Introduction

We come to the wildcard! Which card(s) am I going to pick? I really enjoy the high-precision manufacturing, so I picked two of them below:

Glass engraving with UV laser:

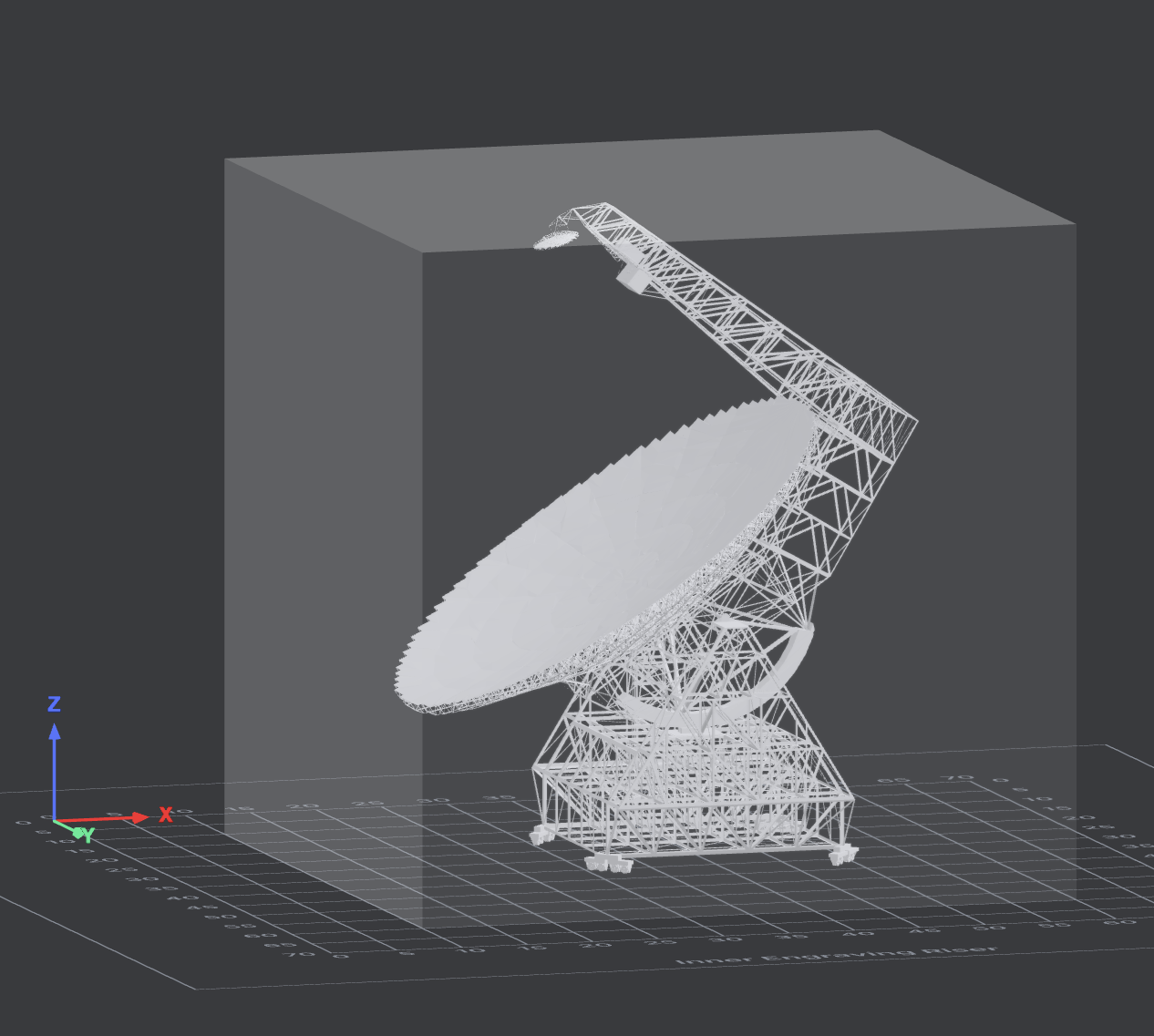

With the latest XTool F2 Ultra laser, we can engrave inside the K9 glass cube to make some 3D structures. The input file is not required to be a solid, closed 3D contour, like 3D printing requirements, which is very good because I only found one Green Bank telescope open-source 3D model, but it’s built purely with triangular faces without volume. However, for the UV engraving, it can be simulated well and smoothly being engraved! For such kinds of 3d models with a very complex mesh structure, the glass engraving is one of the best solutions.

Simulation and results: (the 3d model comes from the internet: Green bank telescope)

I also took a video of this engraving process. It only took ~7 mins, which is pretty fast!

However, the weakness of this glass engraving process is that it can only engrave glass with a flat top; otherwise, the refraction of the laser between air and glass will influence the focusing of the laser.

