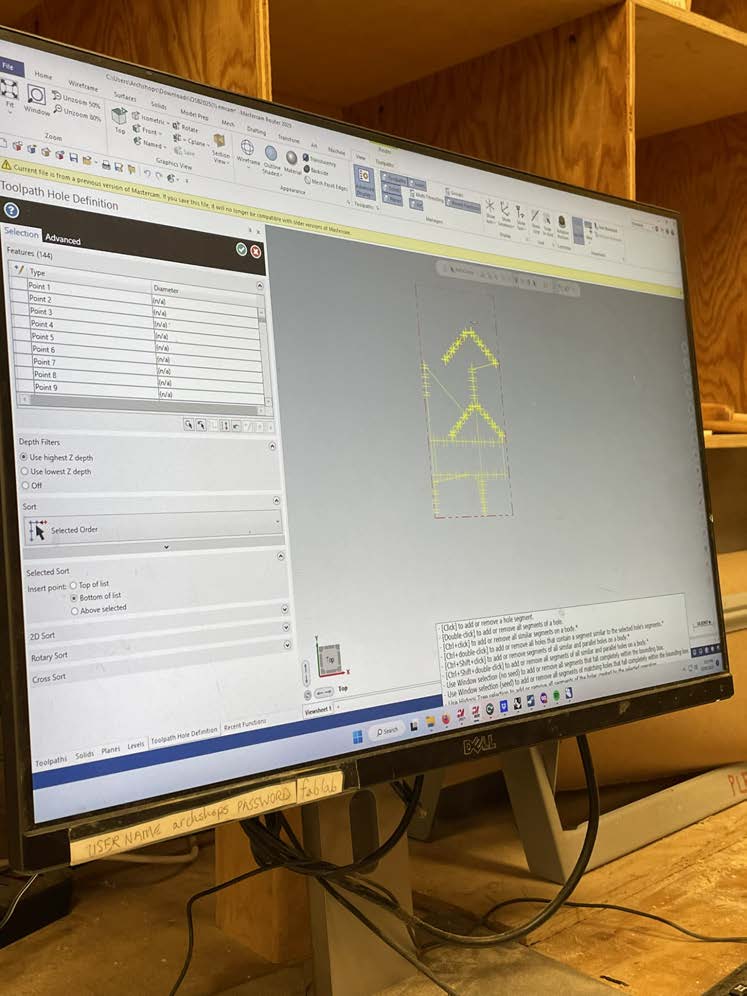

- Problem: Upon running the simulation of the cuts we found that there was a duplicate tool path on the inside of my material — we restarted the file setup and the problem did not persist.

Using the Onsrud CNC setup and Mastercam at our architecture shop, Geoffrey and I programmed the machine to warm up after we secured a sheet of 4x8" 0.44 in thick OSB to the vacuum table, fastening it with screws where it was warped. I placed the finish surface facing up — which reduced the vacuum connection — but allowed me to monitor which regions of the wood were being cut and ensure that the onion skin would not jeopardize the "nice" sides of the material I wanted to preserve. (fig 7)

- We ran an air cut with Z raised one inch above the material. Things looked good, so we lowered the cut down to 0.022 in, which is the calibrated Z-plane for this specific CNC machine. (fig 8)

- Cuts looked good, so we continued through all three tool paths with automatic bit changes. (fig 9)

- The onion skin we programmed was super thin, and some pieces came loose from their matrix immediately. (fig 10)

Finishing

- After clearing the onion skin with a sanding belt and a file, I went to hammer-fitting the pieces together without glue. It was clear that they fit well together — with some filing, it was possible to get clean joints between all pieces.

- Problem: See (fig 15) — in one case, hammering the pieces broke up the tab badly. This would be a big deal for a refined build. A better joint system would need to be designed for stronger tabs. 0.45 in holes might help, but for this prototype, the 0.44 in fit was still the correct choice since the dry joints were strong and rigid. (fig 16)

- I sanded the protruding edges of the diagonal members flush with their neighbors using an orbital sander.

- I glued up the chairs, spending time to ensure everything was aligned and square before leaving them overnight. (fig 17–19)

- They looked great in the morning, stacked well, and had a handsome proportion. Funnily enough, they sat almost flush with the height of my work table, echoing the Judd chairs’ relationship to their own table in-situ. (fig 21–24)