One of the solutions for this is to make a magic “solution” that has nearly the same refractive index. An example on the Internet: laser-engraved-solar-system-crystal-globe

Refractive index reference:

Chlorobenzene (n=1.5248)

Toluene (n=1.4961)

K9 glass (n=1.5163)

Based on the Arago-Biot Rule, the refractive index of a two-component mixture is in proportion to the volume ratio of the two components. So if we find two liquid chemicals while one has a little higher refractive index and another one has a little lower refractive index, by controlling the ratio of the mixture, we can ideally get the same K9 glass refractive index!

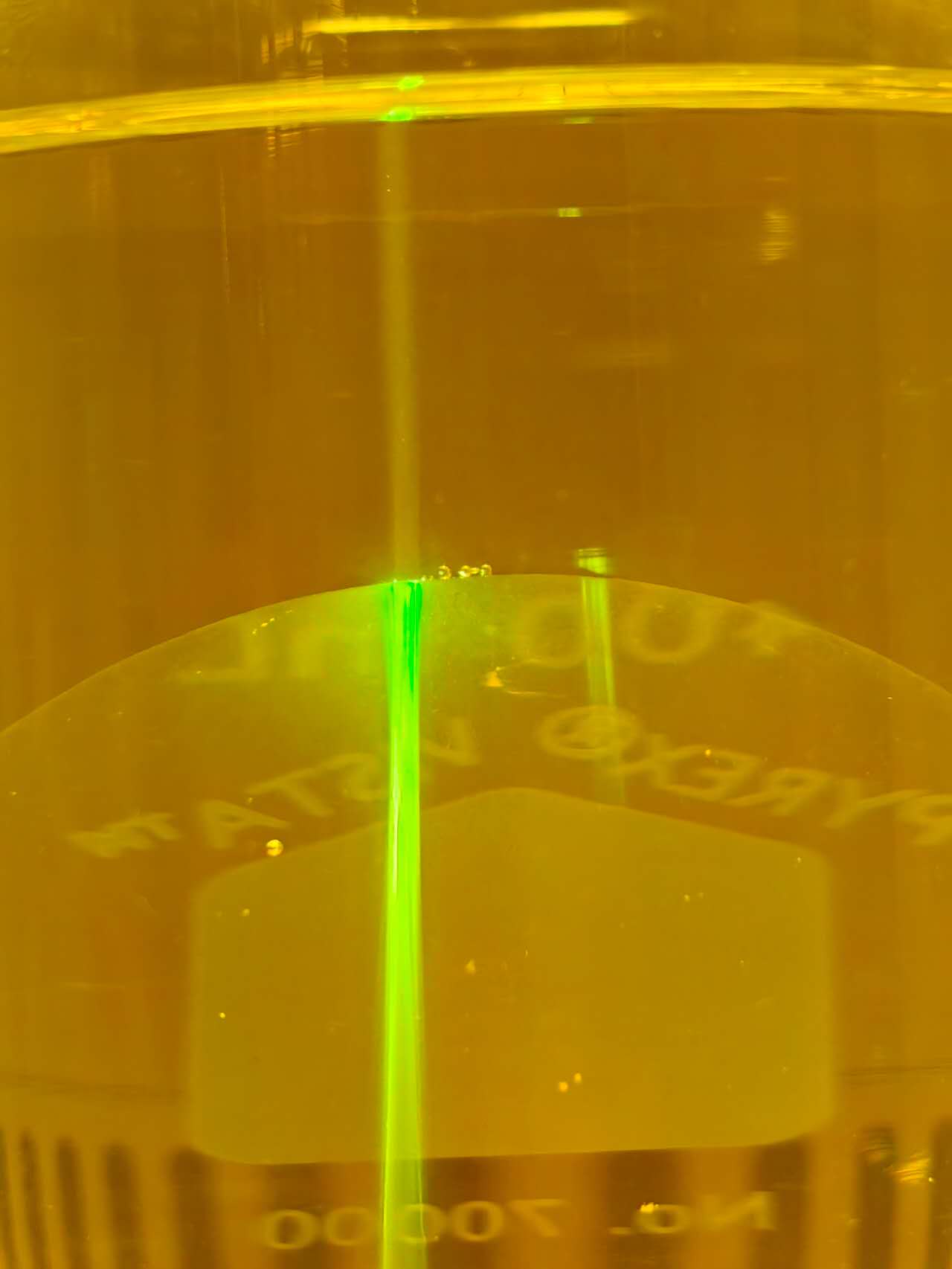

The picture below shows that when I gradually increase the ratio of toluene in chlorobenzene drop by drop, the black line in the back of the beaker (with a glass/solution boundary in the middle) changed from mismatching to fusion again, which means I achieved the optimized ratio to simulate glass refractive index.

However, this experiment still failed after some attempts. I noticed the laser couldn’t get focused inside the glass, so it engraved nothing. After several trials, I found the problem: the solution I made has too low boiling points, and the heat generated by the laser will evaporate a tiny amount of liquid and form bubbles between the surface of the glass and the solution. That bubble will strongly disturb the laser path and ruin the focus point. That’s why we need oil (higher boiling points), but not this kind of organic solvents.

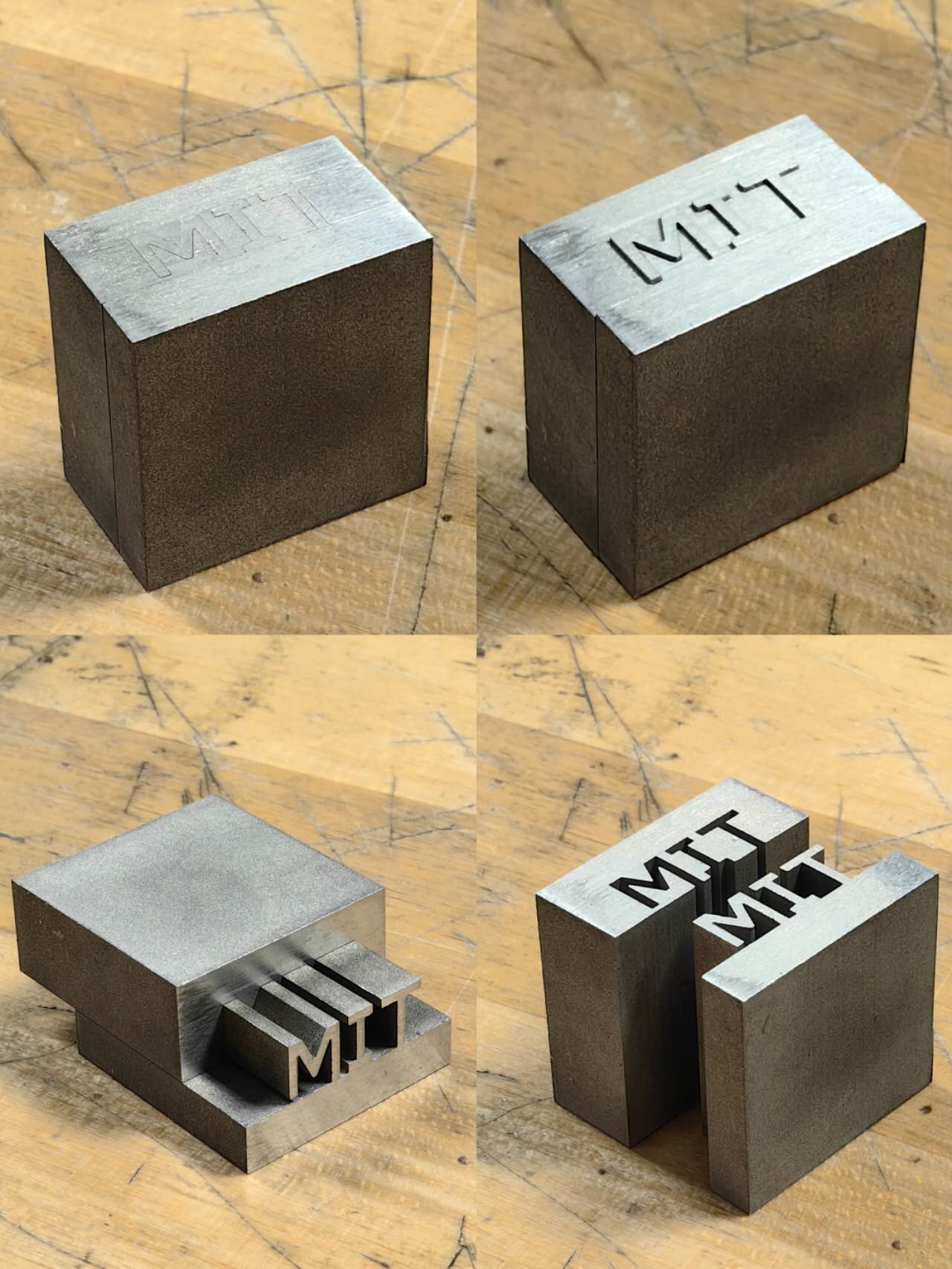

Wire Electronic Discharge Machining(EDM)

I saw some impressive videos showing a two-part metal puzzle with zero error, so when the two parts are combined, you can’t even can’t see the gap between them. This kind of manufacturing needs EDM technology, because it uses a super thin breeze wire to remove materials with discharge spark, and there’s zero force on the stock materials. Here is a photo when wire EDM machine is working:

I made a 2D contour of a two-part puzzle, and the boundary is three letters: “MIT”.

The download link for the DXF files:

The two parts are cut singly, so the surface texture/ scratches of the two parts are a little different. To solve this problem, I manually polished the combined parts, so it’s more like one single bulk now. However, I can still see the gaps when carefully checking, which I assume comes from the kerf with the thickness of that thin wire. If we include and optimize the kerf, it should finally reach the “perfect” match between two parts.